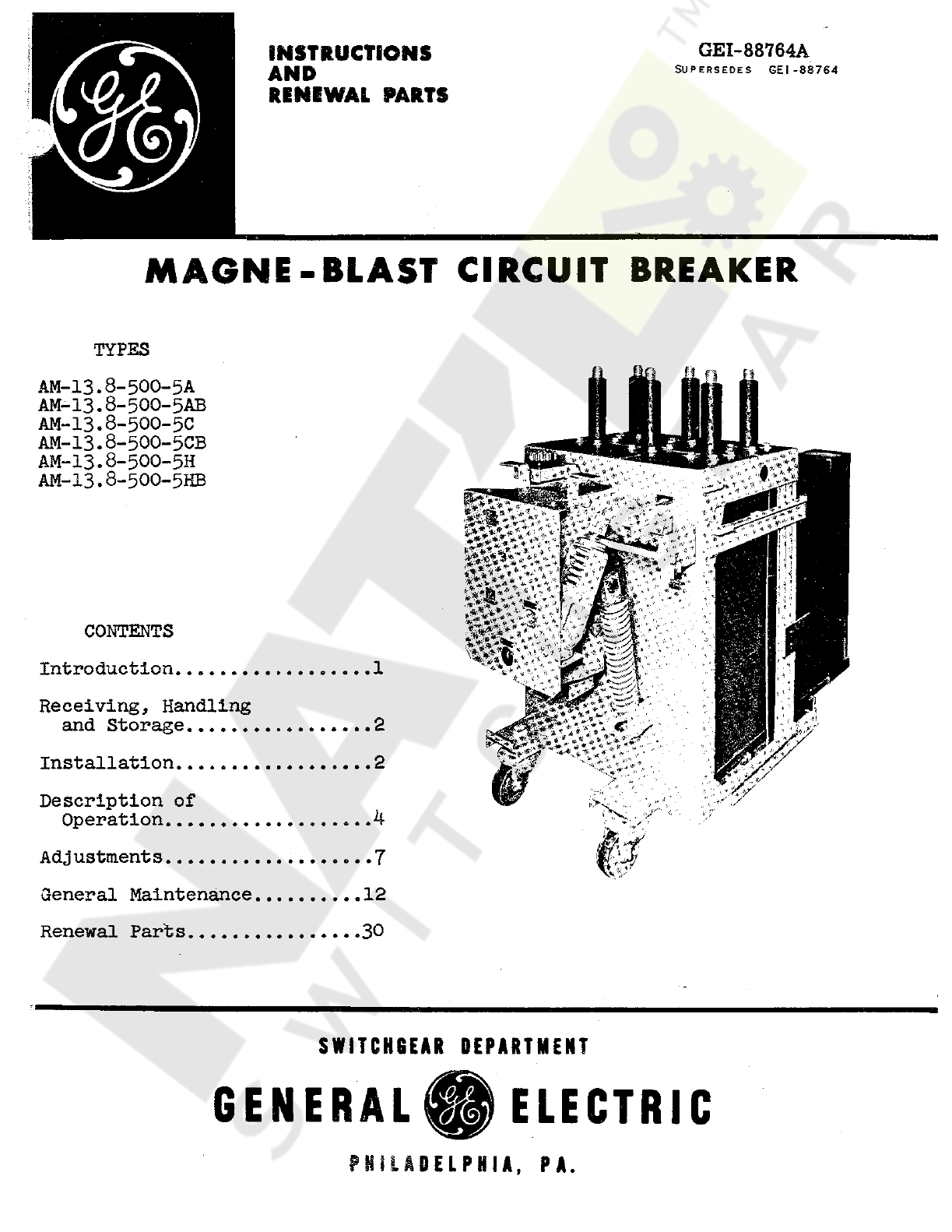

GE AM-13.8-500-5A User manual

Other GE Circuit Breaker manuals

GE

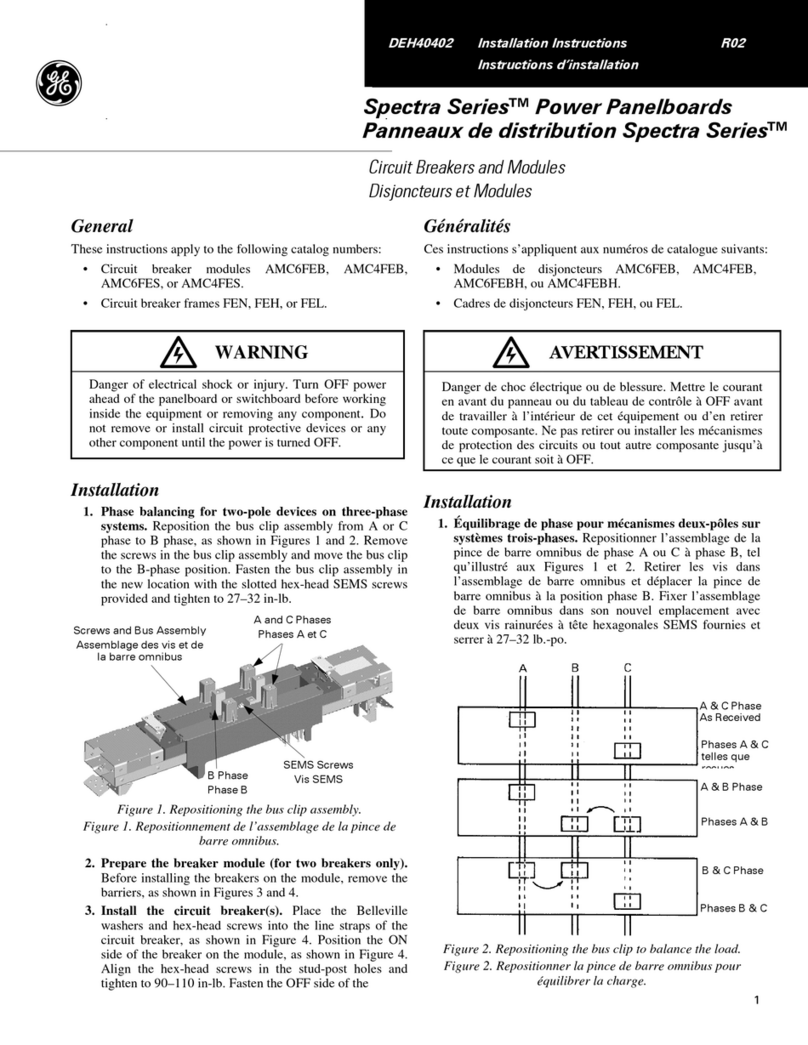

GE Spectra Series AMCB6FGB User manual

GE

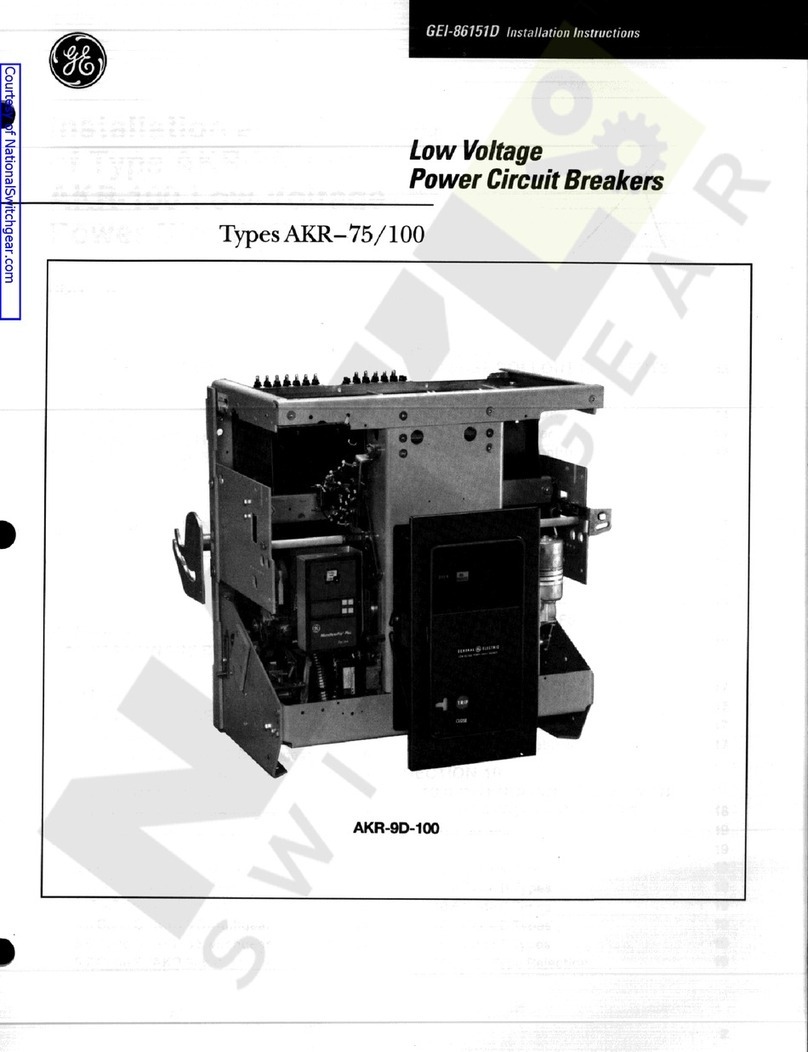

GE MicroVersaTrip AKR-75 User manual

GE

GE GL 310 F3/4031 P/VR User manual

GE

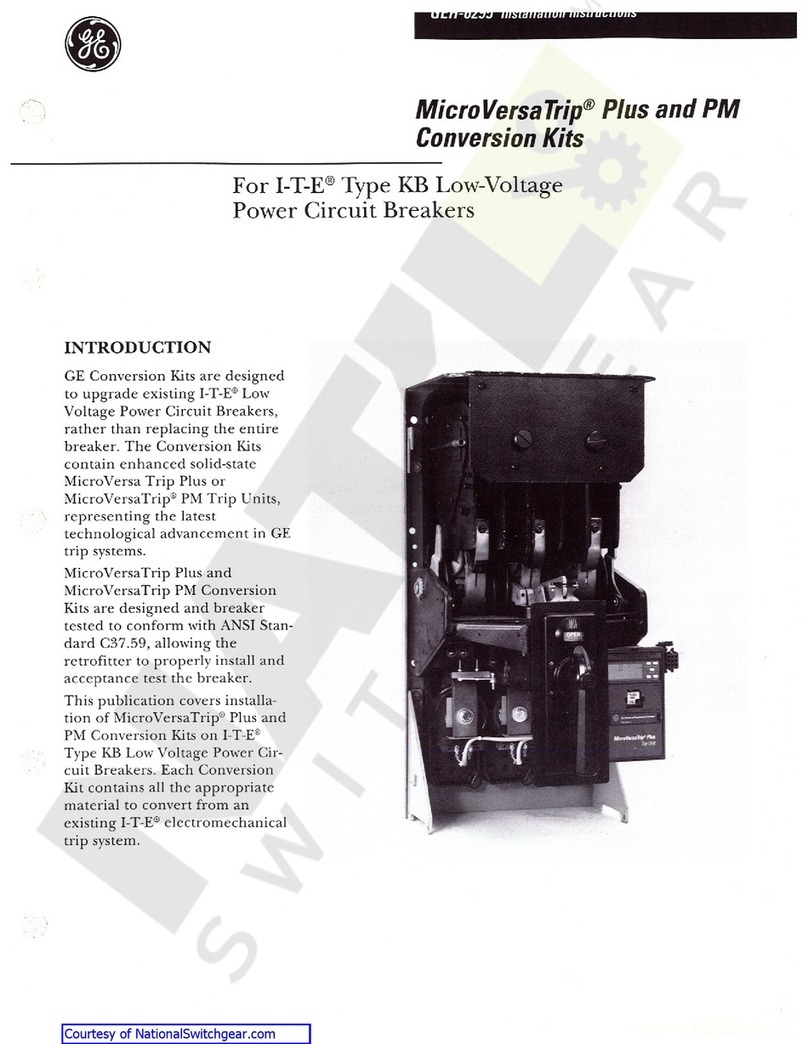

GE MicroVersaTrip Plus User manual

GE

GE SecoVac Series User manual

GE

GE AKR-30S User manual

GE

GE AKR Series Configuration guide

GE

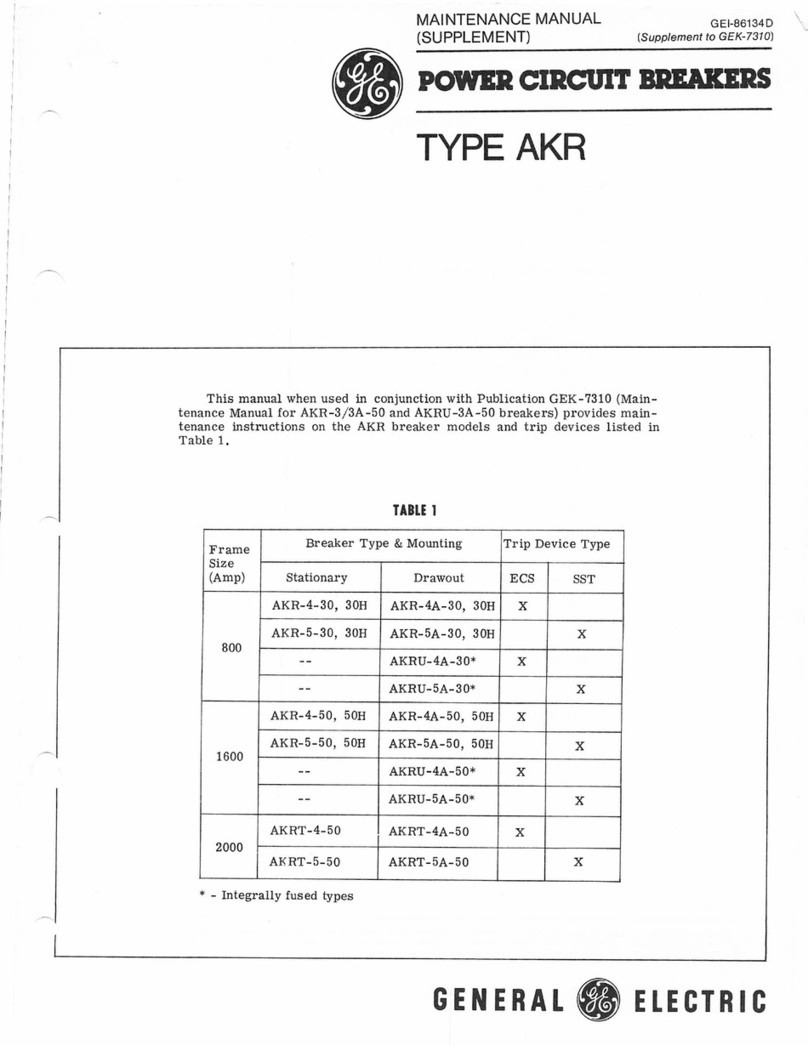

GE AKR User manual

GE

GE AM-2.4/4.16-100/150- 3 User manual

GE

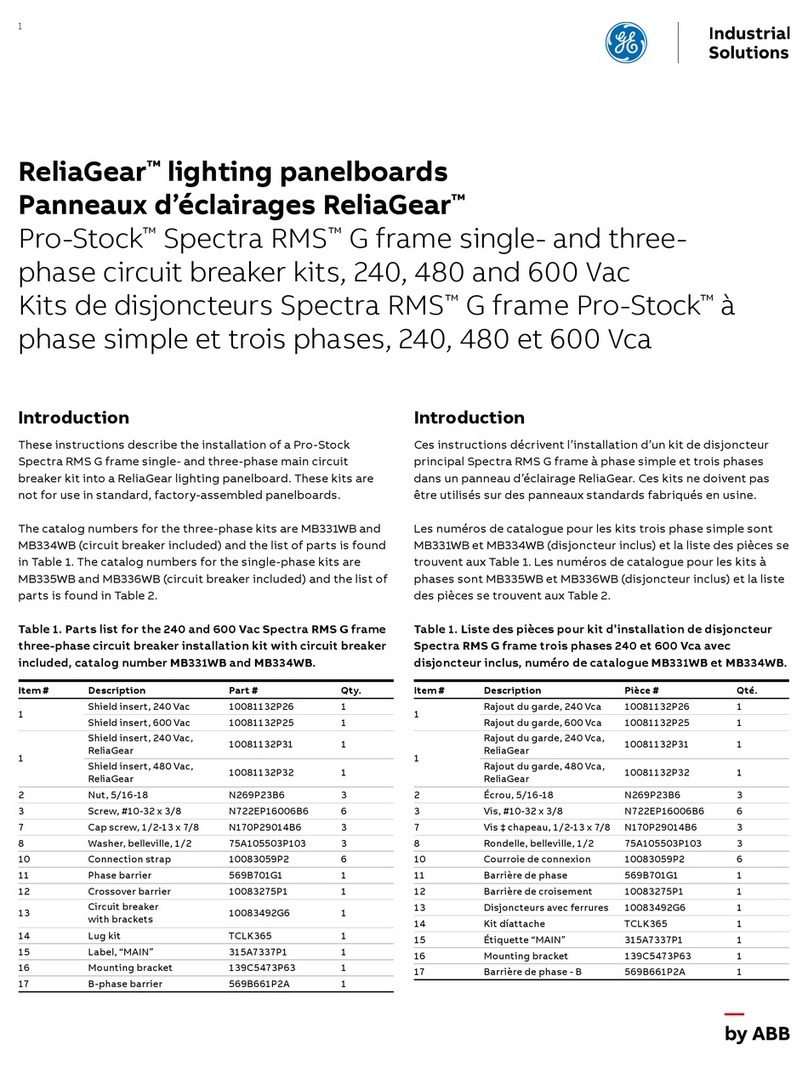

GE Spectra Series User manual

GE

GE GEK-7345 User manual

GE

GE PowerVac GEK-86132G User manual

GE

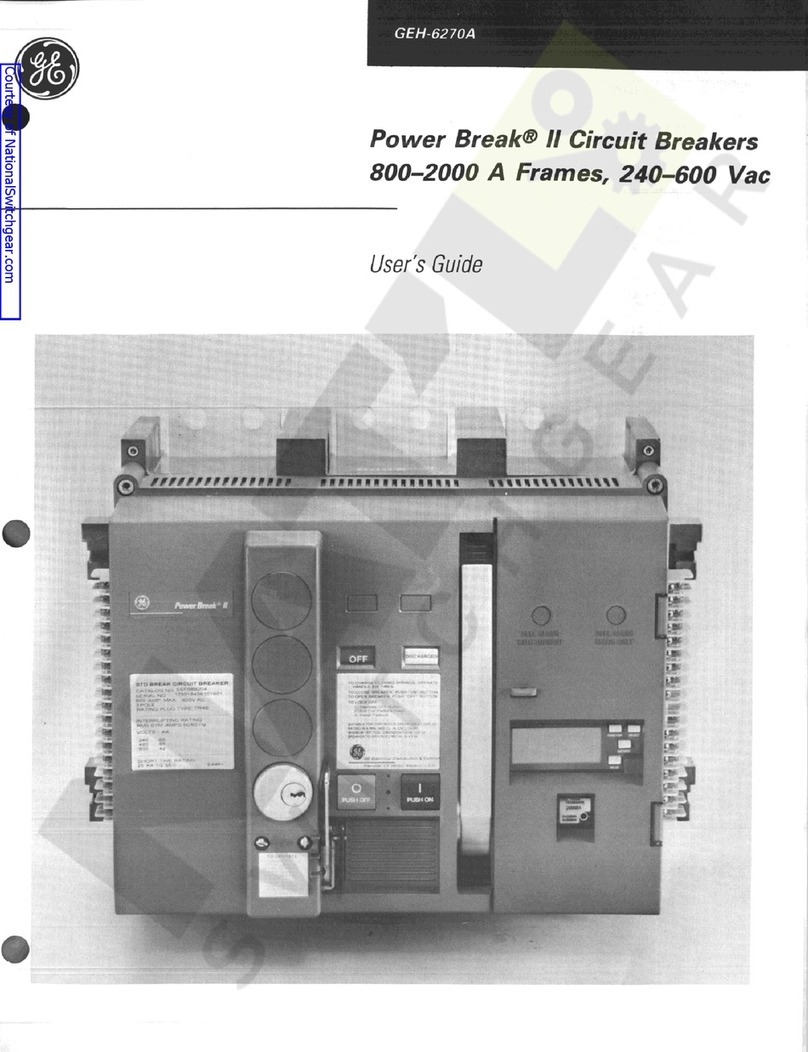

GE POWER BREAK MICRO-VERSATRIP E39ME20 User manual

GE

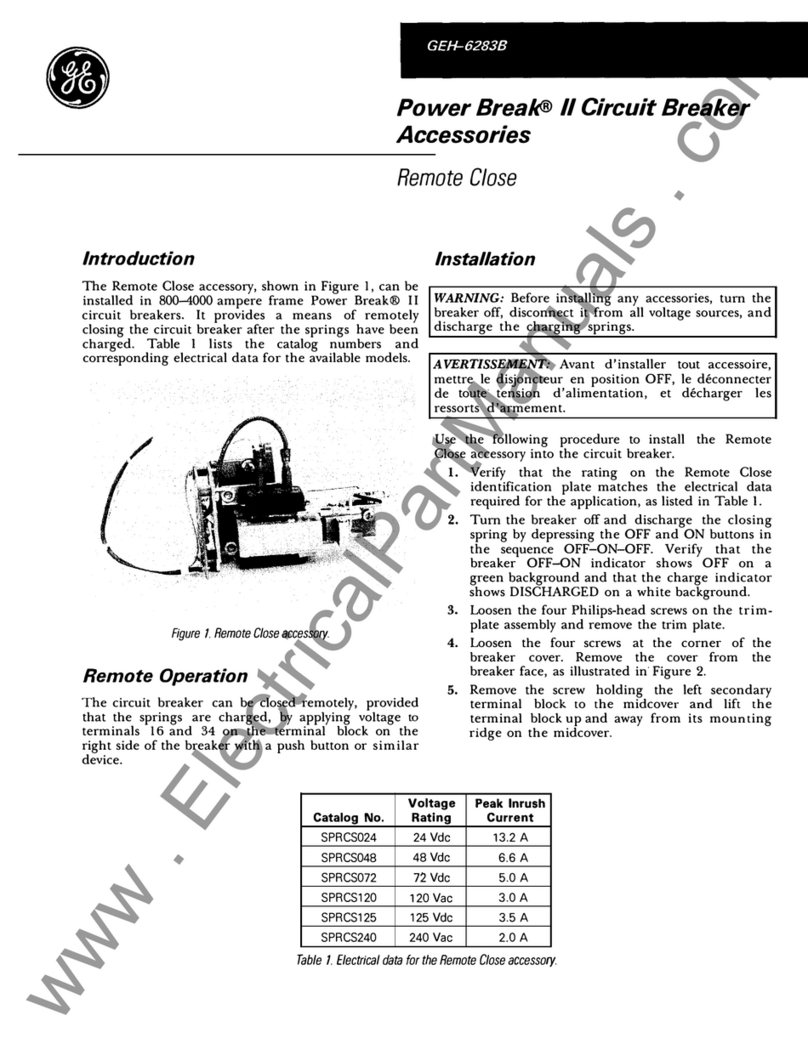

GE SPRCS024 User manual

GE

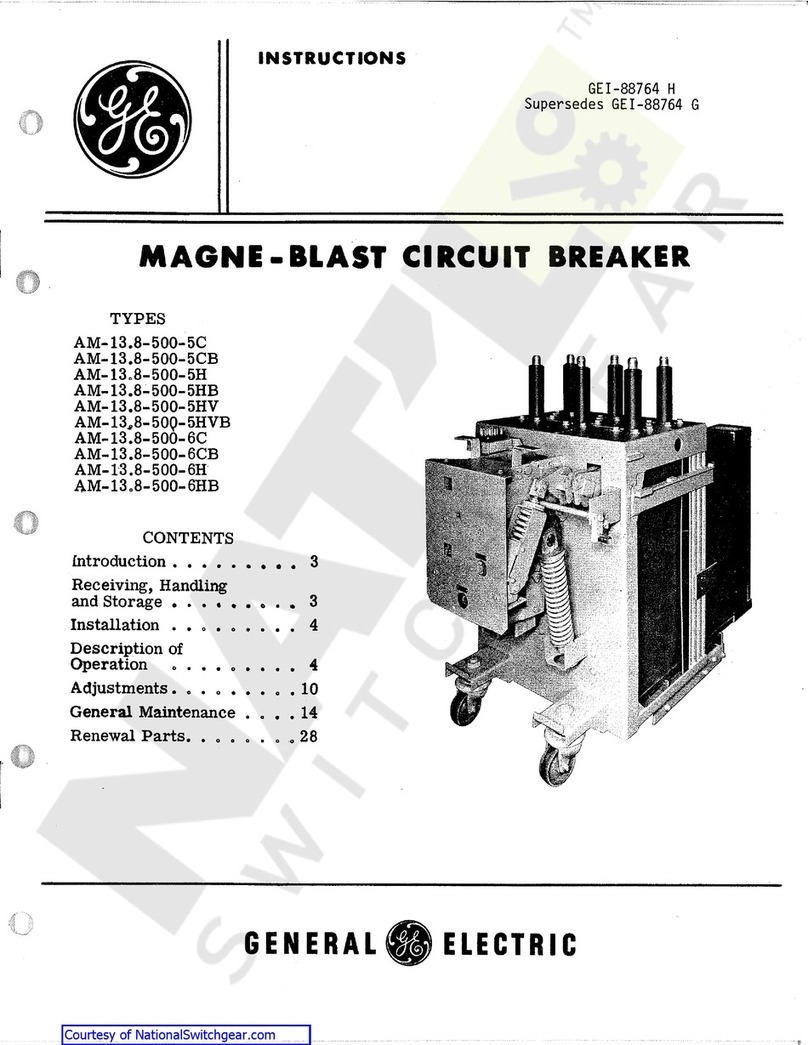

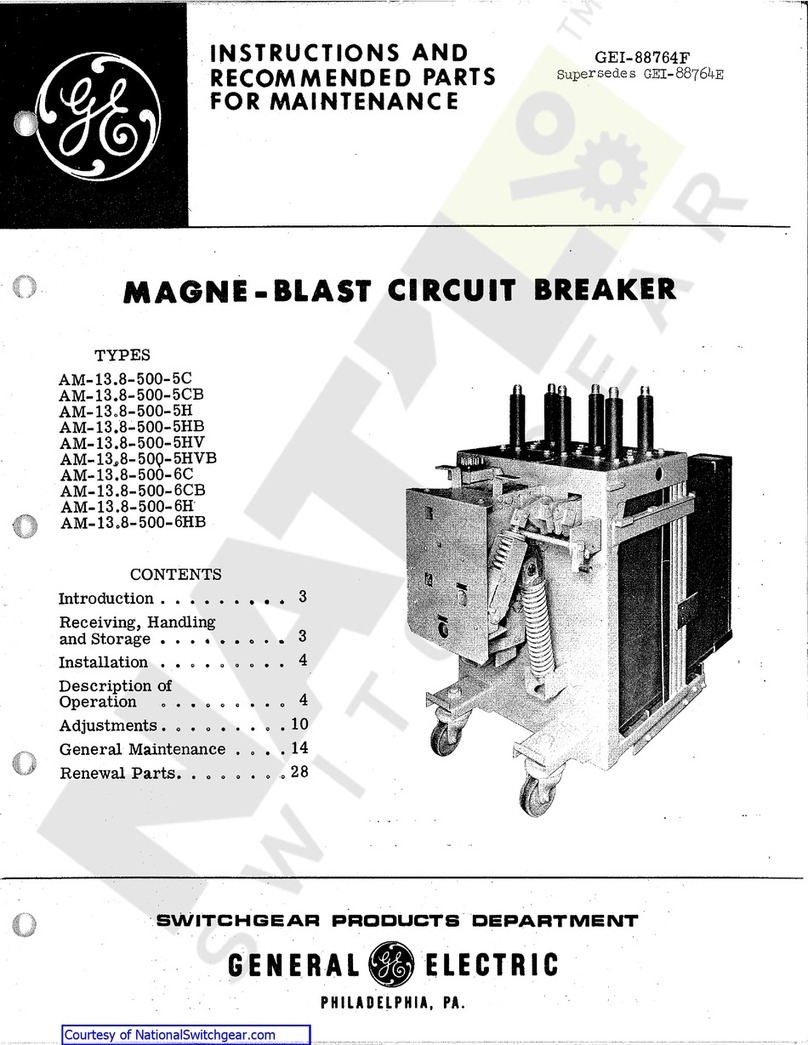

GE AM-13.8-500-5C User manual

GE

GE AK-1-15 Series User manual

GE

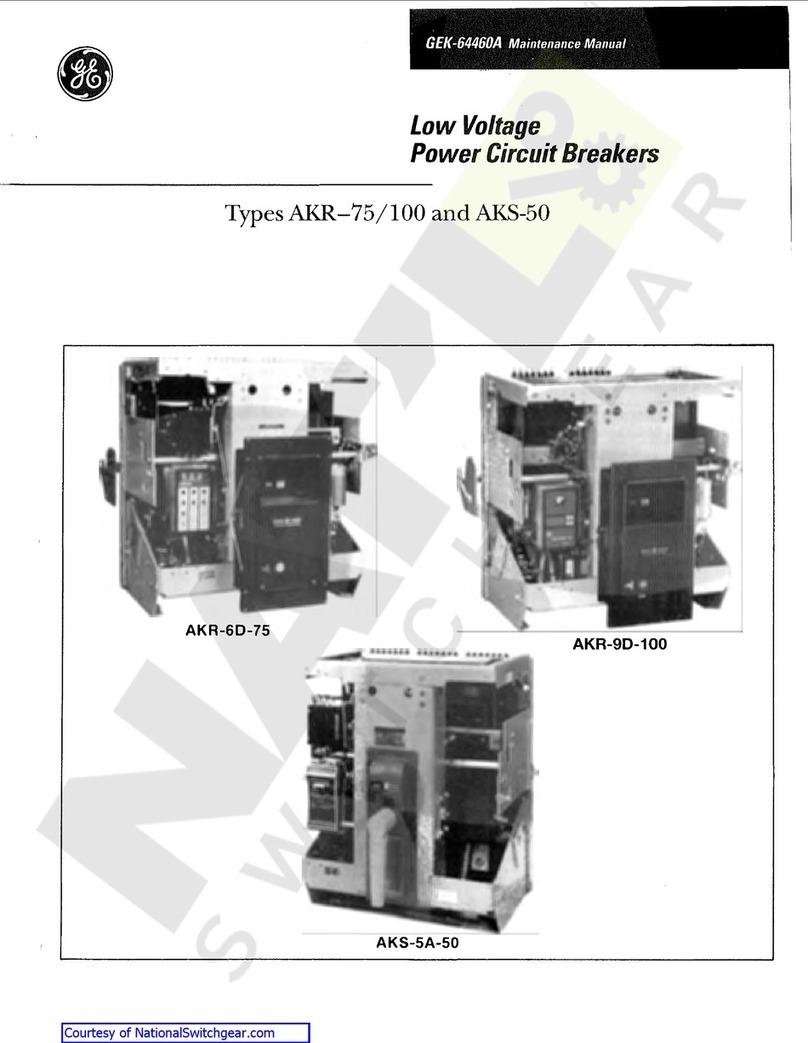

GE MicroVersaTrip AKR-75 User manual

GE

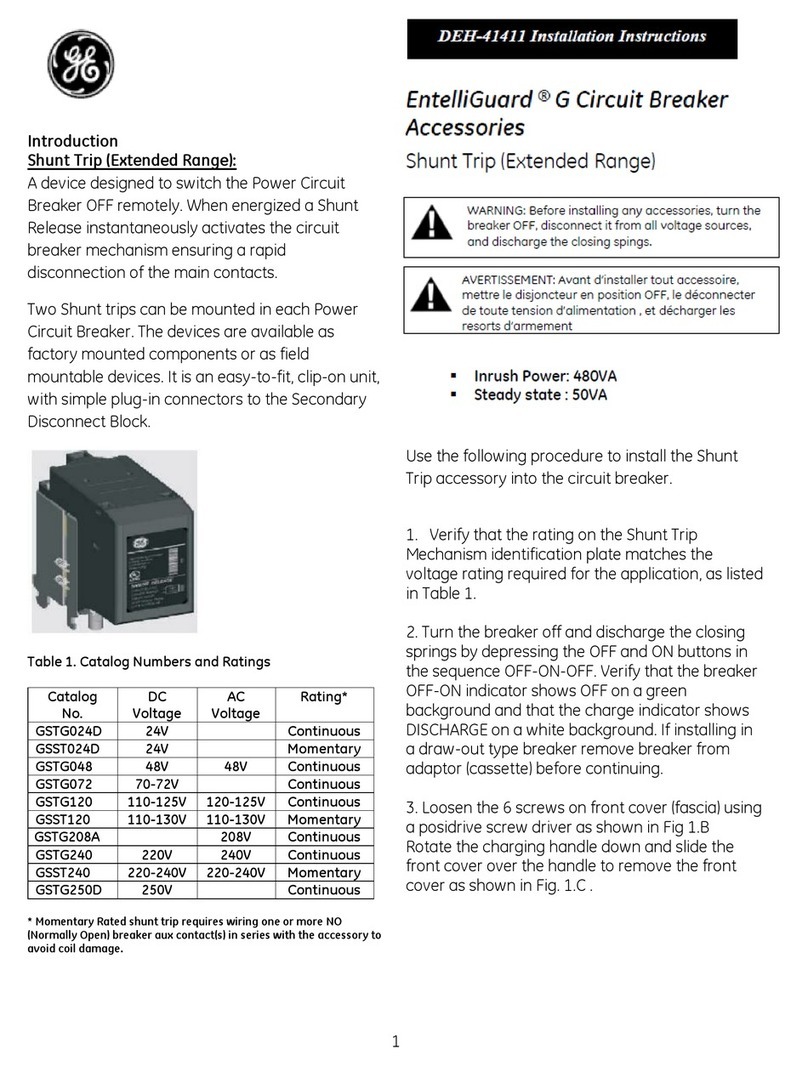

GE GSTG024D User manual

GE

GE MicroVersaTrip Plus Series User manual

GE

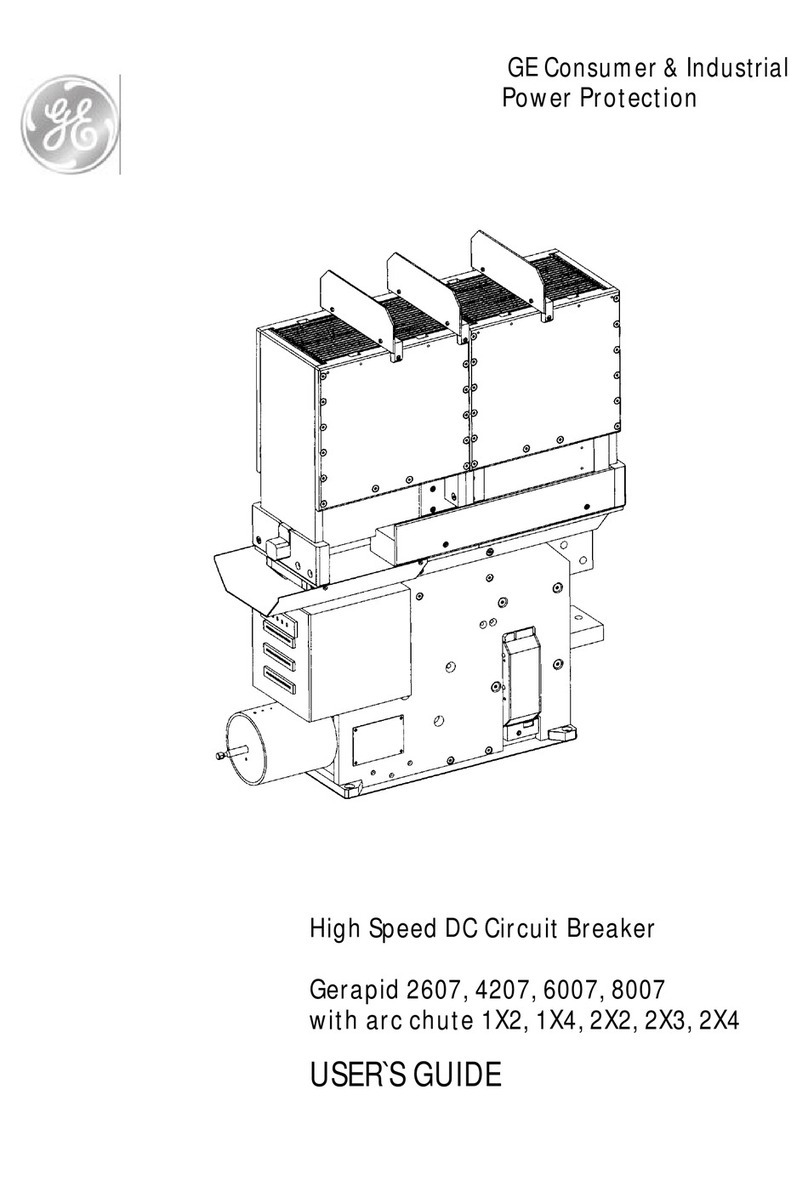

GE Gerapid 2607 User manual

Popular Circuit Breaker manuals by other brands

Siemens

Siemens Sentron 3VA9157-0PK1 Series operating instructions

hager

hager TS 303 User instruction

ETI

ETI EFI-4B Instructions for mounting

nader

nader NDM3EU-225 operating instructions

TERASAKI

TERASAKI NHP TemBreak PRO P160 Series installation instructions

Gladiator

Gladiator GCB150 Installation instruction