PART I - INSTALLATION OF HARDWARE

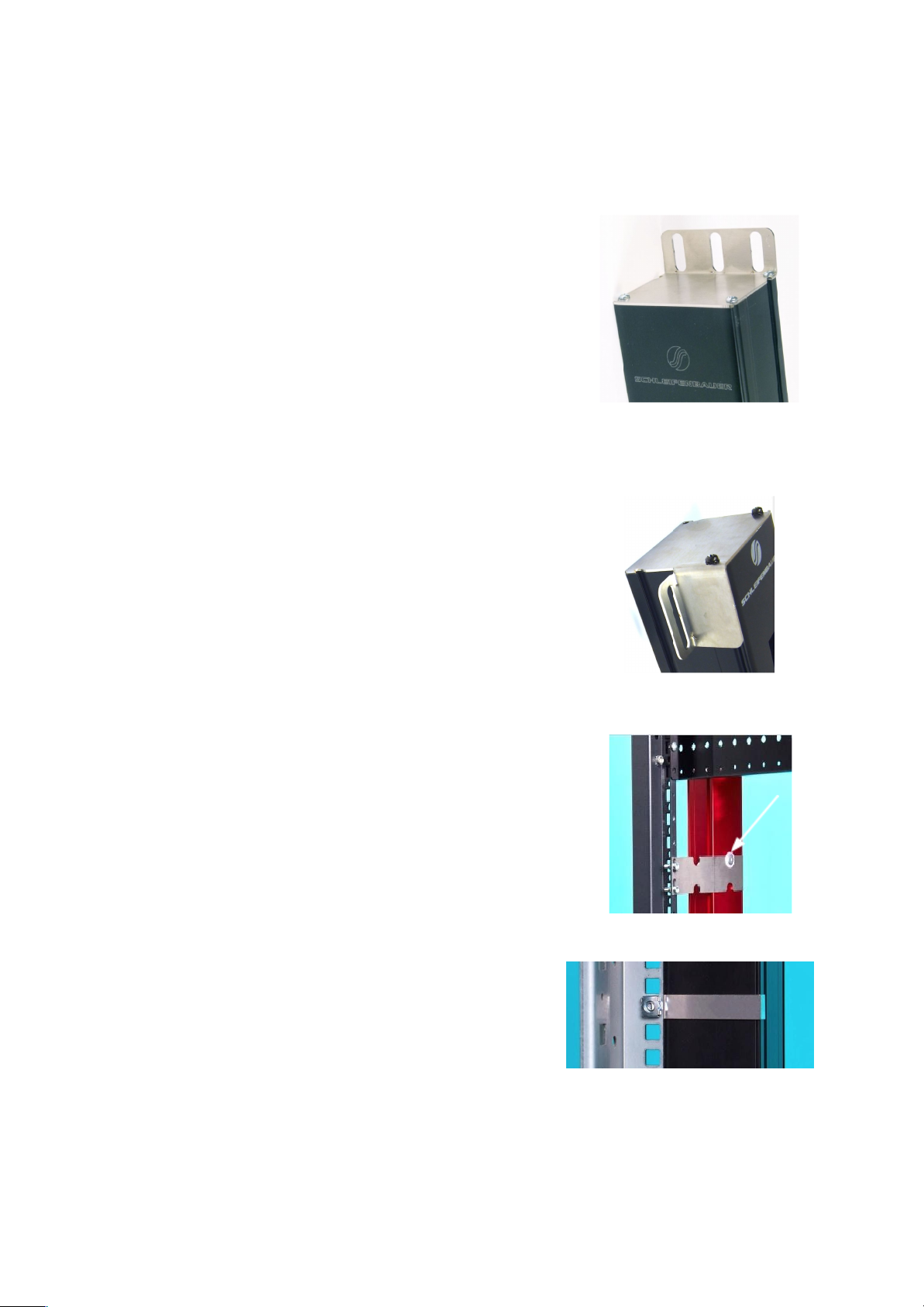

Please use the information in this chapter to inspect, install and connect the Schleifenbauer Intelligent PDU and all

optional mentioned accessories.

SAFETY WARNINGS

This manual contains important safety instructions that should be followed during installation and operation of the PDU.

Please read this manual carefully since there may be serious or fatal personal injury and damage to the equipment if the

safety instructions, warnings and directions are not complied with. Please save this document for future use.

EXPERT PERSONNEL

Installation, maintenance and inspection of the Schleifenbauer Intelligent PDU must be carried out by adequately trained

persons according to NEN EN 50110-1, with full observance of the specifications of NEN EN 50110-1 and NEN 3140.

TECHNICAL INSTALLATION REQUIREMENTS

Before installing and using the system, check whether the characteristics of the electrical system to which connection is to

be made correspond to the product specifications.

●The Schleifenbauer Intelligent PDU has been designed for connection to electrical systems that comply with IEC

60364 or in the Netherlands, NEN 1010.

●The voltage, maximum permitted current and the number of phases must be correct. This information is

displayed on the front side of the PDU.

●The maximum permitted power must be taken into account with regard to the maximum length and the diameter

of the connecting lead.

●The values and characteristics of the in-series protective devices must match the PDU and the protective

elements included in it.

●The environmental factors must correspond to the product specifications.

VISUAL INSPECTION

After opening the cardboard box and removing the packaging material, the PDU should be checked visually. The PDU

should not be put into operation if damage is detected in a way that safe and proper operation cannot be guaranteed. In

such cases, please contact Schleifenbauer Products BV.Note that, in the case of PDUs that are equipped with an

overvoltage protection, the overvoltage protection and the respective overcurrent protection (if applicable) must be

inspected on a regular basis.

The PDU must be installed in a restricted access location

Socket-outlet must be installed near the equipment

Socket-outlet must be easily accessible

Installation by expert personnel only

After installation: default passwords / RC4 keys MUST be changed (see: Part III - Administrator manual)