Teledata SF3500 User manual

SF3500

ANALOGUE CLASS P THERMAL DETECTOR

GENERAL DESCRIPTION

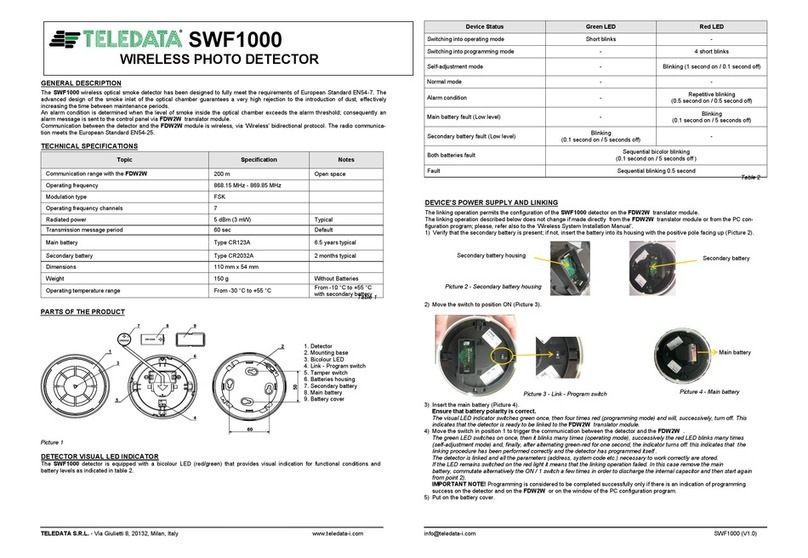

This type of detector (figure 1) continuously samples the temperature variation in the protected area to provide the earliest warning of

fire and yet offers a high level of false alarm rejection.

The digital communication protocol employed by the monitoring control panel provides high rates of information exchange in combi-

nation with comprehensive features that ensure fast and secure responses.

These detectors are designed for open area protection and must only be connected to control panels that use the proprietary ana-

logue-intelligent addressable communication protocol for monitoring and control.

The centrally positioned three-colour LED indicator (red, green and amber) provides 360° visibility and thus does not require any

orientation during installation.

An in-built magnet test allows easy activation to verify correct functioning of the detectors on site.

SHORT CIRCUIT ISOLATOR

All standard series devices are provided with short-circuit monitoring isolators on the intelligent loop’s line and can be activated by

the control panel.

Note: Before installing this device please thoroughly read this leaflet and refer to the applicable European Standards and National

Codes of Practice (e.g. BS5839-1:2002 for UK) for guidance on location, spacing and acceptable use. Also seek guidance from the

compatible control panel instructions to ensure appropriate design criteria and configuration specifications are followed.

Figure 1 - View of the detector on its base.

*Product operates down to 15 V, but without LED indication.

TECHNICAL SPECIFICATIONS

Power supply *from 18 V (min) to 40 V (max)

Average standby current consumption 55 uA @ 24 V

Remote output max current consumption

(externally limited) 20 mA

Operating temperature range -30 °C / +70 °C (no icing)

Humidity 95% RH (no condensation)

Height (standard base included) 54 mm

Diameter 110 mm

Weight (standard base included) 130 g

INSTALLATION

This heat detector must be used in combination with compatible control panels employing the communication protocol. The location

of detectors should follow recognised national or international application codes of practice.

The detector may be mounted on any of the following bases:

adaptor base / deep adaptor base

Universal adaptor base / deep adaptor base

adaptor base with shorting clip / deep adaptor base with shorting clip

Universal adaptor base with shorting clip / deep adaptor base with shorting clip

Bases supplied with a metal shorting clip installed between the two negative terminals allow more flexibility when connecting detec-

tors to the loop and permits the continuity of the loop cabling to be tested after installation and prior to the detectors being fitted.

Care must be taken to ensure that the shorting clip is either cut or removed prior to system commissioning!

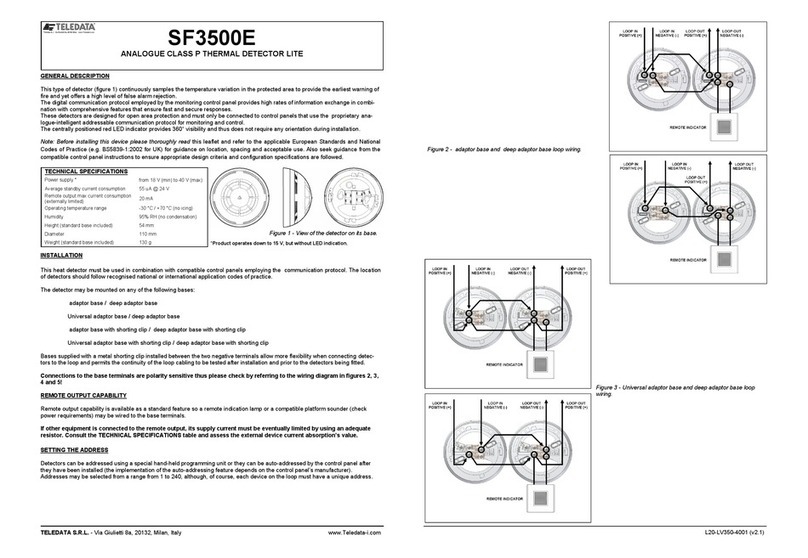

Connections to the base terminals are polarity sensitive thus please check by referring to the wiring diagram in figures 2, 3,

4 and 5!

REMOTE OUTPUT CAPABILITY

Remote output capability is available as a standard feature so a remote indication lamp or a compatible platform sounder (check

power requirements) may be wired to the base terminals.

If other equipment is connected to the remote output, its supply current must be eventually limited by using an adequate

resistor. Consult the TECHNICAL SPECIFICATIONS table and assess the external device current absorption’s value.

Figure 2 - adaptor base and deep adaptor base loop wiring.

Figure 3 - Universal adaptor base and deep adaptor base loop

wiring.

Figure 4 - adaptor base with shorting clip and deep adaptor base

with shorting clip loop wiring.

Figure 5 - Universal adaptor base with shorting clip and deep

adaptor base with shorting clip loop wiring.

TELEDATA S.R.L. - Via Giulietti 8a, 20132, Milan, Italy www.Teledata-i.com L20-V350X-4001 (v2.3)

Heat test

Use a hair dryer of 1000-1500 W or an heat tool from an approved manufacturer. Direct the heat towards the sensor from its side.

Hold the heat source at about 15 cm away from the sensor in order to prevent damage to its cover during testing.

The detector should trigger an alarm message to the control panel, and, successively, the detector’s red LED should be activated

by the control panel itself.

SETTING THE ADDRESS

Detectors can be addressed using a special hand-held programming unit or they can be auto-addressed by the control panel after

they have been installed (the implementation of the auto-addressing feature depends on the control panel’s manufacturer).

Addresses may be selected from a range from 1 to 240, although, of course, each device on the loop must have a unique address.

CAUTION

Dust covers help to protect the devices

during shipping and when first installed.

They are not intended to provide complete

protection against contamination, therefore,

detectors should be removed before con-

struction, major re-decoration or other dust

producing work is started. DUST COVERS

MUST BE REMOVED BEFORE THE SYSTEM

CAN BE MADE OPERATIONAL.

WARNING

Disconnect loop power before installing the

detector.

5. When the detector is firmly engaged verify the alignment

between the detector and the raised reference marks on the

base (figure 7).

6. After all detectors and other loop devices have been

installed, apply power to the loop in accordance with the

control panel’s installation instructions.

7. Test the detectors as described in the section headed

“TESTING”.

1. Position the detector centrally

on its mounting base (ensure it is

level).

2. Rotate clockwise applying

gentle pressure. The detector will

drop into its keyed location.

3. Press more firmly to win the

force of the contacts.

4. Continue to rotate clockwise a

few degrees until the detector has

fully engaged in the mounting

base.

ANTI-TAMPER MECHANICAL BLOCK FEATURE

The detector may be locked onto its base by remov-

ing the small plastic element on the base’s detector

blocking hook by using a suitable tool (e.g. a small

screwdriver) inserted through the access hole on

the side of the mounting base (figure 6).

To remove the detector from the base, if mechani-

cally blocked, insert a suitable tool (e.g. a small

screwdriver) through the access hole on the side of

the mounting base (figure 6).

Figure 6 - The anti-tamper block and its handling.

TAMPER DETECTION

A fault condition is triggered on the protocol compatible control panel if a detector, on the loop, is removed from its mounting base.

TESTING

Detectors should be tested after installation and during periodic maintenance visits (it is recommended each device should be tested

at least once per year). When the system has been reset, allow, after each test, at least one minute for power stabilisation before the

next test. Detectors can be tested as follows:

Magnet test

Position the magnet (model TMD-01, optional) next to the detector, between the two raised marks on the base (figure 7). The magnet

test simulates heat on the thermistor and verifies the function of all electronic circuits of the detector and its communication with the

control panel. The detector should trigger an alarm message to the control panel, and, successively, the detector’s red LED should

be activated by the control panel itself.

If the detector does not respond to the tests correctly it may be necessary to clean it: in this case follow the instructions indicated in

the “MAINTENANCE” paragraph.

If testing fails again after maintenance then replace the detector with a new one and return the faulty one for servicing.

Alignment between the detector and

the base’s reference raised marks.

Figure 7 - The correctly installed detector.

Magnet test position (model TMD-01).

MAINTENANCE

Before starting any maintenance work, isolate and disable the system in order to avoid accidental and unwanted alarm or fault condi-

tions. Remove the detector from its mounting base to allow inspection in good light at ground level. Inspect the thermistor area; use a

small, soft bristle brush to dislodge any evident contaminants such as insects, spider webs, hairs, etc. Use a small vacuum tube or

clean, dry and compressed air to suck up or blow away any remaining small particles from the thermistor area.

Wipe the exterior housing of the detector with a clean, damp, lint free cloth to remove any surface film that can later attract airborne

contaminants. After all detectors have been inspected, repositioned on their mounting bases and power has been re-applied, check

correct operation as described under the “TESTING” paragraph.

WARNINGS AND LIMITATIONS

Our devices use high quality electronic components and plastic materials that are highly resistant to

environmental deterioration. However, after 10 years of continuous operation, it is advisable to replace the

devices in order to minimize the risk of reduced performance caused by external factors. Ensure that this

device is only used with compatible control panels. Detection systems must be checked, serviced and

maintained on a regular basis to confirm correct operation.

Smoke sensors may respond differently to various kinds of smoke particles, thus application advice

should be sought for special risks. Sensors cannot respond correctly if barriers exist between them and

the fire location and may be affected by special environmental conditions.

Refer to and follow national codes of practice and other internationally recognized fire engineering stan-

dards.

Appropriate risk assessment should be carried out initially to determine correct design criteria and up-

dated periodically.

WARRANTY

All devices are supplied with the benefit of a limited 3 year warranty relating to faulty materials or manu-

facturing defects, effective from the production date indicated on each product.

This warranty is invalidated by mechanical or electrical damage caused in the field by incorrect handling

or usage.

Product must be returned via your authorized supplier for repair or replacement together with full informa-

tion on any problem identified.

Full details on our warranty and product’s returns policy can be obtained upon request.

TELEDATA S.R.L.

Via Giulietti, 8

20132, Milano

Italy

EN 54-5

Point type heat detector

Class A1R and B (class P)

EN 54-17:2005

Short circuit isolator

SF3500

Technical data: see docu-

ment

TDS-V350X held by the

manufacturer.

TELEDATA S.R.L. - Via Giulietti 8a, 20132, Milan, Italy www.Teledata-i.com L20-V350X-4001 (v2.3)

Other Teledata Security Sensor manuals

Popular Security Sensor manuals by other brands

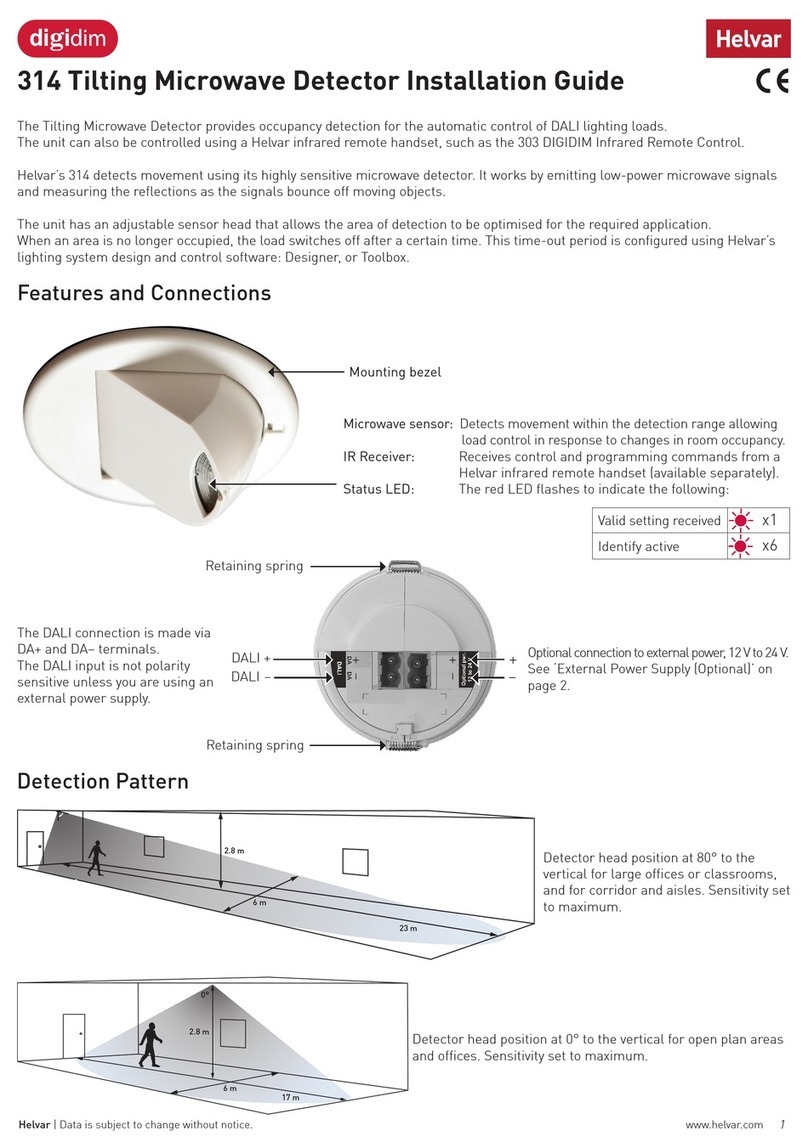

HELVAR

HELVAR 314 Tilting installation guide

mothercare

mothercare wood effect corner cushions user guide

schmersal

schmersal RSS 36-SD-ST manual

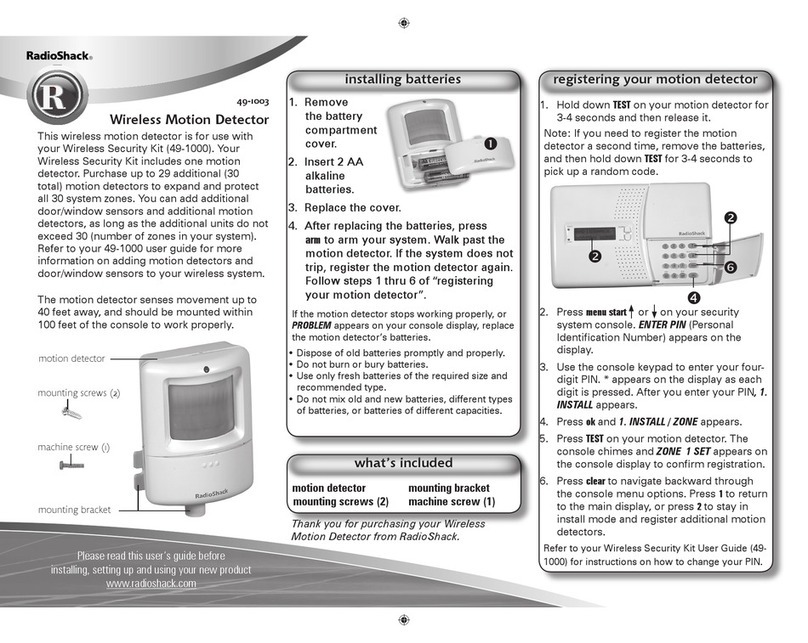

Radio Shack

Radio Shack 49-1003 user manual

Bacharach

Bacharach MGD-100 Installation and operation manual

Solutions

Solutions UWT NivoGuide 3100 Technical Information/Instruction manual