Tela TGM133 User manual

TELA merilni sistemi

Scale Unit TGM133/134

Instruction Manual

ID 430 261 710 000, 4th Edition

TGM133/134 Instruction Manual May 2013 4th Edition 2/24

Safety Precautions

TELAms products are designed in full consideration of safety. However,

improper handling during operation or installation is dangerous and may

lead to fire, electric shock or other accidents, resulting in serious injury or

death. In addition, these actions may also worsen machine performance.

Therefore be sure to read this Manual before operating, installing,

maintaining, inspecting, repairing or otherwise working on this unit.

Warning, Caution

• Do not use this unit with voltages other than specified supply

voltage as this may result in fire or electric shock.

• Do not disassemble or modify the unit as this may result in injury or

damage the internal circuits.

• Be sure to check the machine and device conditions to ensure safety

work on a machine.

• Be sure to switch off the power supply, air and other sources of

drive power before working on the machine.

• When turning on a machine power supply, take care about moving

parts of a machine and corresponding devices.

General precautions

When using TELAms products, observe the following general precautions along

with those given specifically in this manual to ensure proper use of the products.

• Provide adequate safety measures to prevent damages in case the product

should develop malfunctions.

• Use outside indicated specifications or purposes and modification of our

products will void any warranty of functions and performances

• When using our products in combination with other equipment, the functions

and performances as noted in this manual may not be attained, depending on

operating and environmental conditions.

TGM133/134 Instruction Manual May 2013 4th Edition 3/24

Installation precautions

When installing this unit, care should be given to the following points to

prevent noise and electromagnetic wave interference from other equipment.

1. Do not pass lead and connection cables through the same ducts as

power lines.

2. Be sure to install the unit at least 0.5 m or more away from high voltage

or large current sources or high-power relays.

Installation place precautions

1. Mount the scale as closely as possible to the work-piece or to the object

being measured. Further the scale is mounted, greater is measuring error.

2. The scale unit should be used within an ambient temperature range of 0

to 50°C. Avoid locations where the scale is exposed to direct sunlight and

heat sources such as motors.

3. Do not place anything on the mounted scale, or step on it: excessive

force to the scale causes trouble.

Before installation

Do not disassemble parts other than scanning unit holder. All electrical

adjustments have also been completed before shipment. So do not tamper any

additional adjustment at time of its installation.

This scale unit consists of precision mechanism parts and electromagnetic

parts. Therefore, applying excessive pressure to the unit can seriously harm

the performance and service life of the scale. Be careful not to apply

excessive pressure to the scale unit when proceeding with the work.

When the unit is to be carried, support the scale unit and reading head

altogether. Do not hold the unit by the head cable, connectors, etc.

Ensure that the scale unit housing and reading head as well as the circuit

breaker for the supply power are properly grounded.

Standard procedure for EMC compliance.

When equipment such as controller does not function properly due to the effects

of large noise from power line please provide ground lines at one point

intensively. Power source which has a remote sensing function, must be used for

TGM133. Power unit without remote sensing unit may fail to prove optimum

functions. Please provide proper power source by referring to Section 5.

TGM133/134 Instruction Manual May 2013 4th Edition 4/24

Table of contest

1. Outline …………………………………………………….…...

5

1.1. Before Operation…………………………………………...…………………………….

5

1.2. List of Parts Supplied with the Scale Unit……………..……………………………

5

1.3. Model Configuration……………………………………….……………………………

6

2. Specifications………………………………………

…

…

…….

7

3. Name and Function of Part

s

……

…………………

……….

8

4. Mounting ………………………………………………

……….

9

4.1. Mounting Precautions……………………………………

…………………………….

9

4.1.1.

Checking the Mounting P

osture………………

……………………………………

9

4.1.2.

Setting the Operation R

ange…………………………

..

……

………………………

9

4.1.3.

Protection of the Head C

able…………………………..

……………………………

1

0

4.1.4.

Mounting the Protective C

over……………………...

...

……………………………

1

0

4.2.

Tools required for Scale I

nstallation……………………

……………………………

1

1

4.3

.

M

ount

ing procedure

…………………………………………

………………………

…

.

1

2

4.3

.1.

Mounting the Main U

nit

…………………………………

……………………………

1

2

4.3

.2. Mounting the Scanning Unit

………………………....

……………………………

1

3

4.3

.3. Removing the Scanning Unit Holder…………………

……………………………

1

4

4.3

.4. Checking the Operation Range

………………………

……………………………

1

5

4.3

.5. Attaching the Head Cable

…………………………….

……………………………

1

6

4.3

.6. Air Injection

……………………………………………….

…………………………

1

6

5. Connecting to

a

D

evice ……………………………

……….

1

8

5.1. Output Signal……………………………………………….

……………………………

1

8

5.2. Output connector

s

………………………………

…….

…

………

……………………

19

5.

3

. Alarm ( DS version optionally )………………………….

……………………………

2

1

6. Dimensions …………………………………………

…………

2

2

7. T

rouble prevention ………………………………….……….

24

TGM133/134 Instruction Manual May 2013 4th Edition 5/24

1. Outline

1-1. Before Operation

TGM133/134 series is small, light and high-accuracy optical feedback scale.

This series provides Line driver (A, A-, B, B-, RI, RI- digital output) or

Sinusoidal signals (1Vpp or 11µA output).

Output signals are adjusted before shipment, ex.-factory, each signal can be

readily used for connection to control device as it is.

1-2. List of standard parts supplied with scale unit

TGM133 Scale unit

Parts supplied with scale unit

HSB M8 x 20 2 (For mounting channel)

HSB M4 x 20 2 (For mounting scanning unit)

Cable clamp (small) 3 (For cable clamp)

+P M4 x 10 3 (For cable clamp)

Inspection certificate (Accuracy chart) 1

Instruction manual 1

Air injection valve 1

TGM133/134 Instruction Manual May 2013 4th Edition 6/24

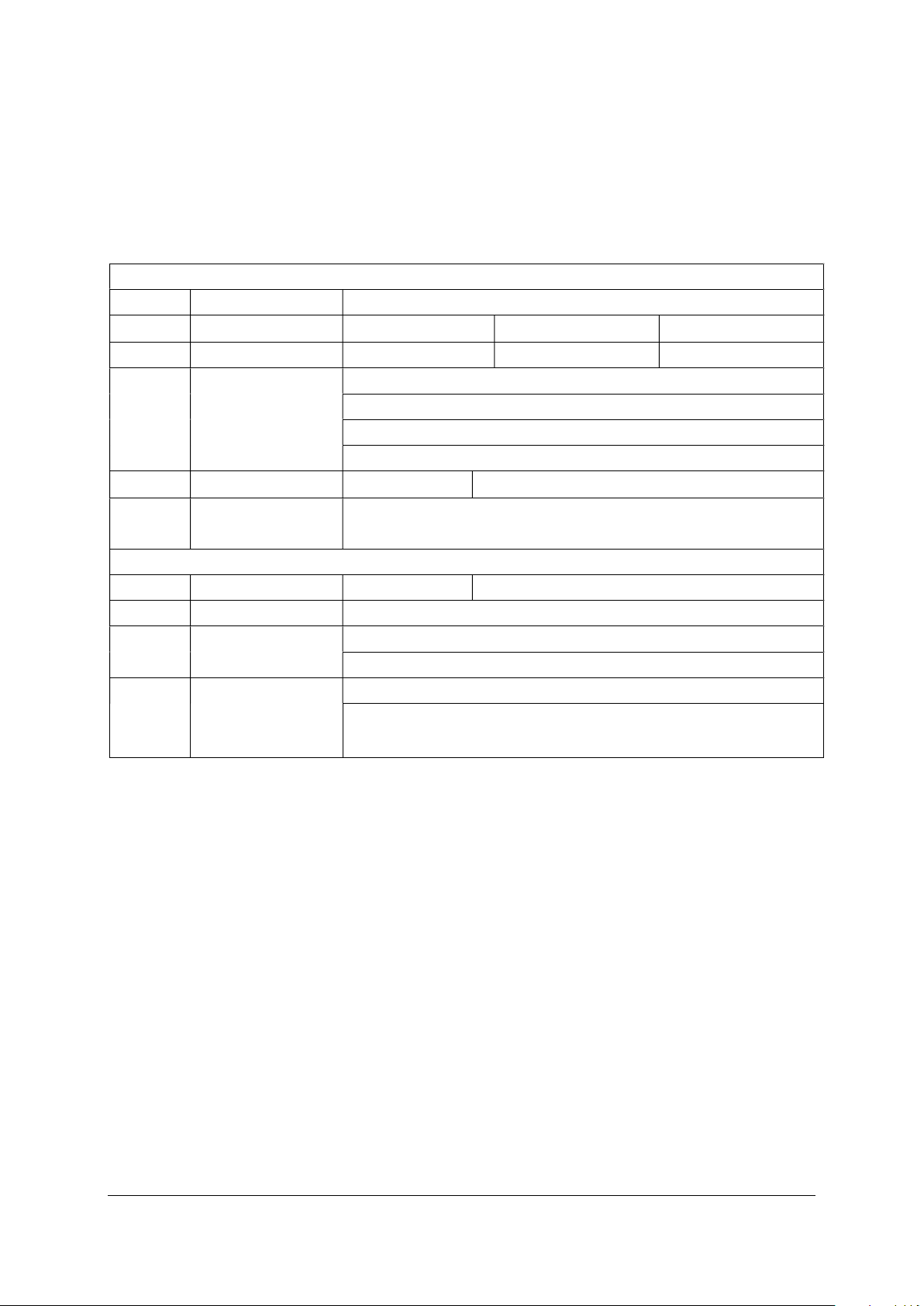

1.3. Model configuration

TGM133-XX1-X2-XX3-X4-X5-XXXX6-XX7-X8-X9-X10

TGM134-XX1-X2-XX3-X4-X5-XXXX6-XX7-X8-X9-X10

Standard requirements

XX

1

Voltage supply

05 … 5V

X2 Resolution

0.1…0.1

m

0.5 … 0.5

m

1 … 1

m

XX

3

Output signals

DS

SI

SV

X4 Reference mark

0 … without

1 … in the middle

2 … on agreement

4 …

distance coded reference

X5 Accuracy

3 …

3

m

5 …

5

m

XXXX6

Measuring

length

Standard length [mm]

(see specifications on next page)

Special requirements:

XX

7

Cable length

3m : 03

Example: 1.5m : 1.5, 25m : 25

X

8

Connector

*

X9 Metal flexib

le

tube

0 … without

1 … with

X10 Mounting bar

0 … without

1…with: recommended for Lm

1240 mm,

required for Lm

1240mm

* Connector is defined with electrical versions SV, DS or SI:

1 … Amphenol 12 pin (DS)

4 … Conntact 12 pin connector (DS, SV)

5 … Conntact 9 pin connector (SI)

6 … Conntact 12 pin coupling (DS, SV)

7 … D-sub 9 pole (DS)

9 … other (specify)

0 … without connector

The difference between TGM133 and TGM134 see in section 6.

TGM133/134 Instruction Manual May 2013 4th Edition 7/24

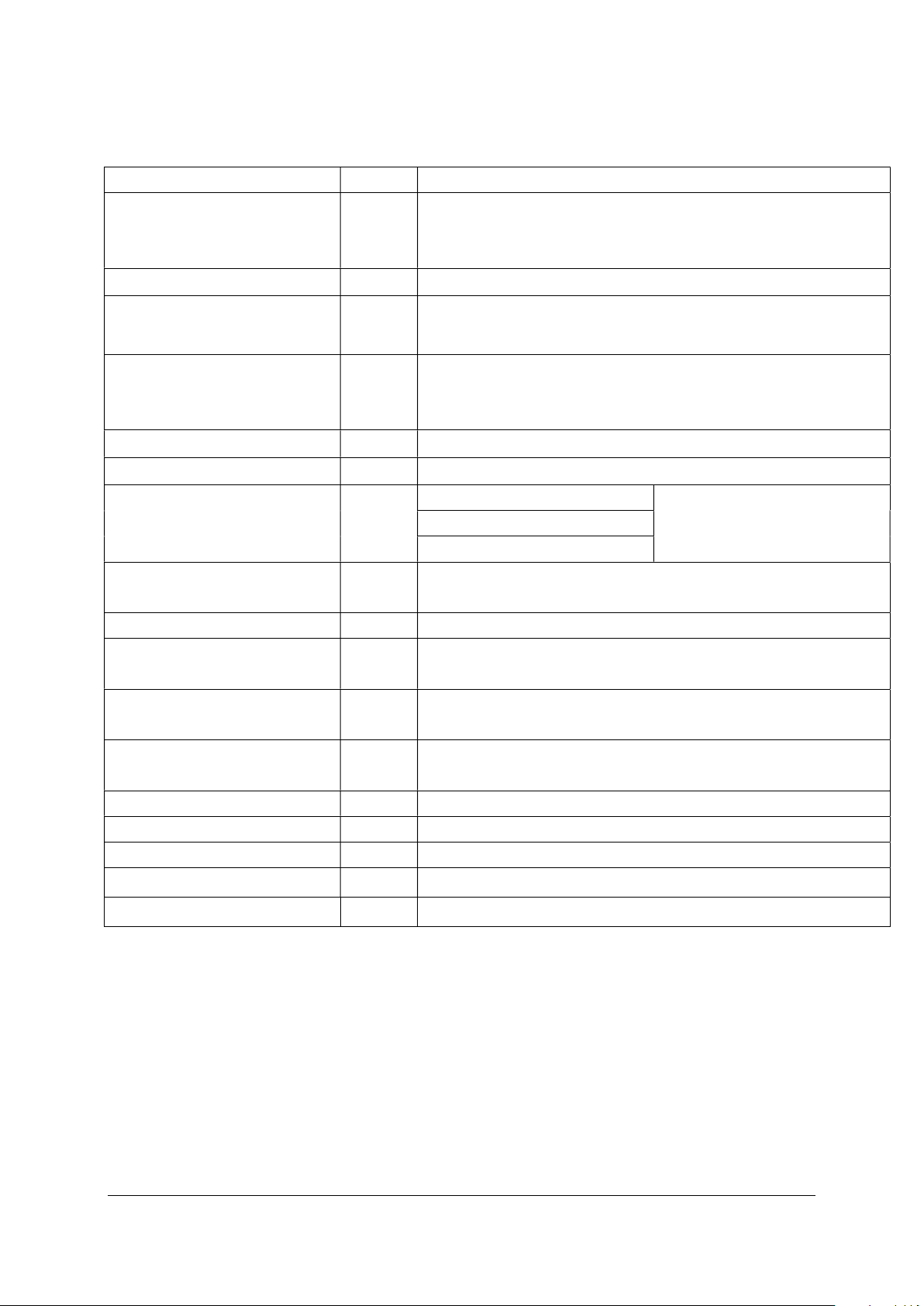

2. Specifications

Items

Unit

TGM133

/134

Measuring length mm 70, 120, 170, 220, 270, 320, 370, 420, 470, 520, 570,

620, 670, 720, 770, 820, 920, 1020, 1140, 1240,

1340, 1440, 1540, 1640, 1740, 1840, 2040

Scale accuracy (at 20

C)

m

3,

5 (per meter)

Output Line driver: A, A-, B, B-, RI, RI-

Sinusoidal signal: 1Vp

p or 11

A

Reference point Distance Coded Reference (position is reproduced

by passing two adjacent reference marks that are

20 mm apart from each other.) (NOTE 1)

Resolution

m

0.1, 0.5, 1.0 (DS signals)

Signal period

m

20

Maximum response

speed m/min

20 (at 0.1 µm)

120 (SI, SV)

50 (at 0.5 µm)

60 (at 1.0 µm)

Scale temperature

expansion coefficient

K-1 (8.8 ± 1) X 10-6

Protection grade

Standard: IP53, with injecting air: IP64

Power supply +5 V 120mA max (DS)

+5 V 1

0

0mA max (SV, SI) (NOT

E 2)

Scanning unit sliding

resistance

N 3

Maximum capable cable

length

m Standard 3 (1, 5, 7, 10, 15, 20, 25, 30, 50, 100, 150

possible) (NOTE 3)

Operating temperature

°C

0 to +50

Storage temperature

°C

-

30 to +70

Operating humidity

%RH

30 to 90 (No

condensation)

Vibration resistance

m/s

2

70

Shock resistance

m/s

2

300

(NOTE 1) Any one location can be designated as the reference point, and

multiple reference points (at a pitch of 20 mm) can also be supported.

(NOTE 2) When load resistance of A/B/RI/ALM is 120, refer to section 5-3

for details of power voltage.

(NOTE 3) SV can perform output range of 0.6 V to 1.2 V as A/B phase output

with 150 m cable made by TELAms.

TGM133/134 Instruction Manual May 2013 4th Edition 8/24

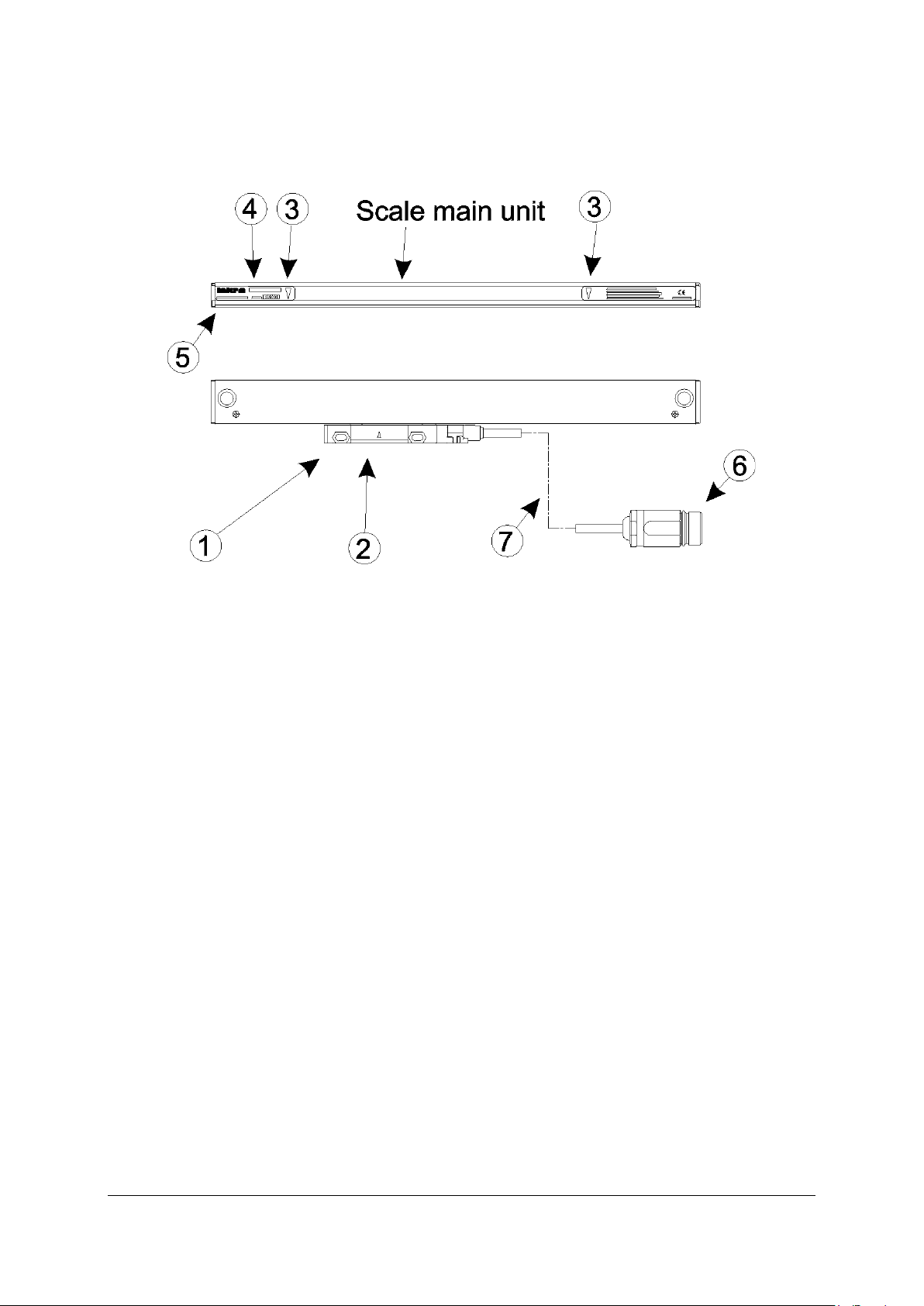

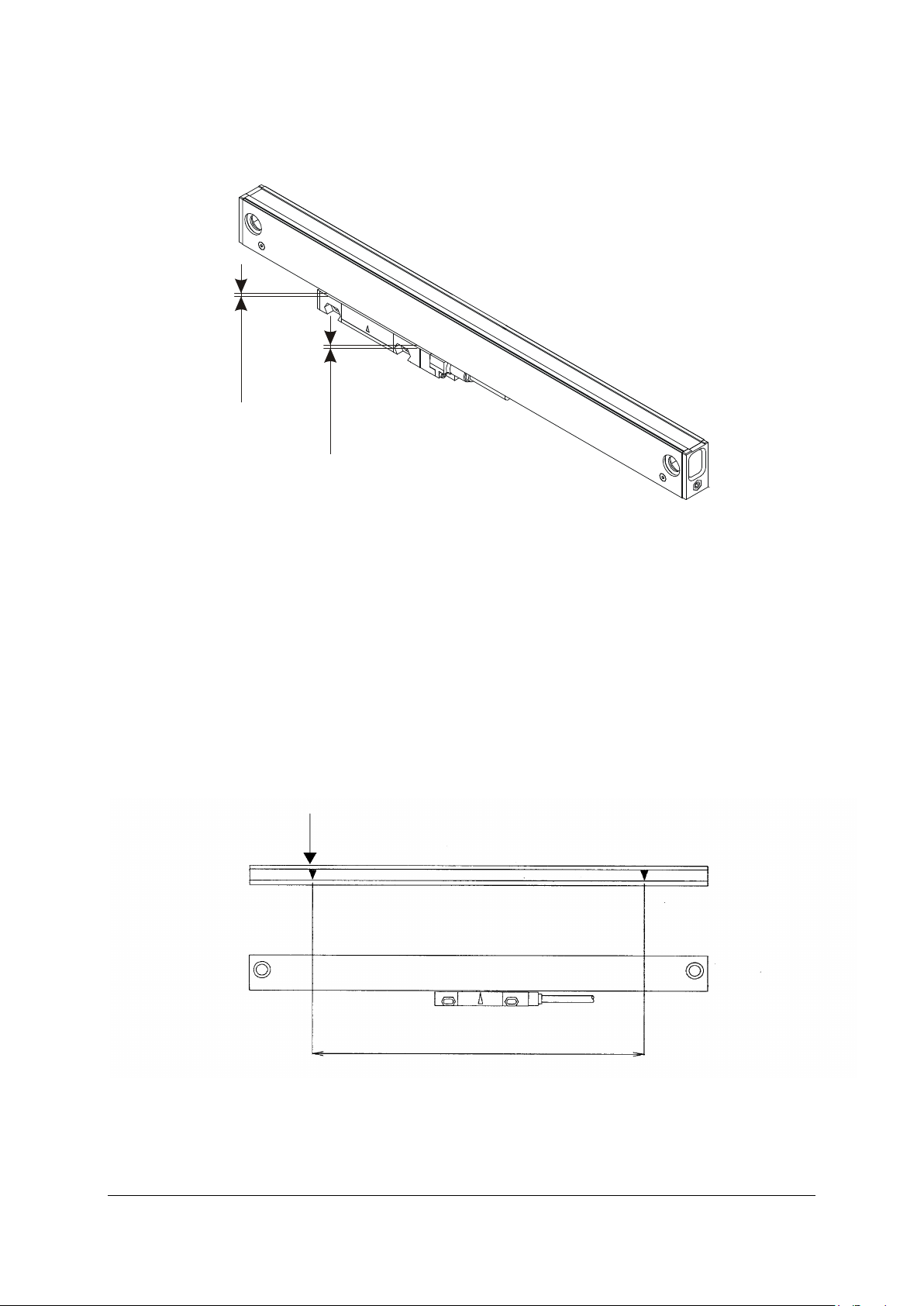

3. Name and Function of Parts

Reading head

This holds the scanning unit. When shipped, it is secured with a scanning unit

holder.

Centre of scanning unit

This indicates the mechanical centre of the scanning unit. It serves as a

reference when viewing the relative position to the measuring length marks.

Measuring length marks

These indicate the effective movement range over which accuracy is assured

with respect to the centre of scanning unit. The measuring length represents

the length of the effective movement range.

Note

When mounting and using the scale unit, be sure to operate the unit within

this range. Using the scale unit in excess of the effective movement range

may damage the unit.

Model name

This indicates the scale unit model name.

Serial No.

This indicates the scale unit serial No.

Connector.

Head cable.

TGM133/134 Instruction Manual May 2013 4th Edition 9/24

4. Mounting

4-1. Mounting precautions

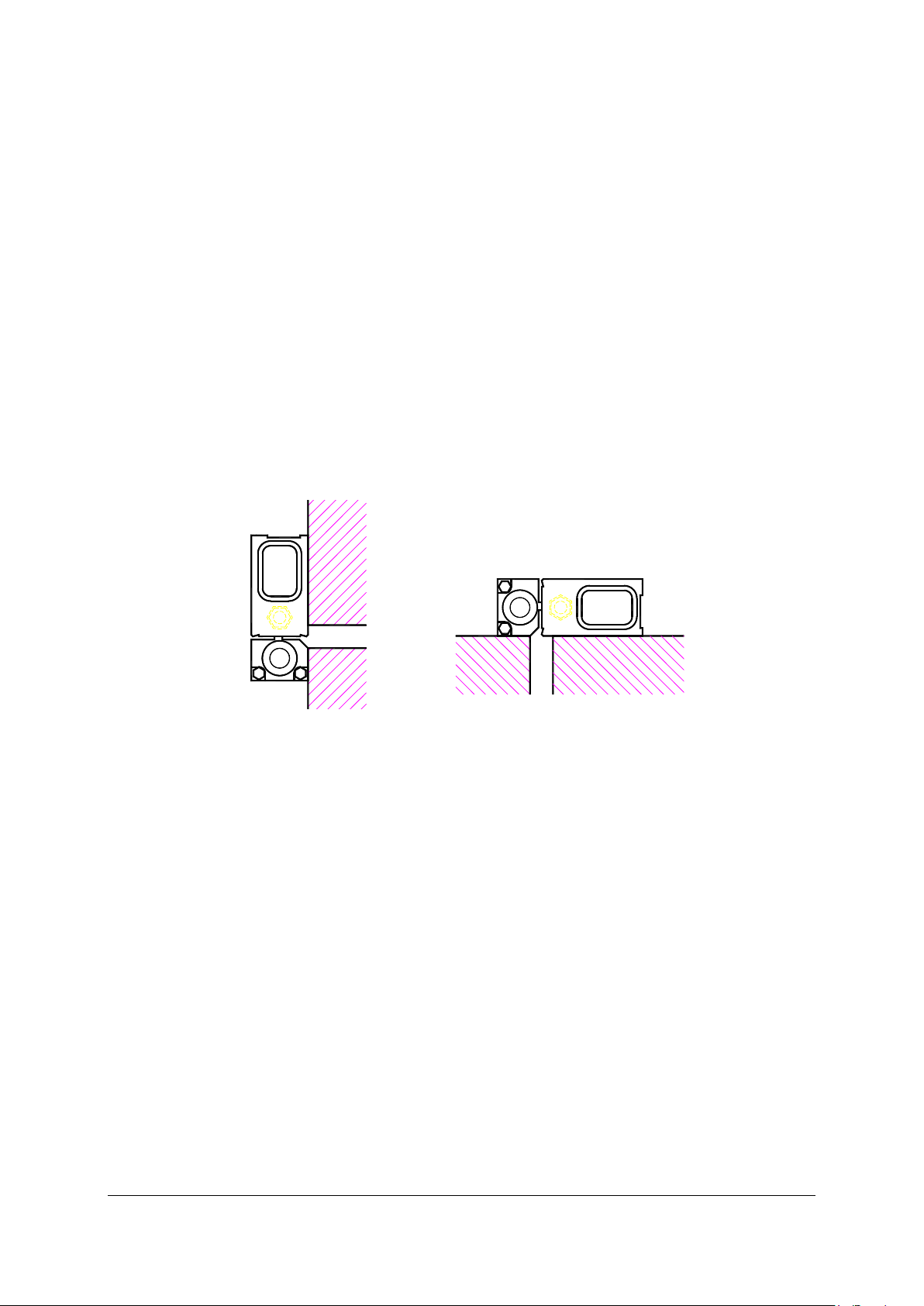

4-1-1. Checking the mounting posture

Check that the scale unit can be mounted in the relative positions shown in the

Fig. 4-1.

Do not mount the scale in any other posture otherwise difficulties in servicing

and maintenance may arise.

The mounting position A in particular is recommended: cutting oil and chips

may be effectively kept out.

Do not install at Position B, in case cutting oils or coolant may fall on the scale.

A B

Fig. 4-1

When a scale is installed on a vertical axis it should be mounted in such a

manner that its scanning unit will face opposite to a work piece (cutting tool).

4-1-2. Setting the operation range

• The measuring length of scale is the distance between the measuring length

marks at the both ends of the scale.

• Mount the scale in such a position that the slider center moves within these

measuring length marks.

• Take special care not to move the scanning unit beyond the range between

measurement length marks otherwise the scale may be damaged.

Mechanical limit mechanism (stoppers, etc.) is required if scanning unit needs

to move for its full stroke in measurement length near to measurement length

marks.

TGM133/134 Instruction Manual May 2013 4th Edition 10/24

Measuring length mark

Be sure to install the scale that the center of scanning unit is held in this area.

Fig. 4-2

4-1-3. Protection of the head cable

The head cable is secured on a slider with screw.

Take care not to pull the cable forcefully or bend it repeatedly otherwise the

cable may be broken or a connector may be damaged.

4-1-4. Mounting a protective cover

If chips or coolant will be splattered directly onto the scale during operation, it is

recommended that a cover which will hide it as much from outside view as

possible be mounted in order to maintain the scale’s performance. Such a cover

is shown in Fig. 4-3.

Fig. 4-3

TGM133/134 Instruction Manual May 2013 4th Edition 11/24

4-2. Tools required for scale installation

In addition to accessories, prepare following tools.

• Bracket for mounting scale (Refer to Fig. 3-4) 1 or 2

• Bracket for mounting scanning unit (Refer to Fig. 3-4)

• 0.01mm pick tester (or Dial gauge) 1 or 2

• Hexagon wrench for M4 (3mm) 1

• Hexagon wrench for M8 (6mm) 1

• Driver No.2 (+) 1

• Tap M4 1

• Tap M8 1

• Drill 3.2 1

• Drill 6.8 1

• Thickness gage = 0,7 mm 1

• Thickness gage = 1,0 mm 1

• Thickness gage = 1,4 mm 1

Accessories

HSB M8 x 20 2 (For mounting channel)

HSB M4 x 20 2 (For mounting scanning unit)

Cable clamp (small) 4

+P M4 x 10 4 (For cable clamp)

TGM133/134 Instruction Manual May 2013 4th Edition 12/24

4-3. Mounting procedure

4-3-1. Mounting scale main unit

1. Machine the mounting surface of the scale main unit to a flatness of 0.1

mm/M (where “M” is the machine guide) over the entire length of the

mounting area.

Fig. 4-4

Although Fig. 3-4 shows that brackets are being used, they are not needed if

the mounting surface of the machine main unit has already been machined to

the designated flatness before the scale is mounted.

2. Check the flatness of the mounting surface, and then attach the scale main

unit to this surface by tightening up the M8 x 20 screws.

Check the parallelism of the top surface of the scale unit at both ends across

a range of 40 mm at each end as shown in Fig. 3-5. The allowable

parallelism value is 0.1 mm.

Fig. 4-5

After adjusting the parallelism to 0.1 mm, attach the M8 screws using a

tightening torque of 22 Nm (220 kgf.cm).

TGM133/134 Instruction Manual May 2013 4th Edition 13/24

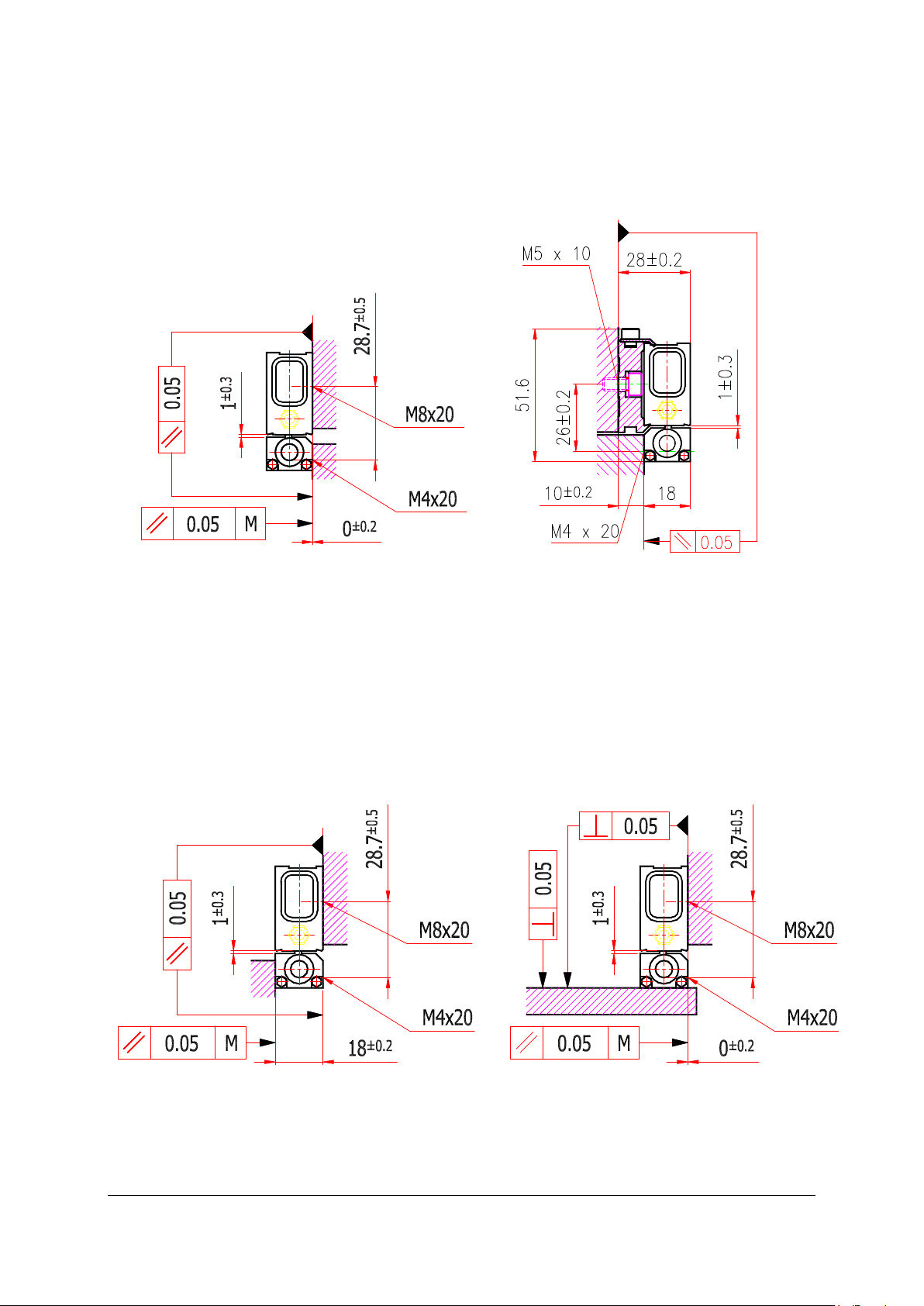

4-3-2. Mounting scanning unit

Setting mounting surface of scanning unit and mounting tolerances (“M” is

the machine guide)

without mounting bar with mounting bar

Fig. 4-6

• The mounting surface must be clean

- free of paint

- dry and without chips

It is also possible to mount in the following condition.

Fig. 4-7

TGM133/134 Instruction Manual May 2013 4th Edition 14/24

Mounting scanning unit

Mount screws with scanning unit holder fixed in order to change

dimensions.

Use screws of two HSB M4 x 20 at screw torque 2.5 Nm (25 kgf.cm).

M4x20

M4x20

Fig. 4-8

4-3-3. Removing scanning unit holder

The scanning unit holder can be removed in a single-action operation. When, as

shown in Fig. 4-9A, area is pressed, the tab attached to the scanning unit is

disengaged so that the scanning unit can then be moved in the lengthwise

direction of the scale unit and completely separated from the scale unit. The

scanning unit holder can now be removed by lifting it free from the scale unit.

1

2

3

Fig. 4-9 A

TGM133/134 Instruction Manual May 2013 4th Edition 15/24

Make sure to install the edge of scanning unit within

1 ± 0.3 mm range.

1

±

0

.

3

1±0.3

Fig. 4-9 B

4.3.4. Checking the operation range

After mounting the scale and scanning unit, be sure to always move the machine

over its entire length to check that the machine movement range is within the

scale measuring length.

Be careful that the scale movement range does not exceed the scale measuring

length + range of movement. If it does, the scale can be damaged.

Fig. 4-10

TGM133/134 Instruction Manual May 2013 4th Edition 16/24

4-3-5. Attaching the head cable

Secure the head cable with a cable clamp so that it does not get entangled.

Note

Note that the wiring should be made to allow enough room for machine

movement during operation.

Fig. 4-11

4.3.6. Air injection

Air can be injected from both sides of the scale side cover (or, optionally, from

the slider).

In the case of using scale unit under circumstances as follows, clean air injection

will minimize their influence.

Dusty

High humidity

Probable condensation inside scale by temperature and humidity change

Actual effects are different depending on working condition. Adopt after

verifying effects enough.

B: Optionally provided

Fig. 4-12

A B

C

TGM133/134 Instruction Manual May 2013 4th Edition 17/24

Air injection to upper scale unit (A) and air injection to slider connector (C) on

Fig. 4-12, is possible with nipple in accessory. But air injection to slider (B) is

optional, so separate order for it required.

An example of air pipe route and device configuration is shown as follows.

Fig. 4-13

The air supply unit and equipment are provided by the customer.

Specifications of standard device are shown for your reference.

Item

Specifications

Guaranteed maximum pressure

1.5 MPa

Max. working pressure

1020 kPa

Adjustable pressure range

20 to 200 kPa

Working fluid

Air

Ambient temperature and working fluid

temperature

-5 to 30°C

(No condensation)

Filtration grade

Air filter: 5 µm

Mist separator: 0.3 µm

Pressure gauge tester connecting bore

2

-

RC (PT) 1/8

Pipe connecting bore IN side: Tube shape

8

OUT side: Tube shape

6

Automatic drain working pressure

150 to 1020 kPa

Table 4-1

Connect to scale

Tube bend radius R15 mm or more

Outside diameter

6, Inside

diameter 4 polyurethane tube

Outside diameter

8 Nylon tube

Distribution parts

Pressure reducer

Filter 5

m Mist separator (0.3

m)

TGM133/134 Instruction Manual May 2013 4th Edition 18/24

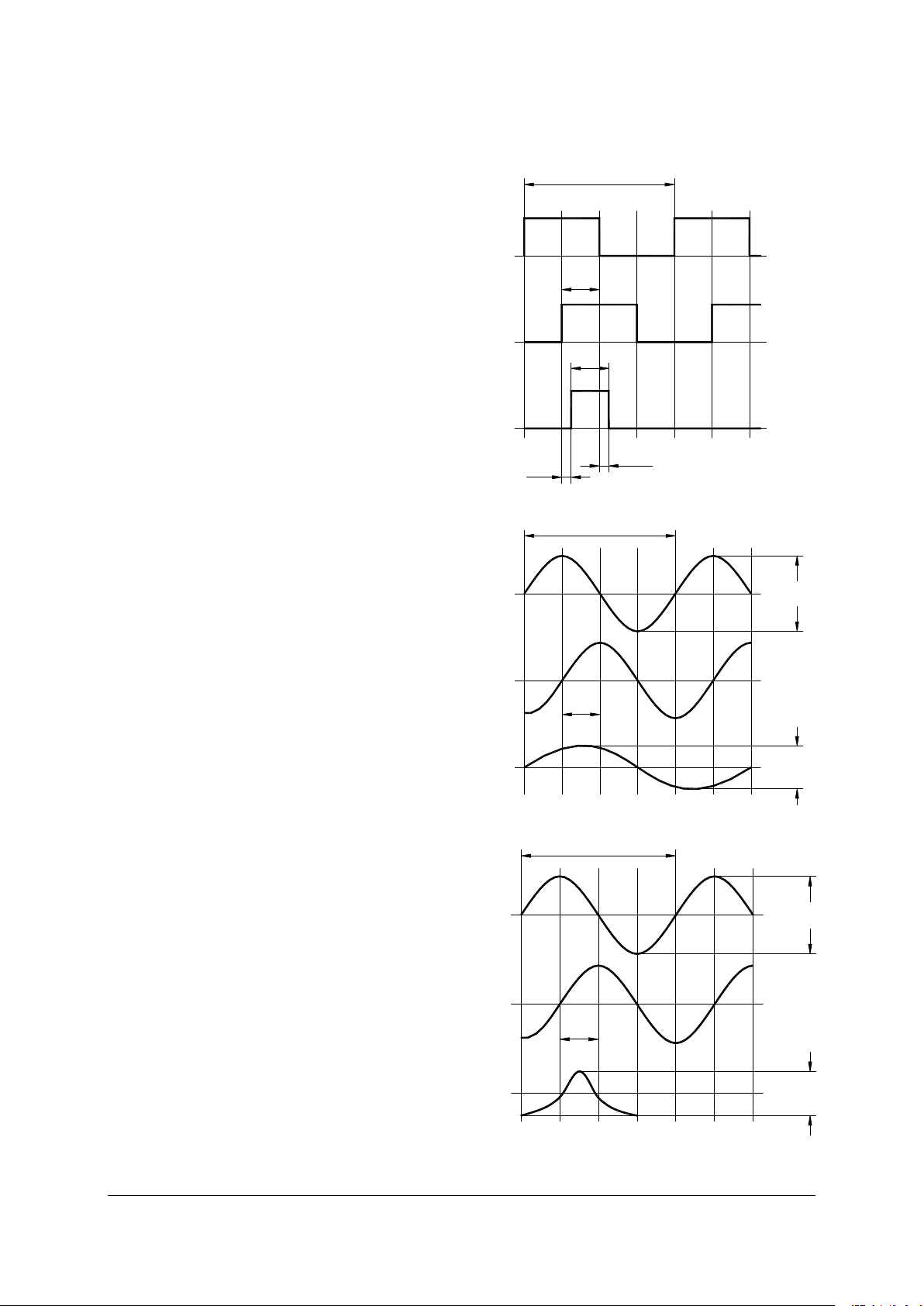

5. Connecting to device

5.1. Output signals

Digital output – DS (TTL):

supply 5V (150mA max.)

t 0.1 s

Sinusoidal output – SV (1Vpp) :

supply 5V (100mA max.)

U0 = 2.5V (Ud/2)

= 20 m

Sinusoidal output – SI (11µA) :

supply 5V (100mA)

Fig. 5-1

Fig. 5-2

RI

B

A

360°

90°

90°

tt

90°

0.5Vp-p

U0RI

360°

U0

U0

B

A

1Vp-p

7-16Ap-p

2-8Ap-p

IRIo

Ibo

90°

360°

Iao

Fig. 5-3

TGM133/134 Instruction Manual May 2013 4th Edition 19/24

5.2. Output connectors

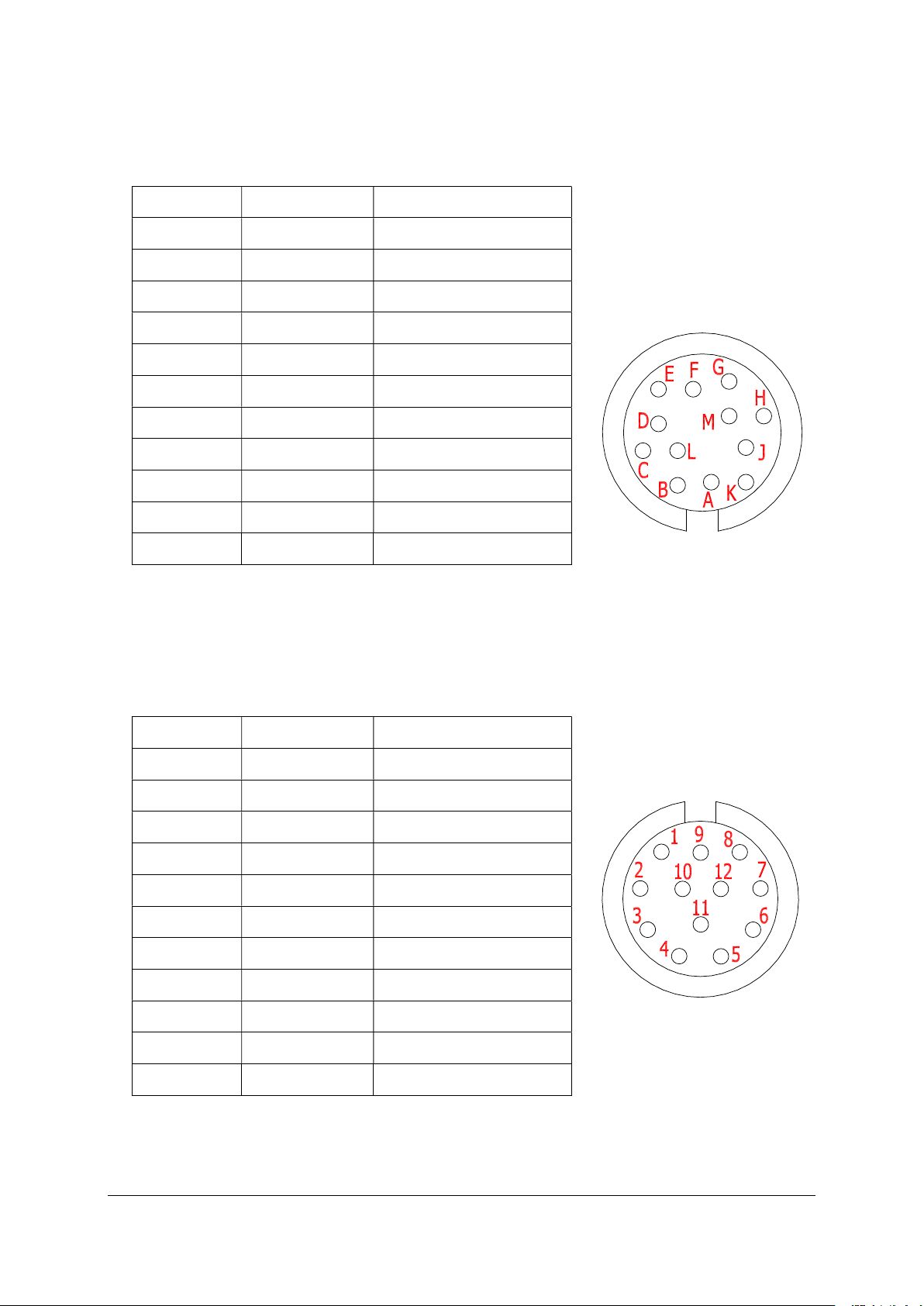

Digital output - DS, 12 pin Amphenol connector:

L B BLACK

D A BROWN

H RI GREY

E BLUE (isolate)

B 0V GREEN/WHITE

0V (sens) VIOLET

E B RED

C A GREEN

G RI PINK

K +5V GREEN/YELLOW

+5V (sens) WHITE

Housing shield SHIELD

Connect shield to connector housing

Digital output - DS, 12 pin Contact connector or coupling:

1 B BLACK

6 A BROWN

4 RI GREY

7 E BLUE

10 0V GREEN/WHITE

11 0V (sens) VIOLET

8 B RED

5 A GREEN

3 RI PINK

12 +5V GREEN/YELLOW

2 +5V (sens) WHITE

Housing shield SHIELD

Connect shield to connector housing

Fig. 5-5

Fig. 5-4

TGM133/134 Instruction Manual May 2013 4th Edition 20/24

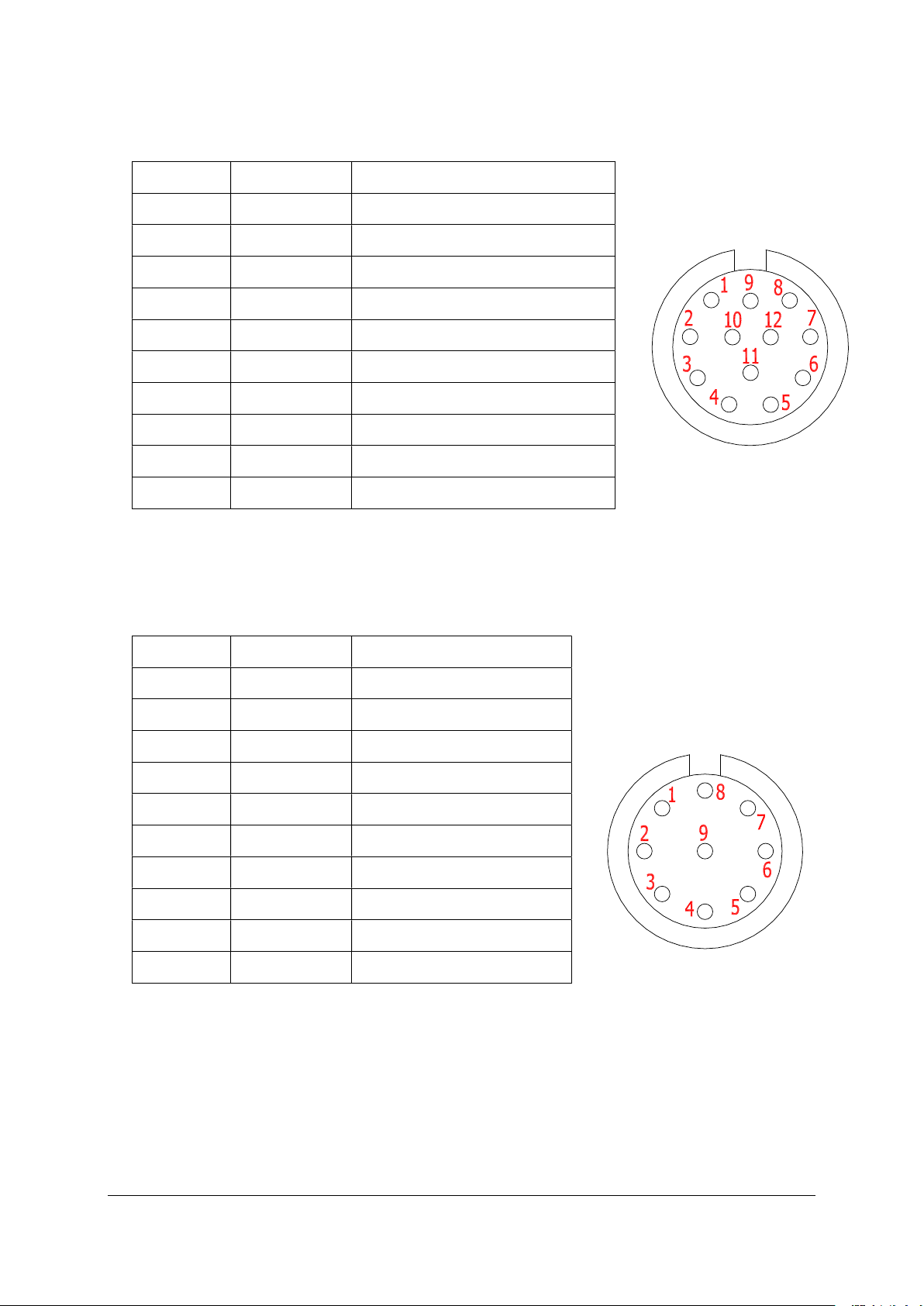

Sinusoidal output – SV (1Vpp), 12 pin Contact connector or coupling:

1 UB RED

6 UA BROWN

4 URI PINK

10 0V GREEN/WHITE + VIOLET

11 0V (sens) BLUE

8 U B BLACK

5 U A GREEN

3 U RI GREY

12 +5V GREEN/YELLOW

2 +5V (sens) WHITE

Housing shield SHIELD

Connect shield to connector housing

Sinusoidal output – SI (11App), 9 pin Contact connector:

6 Ib- RED

2 Ia- BROWN

8 Iri- PINK

4 0V GREEN/WHITE

4 0V VIOLET, BLUE

5 Ib+ BLACK

1 Ia+ GREEN

7 Iri+ GREY

3 +5V GREEN/YELLOW

3 +5V WHITE

Housing (Shield) SHIELD

Connect shield to connector housing

Wires for signals must be twisted pairs, cross section 0.14 mm2 (AWG26)

and voltage supply wires 0,25 mm2 (AWG22), Calculated

Structure: Twisted wire, Electrical resistance: 141 /km or less

Shielding structure: all wires must be covered with braided shield

Fig. 5-6

Fig. 5-7

This manual suits for next models

1

Table of contents