Teknic Hudson 2311 User manual

Hudson Motor User Manual

For Hudson motors purchased at Teknic.com

Rev. 1.21 December 21, 2020

U

SER

M

ANUAL

Hudson Manual / Rev. 1.21 2

TEKNIC,INC. TEL.(585)784-7454

Table of Contents

Table of Contents.............................................................................................................. 2

Introduction ....................................................................................................................... 4

What's in This Document ....................................................................................................... 4

Information on the Web .........................................................................................................4

What are Hudson Motors?..................................................................................................... 5

Safety and Safe Handling Information ............................................................................ 6

General Precautionary Statement .........................................................................................6

Symbols Used in this Manual ................................................................................................6

Safe Handling Practices......................................................................................................... 7

Parts of a Hudson Motor................................................................................................... 8

Interconnect and Wiring................................................................................................... 9

Motor Connector Options.......................................................................................................9

Molex Mini-Fit Jr. Connector .................................................................................................. 9

Souriau Trim-Trio Connector ................................................................................................. 9

Connector Pinouts and Mating Parts ................................................................................... 10

Molex Mini-Fit Jr. Pinout ...................................................................................................... 10

Souriau Trim-Trio Pinout...................................................................................................... 11

Servo Drive Selection ..................................................................................................... 12

Drive Compatibility ............................................................................................................... 12

Supported Commutation Methods .......................................................................................12

Six-Step (Trapezoidal) Commutation ................................................................................... 12

Sine wave Commutation (Better) ......................................................................................... 13

Sine wave commutation with Vector Torque Control (Best)................................................. 13

Encoder and Commutation Signals............................................................................... 15

Encoder & Commutation Board Power Requirements ........................................................15

Encoder Signaling................................................................................................................ 16

Commutation (Hall) Signaling ..............................................................................................17

Commutation Signal and Motor Phase Relaionship............................................................. 17

Wiring Hudson Motors To Third-Party Drives ...................................................................... 18

Hudson Motor FAQ ......................................................................................................... 19

Q: Are Hudson Motors UL or CE certified? .......................................................................... 19

Q: How are Hudson Motors tested?..................................................................................... 19

Q: What type of servo drives will work with a Hudson Motor? ............................................. 19

Q: Which connector should I use? ....................................................................................... 19

Hudson Manual / Rev. 1.21 3

TEKNIC,INC. TEL.(585)784-7454

Q: Which motor winding option should I pick?......................................................................19

Q: Do I need the optional motor shaft seal? .........................................................................20

Q: How do I tune a Hudson motor? ......................................................................................20

Q: How can I change a motor’s “sense of direction”?...........................................................20

Q: Why is the motor warm during operation? .......................................................................21

Q: Where can I find 3D drawings of Hudson motors? ..........................................................21

Appendix A: Hudson Part Number Key.........................................................................22

Appendix B: NEMA 23 Specifications............................................................................23

Appendix C: NEMA 34 Specifications............................................................................24

Appendix D: Motor Dimensions .....................................................................................25

Hudson Motor 3D Models ....................................................................................................25

NEMA 34 Series Dimensions ..............................................................................................25

NEMA 23 Series Dimensions ..............................................................................................26

Appendix E: Motor Cables..............................................................................................27

Cable Drawings....................................................................................................................27

Golden Rules for Motor Cable Construction ........................................................................27

Cable Making Guidelines.....................................................................................................28

Hudson Manual / Rev. 1.21 4

TEKNIC,INC. TEL.(585)784-7454

Introduction

Thank you for choosing Hudson brushless DC servo motors for your motion

control project. Previously, Hudson motors were available for purchase by

high volume OEMs exclusively (i.e., companies buying hundreds or

thousands of units per year). In late 2020, Teknic opened up sales of Hudson

motors to the general public.

Hudson motors are among the most reliable, safe, and rugged servo motors

available, and our production staff are the guardians of Hudson quality. Each

production associate works diligently to build and test every Hudson motor to

an exacting standard, while our administrative staff works hard to ensure that

each of our customers has a great experience when they call in with a

question or problem.

What's in This Document

This document contains technical information on the Hudson family of

brushless DC servo motors, including:

•Wiring information

•Mechanical drawings

•Application tips

•Specifications

Information on the Web

Please visit Teknic's website for more information on the Hudson Family of

brushless servo motors: https://www.teknic.com/products/hudson-motors/

Hudson Manual / Rev. 1.21 5

TEKNIC,INC. TEL.(585)784-7454

What are Hudson Motors?

Hudson motors have been called (more or less correctly) all of the following:

•BLDC motors

•Three-phase, permanent magnet motors

•Synchronous, permanent magnet motors

•AC servomotors (AC because electronic commutation requires a

sinusoidal current to produce constant torque, not to be confused

with AC induction motors)

•DC servomotors (presumably to distinguish them from AC induction

motors)

•3-phase servomotors

Technically speaking, Hudson motors are:

Three-phase, synchronous, permanent magnet,

brushless servo motors.

Definitions

"Servo Motor" refers to a motor that uses one or more feedback devices

(encoder, Hall effect sensors, etc.) to control torque, velocity, and/or position

in a closed loop manner.

"Brushless", aside from the obvious, means the motor requires a drive

(amplifier) that supports electronic, non-contact commutation.

"Permanent Magnet" means that the motor has permanent magnets affixed

to the rotor (brush motors typically have permanent magnets affixed to the

stator).

"Synchronous" means that the rotational speed of the electromagnetic field

is the same as (i.e. synchronous with) the speed of the rotor. There is virtually

no “slip” between them.

“3-phase" means the motor has three separate stator windings connected

together in a delta or wye configuration.

Hudson Manual / Rev. 1.21 6

TEKNIC,INC. TEL.(585)784-7454

Safety and Safe Handling Information

General Precautionary Statement

Always follow appropriate safety precautions when installing and operating

motion control devices. Automated equipment should be designed to prevent

personnel from coming into contact with moving parts and electrical contacts

that could potentially cause injury or death.

Read all cautions, warnings and notes before attempting to operate or service

motion control devices. Follow all applicable codes and standards when using

this equipment. Failure to use this equipment as described may impair or

neutralize protections built into the product.

Symbols Used in this Manual

The following symbols and conventions are used on the equipment and in this

manual. Please read all equipment labels and manuals before using any

motion control device.

Caution, risk of danger

Identifies information about practices or circumstances that can lead to

equipment damage, personal injury, or loss of life.

Shock hazard

Identifies presence of hazardous electrical voltages and currents.

Protective earth terminal

Indicates points that must be connected to a reliable earth system for safety

compliance. Protective earth connections should never be omitted.

Earth ground terminal

Frame or chassis terminal (shield)

Direct current

Note

Identifies information that is critical for successful application and

understanding of the product.

Tip

Identifies additional information that may be helpful in supporting certain

applications.

Hudson Manual / Rev. 1.21 7

TEKNIC,INC. TEL.(585)784-7454

Safe Handling Practices

•Do not hammer pulleys, pinions, etc. onto the motor shaft.

•Do not wrench or pry pulleys, pinions, etc. off the motor shaft.

When removing accessories use a gear puller that pushes on the

center of the shaft (offsetting the applied force).

•Do not exceed the axial force limit (see table below) when

pulling on the shaft or bearing damage will occur.

•Do not pick up a Hudson motor by its pigtail. Note: Maximum

pigtail pull force is 7 lbs.

•Do not allow the Hudson pigtail to flex during routine operation. The

Hudson pigtail is not flex-rated. Use cable ties or other means to

immobilize the motor pigtail during operation.

•Do not install a Hudson motor such that pigtail is pulled taut (has a

constant tension applied to it). Allow for some slack in the pigtail

when securing the motor to your machine.

•When pushing an accessory onto the motor shaft, do not exceed

the axial force limit when pushing into the shaft (see table

below).

Shaft Axial Force Limits, N (Lb.)

Pushing into shaft Pulling out of shaft

NEMA 23 NEMA 34 NEMA 23 NEMA 34

Continuous, operating 90 (20.2) 115 (25.9) 22 (4.9) 32 (7.2)

Static, short term 224 (50.4) 360 (80.9) 112 (25.2) 135 (30.3)

Shock / Impact 45 (10.1) 68 (15.3) 45 (10.1) 68 (15.3)

•ESD Warning: Do not touch the bare pins on a Hudson motor

connector unless you are working in a static-safe environment.

Hudson Manual / Rev. 1.21 8

TEKNIC,INC. TEL.(585)784-7454

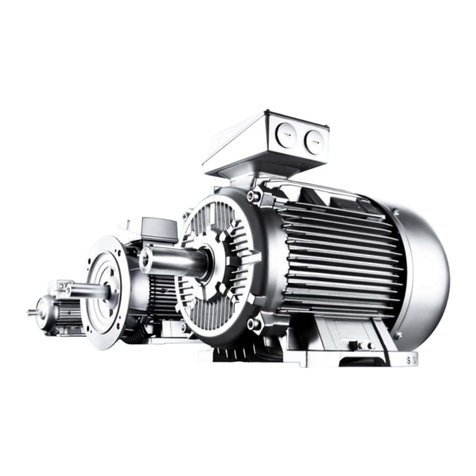

Parts of a Hudson Motor

eaw

12

34

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Inside a Hudson Motor

1. 16 inch pigtail eliminates costly motor

cables in many applications.

2. Single cable, single connector pigtail

results in neater, lower cost installations.

3. Two connector choices: lower cost

automotive-style, and sealed, bayonet-

style.

4. All Hudson motors come with

connectors.

5. Zero-clearance pigtail allows bigger

motors to fit into smaller spaces.

6. Shatter-proof encoder disk eliminates

shock-induced failures.

7. Industry-standard encoder and

com mutation signals.

8. Low-profile encoder allows you to fit

motors into tighter spaces.

9. Precision brass balancing tabs for

smoother motion and less vibration.

10. Epoxy insulation layer allows the use of

higher operating voltages.

11. Compression-fit aluminum stator

housing channels heat out of the motor.

12. Sintered, nickel-plated, rare-earth

magnets generate maximum power.

13. Architectural-quality, anodized finish will

look great for years.

14. Oversized, permanently lubricated front

bearing extends bearing life.

15. Long-stroke, wave spring imparts

consistent bearing preload.

16. Optional high-performance shaft seal for

more protection against dirt and dust.

17. Smooth, radiused transition from

external shaft diameter results in a

stronger shaft.

18. Feather keyway allows easy assembly

(and the key can’t work its way out).

19. Helically skewed stator laminations

improve smoothness of motion.

20. Tightly formed and laced end-turns heat

more evenly for higher reliability and

longevity.

Hudson motor cutaway view

Hudson Manual / Rev. 1.21 9

TEKNIC,INC.PHONE (585)784-7454

Interconnect and Wiring

This section discusses Hudson motor interconnect topics, including the

following:

•Motor connector options

•Mating connector parts and pinout information

Motor Connector Options

Hudson motors are available in two connector options: Molex MiniFit Jr. (at

left below) and Souriau Trim-Trio, free hanging (at right).

Hudson motor connector options

Molex Mini-Fit Jr. Connector

The Molex Mini-Fit Jr. connector provides a gas tight link with four points of

contact. This low cost, rugged connector is rated at up to 10A continuous

current per circuit, and 600V. The connector includes a positive locking

mechanism, and fully isolated, low engagement-force terminals.

Use Molex Mini-Fit Jr. connectors when:

•Lower cost and high reliability is required

•The operating environment is relatively clean and dry (typical dust/dirt

is OK)

•Less than 10A of continuous current per phase is required

Souriau Trim-Trio Connector

The Souriau Trim-Trio bayonet-style connector is a keyed, sealed, positively

locking unit derived from the MIL-C 26482 specification.

Use Souriau Trim-Trio connectors when:

•The pollution level (at the connector) is higher (light spray, mists,

fumes, chips, etc.)

•A water resistant seal (at the connector) is required

•Higher current-carrying capacity (> 10A continuous) is required

Hudson Manual / Rev. 1.21 10

TEKNIC,INC.PHONE (585)784-7454

Connector Pinouts and Mating Parts

Molex Mini-Fit Jr. Pinout

12345678

910 11 12 13 14 15 16

WIRE ENTRY VIEW

Pin# AWG Color Signal Name Notes

1

16

TIN P DRAIN Drain wire for Phase Cable

2

326 GRN COMM S-T commutation (Hall) sensor

426 GRN/WHT COMM R-S commutation (Hall) sensor

526 GRY/WHT COMM T-R commutation (Hall) sensor

626 TIN E DRAIN drain wire for Logic Cable shield

726 BLK GND +5VDC ground (encoder/Hall board return)

826 BLU/WHT ENC A~ encoder out (A~)

9

16

BLK or WHT/BLK PHASE R MOTOR PHASE

10

16

RED or WHT/RED PHASE S MOTOR PHASE

11

16

WHT PHASE T MOTOR PHASE

12 26 RED +5VDC IN +5VDC input (encoder/Hall board power)

13 26 BRN ENC I encoder out (index)

14 26 ORN ENC B encoder out (B)

15 26 BLU ENC A encoder out (A)

16 26 ORN/WHT ENC B~ encoder out (B~)

Mating Parts

Molex / 39-00-0049 (loose) -0048 (reel)

Molex / 39-01-2166

Crimp tool, 22-28AWG

Terminal, male, 16 AWG (motor phases)

Terminal, male, 24 AWG (logic signals)

Connector Housing, panel mount

Pigtail Pinout Table (Molex, Minifit Jr.)

Part Description

Extraction Tool

Molex / 11-03-0044

Mfg. / Part Number

Crimp tool, 16AWG

Molex / 2002182200

Molex / 11-01-0198

Molex / 39-00-0082 (loose) -0081 (reel)

NO CONNECT

Hudson Manual / Rev. 1.21 11

TEKNIC,INC.PHONE (585)784-7454

Souriau Trim-Trio Pinout

A

B

R

V

U

T

S

PC

D

E

F

G

H

J

K

L

M

N

Front View

A

B

R

V

U

T

S

P

C

D

E

FG

H

J

K

L

M

N

Wire Entry View

Pin# AWG Color Signal Name Notes

A

B

16

BLK or WHT/BLK PHASE R MOTOR PHASE

C

16

RED or WHT/RED PHASE S MOTOR PHASE

D

16

WHT PHASE T MOTOR PHASE

E

F26 ORN/WHT ENC B~ encoder out (B~)

G26 GRN COMM S-T commutation (Hall) sensor

H26 GRN/WHT COMM R-S commutation (Hall) sensor

J26 BLU ENC A encoder out (A)

K26 BLU/WHT ENC A~ encoder out (A~)

L26 GRY/WHT COMM T-R commutation (Hall) sensor

M26 TIN E DRAIN Drain wire for Logic Cable shield

N

P

R

16

TIN P DRAIN Drain wire for Phase Cable

S26 BLK GND +5VDC return

T26 RED +5VDC IN +5VDC input (encoder/hall power)

U26 BRN ENC I encoder out (index)

V26 ORN ENC B encoder out (B)

Terminal, female, 16 AWG (motor phases)

Souriau / RC16M23T

Backshell / Clamp

Souriau / UTG16AC

Connector Housing, for panel-mount pigtail

Souriau / UTG616-19S

Terminal, female, 24 AWG (logic signals)

Souriau / SC24M1TK6

Pigtail Pinout Table (Souriau, Trim Trio Connector)

Mating Parts

Part Description

Mfg. / Part Number

Connector Housing, w/ flange (for free-hanging pigtail)

Souriau / UTG016-19S

NO CONNECT

NO CONNECT

NO CONNECT

NO CONNECT

Hudson Manual / Rev. 1.21 12

TEKNIC,INC.PHONE (585)784-7454

Servo Drive Selection

Drive Compatibility

Servo drives intended for use with a Hudson motor must have the capabilities

listed below.

Supported Methods of Commutation (see section below for details)

•Six-Step (trapezoidal)

•Sine Wave

•Sine Wave with Vector Torque Control

Hudson motors have

•5VDC differential encoder signals

•5VDC, 120°optical commutation sensors (analogous to Hall effect

sensors)

•8 poles

•4 electrical cycles per revolution

Supported Commutation Methods

Each Hudson motor has a precision optical encoder disk with 120º optical

commutation sensors (analogous to Hall effect sensors). During assembly the

disk is precisely locked into position such that the commutation tracks line up

with the rotor in a known orientation.

Six-Step (Trapezoidal) Commutation

Note: Six-step commutation (aka "trapezoidal commutation") can be used

with Hudson motors though it is generally not preferred for high precision, low

speed applications due to higher torque ripple and lower operating efficiency.

Six-step is often used in cost-sensitive, lower precision applications, and for

high speed applications where the mechanical system and motor combine to

have sufficient inertia to minimize the effect of torque ripple.

During six-step commutation, the servo drive interprets the rotating

commutation sensor codes from the motor to determine relative rotor to stator

position and uses this information to sequence and time the switching of

current into the motor phases.

Step# Commutation Sensor State

3 channels, 120º separation Current Flow

1 1 0 1 From phase R to phase S

2 1 0 0 From phase R to phase T

3 1 1 0 From phase S to phase T

4 0 1 0 From phase S to phase R

5 0 1 1 From phase T to phase R

6 0 0 1 From phase T to phase S

Hudson Manual / Rev. 1.21 13

TEKNIC,INC.PHONE (585)784-7454

During six-step commutation, current flows in only two phases at a time (the

odd phase is always off). Example: In Step #1 above, when the commutation

sensors read binary (1 0 1) the drive sends current through Phases R and S,

while Phase T remains off. Six-step drives are less complicated in several

ways. In fact, because there is only one current path at any time, only one

loop is required to control motor phase current.

It is useful to understand that the commutation “code” changes state six times

per electrical cycle1, and thus provides a less precise fix on rotor position than

a typical sine wave drive with encoder-based commutation. While this may be

sufficient for less demanding motion applications, a high resolution feedback

device—such as an encoder—is a better choice for high precision positioning

tasks.

Pros and Cons of Six-Step Commutation

Pro: Lower cost of implementation (relatively simple devices)

Con: High torque ripple

Con: No torque control loop, though does have a current loop

Con: Lower torque efficiency (at high speeds)

Sine wave Commutation (Better)

Sine wave commutation is generally better suited to midrange applications

where greater precision of control over position, velocity and/or current is

required.

Most sine wave drives use the commutation sensors to initialize the

commutation process. First, the commutation code is read from the motor to

establish the initial rotor vs. stator position. Then the drive applies current to

the motor windings to achieve the desired relationship between the

permanent and electromagnetic fields. After this relationship is established,

the electromagnetic vector is “locked” to the encoder position, and

commutation continues based on encoder feedback (and not on the Halls).

Though more efficient than six-step drives, sine wave drives run open loop

with respect to torque control. While the current in each motor phase is

individually servo controlled, the actual torque produced at the shaft is not. In

most sine wave drives, torque errors are only corrected indirectly—after they

have resulted in velocity and position errors. This generally means sine wave

drives operate with a wider positioning error band than sine wave drives with

true vector torque control (see next topic).

Sine wave commutation with Vector Torque Control (Best)

Sine wave drives with Vector Torque Control (VTC) are often the drive of

choice for high precision, high throughput positioning and contouring

applications. A sine wave VTC drive is wired, and operates, in basically the

same way as a sine wave drive without VTC. The key difference is how

torque is controlled. While most sine wave drives servo control only the

1Note: Hudson motors are 8-pole motors that have four electrical cycles per mechanical

revolution. This means that Hudson commutation sensors transition (6 states x 4

electrical cycles) 24 times per motor revolution.

Hudson Manual / Rev. 1.21 14

TEKNIC,INC.PHONE (585)784-7454

individual motor phase currents, VTC drives servo control the actual torque

produced at the motor shaft.

The drive simultaneously takes calibrated current measurements from all

motor phases, combines this data with information about rotor position, phase

resistance, inductance and back-EMF, and then applies advanced vector

mathematics to calculate the exact torque being produced at the shaft. This

tight torque feedback loop allows for very rapid corrections in torque error,

resulting in superior dynamic tracking performance.

Hudson Manual / Rev. 1.21 15

TEKNIC,INC.PHONE (585)784-7454

Encoder and Commutation Signals

Hudson motors have differential encoder outputs and single-ended

commutation (Hall) outputs.

Encoder and commutation tracks are optically read from the Hudson encoder

disk and then translated to driven signals present at the motor connector.

Encoder Track

Glass encoder

At left is a Hudson encoder disk. At right is a glass encoder disk on a motor that

was dropped on the floor.

Encoder & Commutation Board Power Requirements

Hudson motors require a 5VDC supply voltage to power the combined

encoder & commutation sensor board.

Input voltage (at motor connector) 4.5-5.5VDC (6.0VDC absolute max.)

Current draw, loaded* 180mA @ 5VDC

Current draw, unloaded 125mA @ 5VDC

*This value is based on a 200 ohm test load.

Hudson Manual / Rev. 1.21 16

TEKNIC,INC.PHONE (585)784-7454

Encoder Signaling

Differential encoders on a Hudson motor have balanced, driven outputs

intended to drive terminated, twisted pair transmission lines. Differential

signals offer excellent common-mode noise immunity and support longer

cable runs than single-ended signaling.

Technical Note

The differential encoder output is driven from an AM26C31 differential line

driver optimized for 120Ωtransmission lines. Refer to the AM26C31 data

sheet for complete specifications.

Differential encoder

signal

complement

To Servo Drive

74HC14

AM26C31

24Ω

ENC I

ENC A

ENC A

ENC B

ENC B

encoder disk

Motor

read head

(one pulse per revolution)

Differential encoder output

Differential encoder signals provide excellent common mode noise immunity,

especially over longer transmission ranges (up to 100 feet). In many

applications, such as plasma cutting, differential encoder signals are superior

to single-ended signals.

Hudson Manual / Rev. 1.21 17

TEKNIC,INC.PHONE (585)784-7454

Commutation (Hall) Signaling

The optical commutation sensors are 5V TTL, totem pole driven outputs with

10mA maximum current.

Commutation Signal and Motor Phase Relaionship

The diagram below illustrates the relationship between commutation (Hall)

outputs and motor phases for properly wired Hudson motors. Refer to this

diagram when wiring third-party servo drives to Hudson motors. When using

the diagram below, bear in mind the following:

•The waveforms below apply to sine wave drives that can process

120° commutation sensor (Hall) signals and use encoder-based

commutation. Note: Six-step drives would produce a different back

EMF signature than shown below.

•The drive must be wired to count up as the motor shaft is turned

CCW (looking into the shaft).

•The commutation sequence shown in gray below is read from right

to left. When spinning the shaft CCW, a properly wired motor should

report commutation codes in the following sequence: 100, 101, 001,

011, 010, 110.

0° 30° 60° 90° 120° 150° 180° 210° 240° 270° 300° 330° 360°

0° 30° 60° 90° 120° 150° 180° 210° 240° 270° 300° 330° 360°

PHASE T

PHASE R

PHASE S

Back EMF

waveforms

Commutation sensor

(Hall effect) signals

COMM. T-R

COMM. S-T

COMM. R-S

110 010 011 001 101 100

(6) (2) (3) (1) (5) (4)

(referenced to phase R)

(referenced to phase S)

(referenced to phase T)

(Decimal)

Binary

Commutation

Sensor Codes

(

read rIght to left

for CCW rotation

)

Note: Motor phase zero-crossings must line up

with commutation sensor transitions as shown

motor phase

zero crossing

commutation

sensor transition

The above diagram shows the back-EMF waveforms you’d see if the motor

shaft was spun counterclockwise (looking into the shaft) with an oscilloscope

probe attached to the phase of interest and the ground clip attached to the

reference phase. The lower part of the diagram shows how the commutation

signals would appear on an oscilloscope when probed signal to ground.

Hudson Manual / Rev. 1.21 18

TEKNIC,INC.PHONE (585)784-7454

The motor is phased correctly when the zero-crossings of motor phases line

up with the transition points of the commutation sensor signals as shown in

the previous illustration.

Wiring Hudson Motors To Third-Party Drives

When wiring a Hudson to a third-party drive, start with a motor that is wired to

show positive encoder counts when spun CCW (viewed looking into the motor

shaft). If this is not the case, swap encoder signals A and B (for single-ended

encoders) or A and A~ (for differential encoders).

Important: the motor phases must align with their associated commutation

signal as follows (refer to phase diagram on previous page):

•Phase T and Comm. T-R

•Phase R and Comm. R-S

•Phase S and Comm. S-T

Note: Within the motion control industry, there is no standardized convention

for the labeling of encoder signals, motor phases or commutation (Hall)

signals. Consult the servo drive manufacturer for questions regarding

the wiring of encoder outputs, commutation (Hall) outputs and motor

phases.

Hudson Manual / Rev. 1.21 19

TEKNIC,INC.PHONE (585)784-7454

Hudson Motor FAQ

Q: Are Hudson Motors UL or CE certified?

A: Yes, both.

Q: How are Hudson Motors tested?

A: Each Hudson motor is rigorously tested before shipment. The tests

include:

•100% HASS tested (Highly Accelerated Stress Screening)

•Mechanical compliance tests

•Encoder integrity test

•Commutation sensor accuracy test

•Full electrical compliance test

•Full functional test

Q: What type of servo drives will work with a Hudson Motor?

A: Hudson servo motors are 3-phase, synchronous, permanent magnet,

brushless, servo motors with an incremental encoder that outputs standard

differential encoder signals and standard 120º optical commutation (Hall)

sensor signals. Hudson BLDC motors will work with the following drive types:

•Six-step (trapezoidal)

•Sine wave

•Sine wave with vector torque control

Q: Which connector should I use?

A: A Hudson motor can be fitted with either a Molex MiniFit Jr. or Souriau

Trim-Trio connector.

For most applications, the Molex MiniFit Jr. connector is a good choice. Use

this type of connector in relatively clean, dry environments (general dust is

OK), and when 10 amps or less motor phase current will be applied.

Consider using Souriau Trim-Trio connectors where the connector may be

subject to water spray, mist or fumes, or when more than 10 amps per phase

may be present. Note: Trim-Trio connectors have a longer lead time.

Q: Which motor winding option should I pick?

A: Hudson motors are available in Series or Parallel winding configurations.

Select the winding that best matches your torque and speed requirements.

Torque-speed graphs are available in the Hudson motor section of our

website.

Hudson Manual / Rev. 1.21 20

TEKNIC,INC.PHONE (585)784-7454

Q: Do I need the optional motor shaft seal?

A: For extra protection beyond the standard double-sealed ball bearings, an

optional dynamic shaft seal is available. The seal is appropriate when the

motor face (side with the shaft comes out) will be exposed to potentially

damaging particulate matter generated during machine operations.

Note: The shaft seal option is not available for 1/4" shaft NEMA 23 motors.

Q: How do I tune a Hudson motor?

A: Please consult the servo drive manufacturer for wiring and tuning

instructions.

Tip: Hudson servo motors have relatively fast electrical time constants. As a

result, they respond very rapidly to changes in winding current which allows

the motor to follow dynamic commands very quickly. If less aggressive servo

response is required for an application, it may be advisable to reduce the

drive's current or torque loop gains.

Q: How can I change a motor’s “sense of direction”?

A: Some drives may include firmware or software controls that allow you to

reverse motor shaft direction by changing a setting. Consult the servo drive

manufacturer for more information.

In some scenarios, you may need to reverse the motor’s sense of positive

and negative motion by modifying the motor cable. Assuming you have a

properly operating motor, except that direction of rotation is reversed,

swapping the following signals will change the direction of rotation:

Motors with Differential Encoders

•Swap Phase S with Phase T

•Swap Comm R-S with Comm T-R

•Swap Enc A with Enc A~

Note: Make wiring changes at the motor extension cable and not at the

motor’s pigtail connector. This generally saves time, money, and preserves

the motor warranty.

This manual suits for next models

8

Table of contents

Other Teknic Engine manuals