Telect T009-5 Series User manual

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 1

Installation Guide

Model T009-5XXXXXXXXXXX

The Telect dual-feed congurable breaker panel provides circuit breaker power protection for a variety of

telecommunications equipment. Panel includes up to 7 circuit breakers per side for a total maximum

continuous load of 40A, 50A or 100A:

• 40A with optional 50A thermal input breakers

• 50A without optional input breakers (screw-tight inputs)

• 100A without optional input breakers (compression inputs only)

White or black panels can be congured with any combination of 1A to 20A Carling, M-Series breakers

[oriented with the “on” symbol ( | ) at either the bottom or top], 50A thermal input breaker and either

screw-tight or compression input connectors. Screw-tight connectors can be oriented for sideways or

top-down wiring.

Feeds A and B are independent except for the replaceable alarm card which contains power and

alarm LEDs for both feeds. Also included are breaker alarm and power-fail relay terminals for wiring to

external indicators.

Hardware is included for ush or extended mounting in 19" or 23" relay racks. See “Accessories” (Page 7) for ordering

optional and replaceable items: output breakers, face plates, lugs, ETSI mounting kit and more.

Overview

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 2

Installation Guide

Mechanical Specications

Dimensions (nominal), without brackets* Width: 17.25" (43.82 cm)

Height: 1.75" (4.44 cm)

Depth: 8.00" (20.32 cm)

Weight without breakers 9 lbs (4.08 kg)

Weight, shipping 10.5 lbs (4.76 kg)

Mounting for standard racks EIA: 19" (48.2 cm)

WECO: 23" (58.4 cm)

ETSI: 21" (53.3 cm)

[Kit sold separately. See “Accessories” (Page 7).]

Ground terminals Quantity:

Stud:

Lugs:

Cable:

Torque:

2

M5 with hex nut. [Use 8mm

(5/16 in.) socket.]

Single or dual-hole compression lug [5/8 in.

(1.59 cm) center to center]

Up to #10 AWG for single-hole lug

Up to #6 AWG for dual-hole lug.

(Conductor size depends on input

interruption device.)

20 in.-lb (~2.25 N•m), max.

Input terminals — Compressions Quantity:

Stud:

Lugs:

Cable:

Torque:

4 — 2 BATT, 2 RTN

M5 with KEPS nut. [Use 8 mm

(5/16 in.) socket.]

Dual-hole compression lug

[5/8 in. (1.59 cm) center to center]

Up to #1 AWG, depending on input

interruption device

20 in.-lb (~2.25 N•m), max.

Input terminals — Phoenix-style screw-tight Slotted screwhead for wire clamping up to

#6 AWG, depending on input interruption

device. Torque screws to 14 in.-lb (~1.5 N•m).

Output terminals — Wire binding Quantity:

Screw:

Cable:

Clearance:

Torque:

28 — 14 BATT, 14 RTN

#6 Phillips** pan head

Up to #10 AWG

0.31 in. (.79 cm) between terminal barriers

9 in.-lb (1.02 N•m), max.

Alarm terminals — Wire binding Quantity:

Screw:

Cable:

Torque

6

#4 Phillips** pan head

#30 to #16 AWG

4 in.-lb (0.45 N•m), max.

Specications

* See Page 11 for

exact dimensions

** Screws with

cross-recessed heads

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 3

Installation Guide

Specications Cont.

Electrical Specications

Operating voltages –20 to –60 VDC, +20 to +30 VDC

Maximum input interruption device rating 125A for a 100A panel

60A for all other panels

Maximum continuous input load rating (total) 100A per feed (with compression inputs but without 50A

thermal input breaker)

50A per feed (with screw-tight inputs but without 50A

thermal input breaker)

40A per feed (with 50A thermal input breaker)

Maximum output interruption device rating 20A per circuit breaker

Maximum continuous output load rating 16A per circuit breaker

Alarm contact ratings, continuous 2A at 30 VDC 0.6A at 60 VDC

Alarm board power ratings @20V: 80mA (1.60W)

@27V: 120mA (3.24W)

@40V: 127mA (5.08W)

@54V: 133mA (7.18W)

@24V: 112mA (2.69W)

@30V: 122mA (3.66W)

@48V: 130mA (6.24W)

@60V: 136mA (8.16W)

Max. operating temperature at max. load ratings 55°C (131°F)

Min. operating temperature at max. load ratings –10°C (14°F)

Ambient operating temp. at half-load 55°C (131°F)

Max. surface temperature of breakers at 26°C

(79°F) ambient

35°C (95°F)

Max. panel heat dissipation at full load 18W per side at 1920W (40A x 48V) per side

20W per side at 2400W (50A x 48V) per side

42W per side at 4800W (100A x 48V) per side

Percentage of full load heat dissipation at

nominal voltage

Less than 1% of total load wattage

118267-2 A0 Page 2

ALERT

!

ALERT! This product must be installed and maintained only by qualified personnel. Verify all connec-

tions meet requirements specified in local electric codes or operating company guidelines before

supplying power. Protect this equipment with a fuse or breaker sufficient to interrupt power levels

specified under “Electrical Specifications”.

Please read these instructions carefully before beginning installation. If you need assistance call Technical Support at

888-821-4856 (domestic calls), or 509-921-6161 (Option 2), or eMAIL us at getinfo@telect.com

1. Inspect equipment after unpacking and compare it to the packing list.

Immediately report any shipping damage, defects, or missing parts to Telect at 1-800-551-4567. Keep all documen-

tation that comes with your shipment.

NOTE

Telect is not liable for shipping damage. If damaged, notify the carrier and call Telect’s Customer Service Department at

1-800-551-4567 (domestic only) or 1-509-926-6000 for further recourse.

NOTE

Panel brackets provide either flush or extended EIA or WECO mounting in a 19" or 23" rack. Panel is configured at the factory

for flush mounting in a 19" rack.

Electrical Specifications

Operating voltages –20 to –60 Vdc, +20 to +30 Vdc

Maximum input interruption device rating 125A for a 100A panel

60A for all other panels.

Maximum continuous input load rating (total) 100A per feed (with compression inputs but without 50A

thermal input breaker)

50A per feed (with screw-tight inputs but without 50A

thermal input breaker)

40A per feed (with 50A thermal input breaker)

Maximum output interruption device rating 20A per circuit breaker

Maximum continuous output load rating 16A per circuit breaker

Alarm contact ratings, continuous 2A at 30 Vdc 0.6A at 60 Vdc

Alarm board power ratings @20V: 80mA (1.60W) @24V: 112mA (2.69W)

@27V: 120mA (3.24W) @30V: 122mA (3.66W)

@40V: 127mA (5.08W) @48V: 130mA (6.24W)

@54V: 133mA (7.18W) @60V: 136mA (8.16W)

Max. operating temperature at max. load ratings 55°C (131°F)

Min. operating temperature at max. load ratings –10°C (14°F)

Ambient operating temp. at half-load 55°C (131°F)

Max. surface temperature of breakers at 26°C (79°F) am-

bient

35°C (95°F)

Max. panel heat dissipation at full load 18W per side at 1920W (40A x 48V) per side

20W per side at 2400W (50A x 48V) per side

42W per side at 4800W (100A x 48V) per side

Percentage of full load heat dissipation at nominal voltage less than 1% of total load wattage

ALERT! This product must be installed and maintained only by qualied personnel. Verify all connections

meet requirements specied in local electric codes or operating company guidelines before supplying power.

Protect this equipment with a fuse or breaker sufcient to interrupt power levels specied under

“Electrical Specications”.

Please read these instructions carefully before beginning installation. If you need assistance call Technical Support at

509.926.6000 or email us at getinfo@Telect.com.

1. Inspect equipment after unpacking and compare it to the packing list. Immediately report any shipping

damage, defects or missing parts to Telect at 509.926.6000. Keep all documentation that comes with

your shipment.

NOTE: Telect is not liable for shipping damage. If damaged, notify the carrier and call Telect at 509.926.6000 for

further recourse.

NOTE: Panel brackets provide either ush or extended EIA or WECO mounting in a 19" or 23" rack. Panel is congured at

the factory for ush mounting in a 19" rack.

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 4

Installation Guide

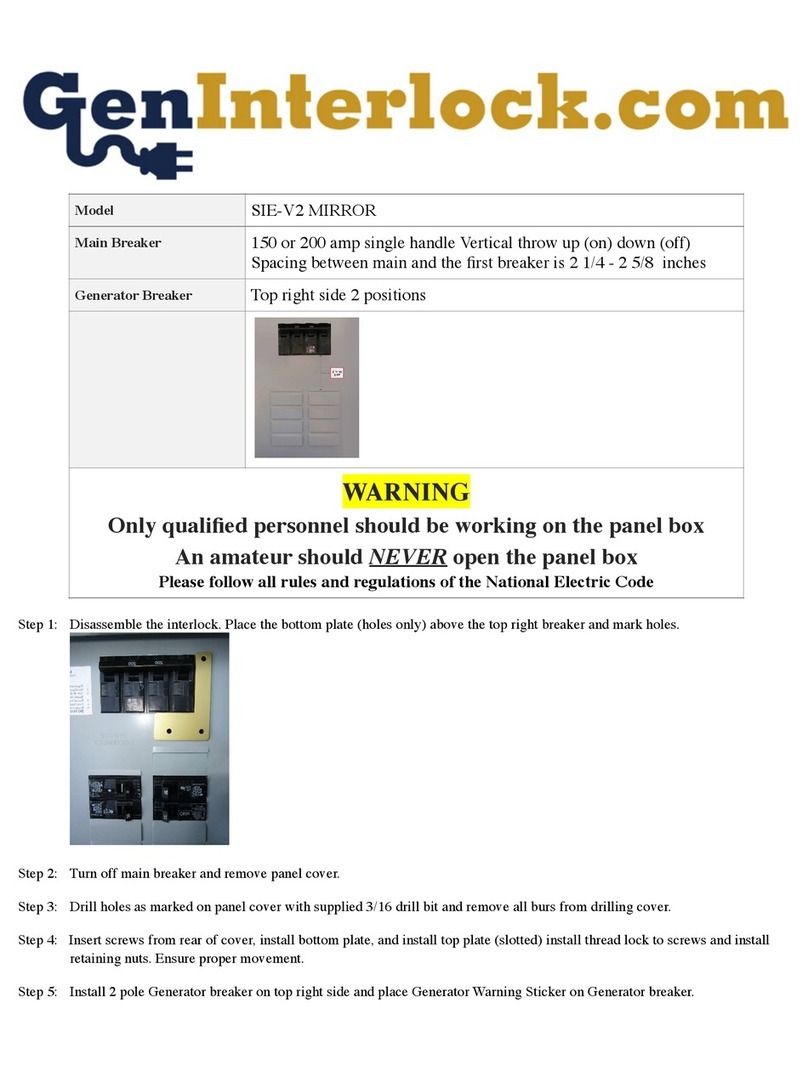

2. If necessary, remove three screws and reposition/realign brackets on

sides of distribution panel, as shown in “Bracket Orientation”.

3. Locate an unused rack position and mount panel using four screws and

lock washers provided, as shown in “Rack Mounting”. (Prefer mounting

panel as high as possible on rack.) Tighten screws to 35 in.-lb (4.29 N•m).

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130316-6 A0

Page 10

4. Before connecting any conductor, use a multimeter to measure the resistance between the

input NEG and POS/RTN terminals at the rear corners of the panel. Expect 500Ωor more for

both Side A and Side B.

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions for

installation personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying

bodies recognized in your country or region such as Underwriter’s Laboratories (UL),

TUV, etc.

5. For ground wiring, use a listed (approved) crimping tool to at-

tach a listed (approved), single- or dual-hole compression lug

(dual hole is highly recommended) suitable for a #10 stud

(~5 mm) on 5/8-in. (15.9 mm) centers onto a suitable ground

wire. (Ground wire can be up to #6 AWG for a dual-hole lug.

Conductor size depends on input interruption device.)

6. Use a coarse, nonmetallic cleaning pad to clean the terminals

and stud(s).

7. Telect recommends that you lightly coat anti-oxidant on the lug, grounding screw(s), and sur-

rounding contacting surface.

8. Connect the lug to the rear panel using the #10 screw(s) provided, as shown in Figure 7.

WARNING

!

WARNING! Before connecting input power cables, make sure the input power to the panel

is turned off.

9. Make sure the input power is off.

10. For input wiring — wiring used as inputs to this

distribution panel,

a. Crimp dual-hole compression lugs for ¼-in. studs

on 5/8-in. (15.9 mm) centers onto suitable copper

wires (#6 to 1/0 AWG) for NEG and POS/RTN ter-

minals, Feeds A and B. Lug width must not exceed

0.52 in. (13.4 mm).

b. Use a coarse, nonmetallic cleaning pad to clean

terminals and studs.

ABF

PWR ALM

Figure 7 - Ground

Lug Connection

Figure 8 - Compression

Lug Inputs

WARNING! Failure to properly ground this equipment can create hazardous

conditions to installation personnel and to the equipment.

WARNUNG! Bei unsachgemäßer Erdung besteht Gefahr für das

Installationspersonal und das Gerät!

¡AVISO! La conexión incorrecta a tierra puede ser peligrosa tanto para los

instaladores como para el equipo.

ADVERTISSEMENT ! Si vous ne reliez pas correctement cet équipement à la

terre, son utilisation présente des dangers pour la personne qui l’installe ainsi

que pour l’équipement.

Bracket Orientation

118267-2 A0

Page 3

2. If necessary, remove 3 screws and reposition/re-align brackets on sides of distri-

bution panel, as shown in “Bracket Orientation”.

3. Locate an unused rack position and mount panel using 4 screws and lockwash-

ers provided, as shown in “Rack Mounting”. (Prefer mounting panel as high as

possible on rack.) Tighten screws to 35 in.-lb (4.29 N•m).

WARNING

!

WARNING! Failure to properly ground this equipment can create haz-

ardous conditions to installation personnel and to the equipment.

WARNUNG! Bei unsachgemäßer Erdung besteht Gefahr für das Instal-

lationspersonal und das Gerät!

¡AVISO! La conexión incorrecta a tierra puede ser peligrosa tanto para

los instaladores como para el equipo.

ADVERTISSEMENT ! Si vous ne reliez pas correctement cet équipe-

ment à la terre, son utilisation présente des dangers pour la personne

qui l'installe ainsi que pour l'équipement.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or

certifying bodies recognized in your country or region such as Underwriter’s

Laboratories (UL), TUV, etc.

4. For ground wiring, use a listed (approved) crimping tool to attach a listed (ap-

proved), single- or dual-hole compression lug onto suitable ground wire. (Use

#10 to #6 AWG, depending on input interruption device.)

5. Use a coarse, nonmetallic cleaning pad to clean terminals and stud(s).

6. Telect recommends that you lightly coat anti-oxidant on lug, grounding terminal,

and surrounding contacting surface. Connect lug to stud using M5 washer and

nut from terminal, as shown in “Ground Lug Connection”. Tighten nut to 20 in.-lb

(~2.25 N•m) using a 8 mm (5/16 in.) socket.

WARNING

!

WARNING! Before connecting input power cables, make sure input

power to panel is turned off.

WARNUNG! Vor Anschluss der Eingangsstromkabel ist sicherzus-

tellen, dass der Eingangsstrom ausgeschaltet ist.

¡AVISO! Antes de conectar los cables de entrada de la alimentación, compruebe que la alimentación

de entrada al panel está cortada.

ADVERTISSEMENT ! Avant de connecter les câbles d'entrée d'alimentation, assurez-vous que l'ali-

mentation électrique du panneau est coupée.

7. Make sure input power is off.

Bracket Orientation

Torque #8 screws to

15 in.-lbs [1.7 N•m]

Mounting

Bracket

3-in. Offset

Position

4-in. Offset

Position

F

lush Position

Rack Mounting

Ground Lug Connection

Torque nuts to 20 in.-lb (2.25 N•m)

A

nti-oxidant

compound

Rack Mounting

ALERT! Only use components and crimping tools approved by agencies

or certifying bodies recognized in your country or region such as

Underwriter’s Laboratories (UL), TUV, etc.

Ground Lug Connection

4. For ground wiring, use a listed (approved) crimping tool to attach

a listed (approved), single- or dual-hole compression lug onto

suitable ground wire. (Use #10 to #6 AWG, depending on input

interruption device.)

5. Use a coarse, nonmetallic cleaning pad to clean terminals

and stud(s).

6. Telect recommends that you lightly coat antioxidant on lug, grounding

terminal and surrounding contacting surface. Connect lug to stud using

M5 washer and nut from terminal, as shown in “Ground Lug Connection”.

Tighten nut to 20 in.-lb (~2.25 N•m) using a 8 mm (5/16 in.) socket.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130316-6 A0

Page 10

4. Before connecting any conductor, use a multimeter to measure the resistance between the

input NEG and POS/RTN terminals at the rear corners of the panel. Expect 500Ωor more for

both Side A and Side B.

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions for

installation personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying

bodies recognized in your country or region such as Underwriter’s Laboratories (UL),

TUV, etc.

5. For ground wiring, use a listed (approved) crimping tool to at-

tach a listed (approved), single- or dual-hole compression lug

(dual hole is highly recommended) suitable for a #10 stud

(~5 mm) on 5/8-in. (15.9 mm) centers onto a suitable ground

wire. (Ground wire can be up to #6 AWG for a dual-hole lug.

Conductor size depends on input interruption device.)

6. Use a coarse, nonmetallic cleaning pad to clean the terminals

and stud(s).

7. Telect recommends that you lightly coat anti-oxidant on the lug, grounding screw(s), and sur-

rounding contacting surface.

8. Connect the lug to the rear panel using the #10 screw(s) provided, as shown in Figure 7.

WARNING

!

WARNING! Before connecting input power cables, make sure the input power to the panel

is turned off.

9. Make sure the input power is off.

10. For input wiring — wiring used as inputs to this

distribution panel,

a. Crimp dual-hole compression lugs for ¼-in. studs

on 5/8-in. (15.9 mm) centers onto suitable copper

wires (#6 to 1/0 AWG) for NEG and POS/RTN ter-

minals, Feeds A and B. Lug width must not exceed

0.52 in. (13.4 mm).

b. Use a coarse, nonmetallic cleaning pad to clean

terminals and studs.

ABF

PWR ALM

Figure 7 - Ground

Lug Connection

Figure 8 - Compression

Lug Inputs

WARNING! Before connecting input power cables, make sure input

power to panel is turned off.

WARNUNG! Vor Anschluss der Eingangsstromkabel ist sicherzustellen,

dass der Eingangsstrom ausgeschaltet ist.

¡AVISO! Antes de conectar los cables de entrada de la alimentación,

compruebe que la alimentación de entrada al panel está cortada.

ADVERTISSEMENT ! Avant de connecter les câbles d’entrée d’alimentation,

assurez-vous que l’alimentation électrique du panneau est coupée.

7. Make sure input power is off.

Torque #8 screws to

15 in.-lbs [1.7 N•m]

Mounting

Bracket

3-in. Offset

Position

4-in. Offset

Position

Flush Position

Torque nuts to 20 in.-lb (2.25 N•m)

Anti-oxidant

compound

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 5

Installation Guide

8. For input wiring — wiring used as inputs to this distribution panel — proceed as follows:

For Compression Lug Inputs For Screw-Tight Inputs

a. Crimp dual-hole compression lugs onto suitable copper

wires (#6 to #1 AWG) for BATT and RTN terminals,

Feeds A and B.

b. Remove the black plastic terminal covers, if installed.

c. Use a coarse, nonmetallic cleaning pad to clean

terminals and studs.

d. Lightly coat antioxidant on lugs, input BATTERY and

RETURN terminals, and then connect lugs to Feed A

and B input terminals on back of panel using M5 KEPs

nuts and washers provided, as shown in “Compression

Lug Inputs”. Tighten lugs to 20 in.-lb (2.25 N•m).

e. Reinstall terminal covers.

a. Strip ¼ in. (0.635 cm.) of insulation from of

input cables.

b. For BATT and RTN of each feed, insert input cables

all of the way into connectors and then tighten to 14

in.-lb (~1.5 N•m).

Compression Lug Inputs Screw-Tight Vertical & Horizontal Inputs

Alarm Indicators

9. Make sure power is off [open breaker, dummy fuse or open fuse holder at power distribution unit, or PDU] before

connecting this panel’s cables to PDU.

10. Make sure breakers on this panel are all off.

11. Enable fuse or breaker at PDU (60A or 125A max., depending on

conguration) to turn on Feed A to Side A of panel; check voltage and

polarity at input connectors of panel. Also, check:

• POWER ON A LED on front of panel turns on (green).

• INPUT BREAKER A LED (for a panel with optional input

breakers) turns on (green).

If not, check that input breakers on rear of panel are pressed in.

• BREAKER ALARM LED turns on (red).

• POWER ON B must be off.

12. With POWER ON A lit (normal operation) — but with POWER ON B LED

off (failure operation) —test power-fail relay and contacts at POWER

FAIL terminals on rear of panel:

• Expect an open circuit (∞Ω) between Terminals Cand NC.

• Expect continuity (0Ω) between Terminals Cand NO.

Alarm Terminals

RTN

BATT

RTN BATT

Heat shrink

tubing

BREAKER

ALARM

ALARM

RESET INPUT

BREAKER

POWER

ON

A B BA

®

SPOKANE, WA 800-551-4567

NO C NC NC C

FUSE ALARM

NO

POWER FAIL

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 6

Installation Guide

13. Repeat Steps 11 and 12 for Feed B and observe that POWER ON B LED turns on (green).

14. Press and hold ALARM RESET on front of panel for 5 seconds to verify that all LEDs are in working order.

15. With one or all circuit breakers off, test fuse alarm relay contacts at FUSE ALARM terminals on rear

of panel:

• Expect an open circuit (∞Ω) between Terminals Cand NC.

• Expect continuity (0Ω) between Terminals Cand NO.

16. With both Feeds A and B on, recheck POWER FAIL terminals:

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

17. Recheck that all circuit breakers on panel are off.

18. For output wiring, do either of the following:

• If using lugs, strip off ⅜ in. (~1 cm) of insulation from one end of copper output wires and then crimp on ring

or forked, single-hole lugs, as required by NEC. (Screw terminals will accommodate lugs for up to 10 AWG.)

• If using bare wire, strip off 5/8 in. (~1.5 cm) of insulation. (Stranded wires should be tinned.)

Remember: Output wires must be rated at or above the amperage rating of the output circuit breaker. For

example, use no smaller than #12 AWG output wiring for 20A output fuses. Do not exceed 16A continuous

load for a 20A breaker.

118267-2 A0

Page 5

13. Repeat Steps 11 and 12 for Feed B and observe that POWER ON B LED turns on (green).

14. Press and hold ALARM RESET on front of panel for 5 seconds to verify that all LEDs are in working order.

15. With one or all circuit breakers off, test fuse alarm relay contacts at FUSE ALARM terminals on rear of panel:

• Expect an open circuit (∞Ω) between Terminals Cand NC.

• Expect continuity (0Ω) between Terminals Cand NO.

16. With both Feeds A and B on, recheck POWER FAIL terminals:

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

17. Recheck that all of circuit breakers on panel are off.

18. For output wiring, do either of the following:

•If using lugs, strip off 3/8 in. (~1 cm) of insulation from one end of copper output wires and then crimp on ring or

forked, single-hole lugs, as required by NEC. (Screw terminals will accommodate lugs for up to 10 AWG.)

•If using bare wire, strip off 5/8 in. (~1.5 cm) of insulation. (Stranded wires should be tinned.)

Remember: Output wires must be rated at or above the amperage rating of the output circuit breaker. For example,

use no smaller than #12 AWG output wiring for 20A output fuses. Do not exceed 16A continuous load for a 20A

breaker.

ALERT

!

ALERT! Local electrical and operating company guidelines recommend that the individual load not exceed

80% of circuit breaker capacity (for example, 10A breaker x .80 = 8A max. load). Total load for all breaker out-

puts on each side must not exceed —

• 40A for a panel with an optional thermal input breaker,

• 50A for a panel having screw-tight inputs connectors, but without an optional thermal input breaker, or

• 100A for a panel having compression input connectors, but without an optional thermal input breaker.

19. Clean output terminals and lugs with a nonabrasive, nonmetallic pad.

20. If installed, remove covers over output and alarm connectors.

21. Telect recommends that you lightly coat anti-oxidant on lugs and output BATTERY and RETURN terminals before

connecting lugs/wires to outputs. (NEC specifies only one lug and load for each output terminal.) Tighten screws to

9 in.-lb (1.01 N•m).

22. Connect other end of output wires to load.

23. Use designation labels (supplied) to record outputs, as specified by

operating company standard installation procedures.

24. Make sure inputs at loads are disabled by removing all power cards or

all input fuses at load equipment.

Always follow recommended operating company guidelines when dis-

abling load equipment.

25. One by one, turn on circuit breakers on this panel and check voltage

and polarity at input of loads.

26. With all circuit breakers on, the BREAKER ALARM LED must go off.

Test fuse alarm relay contacts at FUSE ALARM terminals on rear of

panel:

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

Designation Label

ALERT! Local electrical and operating company guidelines recommend that the individual load not exceed 80%

of circuit breaker capacity (for example, 10A breaker x .80 = 8A max. load). Total load for all breaker outputs

on each side must not exceed —

• 40A for a panel with an optional thermal input breaker

• 50A for a panel having screw-tight inputs connectors, but without an optional thermal input breaker

• 100A for a panel having compression input connectors, but without an optional thermal input breaker

19. Clean output terminals and lugs with a nonabrasive, nonmetallic pad.

20. If installed, remove covers over output and alarm connectors.

21. Telect recommends that you lightly coat antioxidant on lugs and output BATTERY and RETURN terminals before

connecting lugs/wires to outputs. (NEC species only one lug and load for each output terminal.) Tighten screws to 9

in.-lb (1.01 N•m).

22. Connect other end of output wires to load.

23. Use designation labels (supplied) to record outputs, as specied by

operating company standard installation procedures.

24. Make sure inputs at loads are disabled by removing all power cards or

all input fuses at load equipment.

Always follow recommended operating company guidelines when

disabling load equipment.

25. One by one, turn on circuit breakers on this panel and check voltage

and polarity at input of loads.

26. With all circuit breakers on, the BREAKER ALARM LED must go off.

Test fuse alarm relay contacts at FUSE ALARM terminals on rear of panel:

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

Designation Label

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 7

Installation Guide

27. Switch off one of the circuit breakers to simulate a tripped breaker.

Again, the BREAKER ALARM LED should light.

28. Press ALARM RESET on front of panel.

BREAKER ALARM LED should go off again. (Pressing ALARM RESET will reset the BREAKER ALARM LED on

front and clear FUSE ALARM on rear of panel.) Recheck FUSE ALARM terminals and expect the same status as in

Step 26 with all breakers on.

29. If desired, connect remote external audio/visual alarm indicator wires (solid or tinned wires, #30 to #16 AWG) to the

POWER FAIL and FUSE ALARM terminals.

30. One by one, re-enable load equipment and verify proper operation.

31. Reinstall covers over output and alarm terminals.

Replacing Output Circuit Breakers

118267-2 A0 Page 6

27. Switch off one of the circuit breakers to simulate a tripped breaker.

Again, the BREAKER ALARM LED should light.

28. Press ALARM RESET on front of panel.

BREAKER ALARM LED should go off again. (Pressing ALARM RESET will reset the BREAKER ALARM LED on

front and clear FUSE ALARM on rear of panel.) Recheck FUSE ALARM terminals and expect the same status as

in Step 26 with all breakers on.

29. If desired, connect remote external audio/visual alarm indicator wires (solid or tinned wires, #30 to #16 AWG) to the

POWER FAIL and FUSE ALARM terminals.

30. One by one, re-enable load equipment and verify proper operation.

31. Re-install covers over output and alarm terminals.

REPLACING OUTPUT CIRCUIT BREAKERS

ALERT

!

ALERT! Although difficult to remove from the panel, circuit breakers can be disconnected and replaced.

1. Be sure new breaker is the same size as breaker being replaced.

2. Place new breaker within easy reach of panel. Be sure new breaker is off ( O) position.

3. If possible, turn off all breakers on the side (A or B) where the breaker is to be replaced. Then, turn off input power

to that side of panel.

4. Place breaker to be replaced in the off position.

5. Using a very small, flat-tipped screwdriver, carefully pry out on bottom of breaker while applying upward force on

face of breaker.

This should raise the bottom of the breaker so it slightly protrudes out the front of the panel.

6. While preventing breaker from going back into panel, depress bottom tab with the screwdriver and pull out on

breaker.

This starts the tab through the panel front opening so that it is dislodged about 1/16 in. (~.15 cm) at the bottom.

7. While pulling on breaker, work the screwdriver at the top to release the top tab.

If both tabs are released, the breaker should begin to pull out the front of the panel.

8. The breaker conductors can be pulled loose from the assembly at the

rear of the panel. Do not pull out on the breaker more than necessary

when removing and installing the LOAD and LINE connectors.

9. Gently work breaker out front of panel until rear connectors can be ac-

cessed by pliers.

10. Remove LOAD connector from breaker using needle-nose pliers:

• For standard circuit breaker installations, with “O” at the top and “|”

at the bottom, the LOAD connector will be near the bottom.

• For circuit breaker installations with “|” at the top and “O” at the bot-

tom, the LOAD connector will be near the top.

11. Restrain connector to prevent it from traveling back in to panel.

Spade

Connectors

Carlingswitch

Series M

Circuit Breaker

Tab

Tab

LINE

LOAD

ALERT! Although difcult to remove from the panel, circuit breakers can be disconnected and replaced.

1. Be sure new breaker is the same size as breaker being replaced.

2. Place new breaker within easy reach of panel. Be sure new breaker is off ( O ) position.

3. If possible, turn off all breakers on the side (A or B) where the breaker is to be replaced. Then, turn off input power to

that side of panel.

4. Place breaker to be replaced in the off position.

5. Using a very small, at-tipped screwdriver, carefully pry out on bottom of breaker while applying upward force on face

of breaker.

This should raise the bottom of the breaker so it slightly protrudes out the front of the panel.

6. While preventing breaker from going back into panel, depress bottom tab with the screwdriver and pull out on breaker.

This starts the tab through the panel front opening so that it is dislodged about 1/16 in. (~.15 cm) at the bottom.

7. While pulling on breaker, work the screwdriver at the top to release the top tab.

If both tabs are released, the breaker should begin to pull out the front of the panel.

8. The breaker conductors can be pulled loose from the assembly at the rear of the panel. Do not pull out on the breaker

more than necessary when removing and installing the LOAD and LINE connectors.

118267-2 A0 Page 6

27. Switch off one of the circuit breakers to simulate a tripped breaker.

Again, the BREAKER ALARM LED should light.

28. Press ALARM RESET on front of panel.

BREAKER ALARM LED should go off again. (Pressing ALARM RESET will reset the BREAKER ALARM LED on

front and clear FUSE ALARM on rear of panel.) Recheck FUSE ALARM terminals and expect the same status as

in Step 26 with all breakers on.

29. If desired, connect remote external audio/visual alarm indicator wires (solid or tinned wires, #30 to #16 AWG) to the

POWER FAIL and FUSE ALARM terminals.

30. One by one, re-enable load equipment and verify proper operation.

31. Re-install covers over output and alarm terminals.

REPLACING OUTPUT CIRCUIT BREAKERS

ALERT

!

ALERT! Although difficult to remove from the panel, circuit breakers can be disconnected and replaced.

1. Be sure new breaker is the same size as breaker being replaced.

2. Place new breaker within easy reach of panel. Be sure new breaker is off ( O) position.

3. If possible, turn off all breakers on the side (A or B) where the breaker is to be replaced. Then, turn off input power

to that side of panel.

4. Place breaker to be replaced in the off position.

5. Using a very small, flat-tipped screwdriver, carefully pry out on bottom of breaker while applying upward force on

face of breaker.

This should raise the bottom of the breaker so it slightly protrudes out the front of the panel.

6. While preventing breaker from going back into panel, depress bottom tab with the screwdriver and pull out on

breaker.

This starts the tab through the panel front opening so that it is dislodged about 1/16 in. (~.15 cm) at the bottom.

7. While pulling on breaker, work the screwdriver at the top to release the top tab.

If both tabs are released, the breaker should begin to pull out the front of the panel.

8. The breaker conductors can be pulled loose from the assembly at the

rear of the panel. Do not pull out on the breaker more than necessary

when removing and installing the LOAD and LINE connectors.

9. Gently work breaker out front of panel until rear connectors can be ac-

cessed by pliers.

10. Remove LOAD connector from breaker using needle-nose pliers:

• For standard circuit breaker installations, with “O” at the top and “|”

at the bottom, the LOAD connector will be near the bottom.

• For circuit breaker installations with “|” at the top and “O” at the bot-

tom, the LOAD connector will be near the top.

11. Restrain connector to prevent it from traveling back in to panel.

Spade

Connectors

Carlingswitch

Series M

Circuit Breaker

Tab

Tab

LINE

LOAD

9. Gently work breaker out front of panel until rear connectors can be accessed

by pliers.

10. Remove LOAD connector from breaker using needle-nose pliers:

• For standard circuit breaker installations, with “O” at the top and “|”

at the bottom, the LOAD connector will be near the bottom.

• For circuit breaker installations with “|” at the top and “O” at the

bottom, the LOAD connector will be near the top.

11. Restrain connector to prevent it from traveling back into the panel.

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 8

Installation Guide

118267-2 A0

Page 7

ALERT

!

ALERT! The LINE side connection of the breaker has live Vdc. Do not allow contact of the connector (or tools

holding the connector) to grounded ironwork or panel chassis.

12. While holding breaker out from the front of the panel, grasp LINE connector of breaker with needle-nose pliers.

13. Hold the LINE connector with pliers and then pull breaker, wiggling it until breaker is free from connector. Continue

to hold the LINE connector with the pliers. Do not allow the connector to contact the panel chassis.

14. With your free hand, pick up new breaker and check orientation of new breaker.

15. Press spade connector of new breaker into the pliers-held LINE connector until fully seated.

Visually inspect the connection to be sure full contact is made between the LINE connector and the breaker spade

connector.

16. Place the LOAD conductor connector on the LOAD spade connector of the breaker.

Visually inspect the connection.

17. Gently place breaker back into panel. Push on front of breaker until tabs are cleared and breaker is secure in panel.

18. If input power was turned off, restore input power and turn on breakers one at a time.

19. When new breaker is turned on, check output terminal for correct polarity.

ACCESSORIES

The following lists optional and replacement items for the panel. For compression lugs, please refer to Wire Sizing, La-

bel Convention, & Lug Chart (Telect Part No. 117995) included with your panel.

1. Breakers are sold for repair/replacement of field breakers and not for reconfiguring the panel.

NOTE

For service and warranty, see our telect.com website, or eMAIL inquires to getinfo@telect.com, or phone us at

800-551-4567 (domestic only) or 509-926-8915.

Item Description Part Number

Alarm Card With INPUT BREAKER LEDs 400207

Circuit Breaker11A long delay 115268

3A long delay 115266

5A long delay 115267

10A long delay 115269

15A long delay 115265

20A long delay 115270

Blank 113882

ETSI Mounting Brackets Black 090-0041-0030

White 090-0041-0031

Front Cover Clear 090-0001-0001

Designation Label 1-7, A & B 115353

ALERT! The LINE side connection of the breaker has live VDC. Do not allow contact of the connector (or tools

holding the connector) to grounded ironwork or panel chassis.

12. While holding breaker out from the front of the panel, grasp LINE connector of breaker with needle-nose pliers.

13. Hold the LINE connector with pliers and then pull breaker, wiggling it until breaker is free from connector. Continue to

hold the LINE connector with the pliers. Do not allow the connector to contact the panel chassis.

14. With your free hand, pick up new breaker and check orientation of new breaker.

15. Press spade connector of new breaker into the pliers-held LINE connector until fully seated.

Visually inspect the connection to be sure full contact is made between the LINE connector and the breaker

spade connector.

16. Place the LOAD conductor connector on the LOAD spade connector of the breaker. Visually inspect the connection.

17. Gently place breaker back into panel. Push on front of breaker until tabs are cleared and breaker is secure in panel.

18. If input power was turned off, restore input power and turn on breakers one at a time.

19. When new breaker is turned on, check output terminal for correct polarity.

Accessories

The following lists optional and replacement items for the panel. For compression lugs, please refer to Wire Sizing, Label

Convention & Lug Chart (Telect Part No. 117995) included with your panel.

Item Description Part Number

Alarm card With INPUT BREAKER LEDs 400207

Circuit breaker11A long delay 115268

3A long delay 115266

5A long delay 115267

10A long delay 115269

15A long delay 115265

20A long delay 115270

Blank 113882

ETSI Mounting Brackets Black 090-0041-0030

White 090-0041-0031

Front Cover Clear 090-0001-0001

Designation Label 1-7, A & B 115353

1. Breakers are sold for repair/replacement of eld breakers and not for reconguring the panel.

For service and warranty information see our telect.com website, email inquires to getinfo@Telect.com or phone

us at 509.926.6000.

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 9

Installation Guide

LED & Alarm Summary

Normal Operation

• POWER ON A & POWER ON B LEDs will be on (green)

• INPUT BREAKER A & INPUT BREAKER B LEDs will be on (green) for panel with optional input breakers

• BREAKER ALARM LED will be off

• FUSE ALARM relay is de-energized so that —

◊ C to NC is closed and

◊ C to NO is open

• POWER FAIL relay is energized so that —

◊ C to NC is closed and

◊ C to NO is open

Input Power Failure

• POWER ON A or POWER ON B LED(s) will go off

• POWER FAIL relay de-energizes so that —

◊ C to NC opens and

◊ C to NO closes

Input Breaker Opens (input breakers are optional)

• INPUT BREAKER A or INPUT BREAKER B LED(s) will go off

• BREAKER ALARM LED will go on (red)

• POWER FAIL relay de-energizes so that —

◊ C to NC opens and

◊ C to NO closes

• FUSE ALARM relay energizes so that —

◊ C to NC opens and

◊ C to NO closes

Output Breaker Opens (either being tripped or manually turned off)

• BREAKER ALARM will go on (red)

• FUSE ALARM relay energizes so that —

◊ C to NC opens and

◊ C to NO closes

Pressing ALARM RESET turns off BREAKER ALARM LED and de-energizes FUSE ALARM relay.

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 10

Installation Guide

Physical Attributes

1

CHS

GND 1

7

RTN

BATT

7BATT

A

INPUT

BREAKER

RTN

Breaker Positions A1 - A7 Breaker Positions B1 - B7

FRONT VIEW

B-Side Inputs

BATT

1

7

7

POWER FAIL

NO

NCCNO CNC

7

7

POWER FAILFUSE ALARM

NO NCNCC

GND

CHS

NOC

GND

CHS 1

BATT

INPUT

7INPUT

BREAKER

A

7

RTN

RTN

BATT

BREAKER

RTN

B

INPUT

1

RTN

1

FUSE ALARM

7

CNO

7GND

CHS

POWER FAIL

CNCNC NO

A-Side Inputs

Screw-Tight Horizontal Inputs With 50A Input Breakers

Breakers Shown with

O at Top and | at Bottom

Wire Binding B-Side Inputs Wire Binding A-Side Inputs

Compression Inputs With 50A Input Breakers

Screw-Tight Horizontal Inputs Without 50A Input Breakers

Compression Inputs Without 50A Input Breakers (100A max./side)

Screw-Tight Vertical Inputs With 50A Input Breakers

Screw-Tight Vertical Inputs Without 50A Input Breakers

REAR VIEW

CHS

GND

1

1

A

RTN

7

BATT

7

RTN

BREAKER

BREAKER

RTN

INPUT

B

1

RTN

BATT

1

1

7

RTN

BATT

7

A

INPUT

BREAKER

RTN

BATT

FUSE ALARM

GND

CHS

B

BREAKER

INPUT

RTN

1

7

BREAKER

A

INPUT

RTN

BATT

RTN

BATT

FUSE ALARM

GND

CHS

B

BREAKER

INPUT

RTN

1

BATT

1

7

NCCNOCNC

1

1

BATT

RTN

B

BREAKER

INPUT

POWER FAIL

CHS

GND

1

RTN

BATT

1

FUSE ALARM

NO

GND

CHS

7

7

RTN

BATT

7BATT

A

INPUT

BREAKER

RTN

RTN

BATT

7

7

POWER FAIL

NO

NCCNO CNC

1

CHS

GND 1

GND

CHS

NO

1

CHS

GND 1

BATT

RTN

7

RTN

BREAKER

BATT

INPUT

B

1

RTN

BATT

1

7

7

POWER FAIL

C

FUSE ALARM

CNO NCNC

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 11

Installation Guide

Conguration

(Shown in alarm state)

(Optional)

(Optional)

T009-5 X X 0 X X X X X X X

0=Black Enclosure/Standard Breaker Installation with Off (O) at Top

1=White Enclosure/Standard Breakers Installation with Off (O) at Top

2=Black Enclosure/Breakers Installed with On (|) at Top

3=White Enclosure/Breakers installed with On (|) at Top

Panel Color/Breaker Orientation

0=Screw-Tight Horizontal Inputs with 50A Thermal Input Breakers

Inputs (Type of Connector & Input Circuit Breaker)

1=Compression Inputs with 50A Thermal Input Breakers

2=Screw-Tight Horizontal Inputs without Input Breakers

3=Compression Inputs without Input Breakers (100A max./side)

Breaker Positions Per Side

0=Blank

1=1A

3=3A

5=5A

A=10A

F=15A

K=20A

4=Screw-Tight Vertical Inputs with 50A Thermal Input Breakers

5=Screw-Tight Vertical Inputs without Input Breakers

Schematic Drawing

Dual 40/50/100A Congurable Breaker Panel

Power :: T009-5XXXXXXXXXXX

© Telect, Inc., All Rights Reserved, 118267-3 A0

1.509.926.6000 :: telect.com 12

Installation Guide

Assembly Drawing

Telect assumes no liability from the application or use of these products. Neither does Telect convey any license under

its patent rights or the patent rights of others. This document and the products described herein are subject to change

without notice.

INPUT

BREAKER

B

BATT

-24V

-48V

100A

MAX

+24V

RTN

BATT

RTN

GND

CHS CHS

GND INPUT

BREAKER

-24V

RTN

-48V

100A

MAX

+24V

BATT

INPUT

BREAKER

+24V

MAX

RTN

40A

-48V

-24V

BATT

RTN

0.31 [.79]0.18 [.45]

MAX

-48V

-24V

+24V

INPUT

BREAKER

www.telect.com

9.48 [24.1]

[24.1] [20.4]

[10.2]

M5 Studs

[4.32] [3.17]

1.70 1.25

23.00 [58.4]

22.31 [56.7]

18.31 [46.5]

8.05

4.00

17.25 [43.8]

9.48

0.63 [1.59]

9.71 [24.66]

Table of contents

Other Telect Circuit Breaker manuals