Teledata SWF1000 User manual

DEVICE’S POWER SUPPLY AND LINKING

The linking operation permits the configuration of the SWF1000 detector on the FDW2W translator module.

The linking operation described below does not change if made directly from the FDW2W translator module or from the PC con-

figuration program; please, refer also to the ‘Wireless System Installation Manual’.

1) Verify that the secondary battery is present; if not, insert the battery into its housing with the positive pole facing up (Picture 2).

SWF1000

WIRELESS PHOTO DETECTOR

GENERAL DESCRIPTION

The SWF1000 wireless optical smoke detector has been designed to fully meet the requirements of European Standard EN54-7. The

advanced design of the smoke inlet of the optical chamber guarantees a very high rejection to the introduction of dust, effectively

increasing the time between maintenance periods.

An alarm condition is determined when the level of smoke inside the optical chamber exceeds the alarm threshold; consequently an

alarm message is sent to the control panel via FDW2W translator module.

Communication between the detector and the FDW2W module is wireless, via ‘Wireless’ bidirectional protocol. The radio communica-

tion meets the European Standard EN54-25.

TELEDATA S.R.L. - Via Giulietti 8, 20132, Milan, Italy www.teledata-i.com [email protected] SWF1000 (V1.0)

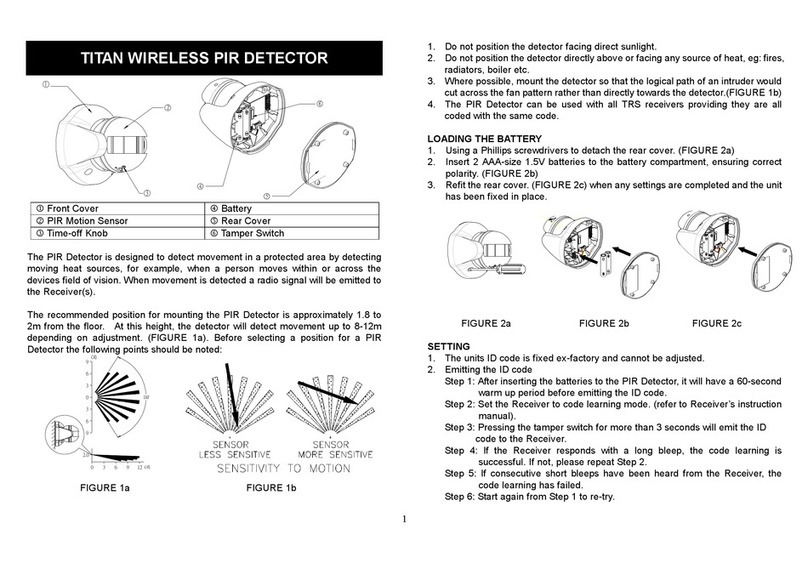

DETECTOR VISUAL LED INDICATOR

The SWF1000 detector is equipped with a bicolour LED (red/green) that provides visual indication for functional conditions and

battery levels as indicated in table 2.

Device Status Green LED Red LED

Switching into operating mode Short blinks -

Switching into programming mode - 4 short blinks

Self-adjustment mode - Blinking (1 second on / 0.1 second off)

Normal mode - -

Alarm condition - Repetitive blinking

(0.5 second on / 0.5 second off)

Main battery fault (Low level) - Blinking

(0.1 second on / 5 seconds off)

Secondary battery fault (Low level) Blinking

(0.1 second on / 5 seconds off) -

Both batteries fault Sequential bicolor blinking

(0.1 second on / 5 seconds off )

Fault Sequential blinking 0.5 second

Topic Specification Notes

Communication range with the FDW2W 200 m Open space

Operating frequency 868.15 MHz - 869.85 MHz

Modulation type FSK

Operating frequency channels 7

Radiated power 5 dBm (3 mW) Typical

Transmission message period 60 sec Default

Main battery Type CR123A 6.5 years typical

Secondary battery Type CR2032А2 months typical

Dimensions 110 mm x 54 mm

Weight 150 g Without Batteries

Operating temperature range From -30 °C to +55 °C From -10 °C to +55 °C

with secondary battery

Table 1

Table 2

Secondary battery housing

Picture 2 - Secondary battery housing

Secondary battery

TECHNICAL SPECIFICATIONS

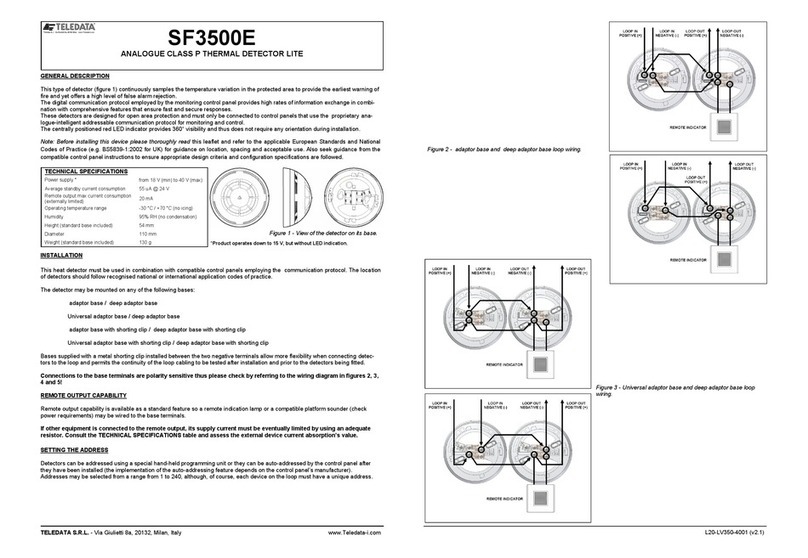

PARTS OF THE PRODUCT

1. Detector

2. Mounting base

3. Bicolour LED

4. Link - Program switch

5. Tamper switch

6. Batteries housing

7. Secondary battery

8. Main battery

9. Battery cover

Picture 1

2) Move the switch to position ON (Picture 3).

3) Insert the main battery (Picture 4).

Ensure that battery polarity is correct.

The visual LED indicator switches green once, then four times red (programming mode) and will, successively, turn off. This

indicates that the detector is ready to be linked to the FDW2W translator module.

4) Move the switch in position 1 to trigger the communication between the detector and the FDW2W .

The green LED switches on once, then it blinks many times (operating mode), successively the red LED blinks many times

(self-adjustment mode) and, finally, after alternating green-red for one second, the indicator turns off: this indicates that the

linking procedure has been performed correctly and the detector has programmed itself .

The detector is linked and all the parameters (address, system code etc.) necessary to work correctly are stored.

If the LED remains switched on the red light it means that the linking operation failed. In this case remove the main

battery, commutate alternatively the ON / 1 switch a few times in order to discharge the internal capacitor and then start again

from point 2).

IMPORTANT NOTE! Programming is considered to be completed successfully only if there is an indication of programming

success on the detector and on the FDW2W or on the window of the PC configuration program.

5) Put on the battery cover.

Main battery

Picture 3 - Link - Program switch Picture 4 - Main battery

DETECTOR PLACEMENT

For specific information regarding detector spacing, placement and special applications refer to your specific national standards.

It is strongly advised to mount the device as far as possible from metal objects, metal doors, metal window openings, etc. as well as

cable conductors, cables (especially from computers), otherwise the operating distance may greatly drop. The device should not be

installed near electronic devices and computer equipment that can interfere with the reception quality.

1) Select the position of the detector before installing and fixing its supporting base. Verify, from that position, that the

communication between the detector and FDW2W is correctly established and working (see the COMMUNICATION

QUALITY ASSESSMENT paragraph).

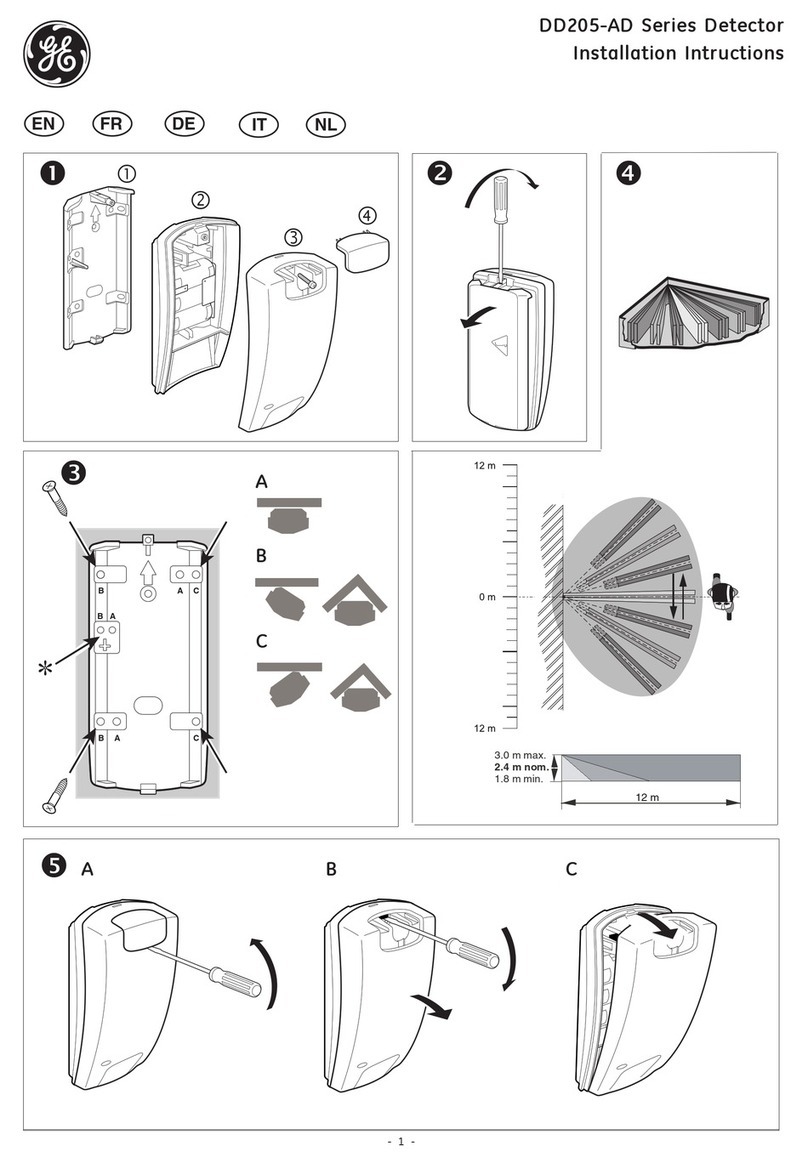

2) Install and fix the base, in the selected position, with the screws provided (Picture 5 and Picture 6).

3) Insert the detector into the base (Picture 5).

TAMPER DETECTION FEATURE

The SWF1000 detector is provided with a tamper switch and, in case of removal of the detector from its base, it sends a tamper

detection message to the control panel (Picture 9).

RESET

To reset the detector from alarm or fault condition it is necessary to send the reset command from the control panel.

TELEDATA S.R.L. - Via Giulietti 8, 20132, Milan, Italy www.teledata-i.com [email protected] SWF1000 (V1.0)

WARNINGS & LIMITATIONS

This product uses high quality electronic components and plastic materials that are highly resistant to environmental deterioration.

However, after 10 years of continuous operation, it is advisable to replace detectors to avoid the risk of reduced performance caused

by external factors. Ensure that these detectors are only used with compatible control panels. Detection systems must be checked,

serviced and maintained on a regular basis to confirm correct operation.

Smoke detectors may respond differently to various kinds of smoke particles, thus application advice should be sought for spe cial

risks. Detectors cannot respond correctly if barriers exist between them and the fire location and may be affected by special environ-

mental conditions. Refer to and follow National Codes of Practice and other internationally recognized fire engineering standards.

Appropriate Risk Assessment should be carried out initially to determine correct design criteria and updated periodically.

WARRANTY

This product is supplied with the benefit of a limited 3 Year Warranty relating to faulty materials or manufacturing defects, effective

from the production date indicated on each product. This warranty is invalidated by mechanical or electrical damage caused in the

field by incorrect handling or usage. Product must be returned, via your authorized supplier, for repair or replacement, together with

full information on any problem identified.

Full details on our Warranty & Products Returns Policy can be obtained upon request.

The warranty does not cover the provided batteries.

To remove the blocked detector from the base, insert a tool, like a small screwdriver, into the hole and remove the detector

(Picture 7).

WIRELESS DETECTOR ANTI-TAMPER BLOCK AND REMOVAL

The base for the SWF1000 wireless detector has a special anti-tamper device block. To lock the sensing device onto the base, cut

off the small plastic lug on the plastic blocking grip on the detector base (Picture 6).

Picture 5 - Detector placement

MAINTENANCE

1) Before starting any maintenance work, isolate and disable the system, in order to avoid accidental and unwanted alarm

conditions.

2) Remove the detector from its mounting base to allow inspection and servicing at ground level and in good light.

Inspect the smoke entry ports around the sensor and use a small, soft bristle brush to dislodge any obvious contaminants such

as insects, spider webs, hairs, etc.

3) Use a small vacuum tube or dry, clean, compressed air to suck up or blow any remaining small particles away from the

smoke entry screen area.

4) Wipe the exterior housing of the detector with a clean, damp, lint-free cloth to remove any surface film that can later

attract airborne contaminants.

5) After all detectors have been inspected and serviced, reinstall them in their mounting bases, re-apply power to the system and

check correct operation as described under the TESTING paragraph.

FAULT SELF-TEST

The SWF1000 detector periodically performs a self-test and, if a fault condition is detected, a fault message is sent to the control

panel via FDW2W.

The fault condition is locally signaled by the visual LED indicator located at the center of the detector (see Table 2).

A fault condition is determined by:

a) Fault on the optical analysis path (chamber, electronic circuit, etc).

b) High level of contamination inside the optical chamber.

c) Low batteries level.

COMMUNICATION QUALITY ASSESSMENT

It is possible to assess the wireless communication quality of the sensor by using a testing feature built in the device.

After a successful linking operation, by commuting the Link-Programming switch on the ON position, the sensor’s indicator will start

blinking according to table 3.

Always remember to reposition the switch to 1 after the assessment operation: device will NOT work operatively while the

switch is commuted on the ON position.

Communication quality Assessment Device’s indication

No connection Fail Two red blinks

Link margin is less than 10 dB Poor One red blink

Robust communication with link margin from 10 dB to 20 dB Good One green blink

Robust communication with link margin over 20 dB Excellent Two green blinks

Table 3

TESTING

The SWF1000 detector has been designed to permit a magnetic functional test. When the test is performed with an appropriate

magnet, a fire alarm message is sent to the control panel via FDW2W.

To perform the magnetic test put and hold the magnet near the surface of the indicated area (Picture 8). The detector must enter into

alarm condition, activate the central LED indicator (blink red as per Table 2) and transmit the alarm message to the control panel.

The detector must be reset by the specific command on the control panel (see the RESET paragraph).

All detectors must be tested after installation and, successively, on a periodic basis.

Picture 8 - Magnetic test area

Magnetic test area

Correct position for magnet test

Picture 9 - Tamper switch Tamper switch

60 mm

Picture 6 - Detector block and holes for the screws

Detector block. Remove the small

plastic lug on the plastic blocking grip,

to allow the block of the detector.

Holes to screw the base into the wall.

Picture 7 - Detector block removal

Tool to remove the

blocked detector

Hole to unblock the detector

Other Teledata Security Sensor manuals