Angle nutrunner PNEUMAT 103 4 CC2 RAH2L H13 X 2 AL /Instructions Manual

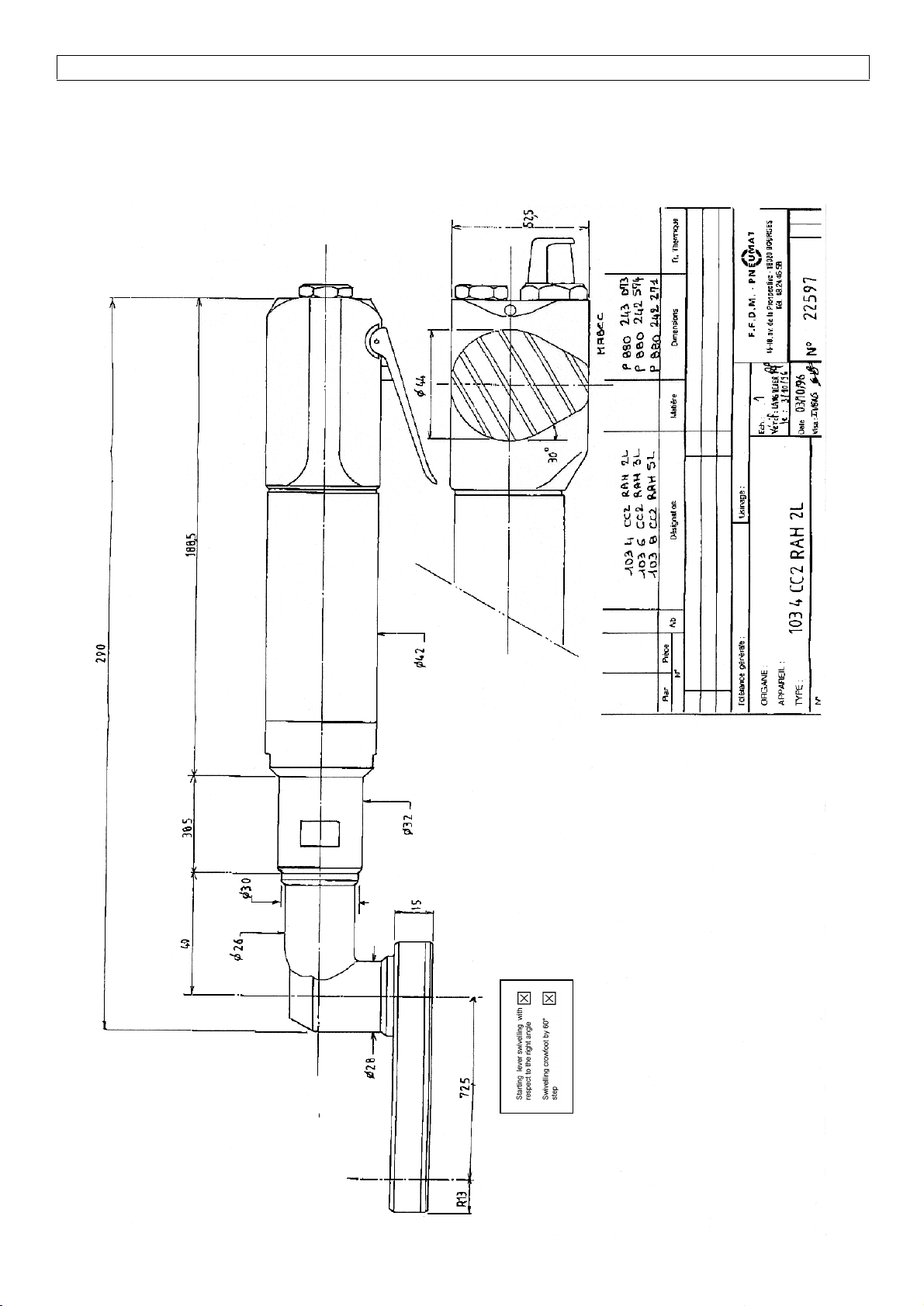

5. TORQUE ADJUSTMENT

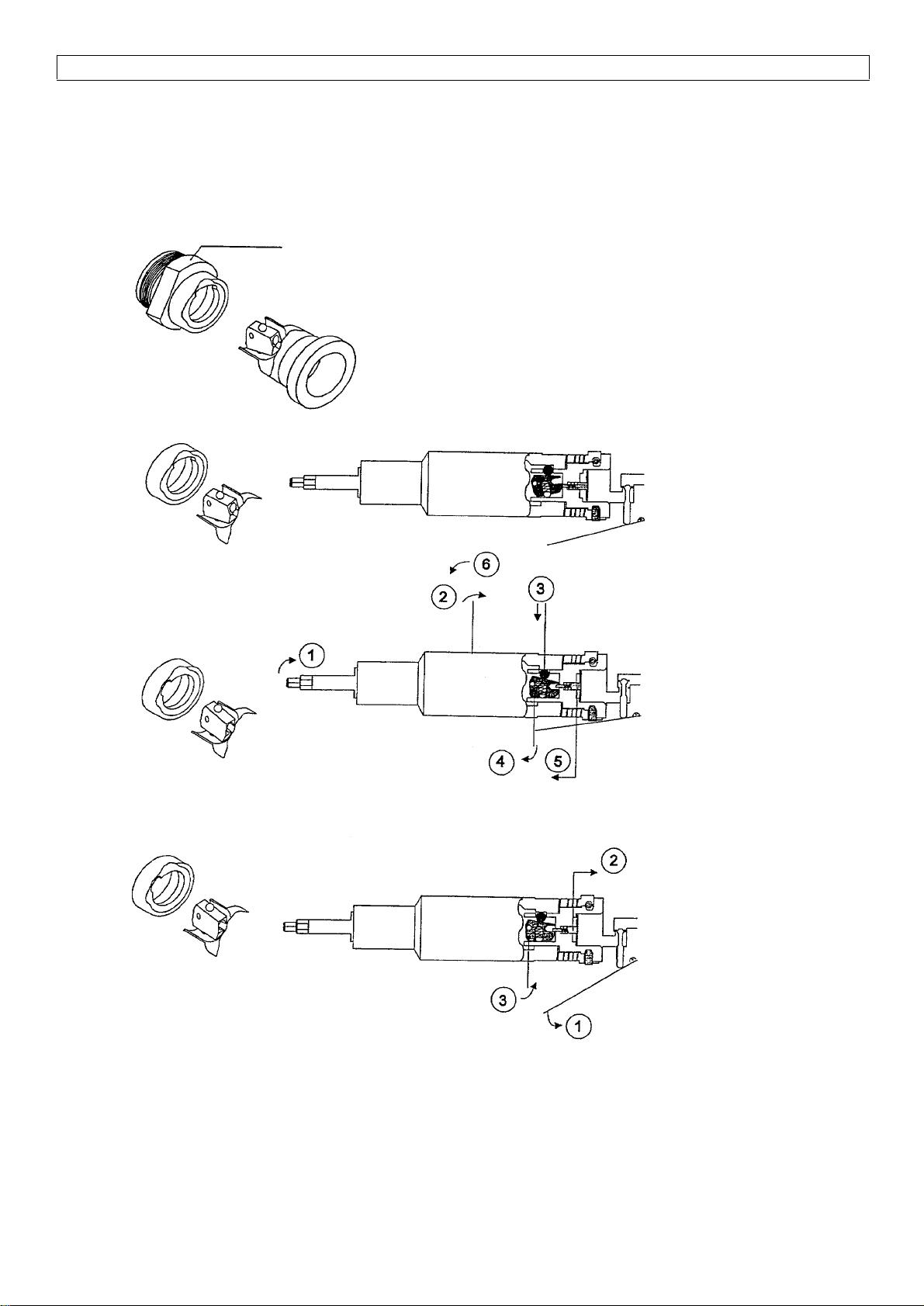

Adjustment procedure :

First, of all, adjustment to the utilized torque, the position corresponding to the minimum torque.

Let the screwdriver turn in free rotation in the screwing sense and after having untightened the blocking

screw (43B), turn the adjusting screw (43C) in the negative sense (anticlockwise) until the screwdriver stops.

Release the lever and activate one more time the lever : the screwdriver musn’t turn.

Turn the adjusting screw in the clockwise direction by

half turn and activate the lever at each phase : when

the screwdriver starts, the adjusting torque

corresponds to the minimum torque.

Proceed to the standstill torque value control by

inserting a rotary transducer between the screwdriver

and the tightening socket in accordance with the 5393

ISO standard procedure.

Change the adjustment until obtaining the desired torque by taking up the adjusting screw play before to

unscrew the clamping screw.

We advise you to act on this screw only by succesive half-turn and to make a control after each adjusting

modification.

Do not make any adjustment on a retightening.

After each intervention on the adjusting screw (43C), retighten moderately the blocking screw.

6. UTILISATION CAUTION FOR CROWFOOT NUTRUNNERS

The nutrunners equipped with crowfoot require a particular care. The train of gears wich permits to make

screwings in hard-to-get to zone, is often proportioned in function of the ensambly working environment in

unusual conditions.

In certain cases where numerous pinions are necessary inside the crowfoot, the train of gears reversibility is

not systematic. We advise you against practising a traction on the screwdriver when it has reached its

screwing torque (after locking due to the limiter). It could bring about a retightening of the ensambly, or if this

action was repeated a premature breaking of the crowfoot or of its pinions.

7. ASSEMBLY AND DISASSEMBLY RECOMMENDATIONS

At each disassembly, clean and study carefully all the spare parts before to proceed to the gears and ball

bearings regreasing.

Lubricate lightly the blade housings in the moment of the motor reassembly.

Use only appropriated wrenches. Do not use vice tightening and multiple slip-joint pliers.

Warning :

The presence of a cutting kerf on a nut symbolize a threading on the left. It is recommended to disassembly

frecuently the exhaust silencers and to clean them with a spray gun after having soak them in a degreasing

agent solution in order to preserve the original caracteristic of the tool.

8. LUBRICATION

Unless otherwise stated, pneumatic tools must be feeded with filtered and lubricated air.

It is recommended to install the lubricator the nearer possible of the tool especially during the screwdriver

utilisation. It is also recommended to watch over to the good functionning and to the oil supply adapted

adjustment.

After a prolonged locking, introduce by the feeding connector some crude drops or clean gas oil drops.

-turn the motor in manual by actionning the output spindle.

Blocking screw

Adjusting screw

Adjusting wrench

Male 6 flats wrench of 3 mm