NHP ATYSC55CIP User manual

1

INSTALLATION MANUAL

Cat No: ATYSCxxCIP

For NHP MCCB BTS up to 3200A

Product Specifications

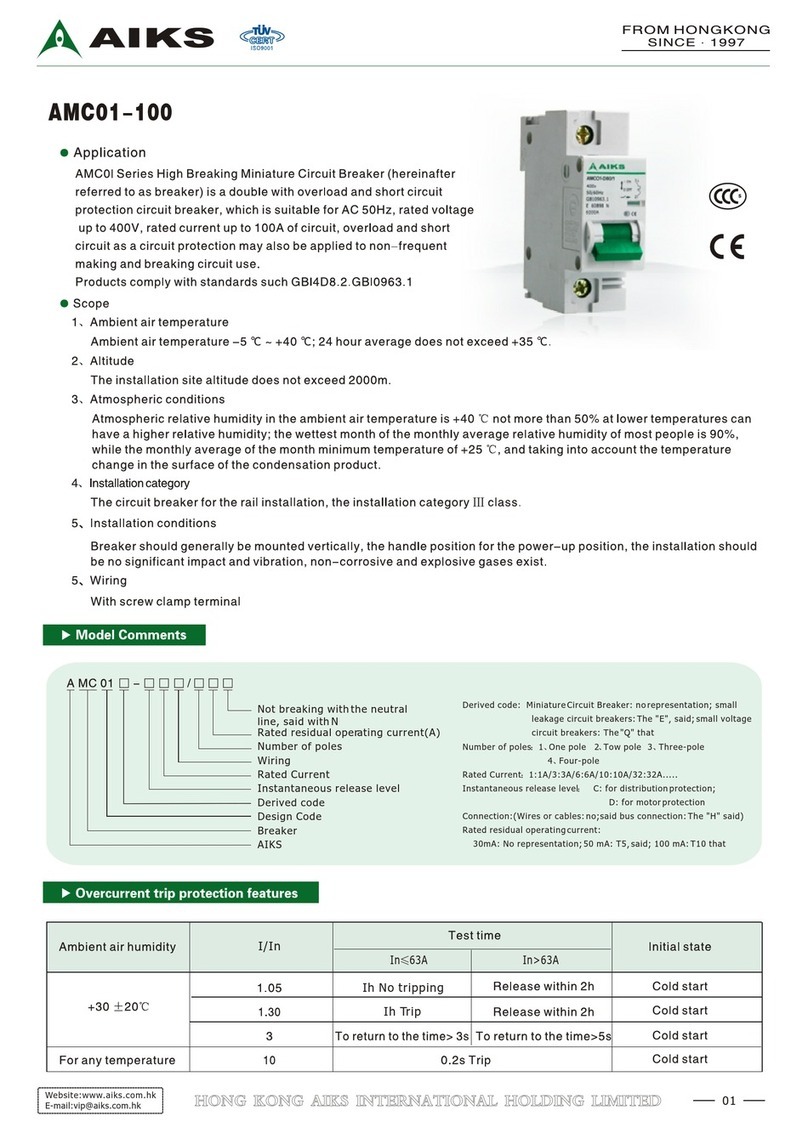

ATYSC55CIP

ATyS C55 Transfer Switch Control Interface for NHP TB2 and TBP BTS

ATYSC65CIP

ATyS C65 Transfer Switch Control Interface for NHP TB2 and TBP BTS

2

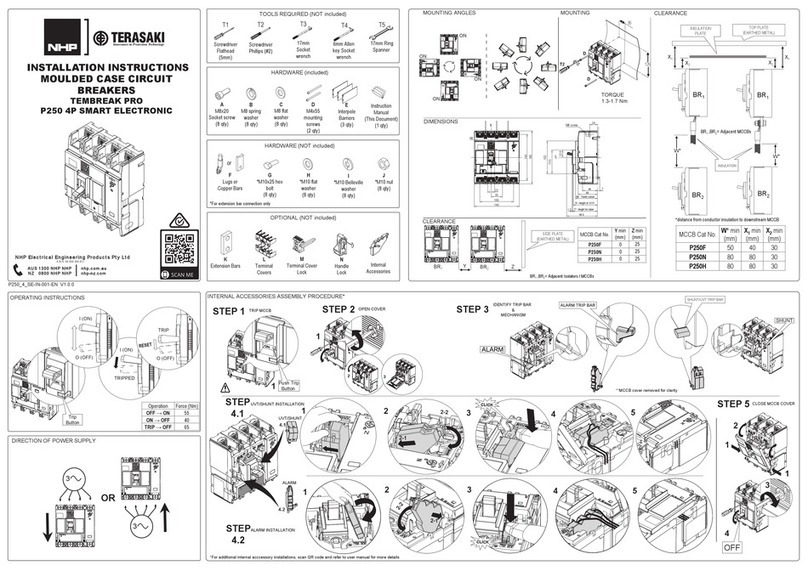

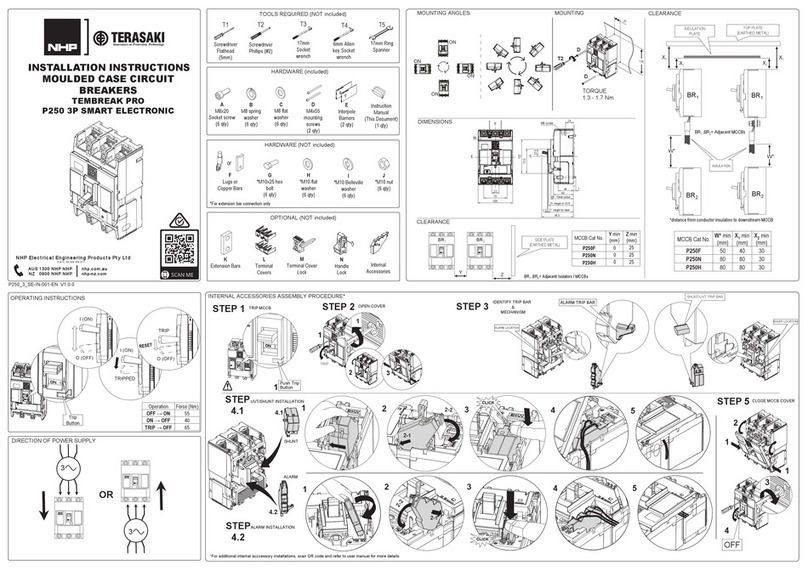

Tools Required (not supplied)

Tools Required (supplied)

Wire Terminating Tool

Risk of damaging the device in case the product is dropped or damaged in any way it is recommended to replace the complete product.

Installation standards must be respected.

WARNING:

Risk of electrocution, burns or injury to persons and / or damage to equipment.

This Installation Manual is intended for personnel trained in the installation and commissioning of this product. For further details refer to the product

instruction manual for the C55 & C65 and refer NHP documentation.

ATTENTION:

•This product must always be installed and commissioned by qualified and approved personnel.

•Maintenance and servicing operations should be performed by trained and authorized personnel.

•Do not handle any control or power cables connected to the product when voltage may be, or may become present on the product, directly through

the mains or indirectly through external circuits.

•Always use an appropriate voltage detection device to confirm the absence of voltage.

•Ensure that no metal objects are allowed to fall in the cabinet (risk of electrical arcing).

T8

Screwdriver Phillips Ph #1Screwdriver Flathead

Wire Strip &

Crimp Tool

Terminal Screwdriver

T1 T2 T3

T4

Drill

T5 T6

Applicable

Cutting Tool

T7

Ruler or

Tape Measure

Non contractual document.

Subject to change without notice

3

Items

Supplied Items

Part Number

Controller Control Interface Panel CIP Looms

& Plugs

IP65 Gasket

ATYSC55CIP

x 1 - C55 - 16000055

x 1

Not available separately

2.5-meter Looms

ATYSLOOMA, B, C

x 1 each Loom

Looms are prewired to CIP

and controller plugs

Not Supplied

16090001

X 1

16090001

ATYSC65CIP

x 1 - C65 - 16000065

Required Items Not Supplied

Part Number

BTSxxxxxxx

x 1

or

NHP Manufactured Basic Transfer Switch TB2/TBP up to 3200A

Scan QR Code for more information

x 1 TemBreak PRO

4

Dimensions

Control Interface Panel

ATyS C55/65 Controller

Dimensions not to scale

63.90 mm

48.10 mm

160 mm

240 mm

220 mm

180 mm

5

Mounting

Installer to select appropriate fasters to suit size 6mm mounting holes of

unit to mounting material

Panel

Base

220 +/-1 mm

160 +/-1 mm

Gasket for IP 65

Ø 6.0 mm

6.0 mm

6.0 mm

188 mm

268 mm

Control Interface Panel

OR

click!

172 –179 mm

150 +/- 1mm

Screw not delivered with product

Clip the mounting feet in

the designated slot

Remove all connectors then place the ATS controller inside the door cut-out and clip the door mounting screws into the side of the controller (2 screws on each side). It

is important to respect the tightening torque indicated below and follow good engineering practise when installing the ATS controller.

1

2

Insert the 4 door mounting

screws in the designated slot

Push back up to

lock in place.

Screw Tightening

torque PH1 / 0.2 Nm

6

Clearances

The below clearance are recommendations to allow for easy of wiring to the Control Interface Panel

Control Interface Panel

Cable must be more than 10mm away from the RTC battery cover and USB.

Do not drill holes above the controller after it has been mounted, to avoid swarf in terminals

Controller

50 mm 50 mm

50 mm

Recommended clearance for

default loom exit (can be moved)

Recommended clearance for cable termination

(*)

(*)

(*)

(*) No recommended minimum clearance

10 mm

10 mm

7

Plugs

Looms

ATYSLOOMA –Normal Supply –Orange Plug

ATYSLOOMB –Emergency Supply –Grey Plug

ATYSLOOMC –Control Panel

Controller

1

2

Plug the emergency side loom into the right

hand side of the BTS (Grey to Grey)

Plug the normal side loom into the left hand side

of the BTS (Orange to Orange)

Both plugs will SNAP into place,

Wiring from CIP to BTS COMPLETE!

snap!

snap!

Looms A, B, & C will be prewired to their required plugs on the Controller.

Match the plugs with there sockets on the Controller

Wiring to Controller COMPLETE!

*C65 Only

*use when current sensing is required for current, power and energy measures on the C65 (1A or 5A CTs)

Application Fuse Wiring Network Setting

Single Phase Source 1

Single Phase Source 2

1P + N

*N1 to 1P1 & N2 to 1P2 links required

2 Phase Source 1

2 Phase Source 2

*separate voltage version of CIP required

2P

2 Phase + N Source 1

2 Phase + N Source 2 2P + N

3 Phase Source 1

3 Phase Source 2

*separate voltage version of CIP required

3P

3 Phase + N Source 1

3 Phase + N Source 2 3P + N

3 Phase + N Source 1

Single Phase Source 2

3P + N / 1P + N

*N2 to 1P2 link required

Single Phase Source 1

3 Phase + N Source 2

3P + N / 1P + N

*Source Priority needs to be set to Source 2

*N1 to 1P1 link required

2 Phase + N Source 1

3 Phase + N Source 2

2P + N

*Disable phase rotation check

8

Fuse Wiring

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

Do not input > 264 VAC (line –neutral) nominal voltage to the Fuse

Terminals

The C55/65 sensing terminals limits are 88 - 576 VAC, however the CPSR’s coil & standard

build BTS are rated for 204 –264 VAC.

The below outlines some of the possible wiring combinations for the Control Interface Panel.

L1 and L2 are the power terminals for the ATyS C55 and C65, however when using the ATYSCxxCIP for single

phase applications link N1 to 1P1, and N2 to 1P2 to power the Controller.

Do not link N1 & 1P1, and N2 & 1P2 if Line power is wired to F2

and F5 respectively.

It will result in a dead short between line and neutral

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

3p + N / 3p + N 1p + N / 1p + N 1p + N / 3p + N3p + N / 1p + N 2p + N / 2p + N 2p + N / 3p + N 2p + N / 2p 3p / 3p

9

Configuration

When configuring an ATyS C55/65 it is recommended to have both Source 1 and Source 2 available to ensure

settings match the required application.

NHP CIP Factory Settings

Language English

Poles & Wires 3P+N

Nominal Voltage 415 V

Nominal Frequency 50 Hz

Phase Rotation A –B –C

Application Type MAIN –GEN

Source Priority Source 1

Switch Technology Circuit Breaker

(Custom)

Tripping Action Total Inhibition

Date Format DD/MM/YY

Date and Time AEDT

Modbus Settings Baud: 38400

Stop: 1 BIT

Parity: None

Address: 006

When purchasing a C55 or C65 outside of the

ATYSCxxCIPxxxx offerings you will be promoted with the

SMART Wizard configuration on first power up. As the

ATYSCxxCIPxxxx is tested in house at NHP manufacturing

prior to despatch this Wizard would have been preformed

and set to:

Navigate to the Wizard

Press the Back/Menu button

1.

2.

3.

4.

5.

6.

Or Navigate to Parameters Menu

Press OK button to enter Parameters

Or Navigate to Wizard Menu (Last option)

Enter the 1000 using the arrows and press OK button to confirm

Press OK button to enter Wizard

Time settings do not change with daylight savings and will need to

be kept up-to-date by the end user

NHP Custom Switch Technology Settings

Input 1 BREAKER 1 CLOSED (N/O)

Input 2 BREAKER 2 CLOSED (N/O)

Input 3 BREAKER 1 TRIPPED (N/C)

Input 4 BREAKER 2 TRIPPED (N/C)

If you would like another configuration follow the

below to get to the SMART Wizard.

Images are taken from Socomec C55/65 Manual for interface reference and don’t reflect the NHP factory settings

If the above settings are not used for an NHP BTS, a trip event on one source could lead to an event

where the opposite source breaker will attempt to close and result in jamming of the BTS.

Input 3 and 4 must to be set in I/O settings and can’t be set via Wizard or Switch Technology Settings

10

Wizard

Once you have selected to start the Wizard you will go through the following 12 windows

1)

2) 2) 2)

3) 4)

5) 5)

1) Smart Config and Manual Config option

2) Date and Time will be important for applications where the logging of events, alarms and faults is critical

3) If SMART Config was selected these fields will be auto filled, it is important to have both Source 1 & 2 available during the SMART Config

4) For use with BTS and ACBs the Switch Technology should be set to Circuit Breaker

5) Modbus RTU communications as standard, if not using communications proceed with the OK button

If the ATyS is still not recognising the sources please check the source OP range settings match the application

requirements.

Under Main Menu –Parameters –Network

Windage generators tend to run at a higher frequency when unloaded.

As a result the S2 OF Fail % (Threshold) and S2 OF RESTORE % (Hysteresis) settings may need to be increased to

allow for higher unloaded running frequency.

The frequency of the generator output should normalise once loaded.

11

Initial Test

As well as routine inspection it is also important to test the installation when first commissioning.

The below will advise how to perform either a Test On Load (TON) or Test Off Load (TOF).

TON is the recommended option however, due to site requirements at the time a TON may not be possible.

TEST ON LOAD will cause a load supply interruption when testing the transfer function as the

load will change from one source to another in open transition.

Test On Load (TON)

TEST ON LOAD / LOAD TEST: will perform a full test including all the timers and operating the switch (full cycle).

As default the Test Button will preform a TON.

Press the Test button

1.

2.

3.

4.

5.

Enter the 1000 using the arrows and press OK button to confirm

Confirm that you wish to preform a TON

A TON will start by sending a start-gen signal to the secondary source (if in Main-Gen), and will initiate a

transfer to the secondary source.

To finish the TON Press the Test Button again and confirm with the OK button,

once the test has ended the switch will transfer back to the priority source.

Test On Load (TOF)

TEST OFF LOAD: Initiates starting of the genset but will not give the order to transfer to the secondary source when it

becomes available.

1.

2.

3.

4.

5.

6.

Press the Back/Menu button

Navigate to Control

and Press OK

Enter the 1000 using the arrows and press OK button to confirm

Navigate to Test

and Press OK

Navigate to Test OFF Load

and Press OK

Once Test is complete you can continue to run other

checks or finish the Test by the Pressing Test Button

12

Tripping Action

In the event of a trip on breaker 1 or break 2 the controller will enter a trip inhibition mode.

This mode will stop the controller from all automatic transfer functions including Gen start if controller power is still

available.

The controller will receive trip feedback from the breakers via inputs 3 and 4, as per NHP factory settings.

When a tripping action is detected the controller will inform the user with a pop-up with the information of which

breaker has tripped.

Bold are NHP default factory settings for ATYSCxxCIP

Tripping Action settings are available under Main Menu –Specific Functions –Tripping Action

Setting Option Description

SWITCH BREAKER 1, BREAKER 2 Selects on which breaker the configuration applies

TRIP ACTION

TRIP = SOURCE LOST, PARTIAL

INHIBITION, INHIBITION, TOTAL

INHIBTION

This setting defines the action to apply when the trip signal for the corresponding

breaker is active.

OP MODE AFTER

TRIP

PREVIOUS MODE,

AUTOMACTIC, PARTIAL

INHIBITION, INHIBITION

This setting allows user to select which operating mode the controller will return to

after the trip signal has been disabled (input has returned to inactive).

CHRG. TIME

STATUS

DISABLED, WHEN OPEN, WHEN

CLOSED

Allows users to configure a charging time for the breaker to give time to charge the

spring mechanism before sending an order. Users can define if the spring is charged

after a close order or open order. If a charging time has been configured the

controller will wait the specified duration before sending another order.

NB: each charging time will be overridden if an input giving the charging status of the

breaker is configured.

CHARGING TIME(s) 0.00-15.00s

Below are the available settings Tripping Action, including the NHP default factory.

To reset a trip on the controller follow the below steps:

1. Ensure the trip has not caused damage to the assembly and inspect circuit breaker according to manufactures

recommendations.

2. Ensure that the cause of the trip has been addressed.

3. Resetting or replacing of the circuit breaker

4. Clear any faults/warning on the controller’s interface

5. Select the operation mode using Auto or Manual mode buttons. (operator code will be required)

Resetting a Trip Event

Resetting a trip event shall only be performed by qualified

persons.

13

ATYSC55CIP

ATYSC65CIP Wiring

Up to 1000A BTS

Spare cores will be available in future updates

E

14

ATYSC55CIP

ATYSC65CIP Wiring

1250A –3200A BTS

E

Spare cores will be available in future updates

15

Legend

16

16

NHP Electrical Engineering Products Pty Ltd AUS 1300 NHP NHP nhp.com.au

A.B.N. 80 004 304 812 NZ 0800 NHP NHP nhp-nz.com

ATYSCxxCIP-001-EN © Copyright NHP 04.11.2021

Version 1.0.0

Troubleshooting

Problem Description

Possible Cause Remedial Advice

Will not transfer to source 2

Generator frequency not back within limits Try adjusting S2 OF Fail & S2 OF RESTORE settings

Incorrect nominal settings Preform a auto-detect or Wizard configuration

Phase Rotation does not match Preform a auto-detect or Wizard configuration

Compare wiring for Source 1 and 2 at Fuse Terminals

Will not recognise source 2

Generator frequency not back within limits Try adjusting S2 OF Fail & S2 OF RESTORE settings

Incorrect nominal settings Preform a auto-detect or Wizard configuration

Phase Rotation does not match

Preform a auto-detect or Wizard configuration

Compare wiring for Source 1 and 2 at Fuse Terminals

Transfer Switch not Automatically

Transferring

Controller is not in Auto Mode Press the Auto button, a Green LED should light up

Check that the controller is no receiving a Inhibit Command

Motors are not responding

Ensure Motors have control power

Check to see if a Fuse has blown

Check Motor interlock cable is not unplugged

(For 160AF to 1000AF)

Controller is Inhibited

Possible Inhibit Inputs:

Padlock, Blocked, Emergency Sign, Inhibit S1, Inhibit S2,

Inhibition, Partial Inhibition, Total Inhibition

Fault Present

Check Faults in Log-Fault Log-In Progress

Possible Faults:

Unexpected Transfer, Failed to Transfer, Max operation per

minutes reached, Externa fault, Unknown position

Reset Faults, by hold the LAMP TEST button & reset with OK

Passwords

Access Level

Description Code

User

Requires no password and it permits the visualization of the parameters and values

measured by the controller through the dashboards. It is the level by default and if another

user stays away from the controller for more than 5 minutes with no actions, the security

level will become Standard user automatically.

No password

Operator

It allows changing the operating mode, sending position orders to the switch and setting

the engine exerciser parameters and alarms. 4000

Configurator

It allows to change any configuration of the controller (operating range, timers, type of

control, display settings, etc) 1000

Maintenance

Is the highest level of security.

It permits resetting counters, rebooting the device, changing and restoring passwords of

other users and entering inspection date and telephone number

1010

These default passwords can be changed in the Parameters / Passwords menu (Configurator or Maintenance

access)

If the above doesn’t cover your problem, more information can be found in the C55/C65 User Manual found on the Socomec website

or alternatively contact NHP

This manual suits for next models

1

Table of contents

Other NHP Circuit Breaker manuals