Tekno EB410.2 Instruction Manual

Introduction

Additional equipment and parts needed:

•

2 Channel radio and receiver

•

1/10th scale ESC and motor system

•

Low prole or standard size high torque steering servo (at least 180 oz/in)

* Running less than the recommended rating will increase the chance of premature servo failure.

•

2S (2 cell, 7.4v) shorty LiPo battery

•

Paint for body

•

1/10th scale 4x4 buggy wheels & tires, CA glue (or premounts)

•

48 pitch pinion 15 tooth - 30 tooth

Tools needed:

•

Hex drivers 1.5mm, 2.0mm, 2.5mm

•

Nut drivers 5.5mm (TKR1108), 7.0mm (TKR1109)

•

Hobby knife

•

Needle-nose pliers

•

Shock tool (TKR1115) OR adjustable (Crescent) wrench (for shock assembly)

•

4mm turnbuckle wrench (TKR1103) AND 5.5/7.0 two sided wrench (TKR1119)

•

Body reamer

Take your time! When you work your way through these building instructions, keep an eye out

for the following important indicators below:

•

RED TEXT - This indicates important areas of the build process that should be observed.

•

YOUTUBE - We also have many useful build videos on Youtube, so be sure to check these out!

https://www.youtube.com/c/teknorc

Thread Lock icons

Thread lock is always used when a screw is inserted into any metal part. (Included with kit)

Thread

Lock

Grease icons

Grease is usually used on areas with movement and for sealing. (Included with kit)

Grease

Disclaimer: Tekno RC is not responsible or liable for any property or personal damage, loss, or injury incurred as a

result of using this product. This kit is meant for use by persons 14 years of age or older and in the strict connes of

a legally permitted RC track or facility.

Warnings: Always double-check that your radio gear is working properly before operating vehicle. Never operate the

vehicle indoors (unless the RC track is an indoor facility). Use caution while operating vehicle so as not to collide with

people who may be turn marshalling or who might otherwise not be aware that a fast moving RC vehicle is in the vicinity.

Warranty: We warrant that the parts included in this kit are free from defects. If you nd a defective part in your kit,

please contact us at [email protected] and we will help to resolve the issue. If you modify any part prior to contacting

us, the warranty claim will be void. We do not warranty parts that may be broken during operation of the vehicle

or otherwise. Refer to the end of this instruction manual for a listing of spare/replacement and option parts.

All spare parts and other info are available on our website (www.teknorc.com) and through our network of

domestic and international dealers and distributors.

Thank you for purchasing the Tekno RC EB410.2 10th 4WD competition electric buggy kit.

We are always working on new projects, so please check our website regularly at www.teknorc.com

or visit us on Facebook at www.facebook.com/teknorc for all the latest news, parts, and kits.

TKR6517

TKR5144

Bag A

Center Dierential

(overview)

TKR6522B

TKR6513X

TKR6550

TKR6550

TKR6515

TKR6511

*TKR6670

(Option)

TKR5144

TKR6517

TKR6515

Step

A-2

Step

A-4

Fill Level

Step

A-3

Step

A-1

TKR5144

Dierential 0-rings

x2

TKR6517

Dierential Shims (5x14mm)

x2

TKR1303

M2.5x10mm Flat Head Screw

x4

TKR1303 x4

TKR6550

TKR6513X

Di

Oil

TKR6522B

*TKR6670

(Option)

TKR6514

TKR6514

TKR6514

TKR6514

TKR6517

TKR6550

TKR5144

TKR1303 x4

3

Grease

Grease

Grease

Grease

Fill with #30,000 CST oil to

1mm below full

DO NOT OVER FILL

Note: Apply grease to the

groove in the outdrive.

Note: These screws

only need to be snug.

Do not over-tighten

or the internal gears

will bind up.

Note: Apply grease to the

groove where the o-ring is

placed as well as the o-ring itself.

TKR6514

TKR6514

Bag B

Front and Rear Dierential

(overview)

TKR6512

TKR6513X

TKR6550

TKR6515

TKR6511

TKR5144

TKR6517

TKR1303 x4

TKR6514

TKR6514

TKR6515

TKR5144

TKR1303 x4

4

Grease

Step

B-1

Step

B-2

Repeat for rear di

Fill Level

Di

Oil

Step

B-3

Step

B-4

Repeat for rear di

TKR5144

Dierential 0-rings

x4

TKR6517

Dierential Shims (5x14mm)

x4

TKR1303

M2.5x10mm Flat Head Screw

x8

Grease

TKR6513X

Repeat for rear di

Fill FRONT with #15,000 CST oil

Fill REAR with #10,000 CST oil

to 1mm below full

DO NOT OVER FILL

Repeat for rear di

TKR6517

TKR5144

Grease

Grease

TKR6550

TKR6514

TKR6514

TKR6512

TKR6514

TKR6514

Note: Apply grease to the

groove in the outdrive.

Note: Apply grease to the

groove where the o-ring is

placed as well as the o-ring itself.

TKR6550

TKR6517

TKR6550

TKR1221

TKR6526C TKR6207

TKR1221

M3x8mm Washer

x8

TKR6208

TKR6208

TKRBB040725

TKRBB040725

TKRBB040725

TKRBB040725

TKR6526C

TKR1402

TKR1402

TKR6526C

Step

C-1

Step

C-2

Thread

Lock

TKR6207

M3x6mm Ball Stud

x1

TKR6208

M3x8mm Ball Stud

x2

Note: Use a 5.5mm wrench

(TKR1119) here to assist in

tightening this assembly.

TKR6627

TKR6627

TKR1602

TKRBB05114

TKR6551

TKRBB05114

TKR6519B

TKR6597

Thread

Lock

TKR6629B

Step

C-3

Step

C-4

TKRBB040725

TKRBB040725

Note: Use a

2mm hex to

pre-thread the

steering posts

into the bulkhead.

This will ensure

that the posts go

in as straight as

possible. After

pre-threading,

remove the posts

and re-install them

with the entire

steering

assembly

as shown.

TKR1301

TKRBB10154

TKRBB10154

TKR6547

Step

C-5

Step

C-6

Grease

TKR6519B

TKR1402

Note: Screw the

TKR1402’s all the

way down, then

back o 1/4 turn.

TKR1221

TKRBB05114

Ball Bearing (5x11x4)

x2

TKR1301

M2.5x6mm Flat Head Screw

x2

TKR1402

M3x8mm Button Head Screw

x4

TKR1602

M4x4mm Set Screw

x1

TKRBB10154

Ball Bearing (10x15x4)

x2

TKRBB040725

Ball Bearing (4x7x2.5)

x4

Bag C

Steering/Bulkhead Assembly

5

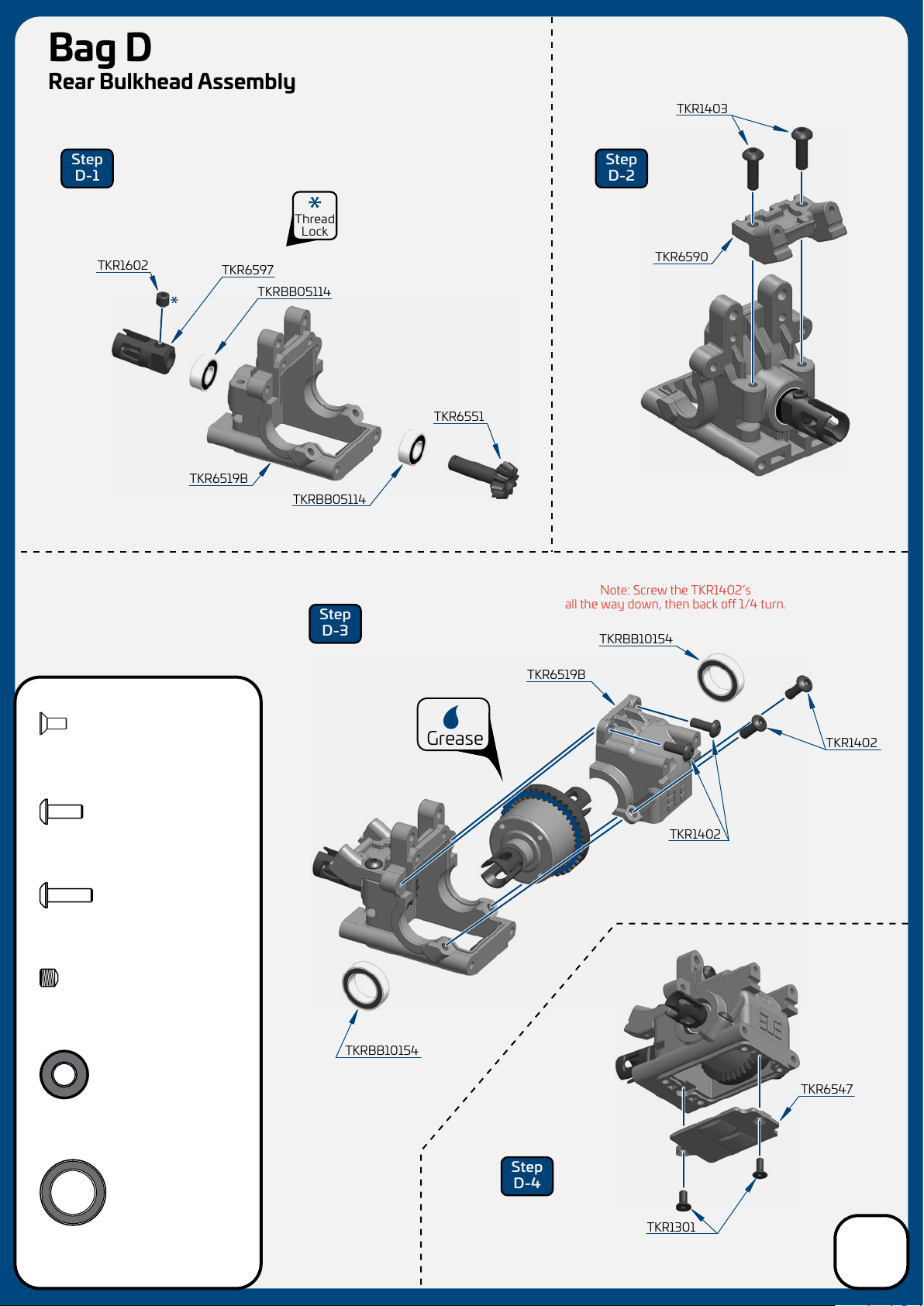

Step

D-1

Step

D-2

Step

D-3

Step

D-4

TKRBB05114

Ball Bearing (5x11x4)

x2

TKR1301

M2.5x6mm Flat Head Screw

x2

TKR1402

M3x8mm Button Head Screw

x4

TKR1403

M3x10mm Button Head Screw

x4

TKR1602

M4x4mm Set Screw

x1

TKRBB10154

Ball Bearing (10x15x4)

x2

Bag D

Rear Bulkhead Assembly

Thread

Lock

TKRBB05114

TKR6597

TKR1602

TKRBB05114

TKR6551

TKR6590

TKR1403

TKR6519B

TKR6519B

TKRBB10154

TKR1402

TKR6547

TKRBB10154

TKR1301

Grease

TKR1402

Note: Screw the TKR1402’s

all the way down, then back o 1/4 turn.

6

TKR1601

TKR6610 - 1.7mm

TKR6547

Note: Do not over-tighten.

Note: Screw

these set screws in

gently, until they

just touch the

sway bar, then

back o just

slightly so the

sway bar is free.

TKR6544B

TKR6542HD

TKR1601

TKR6590

TKR6543HD

TKR6523HD

TKR6544B

TKR1405

Bag E

Rear End

Assembly

Below options sold separately.

*TKR6610 - 1.5mm

*TKR6610 - 1.6mm

*TKR6610- 1.8mm

*TKR6610- 1.9mm

(Option)

Thread

Lock

TKR1611

TKR1601

TKR6555

TKR6206

TKR6253B

TKR6544B

TKR6584

*TKR6524B

(Option)

TKR1409

TKR6544B

x5

TKR1601

M3x4mm Set Screw

Step

E-1

Step

E-2

Step

E-3

TKR1405

M3x14mm Button Head Screw

x2

TKR1463

M2.5x6mm Button Head Screw

x2

TKR1611

M4x8mm Set Screw

x2

TKR6206

M3x6mm Ball Stud

x2

TKR1463

TKR1463

TKR1409

M3x20mm Button Head Screw

x2

7

Stock Position

(”C” Block)

Note: With center dot

inserts, Anti-Squat = 2°

Stock Position

(”D” Block)

Note: With center dot

inserts, Rear Toe = 2°

Wheelbase Shims

1mm

1mm

large 1mm

front

rear

small .5mm

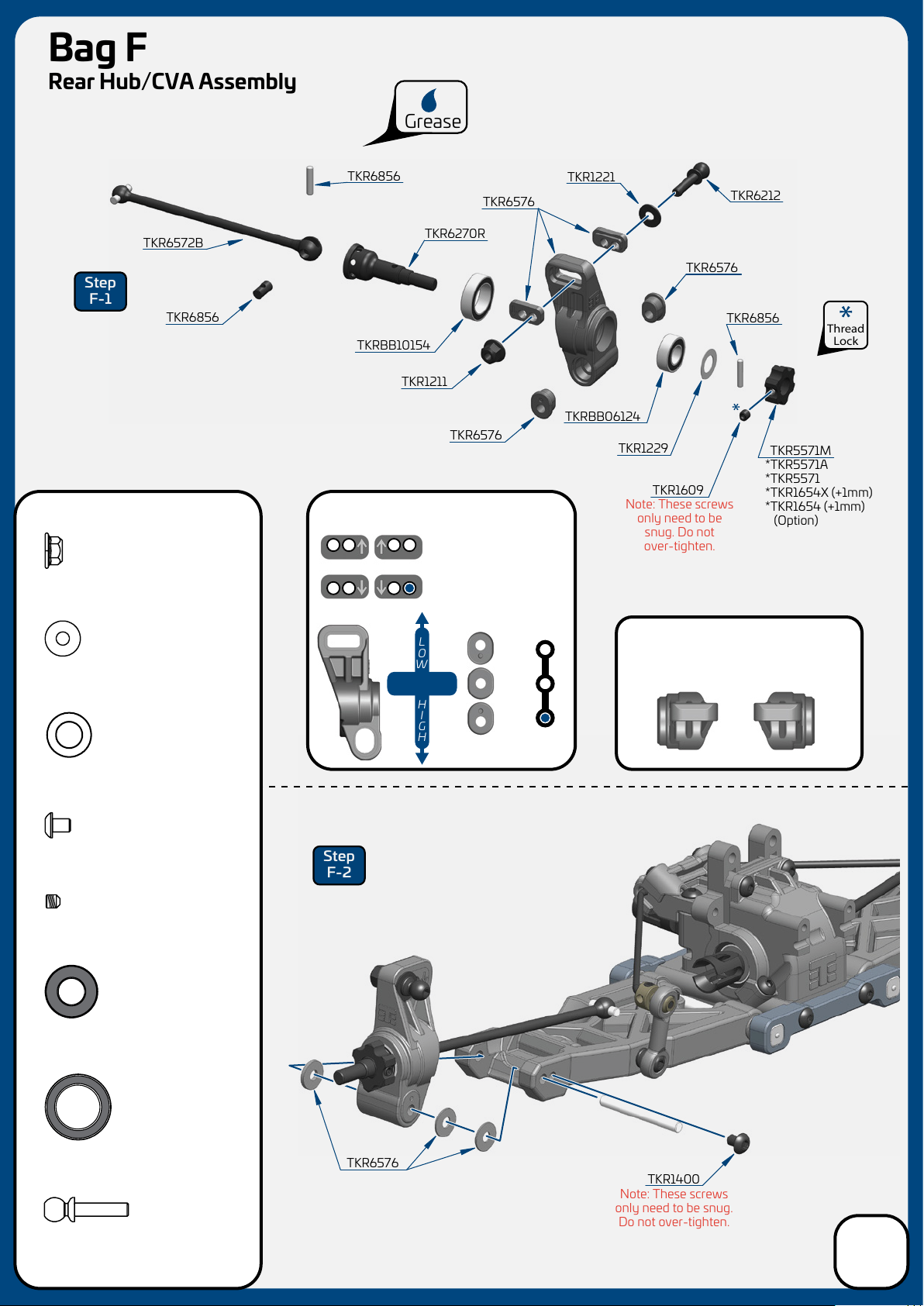

TKR6856

TKR6856

TKR6270R

TKR1221

TKRBB10154

TKRBB06124

TKR5571M

TKR1229

TKR6576

TKR1609

TKR1211

TKR6576

TKR6572B

TKR6576

TKR6212

TKR6856

TKRBB10154

Ball Bearing (10x15x4)

x2

TKR6212

M3x12mm Ball Stud

x2

*TKR5571A

*TKR5571

*TKR1654X (+1mm)

*TKR1654 (+1mm)

(Option)

Note: These screws

only need to be

snug. Do not

over-tighten.

TKR1229

6x10x0.2mm Shim

x2

TKR1609

M3x3mm Set Screw

x2

Step

F-1

Step

F-2

TKRBB06124

Ball Bearing (6x12x4)

x2

Grease

TKR1400

M3x4mm Button Head Screw

x2

Thread

Lock

TKR1400

TKR6576

Note: These screws

only need to be snug.

Do not over-tighten.

TKR1211

M3 Lock Nut Flange Black

x2

TKR1221

M3x8mm Washer

x2

Bag F

Rear Hub/CVA Assembly

8

LOW

HIGH

ROLL CENTER

HUB INSERTS

1

2

3

A C B D

TOP VIEW

HUB ORIENTATION

RightLeft

Rear

Front

TKR6250

TKR6253B

28.50

Note: Notch always

goes on

left side of vehicle.

Note: Always press

on with

T

logo visible.

Actual Size

Left/Right x 2pcs

TKR6253B

TKR6208

TKR6527B

TKR6666

TKR1211

TKR6681

TKR6208

TKR1211

TKR1211

TKR6527B

TKR1211

Step

F-3

Step

F-4

Step

F-5

TKR6208

M3x8mm Ball Stud

x2

Build Note: Hold the turnbuckle stationary with pliers and

push the rod end hard onto the turnbuckle while turning

at the same time. Keep in mind that one end of the

turnbuckle has normal threads and the other has reverse threads.

Start the rod end straight and it will thread on straight.

Build Tip: Use some grease or Chapstick

on the threads to help prevent “pop-o” when

adjustments are being made.

TKR1211

M3 Lock Nut Flange Black

x4

Bag F

Rear Camber Links

9

TKR6538

TKR1411

TKR1411

Step

F-6

Step

F-7

TKR1411

M3x25mm Button Head Screw

x2

TKR1405

M3x14mm Button Head Screw

x4

TKR6546B

TKR1405

Bag F

Rear Tower/Wing Mount

Stock position is 3/D

10

A C B D

TKR1601

Bag G

Front End

Assembly

TKR1405

TKR1409

Step

G-2

Step

G-1

Step

G-3

TKR1409

M3x20mm Button Head Screw

x2

TKR1405

M3x14mm Button Head Screw

x4

TKR1463

M2.5x6mm Button Head Screw

x2

TKR1611

M4x8mm Set Screw

x2

TKR6523HD

TKR6540HD

TKR6547

TKR1463

TKR6544B

TKR6541HD

TKR6525B

TKR1405

TKR6544B

TKR6548

TKR6555

TKR1601

TKR6544B

TKR6544B

TKR1411

TKR6253B

TKR6544B

TKR1463

TKR1601

TKR6611 - 1.4mm

TKR6547

Note: Do not over-tighten.

Below options sold separately.

*TKR6611 - 1.0mm

*TKR6611 - 1.1mm

*TKR6611- 1.2mm

*TKR6611- 1.3mm

(Option)

Note: Refer to page

26 for setting droop.

x5

TKR1601

M3x4mm Set Screw

Note:

Screw these

set screws in

gently, until they

just touch the

sway bar, then

back o just

slightly so the

sway bar is free.

11

Wheelbase Shims

2mm

0mm

large 1mm

front

rear

small .5mm

Stock Position

(”A” Block)

Note: With center dot down

inserts, Arm Sweep = 0°

Stock Position

(”B” Block)

Note: With center dot down

inserts, Kick Up = 10°

TKR1601

TKR6565

Bag H

Front Spindle/CVA Assembly

TKR1400

Step

H-1

Step

H-2

Step

H-3

Step

H-4

Step

H-5

TKR6856

TKR6856

TKR6573F

TKR6553

TKRBB10154

TKRBB06124

TKR6856

TKR1201

TKR1601

TKR6218

TKR1601

TKR6218

TKR5571M

TKR1609

*TKR5571A

*TKR5571

*TKR1654X (+1mm)

*TKR1654 (+1mm)

*TKR1655 (+2mm)

(Option)

Note: These

screws only need to be

snug. Do not over-tighten.

TKR1201

TKR6218

TKR6218

TKR1229

TKR6596

TKR6574B

TKR6648

TKR6596

TKR1601

Grease

Note: These

screws only

need to

be snug.

Note: These screws

only need to be snug.

Do not over-tighten.

Note: These

screws only need to be

snug. Do not over-tighten.

x8

TKR1601

M3x4mm Set Screw

TKR1609

M3x3mm Set Screw

x2

TKRBB06124

Ball Bearing (6x12x4)

x2

TKR1400

M3x4mm Button Head Screw

x4

TKR1221

TKR1400

TKR1229

6x10x0.2mm Shim

x2

TKR1221

M3x8mm Washer

x8

Thread

Lock

TKR6218

M3x8mm Long Neck Ball Stud

x4

TKRBB10154

Ball Bearing (10x15x4)

x2

TKR1201

M3 Lock Nut Black

x2

Note: These optional steering

stop screws and washers are

included in case you are

expreiencing erratic steering

control. They provide a

mechanical limit to the steering throw and

make the car easier to drive by greatly

improving the consistency of the steering.

They are recommended in addition to

limiting steering on your radio to match. Kit

setting just the screw with zero washers.

12

Note:

Pre-thread the

kingpin screws

into the

spindles prior to

installing them

into the spindle

carriers. This

will ensure

there will be no

binding.

16.00

TKR6252

TKR6253B

Right

Right

Left

Right

Left

Left

TKR6253B

TKR6253TKR6253

TKR6253BTKR6253B

TKR6252

TKR6208

TKR6664B

TKR1201

TKR1201

TKR6208

TKR6252

TKR6252

TKR6253BTKR6253B

Note: Notch always

goes on

left side of vehicle.

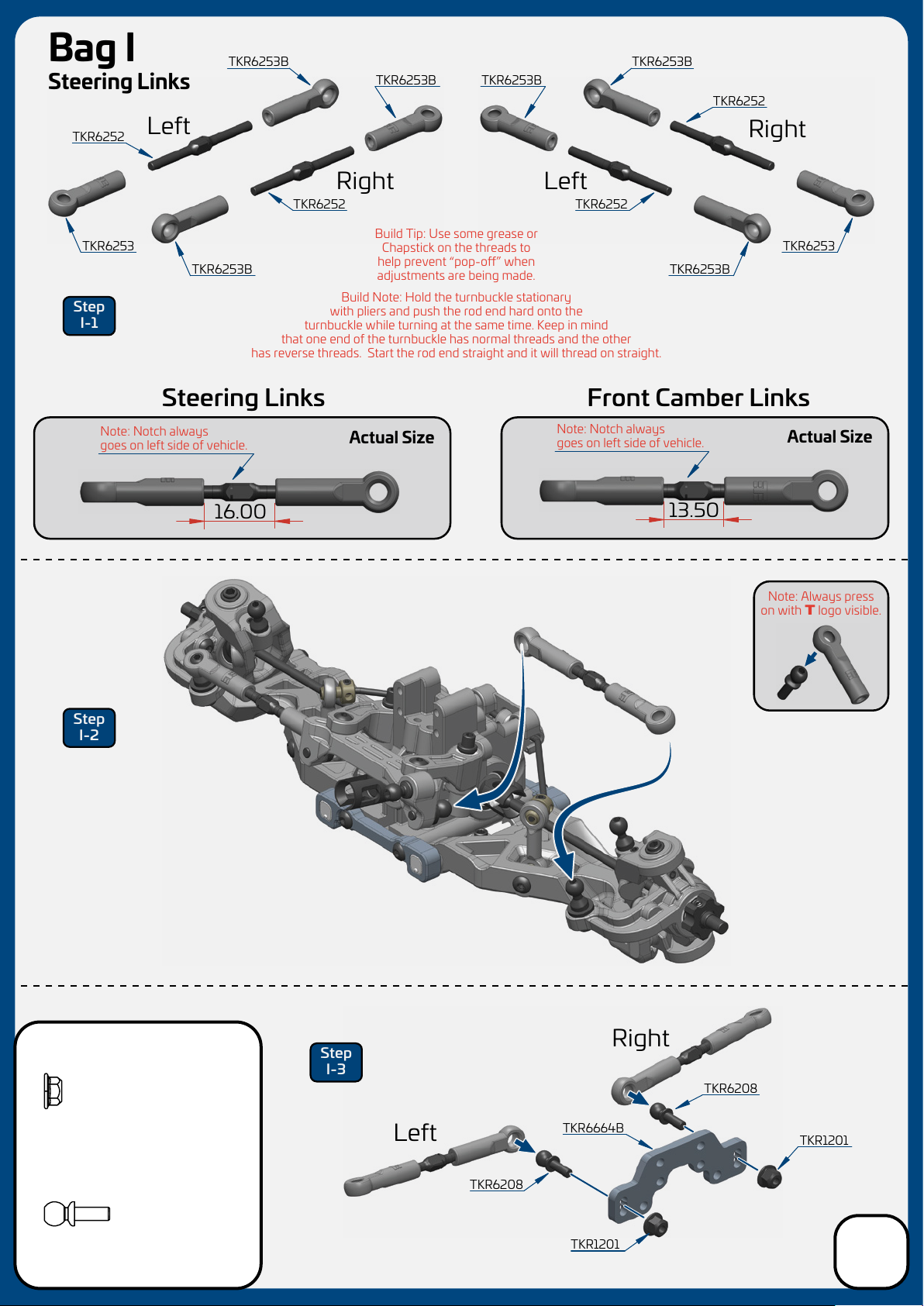

Bag I

Steering Links

Step

I-1

Step

I-2

Step

I-3

TKR6208

M3x8mm Ball Stud

x4

Actual Size

Note: Always press

on with

T

logo visible.

Build Note: Hold the turnbuckle stationary

with pliers and push the rod end hard onto the

turnbuckle while turning at the same time. Keep in mind

that one end of the turnbuckle has normal threads and the other

has reverse threads. Start the rod end straight and it will thread on straight.

Build Tip: Use some grease or

Chapstick on the threads to

help prevent “pop-o” when

adjustments are being made.

13.50

Note: Notch always

goes on

left side of vehicle.

Actual Size

Front Camber LinksSteering Links

TKR1211

M3 Lock Nut Flange Black

x2

13

Stock position is 2/A

TKR1201

M3 Lock Nut Black

x2

Bag I

Front Camber Plate/Tower

Step

I-4

Step

I-5

TKR6527B

TKR6527B

TKR1211

TKR6681

TKR1211

TKR1409 x4pcs

TKR1403

TKR1403

M3x10mm Button Head Screw

x2

TKR6208

M3x8mm Ball Stud

x2

Note: Always press

on with

T

logo visible.

TKR1405

M3x14mm Button Head Screw

x4

14

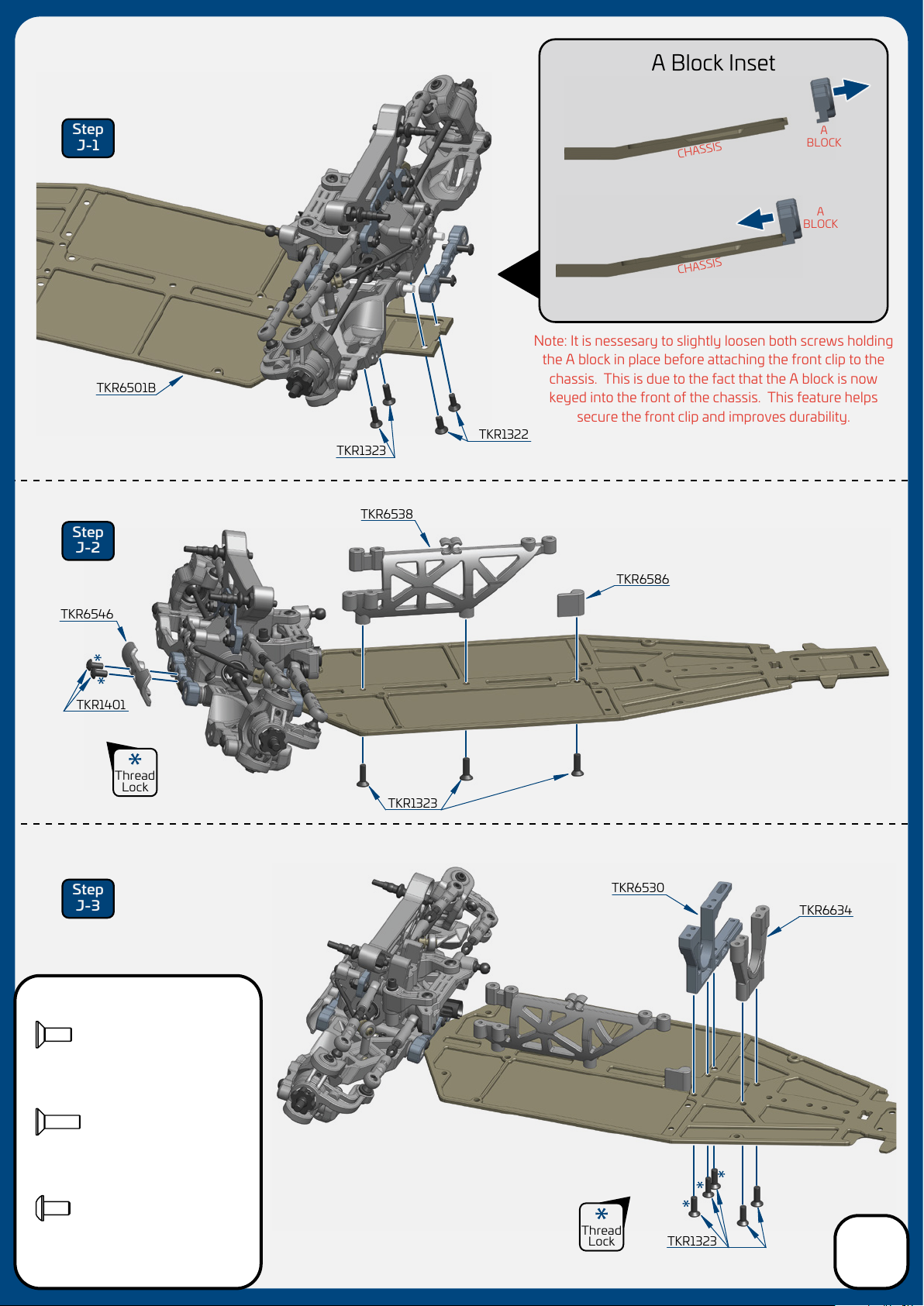

0

A Block Inset

Note: It is nessesary to slightly loosen both screws holding

the A block in place before attaching the front clip to the

chassis. This is due to the fact that the A block is now

keyed into the front of the chassis. This feature helps

secure the front clip and improves durability.

CHASSIS

CHASSIS

A

BLOCK

A

BLOCK

TKR1323

TKR6501B

TKR6586

TKR1323

TKR1322

TKR1401

TKR6546

TKR1323

TKR6530

TKR6634

TKR6538

Step

J-1

Step

J-2

Step

J-3

TKR1322

M3x8mm Flat Head Screw

x2

TKR1401

M3x6mm Button Head Screw

x2

TKR1323

M3x10mm Flat Head Screw

x10

Thread

Lock

Thread

Lock

Bag J

Front/Center Assembly

15

Same / Reversed

Use with

No Riser

(stock setting)

Use with

1mm Riser

Use with

2mm Riser

Thread

Lock

Step

J-4

Step

J-5

Step

J-6

Step

J-7

TKR1402

TKR6634

TKR6634

TKR6600

TKR1211

TKR6538

TKR1409

TKR1323 x 8pcs

TKR6634

TKRBB10154

TKRBB10154

TKR1211

M3 Lock Nut Flange Black

x1

TKR1409

M3x20mm Button Head Screw

x1

TKR1323

M3x10mm Flat Head Screw

x6

TKR1402

M3x8mm Button Head Screw

x4 TKR6599

TKR6538

Note: Use both rear braces

for the least chassis flex.

Use just the long rear for

less flex and short rear for

the most flex. More flex is

best suited for bumpy tracks.

*TKR6635C

(Option)

TKRBB10154

Ball Bearing (10x15x4)

x2

Bag J

Center/Rear

Assembly

16

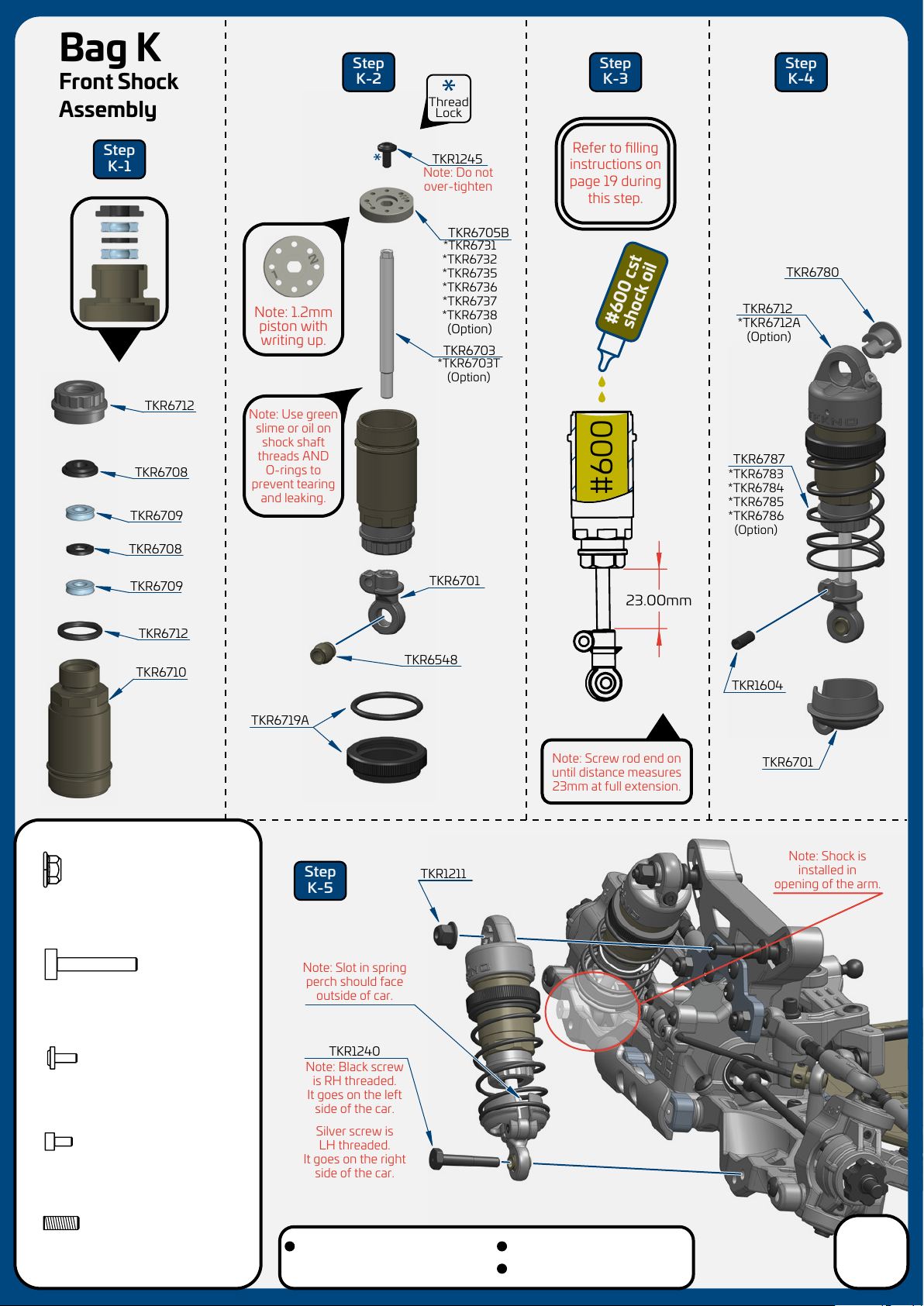

#600 cst

shock oil

TKR1240

Note: Slot in spring

perch should face

outside of car.

Note: Shock is

installed in

opening of the arm.

Note: Black screw

is RH threaded.

It goes on the left

side of the car.

Silver screw is

LH threaded.

It goes on the right

side of the car.

TKR1211

Thread

Lock

TKR6712

TKR6710

TKR6712

TKR6709

TKR6709

TKR6708

TKR6708

TKR1245

TKR6705B

TKR6703

TKR6701

TKR6548

*TKR6703T

(Option)

*TKR6731

*TKR6732

*TKR6735

*TKR6736

*TKR6737

*TKR6738

(Option)

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

Note: Screw rod end on

until distance measures

23mm at full extension.

TKR1604

TKR6701

TKR6712

TKR6780

*TKR6712A

(Option)

#600

Refer to filling

instructions on

page 19 during

this step.

Step

K-1

Step

K-2

Step

K-3

Step

K-4

Step

K-5

TKR1240

M3x18mm Shock Mnt Screw

x2

TKR1248

M2x4mm Emulsion Screw

x2

TKR1245

M2x5mm Piston Screw

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1604

M3x8mm Set Screw

x2

23.00mm

TKR6719A

Note: 1.2mm

piston with

writing up.

Note: Do not

over-tighten

TKR6787

*TKR6783

*TKR6784

*TKR6785

*TKR6786

(Option)

Bag K

Front Shock

Assembly

17

Stock shock position is 2nd

hole from inside on the tower

and outside hole on the arm (2/B)

Shock length (droop) is 78mm

Stock front ride height is 19mm

TKR1240

Note: Slot in spring

perch should face

outside of car.

TKR1211

TKR6712

TKR6709

TKR6711

TKR6709

TKR6708

TKR6708

TKR1245

TKR6701

TKR6548 TKR1604

TKR6701

TKR6712

*TKR6712A

(Option)

TKR6719A

Step

L-1

Step

L-2

Step

L-3

Step

L-4

Step

L-5

TKR1240

M3x18mm Shock Mnt Screw

x2

TKR1248

M2x4mm Emulsion Screw

x2

TKR1245

M2x5mm Piston Screw

x2

TKR1211

M3 Lock Nut Flange Black

x2

TKR1604

M3x8mm Set Screw

x2

#600 cst

shock oil

Note: Screw rod end on

until distance measures

29mm at full extension.

#600

29.00mm

TKR6712

Note: Black screw

is RH threaded.

It goes on the left

side of the car.

Silver screw is

LH threaded.

It goes on the right

side of the car.

TKR6704

*TKR6704T

(Option)

Thread

Lock

Note: Use green

slime or oil on

shock shaft

threads AND

O-rings to

prevent tearing

and leaking.

Note: 1.3mm

piston with

writing up.

Refer to filling

instructions on

page 19 during

this step.

Note: Do not

over-tighten

TKR6705B

*TKR6731

*TKR6732

*TKR6735

*TKR6736

*TKR6737

*TKR6738

(Option)

TKR6793

*TKR6794

*TKR6795

*TKR6796

*TKR6797

(Option)

TKR6780

Bag L

Rear Shock

Assembly

18

Stock shock position is 2nd

hole from inside on the tower

and inside hole on the arm (2/A)

Shock length (droop) is 89mm

Stock rear ride height is 20mm

Shock Filling Instructions

For both front and rear shocks

Step 1. Start by drilling out the emulsion hole if necessary. Use a 1/16th (or 1.6mm) drill bit to drill all the way

through and clear any flashing created by this. Insert the four larger o-rings into the emulsion caps and set

aside. Install the small o-rings onto the small emulsion screws.

Step 2. Fill shock with oil all the way to the top and pump the shock shaft up and down 3-5 times.

Step 3. Screw on the cap all the way tight (shock tool TKR1115 is helpful for holding the shock body).

Be careful to not cross-thread the caps. Start by turning in the oposite direction before tightening.

Step 4. With the shock at about a 45° angle, push and hold the shock shaft to the top of the stroke and

insert the prepared emulsion screw/seal. Oil should leak out during this process. If it does not, add more oil.

Tighten the screw until snug (do not over-tighten). Wipe o excess oil before moving on to step 5.

Step 5. Pump the shock shaft up and down about 20 times vigorously. This emulsifies the oil.

Step 6. With the shock shaft fully extended, remove the emulsion screw from the cap to do the final bleed.

Step 7. With the shock at about a 45° angle, push and hold the shock shaft to the top and insert the

prepared emulsion screw/seal again. Oil will leak out during this process. Finish by tightening the screw

until snug (do not over-tighten).

We've found it's easiest to complete steps 1 & 2 on each shock before moving on to step 3.

By the time you've finished step 2 on the last shock, the first one will be ready for step 3.

Fill with oil,

Pump up and down

3-5 times,

Then screw on cap

Fill with oil,

Pump up and down

3-5 times,

Then screw on cap

Pump up

and down

30 times

Pump up

and down

20 times

Prepare caps by

drilling emulsion hole

AND

inserting seals

AND

Push smaller

screws into small

o-rings

Push shaft up

to bleed air out

THEN

Insert screw snug

(do not over-tighten)

TKR6714

TKR6712

TKR1248

TKR6714

Pull shaft down,

remove screw

THEN

Push shaft up to bleed air,

insert screw snug

(do not over-tighten)

Step

1

Step

2-3

Step

4

Step

5

Step

6-7

19

1/16th Drill Bit

(if needed)

Note: Do not

over-tighten

Note: Do not

over-tighten

TKR1323

M3x10mm Flat Head Screw

x6

TKR1221

M3X8mm Washer

x4

TKR1522

M3x8mm Cap Head Screw

x2

TKR1403

M3x10mm Button Head Screw

x4

TKR1403

TKR1323

TKR1323

TKR1403

TKR1221 TKR6586

TKR6685

TKR1221

TKR6586

TKR6539

TKR1522

Motor (not included)

Step

M-1

Step

M-2

Step

M-3

Thread

Lock

IMPORTANT RADIO SETUP TIPS, MUST READ:

The Tekno RC EB410.2 is highly tunable, but can be very

aggressive depending on track conditions and tires used.

To help with this, we recommend that you are well informed

about setting up your Steering EPA, Servo Speed, Dual Rate,

and Exponential Curves.

PLEASE READ PAGE 28 FOR MORE DETAILS.

Steering servo (not included)

TKR6586

TKR6586

TKR1403

Note: We recommend using

a low profile servo with at least

180 oz/in torque and metal

gears. Running less than our

recommended rating will

increase the chance of

premature servo failure.

Note: This shim only

required if the servo

is hitting chassis,

or if the servo

arm is hitting

the ackerman.

Note: This shim only required if

the servo is hitting chassis,

or if the servo arm is hitting

the ackerman.

TKR1221

(w/2 cell)

(50-80 ft Straight)

Small Track

(48pitch pinion/spur)

Large Track

(48pitch pinion/spur)

(80-150 ft Straight)

Motor

5.5T

6.5T

7.5T

8.5T

10.5T

18/81 tooth

19/81 tooth

20/81 tooth

21/81 tooth

22/81 tooth

19/81 tooth

20/81 tooth

21/81 tooth

22/81 tooth

23/81 tooth

13.5T 22/81 tooth 24/81 tooth

(50-80 ft Straight)

Small Track

(32pitch pinion/spur)

Large Track

(32pitch pinion/spur)

(80-150 ft Straight)

12/53 tooth

12-13/53 tooth

13-14/53 tooth

14/53 tooth

14-15/53 tooth

12-13/81 tooth

13/53 tooth

13-14/53 tooth

14-15/53 tooth

15/53 tooth

14-15/53 tooth 15/53 tooth

Bag M

Final Assembly

20

Table of contents

Other Tekno Motorized Toy Car manuals

Popular Motorized Toy Car manuals by other brands

Power Wheels

Power Wheels K9829 Owner's manual with assembly instructions

Cen

Cen NX series manual

maxam

maxam Wiper M10 Assembly instructions

THUNDER TIGER

THUNDER TIGER G3 EB-4WD 6400-F manual

Kool Karz Playground

Kool Karz Playground KKNL-017 Instructions for installation

King Motor

King Motor Tyrant4 DS instruction manual