tekton TRQ62103 User manual

SPLIT BEAM

TORQUE WRENCH

TRQ62103 - 3/8 in. Drive Split Beam Torque Wrench (20–100 .-lb.)

TRQ62203 - 1/2 in. Drive Split Beam Torque Wrench (40–250 .-lb.)

Product Manual

Before using the torque wrench, be sure to read and understand the entire manual.

This tool is a precision measuring instrument that should be operated, stored, and

maintained with care. Failure to follow instructions could result in damage to the

tool, damage to property, or injury.

Flip the cover down to

access the adjustment knob.

Turn the adjustment knob

to the desired torque value.

Replace the cover over the

adjustment knob to secure

it during use. Confirm the

torque setting is accurate.

Determine the required torque for your application in foot pounds (ft.-lb.). Use the

conversion scale on the torque wrench to convert Nm to ft.-lb. If needed, use page 4

to convert other torque units to foot pounds.

INTERNAL MECHANICS

SETTING THE TORQUE VALUE

Click!

OPERATION

1

Conversion Scale

Torque wrench operates

and measures in the

clockwise direction only.

1

2

3

4

Don't use extensions on the handle.

The torque measurement will be

inaccurate and the tool could

become damaged.

STOP applying torque when you hear and

feel a click. This means you’ve reached the

desired torque value.

2

Click!

APPLYING TORQUE

OPERATION

For off-axis tools, like a crowfoot

wrench, calculate a leverage

adjustment on page 5.

Attach a drive tool to the drive tang.

The flex joint provides clearance for

working around obstacles but, when

flexed, can reduce accuracy by up to

4 percent due to the offset from the

plane of rotation.

Engage the drive tool on the fastener

or fitting. For the most accurate

reading, the ratchet head must be

parallel with the wrench body.

Grip the center of the handle and apply

torque SLOWLY in a clockwise direction.

Don't use the torque wrench on

electrical circuits. The handle

doesn’t provide insulation from

electrical current.

Center of Handle

Parallel Flexed

Flexed

• If the torque wrench is not used regularly, operate it several times at a low torque

setting to redistribute lubricant to the internal moving parts.

• The components in the handle are lubricated for life and should not be oiled. The

ratchet head may be lubricated for smooth use as needed.

• Clean the wrench by wiping it with a clean, dry, lint-free cloth. Do not immerse the

wrench in any type of liquid or cleaner to avoid damaging the internal components.

• The torque wrench should only be serviced or recalibrated by an accredited

measurement laboratory.

The ratchet head can be disassembled, if needed, for lubrication or service. Don’t

disassemble other parts of the wrench.

TORQUE WRENCH DIAGRAM

TORQUE WRENCH CARE

This tool is a precision measuring instrument that should be operated, stored, and

maintained with care.

STORAGE

MAINTENANCE

• Store the torque wrench in the storage case in a dry location.

• The torque wrench can be stored at any torque setting because of its internal design.

By comparison, other torque wrenches, like click-style models, often have to be

stored at the lowest torque setting.

3

Ratchet

Head

Flex

Joint

Adjustment

Knob

Cover Center of

Handle

Torque

Setting

Conversion

Scale Handle

FOOT

POUNDS

(.-lb.)

1

2

3

4

5

10

15

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

1.356

2.712

4.067

5.423

6.779

13.56

20.34

27.12

33.90

40.67

47.45

54.23

61.01

67.79

74.57

81.35

88.13

94.91

101.7

108.5

115.2

122.0

128.8

135.6

149.1

162.7

176.3

189.8

203.4

216.9

230.5

244.0

257.6

271.2

284.7

298.3

311.8

325.4

339.0

0.1383

0.2765

0.4148

0.5530

0.6913

1.383

2.074

2.765

3.456

4.148

4.839

5.530

6.221

6.913

7.604

8.295

8.987

9.678

10.37

11.06

11.75

12.44

13.13

13.83

15.21

16.59

17.97

19.36

20.74

22.12

23.50

24.89

26.27

27.65

29.03

30.42

31.80

33.18

34.56

13.83

27.65

41.48

55.30

69.13

138.3

207.4

276.5

345.6

414.8

483.9

553.0

622.1

691.3

760.4

829.5

898.7

967.8

1037

1106

1175

1244

1313

1383

1521

1659

1797

1936

2074

2212

2350

2489

2627

2765

2903

3042

3180

3318

3456

12

24

36

48

60

120

180

240

300

360

420

480

540

600

660

720

780

840

900

960

1020

1080

1140

1200

1320

1440

1560

1680

1800

1920

2040

2160

2280

2400

2520

2640

2760

2880

3000

192

384

576

768

960

1920

2880

3840

4800

5760

6720

7680

8640

9600

10560

11520

12480

13440

14400

15360

16320

17280

18240

19200

21120

23040

24960

26880

28800

30720

32640

34560

36480

38400

40320

42240

44160

46080

48000

NEWTON

METERS

(Nm)

KILOGRAM

METERS

(kg-m)

KILOGRAM

CENTIMETERS

(kg-cm)

INCH

POUNDS

(in.-lb.)

OUNCE

INCHES

(oz.-in.)

TORQUE CONVERSION

4

INPUT OPERATION

Units

Torque

Value Units

Torque

Value

OUTPUT EXAMPLE

Nm

kg-m

kg-cm

in.-lb.

oz.-in.

×

0.7376

7.233

0.07233

0.08333

0.00521

ft.-lb.

0.7376

7.233

0.07233

0.08333

0.00521

80 Nm × 0.7376 = 59 .-lb.

59 .-lb. ÷ 0.7376 = 80 Nm

Nm

kg-m

kg-cm

in.-lb.

oz.-in.

ft.-lb.

FORMULA INPUTS

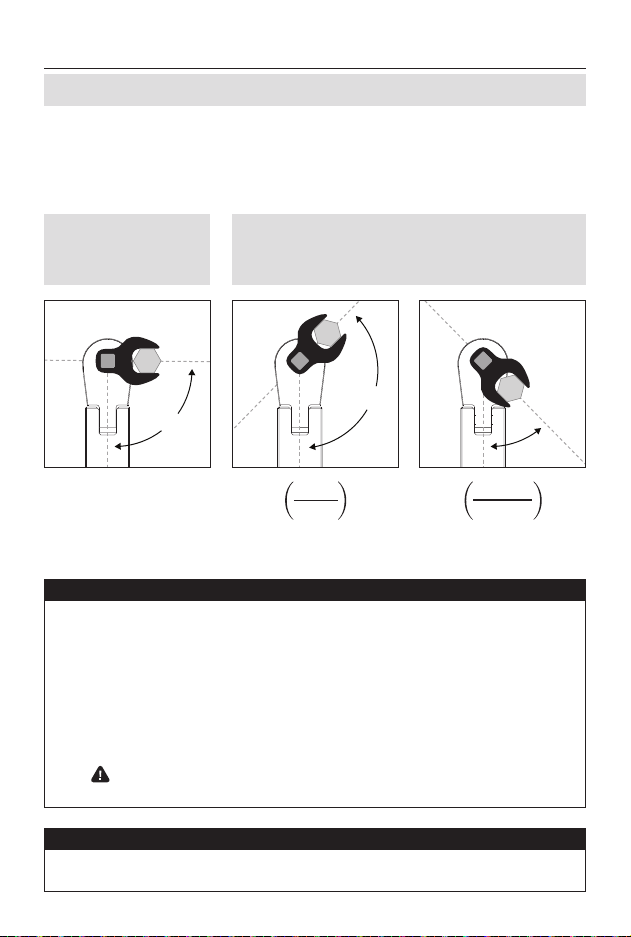

The amount of leverage that's applied to a fastener is affected by the position of a

drive tool in relation to the torque wrench's drive tang. When using an off-axis tool that

doesn’t align with the drive tang, such as a crowfoot wrench, you may need to adjust

your torque setting.

T1 — Torque specification for the fastener

L— Effective length of the torque wrench

TRQ62103: L = 15.62 in.

TRQ62203: L = 19.22 in.

C— Change in length caused by a crowfoot wrench or other drive tool that

doesn’t align with the drive tang

T2 — Torque value you should use

LEVERAGE ADJUSTMENT

T1 × = T2

L

L + C T1 × = T2

L

L + (-C)

90º

>90º

<90º

5

If possible, align the

drive tool at a 90-degree

angle to the drive tang.

If a different angle is required, use one of the formulas

below to determine the appropriate torque value.

No formula is needed. Set

the torque value to the

fastener’s specification.

FORMULA OUTPUTS

Measure from the center of the fastener to the center of the drive tang in

a line parallel to the body of the wrench.

See Example 1 See Example 2

CALCULATION

Example 1

Example 2

Center of Handle

Center of Fastener

Center of Drive Tang

T2 = Torque Value

T1 = Torque Specification

for Fastener

L = Effective Length

C = Change in

Length

80 .-lb. × = 75.7 .-lb.

19.22 in.

19.22 in. + 1.1 in.

6

>90º

T1 = 80 ft.-lb.

C = 1.1 in.

80 .-lb. × = 84.9 .-lb.

19.22 in.

19.22 in. + (-1.1 in.)

<90º

T1 = 80 ft.-lb.

C = 1.1 in.

LEVERAGE ADJUSTMENT

DIAGRAM

We stand behind our products. 888-648-3371

tekton.com/support

KEEP THIS MANUAL IN THE STORAGE

CASE FOR FUTURE REFERENCE

This manual suits for next models

1

Table of contents

Other tekton Power Tools manuals