Telect 06004-01 User manual

© Telect, Inc. All rights reserved. .6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

Page ii

Installation Guide, Part Number 130358-2

Copyright 2017, Telect Inc., All Rights Reserved

Telect and Connecting the Future are registered trademarks of Telect, Inc.

22425 East Appleway Ave. #11, Liberty Lake, WA 99019

Telect assumes no liability from the application or use of these products. Neither does Telect convey any license under

its patent rights nor the patent rights of others. This document and the products described herein are subject to change

without notice.

Telect challenges the status quo and looks beyond what is possible in network connectivity and

power management.

Founded in 1982, Telect is driven by the principles of innovation and customer service. Headquartered in Liberty

Lake, WA, the privately held company supports a global network of customers with a comprehensive product portfolio

and a values-driven corporate culture.

Our products and solutions are found across communications service-provider networks, data centers and utility

networks around the globe.

At Telect, we pride ourselves on our ability to respond to customer challenges, building a reputation among

communications service providers for delivering solutions uniquely tailored to their needs.

We simplify networks.™

Connecting the future for over 30 years

• Exceptional lead-times

• Custom integrated solutions

• Rapid collaborative development and prototyping

• UL and NEBs expertise

Technical Support

Email: [email protected]

Phone: 509-926-6000

© Telect, Inc. All rights reserved. .6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

Page iii

Table of Contents

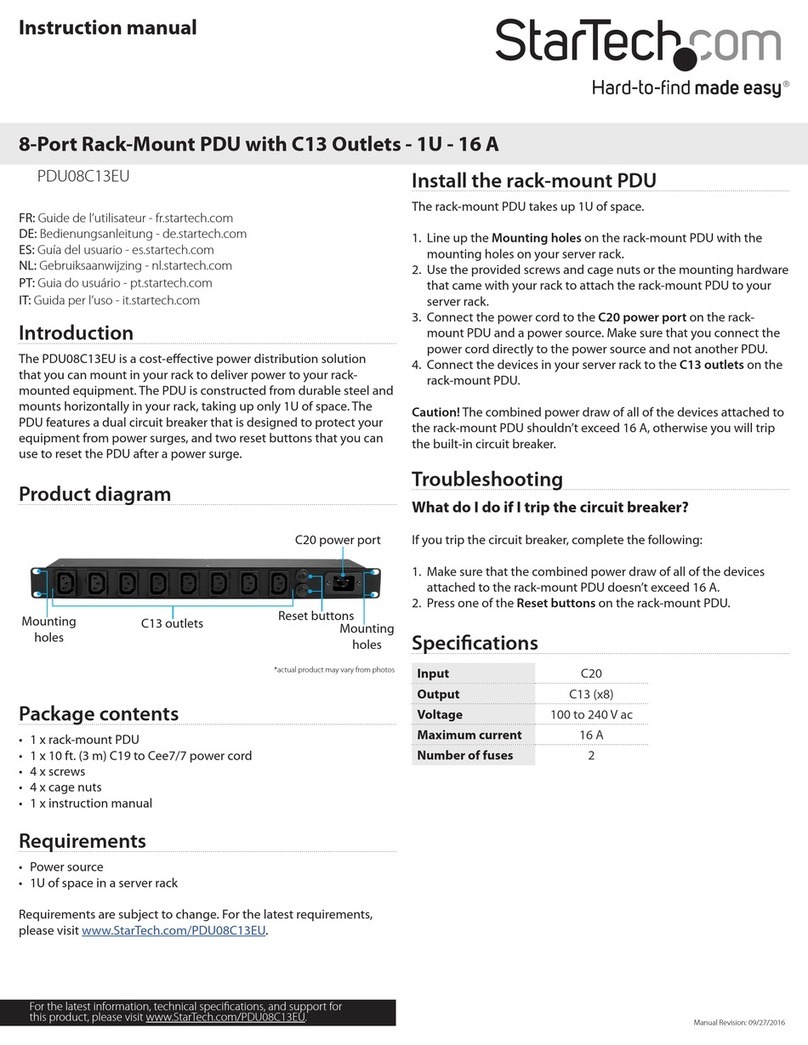

1.1 Overview..............................................................................................................................................................1

1.2 Specications ......................................................................................................................................................3

1.3 Inspection ............................................................................................................................................................4

1.4 Installation ...........................................................................................................................................................5

1.5 Alarm Wiring ......................................................................................................................................................10

1.5.1 Standard Alarms..........................................................................................................................................10

1.5.2 Auxiliary Alarms ...........................................................................................................................................10

1.6 GMT Fuses........................................................................................................................................................12

1.7 Schematics........................................................................................................................................................12

List of Figures

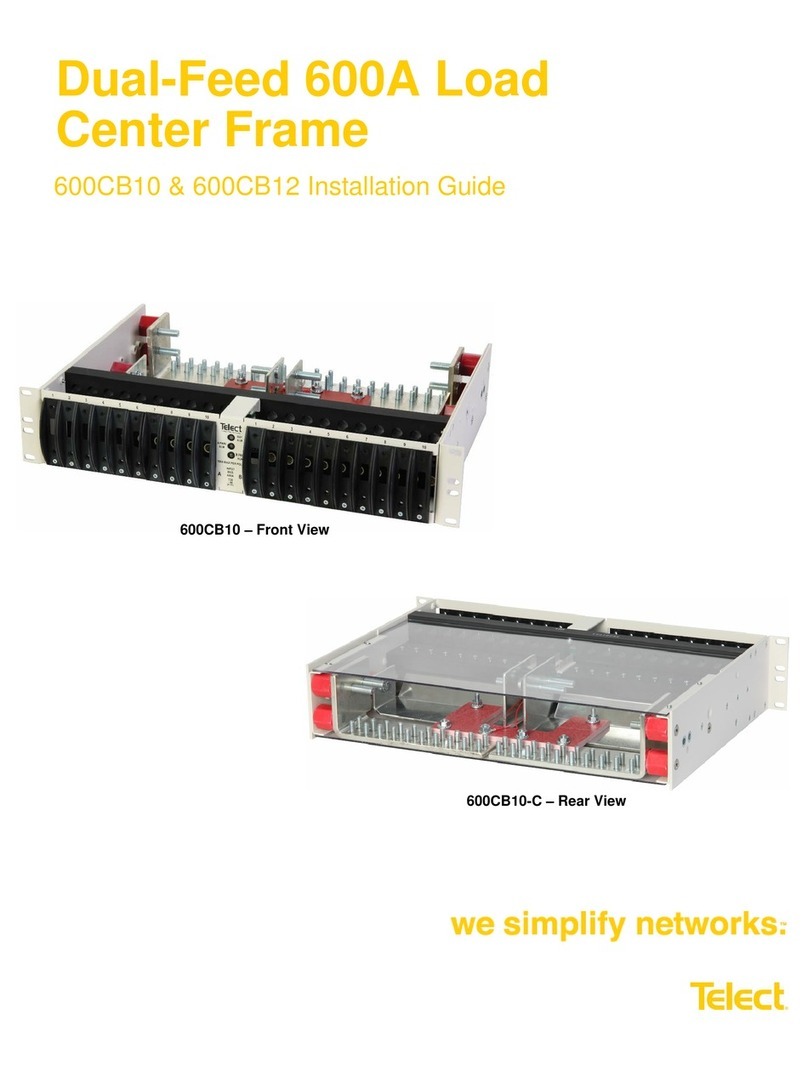

Figure 1 - Model 06004 .............................................................................................................................................1

Figure 2 - Front View.................................................................................................................................................1

Figure 3 - Model 06004-01 (Rear View) ....................................................................................................................2

Figure 4 - Model 06004-11 (Rear View) ....................................................................................................................2

Figure 5 - Panel with Mounting Brackets in Stowed Position for Shipping................................................................ 5

Figure 6 - Bracket Installation (Examples).................................................................................................................6

Figure 7 - Mounting the Panel ...................................................................................................................................6

Figure 8 - Connecting the Lug to the Rear Panel......................................................................................................7

Figure 9 - Inserting Conductors.................................................................................................................................7

Figure 10 - Fail Relay Alarm Pins..............................................................................................................................8

Figure 11 - Designation Card.....................................................................................................................................9

Figure 12 - Inserting the Designation Card..............................................................................................................10

Figure 13 - Standard Alarm Wiring ..........................................................................................................................10

Figure 14 - Auxiliary Alarm Wiring ........................................................................................................................... 11

Figure 15 - Block Diagram.......................................................................................................................................12

Figure 16 - Rear, Top and Front Views....................................................................................................................13

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

1

1.1 Overview

The Telect 1RU Traditional Low-Current GMT Series Fuse

Panels provide protected secondary -24 VDC to -48 VDC

power distribution to telecommunications equipment at the

bay level. Fuse panels are available for GMT outputs up to

10A per position in dual-circuit panel congurations having

20 GMT fuse positions per circuit.

Front

Rear Figure 1 - Model 06004

• Model 06004-01 is the standard panel containing separate Side A and Side B GMT fuse failure alarms and

corresponding LEDs. Standard features for Model 06004-01 include:

– Dual-circuit, separately fused input buses for Sides A and B

– Minimal rack space: one, 1.75" EIA or 2" WECO rack unit (1RU) for rear access connections

– 20 GMT outputs per side with each side protected by a Type ABC 20A ceramic input fuse

– Dummy GMT fuses provided for all fuse holders

– Two sets of Form C relay contacts per side for reliable fail alarm connections

– Side A and B alarms can be wired for separate or common alarming. (All basic and auxiliary alarms

can be wired for separate or common alarming.)

– 19" or 23" rack mounting, with mounting brackets provided

• Model 06004-11 adds separate power failure auxiliary alarms for Sides A and B along with a load-sharing

fail-safe circuit. (All basic and auxiliary alarms can be wired for separate or common alarming.) If power fails

on one bus, the other picks up the loads on the failed bus.

Both Models are UL Recognized for US and Canada, E199668 and NEBS3 Compliant

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 1

Low-Current 20/20 GMT Series Fuse Panels

Models 06004-01 & 06004-11 Installation Guide

1.1 Overview

Telect’s 1RU Traditional Low-Current

GMT Series Fuse Panels provide pro-

tected secondary -24 Vdc to -48 Vdc

power distribution to telecommunica-

tions equipment at the bay level. Fuse

panels are available for GMT outputs up

to 10A per position in dual-circuit panel

configurations having 20 GMT fuse positions per circuit.

• Model 06004-01 is the standard panel containing separate Side A and Side B GMT fuse fail-

ure alarms and corresponding LEDs. Standard features for Model 06004-01 include

−Dual-circuit, separately fused input buses for Sides A and B

−Minimal rack space: one, 1.75-in. EIA or 2-in. WECO rack unit (1RU) for rear

access connections

−20 GMT outputs per side with each side protected by a Type ABC 20A ceramic input fuse

−Dummy GMT fuses provided for all fuse holders

−Two sets of Form C relay contacts per side for reliable fail alarm connections

−Side A and B alarms can be wired for separate or common alarming. (All basic and auxil-

iary alarms can be wired for separate or common alarming.)

−19-in. or 23- in. rack mounting, with mounting brackets provided

• Model 06004-11 adds separate power failure auxiliary alarms for Sides A and B along with a

load-sharing fail-safe circuit. (All basic and auxiliary alarms can be wired for separate or com-

mon alarming.) If power fails on one bus, the other picks up the loads on the failed bus.

Both Models are UL Recognized for US and Canada, E199668, and NEBS3 Compliant.

Front

Rear

Figure 1 - Model 06004

POWER A

1510 15 20

POWER B

1510 15 20

A

B

FAIL SAFE

AB

ALARM

20A Input Fuses for Circuits A & B

Fuse Alarm LEDs for Circuits A & B

Designation Card Holder

Circuit A Output

"FAIL SAFE" Applies

only to Model 06004-11

GMT Fuse Holders

Circuit B Output

GMT Fuse Holders

Figure 2 - Front View

Figure 2 - Front View

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

2

GMT output fuses are available in capacities ranging from 0.18A to 10A. GMT splash covers are optional for maximum

safety when fuses blow. (Visit our website at www.telect.com or see Section “1.6 GMT Fuses” on page 12 for ordering

GMT fuses.) The panel is delivered with “dummy” fuses in all positions.

The standard front panel includes a tri-color fuse alarm LED for each circuit (ALARM A and ALARM B):

• The ALARM LEDs are green when all installed input and output fuses are operational

• The ALARM LED is red when any output fuse blows

• The ALARM LED is orange when either of the input fuses blows

The back contains input and output terminal connections (NEG connections at top; POS RTN connections below),

chassis ground connections and wire-wrap pins for external alarm hookups.

Plastic Caps*

Caution: Do not reverse polarity

Alarm Pins for Circuits

A & B

Screw-Tight, Wire Clamping

Output Terminals

-A -B +A +B

Screw-Tight, Wire-Clamping

Input Terminals

* Plastic caps cover screw-tight terminals used by the manufacturer for installing interior wiring.

DO NOT REMOVE CAPS or LOOSEN CLAMPING SCREWS.

Figure 3 - Model 06004-01 (Rear View)

Plastic Caps*

Caution: Do not reverse polarity

Alarm Pins for Circuits

A & B

Screw-Tight, Wire Clamping

Output Terminals

* Plastic caps cover screw-tight terminals used by the manufacturer for installing interior wiring.

DO NOT REMOVE CAPS or LOOSEN CLAMPING SCREWS.

-A -B +A +B

Screw-Tight, Wire-Clamping

Input Terminals

Figure 4 - Model 06004-11 (Rear View)

Model 06004-11 includes a fail-safe circuit. Schottky diodes are cross-connected at the input to the power distribution

circuits. When both power supplies are energized, power is balanced between the two supplies by the diodes. If one of

the power supplies loses its power or is shut down, the other supply shares its power with both outputs (A and B) through

the Schottky diodes. The positive battery return circuits for A and B are common since both circuits must operate from

either the A or B power source. The fail-safe feature limits the A and B inputs to 15A maximum for each bus (total 30A

per panel).

NOTE: For the Fail Safe load sharing to function properly, the capacity of each of the user-supplied external feeder fuses

or breakers must be greater than the total load of the panels A and B outputs combined. For example, if the panel’s total

Load A = 10A and Load B = 10A, then the feeder fuse for Side A and Side B must each be at least 20A.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

3

1.2 Specications

Physical: Specications:

Dimensions (nominal without bracket)* Width: 17 in. (432 mm)

Height: 1.75 in. (44.4 mm)

Depth: 9.25 in. (235 mm)

Weight 8.5 lb (~3.8 kg)

Ground terminals Screws: #10-32 Phillips** panhead

Torque: 20 in.-lb (~2.26 N•m), max.

Wire: Same size as input terminals

Ring Lug: Burndy T1010, 12 AWG, no insulation; AMP 35771,

12-10 AWG, no insulation

Material†† Cold-rolled steel, powder-coat telcom grey

* See “1.7 Schematics” on page 12 for complete dimensions

** Screws with cross-recessed heads

†† Custom color/nish available

Mechanical: Specications:

Input terminals Type: Screw-tight, wire-clamping

Wire: 14 to 6 AWG, copper wire

Torque: 16 in.-lb (1.80 N•m), max.

Output terminal Type: Screw-tight, wire clamping

Wire: 22 to 14, copper wire

Torque: 4.5 in.-lb (0.51 N•m), max.

Alarm terminals–Wire wrap .045 in. square wire-wrap pins on .200 in. centers.

Use 18 to 22 AWG copper

Environment: Specications:

Temperature range, ambient -17°C to 49°C (0°F to 120°F)

Humidity 0% to 90%, non-condensing

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

4

Electrical Interface: Specications:

Operating voltages, nominal -24 VDC to -48 VDC

Current capacity 06004-01 20A per bus (40A total for both buses), max. with 20A ceramic input

fuse (Type ABC)

06004-11 15A per bus (30A total for both buses), max. with 20A ceramic input

fuse (Type ABC)

Fuse capacity 20 (each side)

Maximum output interruption device rating 10A GMT fuse

Maximum continuous output load rating 7A for a 10A fuse

Alarm contact relay 2A @ 30 VDC

Panel heat dissipation per 20A bus 3.9W (13.3 Btu/hr) @ 0% load

Percentage of full load heat dissipation at

nominal voltage

Less than 1% of total load wattage

Reliability:

MTBF 200,000 hr

1.3 Inspection

Please read these instructions carefully before beginning installation. If you need assistance, call Telect at

Inspect equipment after unpacking and compare it to the packing list.

Immediately report any shipping damage, defects or missing parts to Telect at 509-926-6000.

Keep all documentation that comes with your shipment.

Telect is not liable for shipping damage. If the product is damaged, notify the carrier and call Telect at 509-926-6000 or

NOTE: For service or warranty information, please visit the Telect website at www.telect.com, email inquiries to

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

5

1.4 Installation

ALERT

!

ALERT! Install this product within a restricted access location where access is through the use of a

tool, lock and key, or other means of security and is controlled by the authority responsible for the

location. Only qualied personnel may install and maintain this product.

ALERT

!

ALERT! Verify all connections meet requirements specied in local electric codes or operating

company guidelines before supplying power. Protect this equipment with a fuse or breaker

sufcient to interrupt power levels specied under “Electrical Specications.”

ALERT

!

ALERT! Each panel is tested at the factory. Telect recommends that you perform the testing outlined

in the following procedure to ensure that no damage has occurred during shipping and handling. Both

sides A and B input circuits, as applicable, need to be tested.

Brackets are provided for either ush or extended (increments of 0.5 in. [12.7 mm]) mounting in a 19-in. or 23-in. rack with

either EIA or WECO spacing. For shipping, both pairs of brackets are afxed to the sides of the panel.

1. Remove the brackets, shown in the following illustration, from the sides of the panel.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 5

1.4 Installation

ALERT

!

ALERT! Install this product within a restricted access location where access is through

the use of a tool, lock and key, or other means of security, and is controlled by the

authority responsible for the location. Only qualified personnel may install and maintain

this product.

ALERT

!

ALERT! Verify all connections meet requirements specified in local electric codes or op-

erating company guidelines before supplying power. Protect this equipment with a fuse or

breaker sufficient to interrupt power levels specified under “Electrical Specifications.”

ALERT

!

ALERT! Each panel is tested at the factory. Telect recommends that you perform the test-

ing outlined in the following procedure to ensure that no damage has occurred during

shipping and handling. Both Sides A and B input circuits, as applicable, need to be tested.

Brackets are provided for either flush or extended (increments of 0.5 in. [12.7 mm]) mounting in a

19-in. or 23-in. rack with either EIA or WECO spacing. For shipping, both pairs of brackets are

affixed to the sides of the panel.

1. Remove the brackets, shown in the following illustration, from the sides of the panel.

Right Bracket

for 19-in. Rack

Left Bracket

for 23-in. Rack

Right Bracket

for 23-in. Rack

Left Bracket

for 19-in. Rack

Remove Screws (4) on Each

Side of Panel to Remove

Brackets from Stowed Position

Figure 5 - Panel With Mounting Brackets in Stowed Position for Shipping

Figure 5 - Panel with Mounting Brackets in Stowed Position for Shipping

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

6

2. Select the proper pair of brackets and discard the other two.

3. Mount the brackets to sides of the panel, as shown in the following examples. Tighten screws

to about 29 in.-lb (~3.3 N•m).

The panel can be mounted so that the panel’s face is ush or extended in 0.5-in. (12.7 mm) increments

from the rack. (The clover-leaf pattern on the face of the bracket points downward on the right side of the

panel and upward on the left.)

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 6

2. Select the proper pair of brackets and discard the other two.

3. Mount the brackets to sides of the panel, as shown in the following examples. Tighten screws

to about 29 in.-lb (~3.3 N•m).

The panel can be mounted so that the panel’s face is flush or extended in 0.5-in. (12.7 mm)

increments from the rack. (The clover-leaf pattern on the face of the bracket points downward

on the right side of the panel and upward on the left.)

4. Locate an unused rack position and mount the panel

using the four, 12-24 thread-cutting screws and lock-

washers provided, as shown on the right.

5. Tighten the screws to 35 in.-lb (4.29 N•m).

6. Before connecting any conductor, use a multimeter to

measure the resistance between the input terminal of

each side (+A and -A for Side A; +B and -B for Side

B) at the rear corner of the panel. Expect 500Ωor

more for both Side A and Side B.

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions to

installation personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying

bodies recognized in your country or region such as Underwriter’s Laboratories (UL),

TUV, etc.

7. For ground wiring, use a listed (approved) crimping tool to attach a listed (approved), single-

hole compression lug suitable for a #10 (~5 mm) screw onto a suitable ground wire.

Bracket for a

19-in. Rack

Bracket for a

23-in. Rack

(Flush Mount) (Flush Mount)

Bracket for a

19-in. Rack

(Extended 2 in.)

Clover-Leaf Pattern Points Downward

on Right Side of Panel.

Figure 6 - Bracket Installation (Examples)

Figure 7 - Mounting the Panel

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 6

2. Select the proper pair of brackets and discard the other two.

3. Mount the brackets to sides of the panel, as shown in the following examples. Tighten screws

to about 29 in.-lb (~3.3 N•m).

The panel can be mounted so that the panel’s face is flush or extended in 0.5-in. (12.7 mm)

increments from the rack. (The clover-leaf pattern on the face of the bracket points downward

on the right side of the panel and upward on the left.)

4. Locate an unused rack position and mount the panel

using the four, 12-24 thread-cutting screws and lock-

washers provided, as shown on the right.

5. Tighten the screws to 35 in.-lb (4.29 N•m).

6. Before connecting any conductor, use a multimeter to

measure the resistance between the input terminal of

each side (+A and -A for Side A; +B and -B for Side

B) at the rear corner of the panel. Expect 500Ωor

more for both Side A and Side B.

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions to

installation personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying

bodies recognized in your country or region such as Underwriter’s Laboratories (UL),

TUV, etc.

7. For ground wiring, use a listed (approved) crimping tool to attach a listed (approved), single-

hole compression lug suitable for a #10 (~5 mm) screw onto a suitable ground wire.

Bracket for a

19-in. Rack

Bracket for a

23-in. Rack

(Flush Mount) (Flush Mount)

Bracket for a

19-in. Rack

(Extended 2 in.)

Clover-Leaf Pattern Points Downward

on Right Side of Panel.

Figure 6 - Bracket Installation (Examples)

Figure 7 - Mounting the Panel

Figure 6 - Bracket Installation (Examples)

4. Locate an unused rack position and mount the panel

using the four, 12-24 thread-cutting screws and

lock washers provided, as shown on the right.

5. Tighten the screws to 35 in.-lb (4.29 N•m).

6. Before connecting any conductor, use a multimeter to

measure the resistance between the input terminal of

each side (+A and -A for Side A; +B and -B for Side B)

at the rear corner of the panel. Expect 500Ω or more for

both Side A and Side B.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 6

2. Select the proper pair of brackets and discard the other two.

3. Mount the brackets to sides of the panel, as shown in the following examples. Tighten screws

to about 29 in.-lb (~3.3 N•m).

The panel can be mounted so that the panel’s face is flush or extended in 0.5-in. (12.7 mm)

increments from the rack. (The clover-leaf pattern on the face of the bracket points downward

on the right side of the panel and upward on the left.)

4. Locate an unused rack position and mount the panel

using the four, 12-24 thread-cutting screws and lock-

washers provided, as shown on the right.

5. Tighten the screws to 35 in.-lb (4.29 N•m).

6. Before connecting any conductor, use a multimeter to

measure the resistance between the input terminal of

each side (+A and -A for Side A; +B and -B for Side

B) at the rear corner of the panel. Expect 500Ωor

more for both Side A and Side B.

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions to

installation personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying

bodies recognized in your country or region such as Underwriter’s Laboratories (UL),

TUV, etc.

7. For ground wiring, use a listed (approved) crimping tool to attach a listed (approved), single-

hole compression lug suitable for a #10 (~5 mm) screw onto a suitable ground wire.

Bracket for a

19-in. Rack

Bracket for a

23-in. Rack

(Flush Mount) (Flush Mount)

Bracket for a

19-in. Rack

(Extended 2 in.)

Clover-Leaf Pattern Points Downward

on Right Side of Panel.

Figure 6 - Bracket Installation (Examples)

Figure 7 - Mounting the Panel

Figure 7 - Mounting the Panel

WARNING

!

WARNING! Failure to properly ground this equipment can create hazardous conditions to installation

personnel and to the equipment.

ALERT

!

ALERT! Only use components and crimping tools approved by agencies or certifying bodies

recognized in your country or region such as Underwriter’s Laboratories (UL), TUV, etc.

7. For ground wiring, use a listed (approved) crimping tool to attach a listed (approved), single-hole compression lug

suitable for a #10 (~5 mm) screw onto a suitable ground wire.

Ground wire should be same gauge as the input wiring. Input wiring size depends solely on input interruption device

at the primary power distribution unit.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

7

8. If necessary, use a coarse, non-metallic cleaning pad

to clean the lug and stud.

9. Telect recommends that you lightly coat antioxidant

on the lug, grounding screw and surrounding

contacting surface.

10. Connect the lug to the rear panel using the ground

screw provided. See Figure 1.

11. Tighten the screws to 20 in.-lb (~2.26 N•m).

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 7

Ground wire should be same gauge as the input wir-

ing. Input wire size depends solely on input interrup-

tion device at the primary power distribution unit.

8. If necessary, use a coarse, non-metallic cleaning pad

to clean the lug and stud.

9. Telect recommends that you lightly coat anti-oxidant

on the lug, grounding screw, and surrounding

contacting surface.

10. Connect the lug to the rear panel using the ground

screw provided. See Figure 1.

11. Tighten the screws to 20 in.-lb (~2.26 N•m).

WARNING

!

WARNING! Before connecting input power cables,

make sure input power to panel is turned off.

12. For input wiring — wiring used as inputs to this distri-

bution panel — strip approximately 3/8 in.

(~10 mm) of insulation from the end of suitable

input conductors.

Input conductor (14 to 6 AWG) must match or exceed

the rating of the fuse or breaker at the PDU. (Strand-

ed wires should be tinned.)

13. Lightly coat anti-oxidant on the bare conductors.

14. Insert the conductors at the bottom of the screw-tight

terminals, as shown on the right.

15. Tighten screws to 16 in.-lb (1.80 N•m).

ALERT

!

ALERT! -24 Vdc to -48 Vdc always goes to -A and -B. RTN always goes to +A and +B. RTN

always goes to the other terminal. For Model 06004-11 with fail-safe circuitry, make sure

that RTN is common to both Side A and B.

16. Make sure power is off (open breaker, dummy fuse, or vacant fuse holder at the power distri-

bution unit [PDU]) before connecting this panel’s cables to the PDU.

17. Make sure that only dummy GMT fuses are installed in this panel or that the GMT fuse hold-

ers are vacant.

18. Enable the fuse or breaker at the PDU (25A max. for Model 06004-01; 35A max. for Model

06004-11 which contains a fail-safe circuit) to turn on Feed A to Side A of the panel.

FAIL

RELAY

NO CNC

A

NO C

NC

Figure 8 - Connecting the Lug to

the Rear Panel

Figure 9 - Inserting Conductors

Figure 8 - Connecting the Lug to the Rear Panel

WARNING

!

WARNING! Before connecting input power cables,

make sure input power to panel is turned off.

12. For input wiring — wiring used as inputs to this

distribution panel — strip approximately ⅜ in. (~10 mm)

of insulation from the end of suitable input conductors.

Input conductor (14 to 6 AWG) must match or exceed

the rating of the fuse or breaker at the PDU. (Stranded

wires should be tinned.)

13. Lightly coat antioxidant on the bare conductors.

14. Insert the conductors at the bottom of the screw-tight

terminals, as shown on the right.

15. Tighten screws to 16 in.-lb (1.80 N•m).

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 7

Ground wire should be same gauge as the input wir-

ing. Input wire size depends solely on input interrup-

tion device at the primary power distribution unit.

8. If necessary, use a coarse, non-metallic cleaning pad

to clean the lug and stud.

9. Telect recommends that you lightly coat anti-oxidant

on the lug, grounding screw, and surrounding

contacting surface.

10. Connect the lug to the rear panel using the ground

screw provided. See Figure 1.

11. Tighten the screws to 20 in.-lb (~2.26 N•m).

WARNING

!

WARNING! Before connecting input power cables,

make sure input power to panel is turned off.

12. For input wiring — wiring used as inputs to this distri-

bution panel — strip approximately 3/8 in.

(~10 mm) of insulation from the end of suitable

input conductors.

Input conductor (14 to 6 AWG) must match or exceed

the rating of the fuse or breaker at the PDU. (Strand-

ed wires should be tinned.)

13. Lightly coat anti-oxidant on the bare conductors.

14. Insert the conductors at the bottom of the screw-tight

terminals, as shown on the right.

15. Tighten screws to 16 in.-lb (1.80 N•m).

ALERT

!

ALERT! -24 Vdc to -48 Vdc always goes to -A and -B. RTN always goes to +A and +B. RTN

always goes to the other terminal. For Model 06004-11 with fail-safe circuitry, make sure

that RTN is common to both Side A and B.

16. Make sure power is off (open breaker, dummy fuse, or vacant fuse holder at the power distri-

bution unit [PDU]) before connecting this panel’s cables to the PDU.

17. Make sure that only dummy GMT fuses are installed in this panel or that the GMT fuse hold-

ers are vacant.

18. Enable the fuse or breaker at the PDU (25A max. for Model 06004-01; 35A max. for Model

06004-11 which contains a fail-safe circuit) to turn on Feed A to Side A of the panel.

FAIL

RELAY

NO CNC

A

NO CNC

Figure 8 - Connecting the Lug to

the Rear Panel

Figure 9 - Inserting Conductors

Figure 9 - Inserting Conductors

ALERT

!

ALERT! -24 VDC to -48 VDC always goes to -A and -B. RTN always goes to +A and +B. RTN

always goes to the other terminal. For Model 06004-11 with fail-safe circuitry, make sure

that RTN is common to both Side A and B.

16. Make sure power is off (open breaker, dummy fuse or vacant fuse holder at the power

distribution unit or PDU), before connecting this panel’s cables to the PDU.

17. Make sure that only dummy GMT fuses are installed in this panel or that the GMT

fuse holders are vacant.

18. Enable the fuse or breaker at the PDU (25A max. for Model 06004-01; 35A max.

for Model 06004-11 which contains a fail-safe circuit) to turn on Feed A to Side A of

the panel.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

8

19. Check voltage and polarity at the input connectors of the panel. Also, check that:

• The ALED on front of the panel turns on (green)

• The BLED must remain red

If the ALED doesn’t turn green, recheck polarity at input connectors.

(Reversing input connections will not harm the panel.) However, if the input

power leads were reversed, the fuse fail relay will fail to energize, causing

the normally open contacts to remain closed and normally closed contacts to

remain open. If necessary, check across the FAIL RELAY alarm pins located

on the rear of the panel as shown in Figure 9.

20. On the rear of the panel, with ALED lit (normal operation), but with B LED off

(failure operation), test the Side-A FAIL RELAY pins:

• Expect continuity (0Ω) between Terminals Cand NC

• Expect an open circuit (∞Ω) between Terminals Cand NO

21. Conversely, when testing the Side-B pins:

• Expect an open circuit (∞Ω) between Terminals Cand NC

• Expect continuity (0Ω) between Terminals Cand NO

22. Repeat Steps 18 to 21 for Feed B and observe that the BLED turns green. Across all FAIL

RELAY alarm pins:

• Expect continuity (0Ω) between Terminals Cand NC

• Expect an open circuit (∞Ω) between Terminals Cand NO

23. For output wiring, strip off ¼ in. (~7 mm) of insulation.

Like the input terminals, the output terminals are screw-tight, wire-clamping. The output terminals

will accommodate 14-AWG to 6-AWG conductors. Like the output terminals, stranded wires

for outputs should be tinned.

Remember: output conductors must be rated at or above the amperage rating of the GMT fuse. For example, use no

smaller than #16-AWG output wiring for 10A output fuses. Do not exceed 8A continuous load for a 10A fuse.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 8

19. Check voltage and polarity at the input connectors of the

panel. Also, check that

• The A LED on front of the panel turns on (green).

• The B LED must remain red.

If the ALED doesn’t turn green, recheck polarity at input con-

nectors. (Reversing input connections will not harm the pan-

el.) However, if the input power leads were reversed, the fuse

fail relay will fail to energize, causing the normally open contacts to remain closed and nor-

mally closed contacts to remain open. If necessary, check across the FAIL RELAY alarm pins

located on the rear of the panel and shown in Figure 9.

20. On the rear of the panel, with ALED lit (normal operation), but with BLED off (failure opera-

tion), test the Side-A FAIL RELAY pins.

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

21. Conversely, when testing the Side-B pins,

• Expect an open circuit (∞Ω) between Terminals Cand NC.

• Expect continuity (0Ω) between Terminals Cand NO.

22. Repeat Steps 18 to 21 for Feed B and observe that the BLED turns green. Across all FAIL

RELAY alarm pins

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

23. For output wiring, strip off ¼ in. (~7 mm) of insulation.

Like the input terminals, the output terminals are screw-tight, wire-clamping. The output ter-

minals will accommodate 14-AWG to 6-AWG conductors. Like the output terminals, stranded

wires for outputs should be tinned.

Remember: output conductors must be rated at or above the amperage rating of the GMT fuse.

For example, use no smaller than #16-AWG output wiring for 10A output fuses. Do not exceed

8A continuous load for a 10A fuse.

ALERT

!

ALERT! GMT fuses have a small inherent electrical resistance resulting in a small inher-

ent power loss. For this reason, the GMT fuse manufacturer recommends that the load for

GMT fuses up to and including 7.5A not exceed 80% of the fuse rating and that the load for

10A GMT fuses not exceed 70% of the fuse rating. (For example, 10A fuse x .70 = 7A max.

load). Total load for all GMT outputs on each side must not exceed 20A for a panel without

a fail-safe circuit, or 15A for a panel with a fail-safe circuit.

FAIL

RELAY

NO CNC

AB

NO CNC

Figure 10 - Fail Relay

Alarm Pins

Figure 10 - Fail Relay

Alarm Pins

ALERT

!

ALERT! GMT fuses have a smaller inherent electrical resistance resulting in a small inherent pow-

er loss. For this reason, the GMT fuse manufacturer recommends that the load for GMT fuses up

to and including 7.5A not exceed 80% of the fuse rating and that the load for 10A GMT fuses not

exceed 70% of the fuse rating. (For example, 10A fuse x .70 = 7A max. load). Total load of all GMT

outputs on each side must not exceed 20A for a panel without a fail-safe circuit or 15A for a panel

with a fail-safe circuit.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

9

24. Telect recommends that you lightly coat antioxidant on bare wires before

connecting to output terminals. (NEC species only one conductor and load for

each output terminal.)

25. Tighten the screws to 4.5 in.-lb (0.51 N•m).

26. Connect the other end of output wires to load.

27. Record the circuits on the designation card provided, as specied by the

operating company procedure. (The front side of the card is shown in Figure 10.)

The designation card has entries for Outputs 1-10 on the front and 11-20 on

the rear. Use the left half of each side for Side A outputs and the right half for

Side B outputs.

28. Make sure the inputs at the loads are disabled by removing all power cards or

all input fuses at the load equipment. (Always follow recommended operating

company guidelines when disabling load equipment.)

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 9

24. Telect recommends that you lightly coat anti-oxidant on bare wires before connecting to out-

put terminals. (NEC specifies only one conductor and load for each output terminal.)

25. Tighten the screws to 4.5 in.-lb (0.51 N•m).

26. Connect the other end of output wires to load.

27. Record the circuits on the designation card provided, as speci-

fied by the operating company procedures.(The front side of

the card is shown in Figure 10.)

The designation card has entries for Outputs 1-10 on the front

and 11-20 on the rear. Use the left half of each side for Side A

outputs and the right half for Side B outputs.

28. Make sure the inputs at the loads are disabled by removing all

power cards or all input fuses at the load equipment. (Always

follow recommended operating company guidelines when dis-

abling load equipment.)

WARNING

!

WARNING! Use only UL-listed or UL-recognized component secondary

protection devices.

29. Insert the proper sizes of GMT fuses in designated fuse holders using the designation card to

identify circuits. Check voltage and polarity at input of loads.

30. After all designated GMT fuses have been installed, check that the Aand B LEDs are still

green. If an output fuse blows, the corresponding Aor BLED will turn red; if an input fuse

blows, the corresponding Aor BLED will be orange or amber.

Again, test FAIL RELAY alarm pins on rear of the panel. As before

• Expect continuity (0Ω) between Terminals Cand NC.

• Expect an open circuit (∞Ω) between Terminals Cand NO.

31. If available, replace one of the output fuses with a blown fuse and check that the Aor BLED

changes to red. Check the FAIL ALARM pins again:

• Expect an open circuit (∞Ω) between Terminals Cand NC.

• Expect continuity (0Ω) between Terminals Cand NO.

32. When finished, re-install the operable fuse.

33. Do the same with one of the input fuses. Notice that the Aor BLED changes to amber. The

FAIL RELAY alarm pins will indicate a failure condition.

INPUT FUSE

FUSE

1

2

3

4

5

AMP CIRCUIT

INPUT FUSE

FUSE

1

2

3

4

5

AMP CIRCUIT

INPUT FUSE

FUSE

6

7

8

9

10

AMP CIRCUIT

INPUT FUSE

FUSE AMP CIRCUIT

6

7

8

9

10

Figure 11 -

Designation Card

Figure 11 - Designation Card

WARNING

!

WARNING! Use only UL-listed or UL-recognized component secondary protection devices.

29. Insert the proper sizes of GMT fuses in designated fuse holders using the designation card to

identify circuits. Check voltage and polarity at input of loads.

30. After all designated GMT fuses have been installed, check that the Aand BLEDs are still

green. If an output fuse blows, the corresponding Aor BLED will turn red; if an input fuse

blows, the corresponding Aor BLED will be orange or amber.

Again, test FAIL RELAY alarm pins on rear of the panel. As before:

• Expect continuity (0Ω) between Terminals Cand NC

• Expect an open circuit (∞Ω) between Terminals Cand NO

31. If available, replace one of the output fuses with a blown fuse and check that the Aand BLED

changes to red. Check the FAIL ALARM pins again:

• Expect an open circuit (∞Ω) between Terminals Cand NC

• Expect continuity (0Ω) between Terminals Cand NO

32. When nished, re-install the operable fuse.

33. Do the same with one of the input fuses. Notice that the Aor BLED changes to amber. The

FAIL RELAY alarm pins will indicate a failure condition.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

10

34. If desired, wire-wrap the remote external

audio/visual alarm indicator wires (solid

copper wires, #22 to #18 AWG) to the

alarm terminals. See “Alarm Wiring”,

following this section.

35. One by one, re-enable the load equipment

and verify proper operation.

36. Fold the designation card on the score line

and slip into the holder on the front of the

panel, as shown in Figure 11.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 10

34. If desired, wire-wrap the remote external

audio/visual alarm indicator wires (solid

copper wires, #22 to #18 AWG) to the

alarm terminals. See “Alarm Wiring,” fol-

lowing this section..

35. One by one, re-enable the load equipment

and verify proper operation.

36. Fold the designation card on the score line

and slip into the holder on the front of the

panel, as shown in Figure 11.

1.5 Alarm Wiring

Model 06004-01 has a standard alarm relay (FAIL RELAY) for each feed — one for Side A and

one for Side B. Model 06004-11 contains the standard alarm relay plus an auxiliary relay (AUX

RELAY) that can be triggered externally. All relays have two sets of Form C dry contacts for

wiring to audible and visual alarm indicators.

Audible and/or visual failure indicators can be wired to the alarm pins in several ways.

1.5.1 Standard Alarms

When an input or output fuse blows the relay is de-energized and the normally open contacts

close and the normally closed contacts open to indicate the failure.

1.5.2 Auxiliary Alarms

Auxiliary alarms are triggered from either an external CO or site source or by the standard alarm

relay. Like the standard relay, when triggered, the auxiliary relay is de-energized, causing the

normally open contacts to close and the normally closed contacts to open.

Designation Card Holder

Figure 12 - Inserting the Designation Card

FAIL

RELAY

NO CNC

AB

NO CNC

NEG (or -GND) +GND (or POS) NEG (or -GND)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

FAIL

RELAY

NO CNC

AB

NO CNC

NEG (or -GND) +GND (or POS)

External

Alarm Device

External

Alarm Device

a. Separate Alarms for Side A & Side B b. Combined Alarms for Side A & Side B

Figure 13 - Standard Alarm Wiring

Figure 12 - Inserting the Designation Card

1.5 Wiring

Model 06004-01 has a standard alarm relay (FAIL RELAY) for each feed — one for Side A and one for Side B. Model

06004-11 contains the standard alarm relay plus an auxiliary relay (AUX RELAY) that can be triggered externally. All

relays have two sets of Form C dry contacts for wiring to audible and visual alarm indicators.

Audible and/or visual failure indicators can be wired to the alarm pins in several ways.

1.5.1 Standard Alarms

When an input or output fuse blows the relay is de-energized and the normally open contacts close and the normally

closed contacts open to indicate the failure.

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 10

34. If desired, wire-wrap the remote external

audio/visual alarm indicator wires (solid

copper wires, #22 to #18 AWG) to the

alarm terminals. See “Alarm Wiring,” fol-

lowing this section..

35. One by one, re-enable the load equipment

and verify proper operation.

36. Fold the designation card on the score line

and slip into the holder on the front of the

panel, as shown in Figure 11.

1.5 Alarm Wiring

Model 06004-01 has a standard alarm relay (FAIL RELAY) for each feed — one for Side A and

one for Side B. Model 06004-11 contains the standard alarm relay plus an auxiliary relay (AUX

RELAY) that can be triggered externally. All relays have two sets of Form C dry contacts for

wiring to audible and visual alarm indicators.

Audible and/or visual failure indicators can be wired to the alarm pins in several ways.

1.5.1 Standard Alarms

When an input or output fuse blows the relay is de-energized and the normally open contacts

close and the normally closed contacts open to indicate the failure.

1.5.2 Auxiliary Alarms

Auxiliary alarms are triggered from either an external CO or site source or by the standard alarm

relay. Like the standard relay, when triggered, the auxiliary relay is de-energized, causing the

normally open contacts to close and the normally closed contacts to open.

Designation Card Holder

Figure 12 - Inserting the Designation Card

FAIL

RELAY

NO CNC

AB

NO CNC

NEG (or -GND) +GND (or POS) NEG (or -GND)

External

Alarm D evice

External

Alarm D evice

External

Alarm D evice

External

Alarm D evice

FAIL

RELAY

NO CNC

AB

NO CNC

NEG (or -GND) +GND (or POS)

External

Alarm D evice

External

Alarm D evice

a. Separate Alarms for Side A & Side B b. Combined Alarms for Side A & Side B

Figure 13 - Standard Alarm Wiring

a. Separate Alarms for Side A & Side B b. Combined Alarms for Side A & Side B

Figure 13 - Standard Alarm Wiring

1.5.2 Auxiliary Alarms

Auxiliary alarms are triggered from either an external CO or site source or by the standard alarm relay. Like the standard

relay, when triggered, the auxiliary relay is de-energized, causing the normally open contacts to close and the normally

closed contacts to open.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

11

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 11

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND) NEG (or -GND)

+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND)

+GND (or POS)

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN

FA -24/48V IN

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

FAIL

RELAY

+GND (or POS)

NEG (or -GND)

NEG (or -GND)+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

Figure 14 - Auxiliary Alarm Wiring

c. Using the Standard Alarm to Trigger Auxiliary Alarms When a Fuse Blows

b. Combined Alarms for Side A & Side B

a. Separate Alarms for Side A & Side B

a. Separate Alarms for Side A & Side B

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 11

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND) NEG (or -GND)

+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND)

+GND (or POS)

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN

FA -24/48V IN

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

FAIL

RELAY

+GND (or POS)

NEG (or -GND)

NEG (or -GND)+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

Figure 14 - Auxiliary Alarm Wiring

c. Using the Standard Alarm to Trigger Auxiliary Alarms When a Fuse Blows

b. Combined Alarms for Side A & Side B

a. Separate Alarms for Side A & Side B

b. Combined Alarms for Side A & Side B

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 11

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND) NEG (or -GND)

+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN**

FA -24/48V IN*

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

* NEG (or -GND) trigger.

** POS (or +GND) trigger.

Internal Wiring

FAIL

RELAY

NEG (or -GND)

+GND (or POS)

External

Alarm Device

External

Alarm Device

FA AUX RLY

FA AUX RLY

FA +GND IN

FA -24/48V IN

NO CNC

AB

NO CNC

Auxiliary Relay

Trigger

Auxiliary Relay

Contacts

FA +GND IN**

FA -24/48V IN*

Nomenclature is

for contacts

FAIL

RELAY

+GND (or POS)

NEG (or -GND)

NEG (or -GND)+GND (or POS) +GND (or POS)

External

Alarm Device

External

Alarm Device

External

Alarm Device

External

Alarm Device

Figure 14 - Auxiliary Alarm Wiring

c. Using the Standard Alarm to Trigger Auxiliary Alarms When a Fuse Blows

b. Combined Alarms for Side A & Side B

a. Separate Alarms for Side A & Side B

c. Using the Standard Alarm to Trigger Auxiliary Alarms When a Fuse Blows

Figure 14 - Auxiliary Alarm Wiring

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

12

1.6 GMT Fuses

GMT Fuse Part Numbers GMT Fuse

.18A Yellow (YEL) 130781

¼A Violet (VIO) 100151

½A Red (RED) 004001

¾A Brown (BRN) 004008

1A Gray (GRY) 100991

1-⅓A White (WHT) 004006

1-½A White/Yellow (WHT/YEL) 004011

2A Orange (ORN) 004002

2.5A White/Orange (WHT/ORN) 130783

3A Blue (BLU) 004012

3.5A White/Blue (WHT/BLU) 130782

4A White/Brown (WHT/BRN) 004013

5A Green (GRN) 004014

7-½A Black/White (BLK/WHT) 004010

10A Red/White (RED/WHT) 004015

Order E70319-001RC for each ¼ X ¼, 20A 250V input fuse.

For dummy fuses order 101557. For GMT safety (splash/splatter) covers order 116915.

1.7 Schematics

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 12

1.6 GMT Fuses

Order E70319-001RC for each ¼ X 1¼, 20A 250V input fuse.

For dummy fuses order 101557. For GMT safety (splash/splatter) covers order 116915.

1.7 Schematics

GMT Fuse

Part

Numbers

GMT Fuse GMT Fuse

Part

Numbers

GMT Fuse

.18A Yellow (YEL) 130781 2.5A White/Orange (WHT/ORN) 130783

¼A Violet (VIO) 100151 3A Blue (BLU) 004012

½A Red (RED) 004001 3.5A White/Blue (WHT/BLU) 130782

¾A Brown (BRN) 004008 4A White/Brown (WHT/BRN) 004013

1A Gray (GRY) 100991 5A Green (GRN) 004014

11/3A White (WHT) 004006 7½A Black/White (BLK/WHT) 004010

1½A White/Yellow (WHT/YEL) 004011 10A Red/White (RED/WHT) 004015

2A Orange (ORN) 004002

A POWER OUTPUT

GROUND

OUTPUT

A

GROUND

OUTPUT

B

B POWER OUTPUT

B

T

R

N

FAIL SAFE

LOAD SHARING

B

A

A

T

T

A

T

T

B

T

R

N

Figure 15 - Block Diagram

Figure 15 - Block Diagram

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

13

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 13

Telect assumes no liability for the application or use of these products. Neither does Telect

convey any license under its patent rights or the patent rights of others. This document and the

products described herein are subject to change without notice.

POWER A

1510 15 20

POWER B

1510 15 20

A

B

FA IL SA FE

AB

ALARM

"FAIL SAFE" Applies

only to Model 06004-11

FA AUX RLY

FA AUX RLY

FA +G ND IN

FA -24/48V IN

FA IL

RELAY

NO CNC

AB

NO CNC

AB

-24V

TO

-48V

RTN

FA IL

RELAY

NO CNC

AB

NO CNC

AB

-24V

TO

-48V

RTN

23.02 [584.6]

19.00 [482.6]

22.31 [566.7]

18.31 [465.1]

1.00 [25.4]

1.75 [44.5] 1.25 [31.7]

0.39 [9.9]

2.50 [63.5]

Face of panel can be extended

beyond rack flange by as much

as 2.50 in. (63.5 mm) in 0.5 in.

(12.7 mm).

17.02 [432.2]

8.17 [207.5]

0.77 [19.7]

0.19 [4.9]

Model 06004-11

Model 06004-01

#10-32 Panhead Screw R0.21 [R5.4]

Min. length of lug tongue is 0.43 in. (10.8 mm)

REAR VIEWS

TOP VIEW

FRONT VIEW

(ROTATED)

Figure 16 - Rear, Top, and Front Views

Model 06004-01

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 13

Telect assumes no liability for the application or use of these products. Neither does Telect

convey any license under its patent rights or the patent rights of others. This document and the

products described herein are subject to change without notice.

POW ER A

1510 15 20

POW ER B

1510 15 20

A

B

FAIL SAFE

AB

ALARM

"FAIL SAFE" Applies

only to Model 06004-11

FA AUX RLY

FA AUX RLY

FA +G ND IN

FA -24 /48V IN

FA IL

RELAY

NO CNC

AB

NO CNC

AB

-24V

TO

-48V

RTN

FA IL

RELAY

NO CNC

AB

NO CNC

AB

-24V

TO

-48V

RTN

23.02 [584.6]

19.00 [482.6]

22.31 [566.7]

18.31 [465.1]

1.00 [25.4]

1.75 [44.5] 1.25 [31.7]

0.39 [9.9]

2.50 [63.5]

Face of panel can be extended

beyond rack flange by as much

as 2.50 in. (63.5 mm) in 0.5 in.

(12.7 mm).

17.02 [432.2]

8.17 [207.5]

0.77 [19.7]

0.19 [4.9]

Model 06004-11

Model 06004-01

#10-32 Panhead Screw R0.21 [R5.4]

Min. length of lug tongue is 0.43 in. (10.8 mm)

REAR VIEWS

TOP VIEW

FRONT VIEW

(ROTATED)

Figure 16 - Rear, Top, and Front Views

Model 06004-11

#10-32 Panhead Screw R 0.21 [R5.4]

Min. Length of lug tongue is 0.43 in. (10.8 mm) REAR VIEWS

(Rotated)

0.77 [19.7]

8.17 [207.5]

0.19 [4.9]

2.50 [63.5]

Face of panel can be

extended beyond rack

ange by as much as

2.50 in. (63.5 mm) in

0.5 in. (12.7 mm).

TOP VIEW

FRONT VIEW

Figure 16 - Rear, Top and Front Views

“FAIL SAFE” applies

only to Model 06004-11

1.25 [31.7]1.75 [44.5] 1.00 [25.4]

0.39 [9.9]

17.02 [432.2]

18.31 [465.1]

19.00 [482.6]

22.31 [566.7]

23.02 [584.6]

Telect assumes no liability for the application or use of these products. Neither does Telect convey any license

under its patent rights or the patent rights of others. This document and the products described herein are subject

to change without notice.

© Telect, Inc. All rights reserved. 3.6.17 v.2

1.509.926.6000 :: telect.com

Low-Current 20/20 GMT Series Fuse Panels

Power :: Models 06004-01 & 06004-11 Installation Guide

14

Telect, Inc. • USA +1.509.926.6000 • Mexico +52.33.3836.37.52

www.telect.com • © 2010 Telect, Inc., All Rights Reserved, 130358-2 A0.1

Page 14

U.S. Conformity Assessment Body

Certificate of Conformity

No. 174-0923-1-0

Upon assessment of Technical Construction File 174-0923-1-0-TCF

it has been determined that the

Hendry Telephone Products

Power Distribution and Fan Panels

conform to the protection requirements set out in article 4 of

EMC Directive 89/336/EEC

as per EN 55022 :94 with A1 :95 & A2 :97 (class A),

EN 61000-3-2 :95, EN 61000-3-3 :95, EN 300 386 V1.2.1 :00-03,

and ETS 300 132-2;

and in accordance with the Agreement on Mutual Recognition between the United

States of America and the European Community, Sectoral Annex for EMC, this

U.S. Conformity Assessment Body hereby certifies attestations of compliance to the

EMC requirements so demonstrated.

National Technical Systems

1536 E. Valencia Drive; Fullerton, CA, USA 92831-4797; Tel (714) 879-6110; Fax (714) 879-6117

®

This manual suits for next models

2

Table of contents

Other Telect Power Distribution Unit manuals