Teledyne Continental Motors Sandcast Series User manual

MODEL IO-550-D, E, F & L

SANDCAST SERIES

CONTINENTAL©AIRCRAFT ENGINE

MAINTENANCE AND

OPERATOR’S

MANUAL

Teledyne Continental Motors, Inc.

TM

FORM X30605 FAA APPROVED

©1990 TELEDYNE INDUSTRIES, INC. APRIL 1990

MAINTENANCE

AND

OPERATOR'S

MANUAL

-

NOTICE

-

Teledyne Continental Motors (TCM)engine operatingin-

structions are generated prior to and independently of

the aircraft operating instructions established by the

airframe manufacturer. TCM's operatinginstructionsare

developed using factory controlled parameters that are

not necessarily the same as those specifications re-

quired to satisfy a specific aircraft

/

engine installation.

Because of this difference the aircraft operator should

use the airframe manufacturer's operating instructions

found

in

the Pilots Operating Handbook

(POH)

while

operating the aircraft unless otherwise specified bythe

original airframe manufacturer.

FORM

NO.

X30605

MAINTENANCE

AND

OPERATOR'S MANUAL

FOR

10-550t),E,F,L

AIRCRAFT ENGINE

The operator must complywith allthe instructionscontainedinthis manualinorderto assure

safe and reliableengine performance. Failureto complywill be deemed misuse,thereby reliev-

ingthe engine manufacturer

of

responsibilityunder itswarranty.

This manualcontains

no

warranties,eitherexpressedor implied. The informationand proce-

dures containedhereinprovidetheoperatorwithtechnical informationand instructionsapplica-

bleto safe operation.

CHAPTER

INDEX

Chapter Page

...............................................

1 Introduction 1-1

..........................................

2 Toolsand Equipment 2-1

......................................

3

DetailedEngine Description 3-1

..............................

4

EngineSpecificationsandOperatingLimits 4-1

..............................

5

Unpacking. Installation.Testing

&

Removal 5-1

.....................................

6

NormalOperatingProcedures 6-1

...................................

7

EmergencyOperatingProcedures 7-1

..................................

8

Abnormal EnvironmentalConditions 8-1

.......................................

9

Service and Maintenance 9-1

...........................................

10 Troubleshooting 10-1

..................................

11 EnginePreservationand Storage 11-1

.......................................

12 AirworthinessLimitations 12-1

...............................

13 EnginePerformanceand Cruise Control 13-1

INTRODUCTION

1-1

SCOPE

Recommendations, cautions andwarnings regardingoperationof this engineare not intendedto impose

undue restrictions, but are insertedto enablethe pilottoobtain maximum performancefrom the engine

commensurate with safety and efficiency. Abuse, misuse, or neglect

of

any piece of equipment can

causeeventual failure. Inthe case of anaircmft engine

it

should

be

obviousthat

a

failuremayhavedisas-

trous consequences. Failuretoobservethe instructionscontainedinthis manualconstitutesunautho-

rized

operationinareas unexploredduringdevelopmentof theengine, or inareaswhich experience has

provedto be undesirableor detrimental.

Notes, Cautions and Warnings are indudedthroughoutthis manual. Application is as follows:

NOTE.

.

.Special interest informationwhich mayfacilitatethe operationof equipment.

CAUTION.

.

.Informationissuedto emphasizecertaininstructionsorto preventpossibledamage to en-

gineoraccessories.

WARNING.

.

.Informationwhich, if disregarded, may result insevere damage to or destructi~nof

the engine

or

endangermentto personnel.

1-2

RELATED

PUBLICATIONS

1. OverhaulManualfor 10-550D,E,F,L Series Aircraft

Engine. FormX30607A.

2.

IllustratedPartsCatalogfor 10-550Series Aircraft

Engine. FormX30606A.

3. Teledyne ContinentalMotorsAircraft Engine Ser-

vice Bulletins.

4.

Fuel InjectionManual. FormX30593A.

The above publicationscanbe orderedthrough your

Teledyne ContinentalMotorsDistributoror ordered

directly,

if

prepaid,from:

Teledyne ContinentalMotors

Aircraft ProductsDivision

P.

0.

Box 90

Mobile,AL 36601

Attn: Accounts Receivable

II. Accessory Manuals:

A. IgnitionSystem

MasterServiceManual

TCM lgnitionSystems and Com-

ponents

FormX40000

TeledyneContinentalMotors

Aircraft Products Division

P.

0.

Box 90

Mobile,Alabama36601

Attn: PublicationsDept.

B. Starter Motor

ServiceManual

TeledyneContinentalMotors

Aircraft ProductsDivision

P.

0.

Box 90

Mobile,Alabama36601

Attn: PublicationsDept.

C. Alternator

Alternator ServiceInstructions

FormX30531-3

TeledyneContinentalMotors

Aircraft ProductsDivision

P.

0.

Box 90

Mobile,Alabama36601

Attn: PublicationsDept.

1-3

ABBREVIATIONS AND GLOSSARY OFTERMS

Abbreviation

A.B.C.

ADMP

Approx.

A.T.C.

Bar

B.B.C.

B.H.P.

BSFC

BSOC

B.T.C.

C.A.R.

C.G.

c.f.m.

C.H.T.

CW

CCW

Dia.

EGT

FAA

Fig.

Front

Ft.

F.T.

FT-LBS

G.P.M.

gms

Hex

H20

Hg.

hr.

I.D.

IN-LBS

in.

(")

Left Side

Lbs.

Lockwire

Man.

After BottomCenter

Absolute Dry Manifold Pressure

Approximately

After Top Center

Barometric

Before BottomCenter

BrakeHorsepower

BrakeSpecific FuelConsumption

BrakeSpecificOilConsumption

BeforeTopCenter

CivilAir Regulations

Center of Gravity

Cubic Feet Per Minute

Cylinder HeadTemperature

Clockwise Rotation

CounterclockwiseRotation

DegreesCelsius

Degrees Fahrenheit

Degreesof Angle

Diameter

ExhaustGasTemperature

FederalAviationAdministration

Figure(Illustration)

PropellerEndof Engine

Footor Feet

FullThrottle

Foot PoundsTorque

Gallons Per Minute

Grams

Hexagon

Water

Mercury

Hour

InsideDiameter

InchPoundsTorque

Inches

SideonwhichNo's

2,4

and

6

cylindersare located.

Pounds

Soft stainlesssteelwire usedto safety connections,etc.

Manifoldor Manometer

Abbreviation

MAP

Max.

Min.

N.P.T.

N.R.P.

N.C.

N.F.

O.A.T.

O.D.

02.

PPH

Press.

p.s.i.

PSlA

PSlG

Rear

RightSide

R.P.M.

Std.

TBO

T.C.D.P.

T.D.C.

Temp.

T.I.T.

Torque

1

OOLL

1-3-5

2-4-6

30'

Glossarv

ADMP

Ambient

BHP

ManifoldAbsolutePressure

Maximum

Minimum

NationalPipeThread(Tapered)

NormalRatedPower

NationalCourse(Thread)

NationalFine(Thread)

Outside Air Temperature

Outside Diameter

Ounce

Pounds Per Hour

Pressure

PoundsPerSquare lnch

Power Per Square lnchAbsolute

Power PerSquare lnchGauge

Accessory Endof Engine

Sideonwhich No's 1,3 and 5 cylindersare located.

RevolutionsPer Minute

Standard

Time BetweenOverhaul

Turbocharger Deck Pressure

Top DeadCenter

Temperature

Turbine InletTemperature

Force

x

leverarm (125 ft.-lbs. torque

=

125lbs. Forceapplied

one ft. from bolt center or 62-1/2lbs 2ft. from center)

100Octane Low Lead Fuel

Cylinder numberingright side of engine (rearto front)

Cylindernumberingleft sideof engine (rearto front)

Thirty minutes of angle (60'equal one degree)

Absolute dry manifold pressure, is usedin establishing a baselinestandard of

engine performance. Manifoldpressure is the absolute pressure inthe intake

manifold; measured ininchesof mercury.

Atermusedtodenoteaconditionof surroundingatmosphereat aparticulartime.

Forexample; Ambient TemperatureorAmbient Pressure.

Brake Horsepower. The power actually deliveredto the engine propeller shaft.

Itisso calledbecauseitwasformerly measuredbyapplyingabraketothe power

shaft of an engine. The requiredeffortto brake the engine could be converted

to horsepower

-

hence:"brake horsepower".

BSFC

Cavitation

ColdSoaking

Corrosion

CriticalAltitude

Density Altitude

DynamicCondition

E.G.T.

ExhaustBack Pressure

Four Cycle

FuelInjection

Gallery

Gallingor Scuffing

Hg"

Heat Soaked

Humidity

ImpulseCoupling

LeanLimit Mixture

Brake Specific FuelConsumption. Fuelconsumptionstated inpounds per hour

per brake horsepower. For example, an engine developing

300

horsepower

while burning

150

poundsof fuelper hour, has a BSFCof

.5.

Fuel

Qmsmwtionin PPH

5

-

-.

BrakeHorsepower

Formationof partialvacuums in aflowing liquid as a result of the separation of

itspart.

Prolonged exposure of an object to cold temperatures so that its temperature

throughoutapproachesthat of ambient.

Deteriorationof a metalsurfaceusuallycausedby oxidationof the metal.

"CriticalAltitude"meansthe maximumaltitudeat which, instandardatmosphere,

it ispossible to maintain,at a specified rotationalspeed, a specified power or a

specifiedmanifoldpressure. Unlessotherwise stated.

Altitude as determinedbypressurealtitude andexistingambienttemperature. In

StandardAtmosphere (IAS)density andpressurealtitudesareequal. Foragiven

pressurealtitude,the higherthetemperature, the higherthe density altitude.

Aterm referringto propertiesof a body in motion.

Exhaust GasTemperature. Measurementof this gastemperatureissometimes

usedas an aidto fuel management.

Oppositiontotheflow of exhaustgas, primarilycausedby the size andshapeof

the exhaust system. Atmospheric pressure also affectsbackpressure.

Short for "Four Stroke Cycle." It refers to the four strokes of the piston in

completing a cycle of engine operation (Intake, Compression, Power and Ex-

haust).

A processof meteringfuel intoan engine by means otherthanacarburetor.

A passagewayinthe engine or subcomponent. Generallyone throughwhich oil

isflowed.

Excessivefrictionbetweentwo metalsurfacesresultinginparticlesof the softer

metalbeingtorn away and literallyweldedto the harder metal.

Inchesof Mercury.

A

standardfor measuring pressure, especially atmospheric

pressureor manifoklpressure.

Prolonged exposure of an object to hot temperature so that its temperature

throughoutapproachesthat of ambient.

Moisture in the atmosphere. Relative humidity, expressed in percent, is the

amountof moisture(watervapor)inthe aircomparedwiththe maximumamount

of moisturethe aircouldcontain at agiventemperature.

A mechanicaldevice usedinsome magnetosto retardthe ignitiontiming and

providehighervoltage at crankingspeeds for starting.

The leanest mixtureapprovedfor any givenpowercondition. Itisnot necessarily

the leanest mixtureat which the engine willcontinue to operate.

ManifoldPressure

Mixture

NaturallyAspirated (Engine)

NRP

O.A.T.

OctaneNumber

OilTemperature ControlValve

OverboostValves

OverheadValves

Overspeed

PerformanceRating

PressureAltitude

PropellerLoadCurve

PropellerPitch

Ram

RatedPower

RetardBreaker

Rich Limit

RockerArm

RunOut

ScavengePump

Pressure as measured inthe intake manifoM down-streamof the air throttle.

Usuallymeasuredininchesof mercury.

Mixture ratio. The proportionof fuelto air usedfor combustion.

A term used to describe an engine which obtains induction air by drawing it

directlyfromthe atmosphere intothe cylinder. A nonsuperchargedengine.

Normal RatedPower.

OutsideAir Temperature.

A

ratingwhich describes relative anti-knock (detonation)characteristicsof fuel.

Fuelswithgreaterdetonationresistancethan 100octanearegivenperformance

ratings.

Athermostaticunitto divert oilthroughor aroundthe oilcooler,as necessary,to

maintainoiltemperaturewithindesiredlimits.

A pressure relief valve, set slightly in excess of maximum deck pressure, is

providedto prevent damagingoverboost inthe event of

a

systemmalfunction.

An engineconfigurationinwhichthevalvesare locatedinthecylinderheaditself.

When anengine has exceededitsratedrevolutionsper minute.

Aratingsystemusedtodescribedtheabilityof fueltowithstandheatandpressure

of cornbustion as comparedwith 100octanefuel. For example, an enginewith

highcompressionandhightemperature needsahigher PerformanceRatedfuel

than a

low

compression engine. A rating of 1001130 denotes performance

characteristicsof lean(100) and rich(130)mixturesrespectively.

Altitude,usuallyexpressedinfeet,(usingabsolutestaticpressureas areference)

equivalentto altitude abovethe standardsea levelreferenceplane (29.92 Hg).

Aplotof horsepower,fuelflow,ormanifoldpressureversus RPMthroughthefull

power range of one engine using a fixed pitch propeller or

a

constant speed

propellerrunningonthe lowpitchstops. This curveisestablishedordetermined

duringdesignanddevelopmentof the engine.

The angle betweenthe meanchordof the propeller and the planeor rotation.

Increasedairpressuredueto forwardspeed.

The maximumhorsepowerat whichanengineisapprovedfor operation. Rated

powermaybeexpressedinhorsepowerorpercent.

Adeviceusedinmagnetostodelay ignitionduringcranking. Itisusedtofacilitate

starting.

The richest fuellaif ratio permitted for any given power condition. It

is

not

necessarilythe richestconditionat which the enginewillrun.

A mechanicaldevice usedto transfermotionfrom the pushrodto the valve.

Eccentricityofwobble of a rotatingpart.

A pump (especially an oil pump) to prevent accumulation of liquid in some

particulararea.

Sonic Venturi

StandardDay

Static Condition

Sump

TBO

TDC

ThermalEfficiency

Torque

Turbocharger

Vapor Lock

VariableAbsoluteController

VernathermValve

Viscosity

Volatility

Volumetric Efficiency

A restriction, especially in cabin pressurizationsystems, to limitthe flow of air

throughaduct.

Bygeneralacceptance,temperature-59°~/150~,pressure

-29.92

In. Hg.

Aterm referringto propertiesof a bodyat rest.

The lowestpartof asystem. The mainoil sump on awet sump engine contains

the oilsupply.

Time BetweenOverhauls. Usually expressedinoperatinghours.

Top Dead Center. The positionin which the piston has reachedthe top of its

travel.

A

linedrawnbetweencrankshaftrotationaxis,throughtheconnectionrod

andaxisandthepistonpincenterwouldbestraight line. Ignitionand valvetiming

are statedinterms of degrees beforeor afterTDC.

Regardingengines,the percentof total heat generatedwhich is converted into

usefulpower.

Turbine Inlet Temperature. The measurement of E.G.T. at the turbocharger

turbine inlet.

Twistingmomentor leverage,stated inpounds-foot(orpounds-inch).

Adevice usedto supply increasedamountsof airto engine inductionsystem. In

operation, aturbine is driven

by

engine exhaust gas. Inturn, the turbine directly

drivesacompressorwhich pumps air intothe engine intake.

Aconditioninwhich the properflow of a liquidthrough a system is disturbedby

the formation of vapor. Any liquidwill turn to vapor

if

heated sufficiently. The

amount of heat requiredforvaporizationwilldependonthe pressureexertedon

the liquid.

A device used to control the speed, and thus the output pressure of the

tuwcharger. Itdoes so byoperatingthe wastegate whichdiverts,moreor less,

exhaustgas overthe turbine.

A thermostatic valve used to divert oil through or around the oil cooler, as

necessary,to maintainoiltemperaturewithindesiredlimits.

The characteristicof aliquidto resistflowing. Regardingoil, highviscosity refers

to thicker or "heavier" oilwhile low viscosity oil is thinner. Relativeviscosity is

indicatedby the specific "weight" of the oil such as 30 "weight" or 50"weight".

Some oilsare specifiedas multiple-viscositysuch' as 10W30. Insuch cases,this

oilis more stable and resiststhetendencytothin when heatedorthickenwhen

it

becomescold.

The tendency of aliquidtovaporize.

The abilityof an engine to fill its cylinderswith air comparedto their capacityfor

air under static conditions.

A

"normally aspirated engine will always have a

volumetric efficiency of slightly less than loo%, whereas superchargerspermit

volumetric efficiencies in excess of 100%.

WastegateValve

f

Hydraulic)

WastegateValve

(Manual)

CriticalAltitude

A

unit, usedonturbocharged engines, todivert exhaust gas throughor around

the turbine, as necessaryto maintainturbine speed. As more air is demanded

by the engine, due to throttle operation, the compressor must work harder. In

orderto maintaincompressorandturbine speeds, moreexhaust must beflowed

throughthe turbine. The wastegate valve closes and causes gas, whichwould

go

directly overboard, to pass through the turbine. The wastegate is usually

operatedby an actuatorwhichgets signalsfrom theturbochargercontroller.

Agroundadjustablebypasslocatedintheturbineexhaust (FixedOrifice)bypass

duct. The positionof the fixedorificewastegatevalve remainsconstantthrough-

out allmodes of engineoperation.

The maximumaltitudeat whichacomponentcanoperateat 100%capacity. For

example, an enginewith a criticalaltitudeof 16,000 feet cannot produce 100%

of itsratedmanifoldpressureabove 16,000feet.

Dynamic Condition Aterm referringto propertiesof a body inmotion.

E.G.T. ExhaustGasTemperature. Measurementof thisgastemperatureis sometimes

usedas an aidto fuelmanagement.

ExhaustBack Pressure Oppositiontotheflowof exhaustgas, primarilycausedbythe size andshape of

the exhaust system. Atmospheric pressurealso affects back pressure.

1-4

MANUAL REVISIONS

This manual and Teledyne Continental Motors

related manuals are current and correct to the

bestof TeledyneContinentalMotors'knowledge

at the time of publication. Any errors, recom-

mended changes, or questions should

be

sub-

mittedinwritingto:

TechnicalPublicationsDepartment

Teledyne ContinentalMotors

P.O.

Box

90

Mobile,Alabama 36601

Manualswill be revised and updatedas neces-

sary.

Consult Teledyne Continental Motors' Service

Bulletin publications for latest technical in-

formationavailable.

INTENTIONALLY

LEFT

BLANK

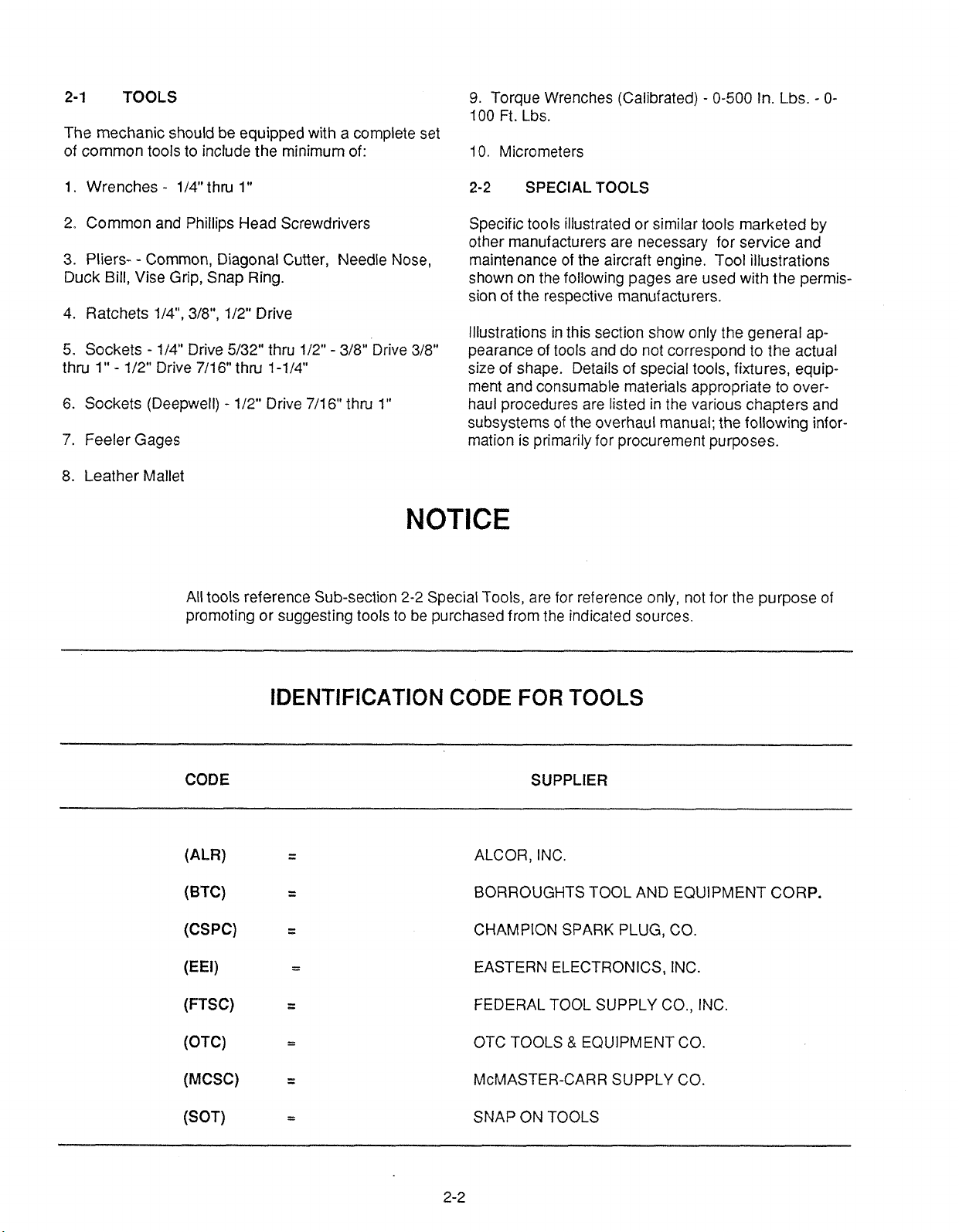

2-1

TOOLS

9.

TorqueWrenches (Calibrated)

-

0-500 In. Lbs.

-

0-

100

Ft.

Lbs.

The mechanicshouldbe equippedwith

a

complete set

of commontoolsto include the minimumof:

10.

Micrometers

1.

Wrenches

-

114"thru

1

"

2-2

SPECIAL TOOLS

2. Common and Phillips HeadScrewdrivers

3. Pliers-

-

Common, DiagonalCutter, Needle Nose,

Duck Bill, Vise Grip, Snap Ring.

4. Ratchets 1/4",318", 1/22'' Drive

5.

Sockets

-

114" Drive5/32" thru 112"

-

318" Drive318"

thru 1"

-

112" Drive7/16" thru 1-114"

6.

Sockets (Deepwell)

-

112" Drive7/16"thru 1"

7.

FeelerGages

Specifictools illustratedor similar tools marketed by

other manufacturersare necessary for service and

maintenance of the aircraft engine. Tool illustrations

shownonthe followingpages are usedwith the permis-

sionof the respective manufacturers.

lllustrations inthis sectionshow only the generalap-

pearanceof tools anddo not correspondto the actual

size of shape. Detailsof specialtools, fixtures, equip-

ment andconsumablematerialsappropriate to over-

haulproceduresare listed inthe various chapters and

subsystemsof the overhaul manual;the following infor-

mationis primarilyfor procurementpurposes.

8. Leather Mallet

NOTICE

All tools reference Sub-section

2-2

SpecialTools, are for referenceonly, not for the purposeof

promotingor suggestingtoolsto be purchasedfrom the indicatedsources.

IDENTIFICATION

CODE

FOR TOOLS

CODE SUPPLIER

(ALR)

(BTC)

(CSPC)

(FTSC)

(OTC)

(MCSC)

(SOT)

ALCOR, INC.

BORROUGHTSTOOL AND EQUIPMENT CORP.

CHAMPIONSPARK PLUG, CO.

EASTERNELECTRONICS,INC.

FEDERALTOOL SUPPLY CO., INC.

OTC TOOLS

&

EQUIPMENTCO.

McMASTER-CARR SUPPLYCO.

SNAPONTOOLS

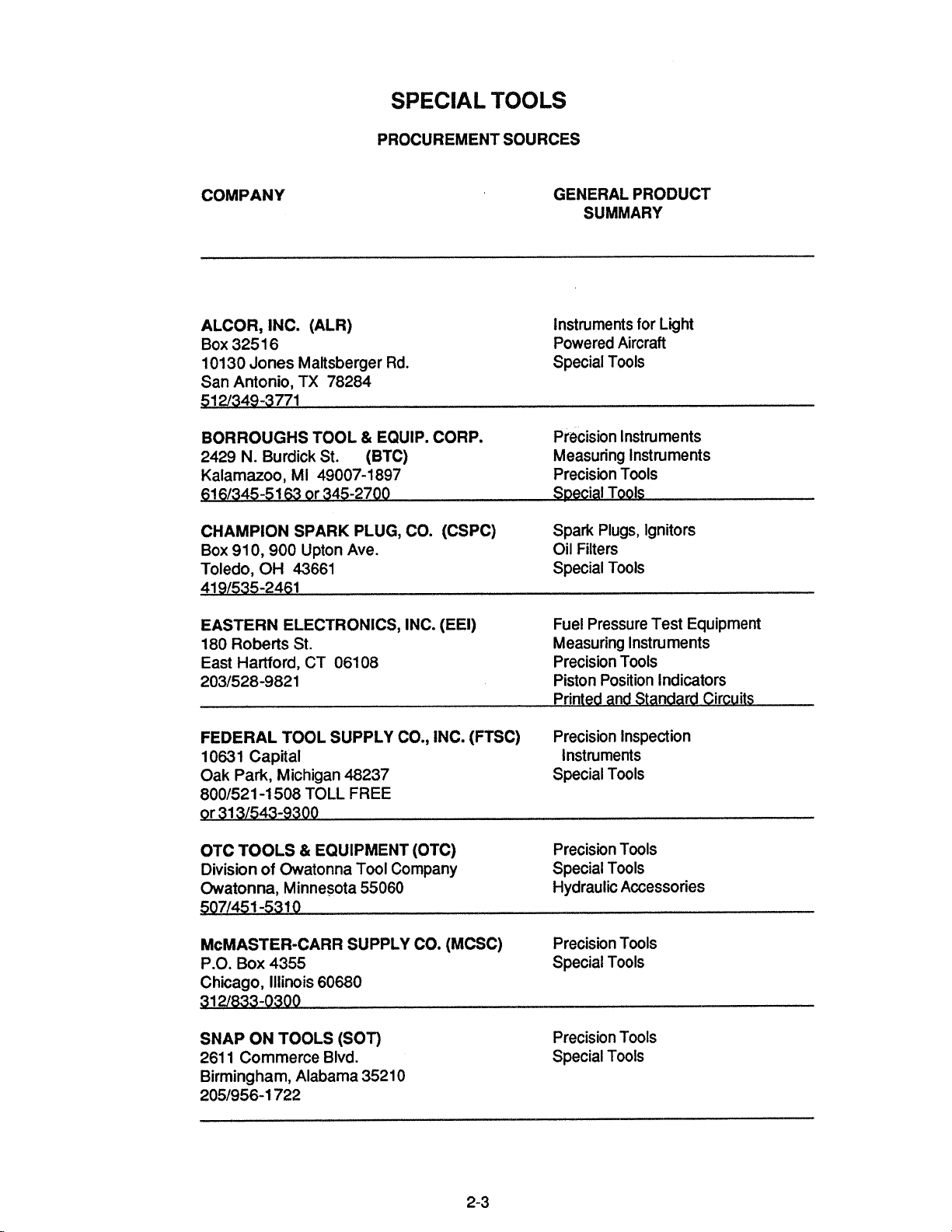

SPECIAL

TOOLS

PROCUREMENTSOURCES

COMPANY GENERAL PRODUCT

SUMMARY

ALCOR, INC. (ALR)

Box 32516

10130Jones MaltsbergerRd.

SanAntonio, TX 78284

Instrumentsfor Light

PoweredAircraft

SpecialTools

BORROUGHSTOOL

&

EQUIP.CORP.

PrecisionInstruments

2429

N.

BurdickSt.

(BTC)

MeasuringInstruments

Kalamazoo,MI 49007-1897 PrecisionTools

5161345-51

63

or 345-2700 S~ecialTools

CHAMPION SPARK PLUG,CO. (CSPC)

Spark Plugs, Ignitors

Box 910,900 UptonAve. OilFilters

Toledo, OH 43661 SpecialTools

4191535-2461

EASTERNELECTRONICS,INC. (EEI)

FuelPressureTest Equipment

180RobertsSt. MeasuringInstruments

East Hartford, CT 06108 PrecisionTools

2031528-9821 PistonPositionIndicators

Printedand Standard Circuits

FEDERALTOOL SUPPLY CO., INC. (FTSC)

PrecisionInspection

10631Capital Instruments

Oak Park, Michigan48237 SpecialTools

8001521-1508TOLL

FREE

9r3131543-9300

OTC TOOLS

&

EQUIPMENT(OTC)

PrecisionTools

Divisionof OwatonnaToolCompany SpecialTools

Owatonna,Minnesota55060 HydraulicAccessories

5071451-5310

McMASTER-CARR SUPPLY CO. (MCSC)

PrecisionTools

P.O. Box 4355 SpecialTools

Chicago, Illinois60680

SNAP ONTOOLS (SOT)

2611 CommerceBlvd.

Birmingham,Alabama 35210

2051956-1722

PrecisionTools

SpecialTools

Special

Tools

Item

&

Nomenclature

Application

Vendor

Part

Number

1.

GA333

GA340

YA341

2.

CT-470

3.

3882

4.

8079

5.

5203

&

5204

6.

8121

7.

CFLIO0

8.

4965A

3604

3607

3607-1

8068

9.

52213A

10.

5221

B

11.

122

12.

80866

13.

7521

A

14.

3611

2874

15.

4912

3619

2842

16.

8118

17.

4901

2839

3618

18.

4901

B

4901

A

3601

2839A

19.

3170

20.

3602

21.

68-3

22.

4951

A

23.

4981

24.

8086

25.

4910

4956

26.

8116

Strap

Wrench

Strap

Wrench

Strap

Wrench

Oil

Filter Can

Cutter

Cylinder

Base

Nut

Wrenches

Cylinder

Base

Nut

Wrenches

Cylinder

Base

Nut

Wrenches

Piston

Pin

Removers

Cylinder

Hone

Crankshaft

Blade

and

Damper

Bushing

Remover/

Replacer

Crankshaft

Blade and

Damper

Bushing Remover/

Replacer

Crankshaft

Blade

and

Damper

Bushing

Remover/

Replacer

Crankshaft

Blade

and

Damper

Bushing

Remover/

Replacer

Crankshaft

Blade

and

Damper

Bushing

Remover/

Replacer

Holding

Fixture

Adapters

Holding

Fixture

Valve

Guide

Cleaner

Seal Seat

Cutter

Spring

Checker

Valve

Guide

Remover

Valve

Guide

Remover

Valve

Guide

Replacer

Valve

Guide

Replacer

Valve

Guide

Replacer

Rocker

Arm

Bushing

Remover/Installer

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Ring

Compressor

Floating

Holder

Valve

Spring

Compressor

Push

Rod

Spring

Compressor

Flaring

Tool

Push Rod

Hsg.

Valve

Guide

Remover

Valve Seat

Insert

R&R

Installer

Valve

Seat

Insert

Installer

Valve

Seat

Insert

Common

Parts

Kit

Oil

Filter

Removal

3: to

3

3/8"

Oil

Filter Removal

3

1/2"

to

3

7/8"

Oil

Filter

Removal

4

1/8"

to

4

7/16"

Oil

Filter

Sludge

Inspection

Cylinder

Removal

Cylinder

Removal

Cylinder

Removal

Piston

Removal

Cylinder

Reconditioning

Crankshaft

Reconditioning

Crankshaft

Reconditioning

Crankshaft

Reconditioning

Crankshaft

Reconditioning

Crankshaft

Reconditioining

Cylinder

Hold

Down

Cylinder

Hold

Down

Cylinder

Reconditioning

Cylinder

Reconditioning

Spring

Inspection

Cylinder

Reconditioning

Cylinder Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Rocker

Arm

Reconditioning

Engine

Assembly

Engine

Assembly

Engine

Assembly

Engine

Assembly

Engine

Assembly

Engine

Assembly

Engine

Assembly

Cylinder

Reconditioning

Cylinder Assembly/Disassembly

Push

Rod

Housing

Installation/Removal

Push

Rod

Housing

Reconditioning

Cylinder

Reconditioning

Cylinder Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

2-4

SOT

SOT

SOT

CSPC

BTC

BTC

BTC

BTC

SOT

SOT

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC,

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC-

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

item

&

Nomenclature Application

Vendor

Part

Number

27.

8116-24

thru

-29

28.

8116-1iR

thru

15R

29.

8116-l

B

thru

15B

30.

8116-1

thru

1

6

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

.41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

Valve

Stem

Hole

Reamiers

Reamers

Boring

Bars

Expanding

Guide

Bodies

4909 Valve

Seat

(Straight Side)

insert Cutters

4954 Valve

Seat (Straight Side)

Insert

Cutters

5224

Valve

Seat

(Straight

Side)

Insert

Cutters

5225

Valve

Seat

(Straight

Side)

Insert

Cutters

8135

Valve Seat (Step

Side)

Insert

Cutters

8136

Valve

Seat

(Step

Side)

Insert

Cutters

8138

Valve Seat

(Step

Side)

Insert

Cutters

2769A1

3

RosanR

Stud

Remover

8111

A

Connecting

Rod

Fixture

8042C Adapter

Kit

874-40,41

Reamers

Conrod

Bushing

5008,8071

Reamers

Conrod

Bushing

8098 Remover/installer

Set

Connecting

Rod

Bushing

8122A

Common

Drive

Handle

8139,40,41

Pilots

23-1

Needle Bearing

Installer

8053 Needle

Bearing

Installer

8077A&B

Bushing

R/R

Set

8077C

Bushing

R/R Counterweight

8104

Engine

Stand

7726

Tork Band

Tension

Adjuster

4973 Generator

Drive

Holders

8156

Cylinder Heating

Stand

8093C

Bearing

Puller

8093D

Bearing

Puller

5210

Differential

Pressure

Gauge

7251

Differential Pressure

Cylinder Checker

BT-33-73F

Belt

Tension

Gauge

BT-60C

Hydraulic

Valve

Lifter

Tester

8091

GEN/ALT Tester

2608A

Timing Disc

4974

Pulley Holder

8082

Alignment

Gage

Bar

8094A

8334

Crankcase

Drill

Fixture

Vacuum

Pump

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Cylinder Reconditioning

Cyiinder Reconditioning

Cylinder Reconditioning

Cylinder Reconditioning

Cylinder Reconditioning

Cylinder

Reconditioning

Stud

Remover

Connecting

Rod

Inspection

Connecting

Rod

Inspection

Connecting

Rod

Reconditioning

Connecting

Rod

Reconditioning

Connecting

Rod

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Needle

Beaning

Replacement

Needle

Bearing

Replacement

Crankshaft

Reconditioning

Crankshaft

Reconditioning

Engine

Assembly/Disassembly

Generator/Altemator

Belt

Tensioning

Genierator/Alternator

Disassembly

Cylinder Reconditioning

Bearing Removal

Starter

Clutch

Shaft

Bearing Removal

Starter

Clutch

Shaft

Setting

Differential

Fuel

Pressure

Checking

Cylinder

Compression

Alternator/Generator

Belt

Adjustment

Hydraulic

Lifter

Testing

Checking

GEN/ALT

Output

Setting

Engine

Timing

Sheave

Removal

Checking

Camp

&

Driver

Sheave

Alignment

Crankcase

Modification

Vacuum

Testing

2-5

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

MCSC,

BTC

BTC

BTC

BTC

TC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

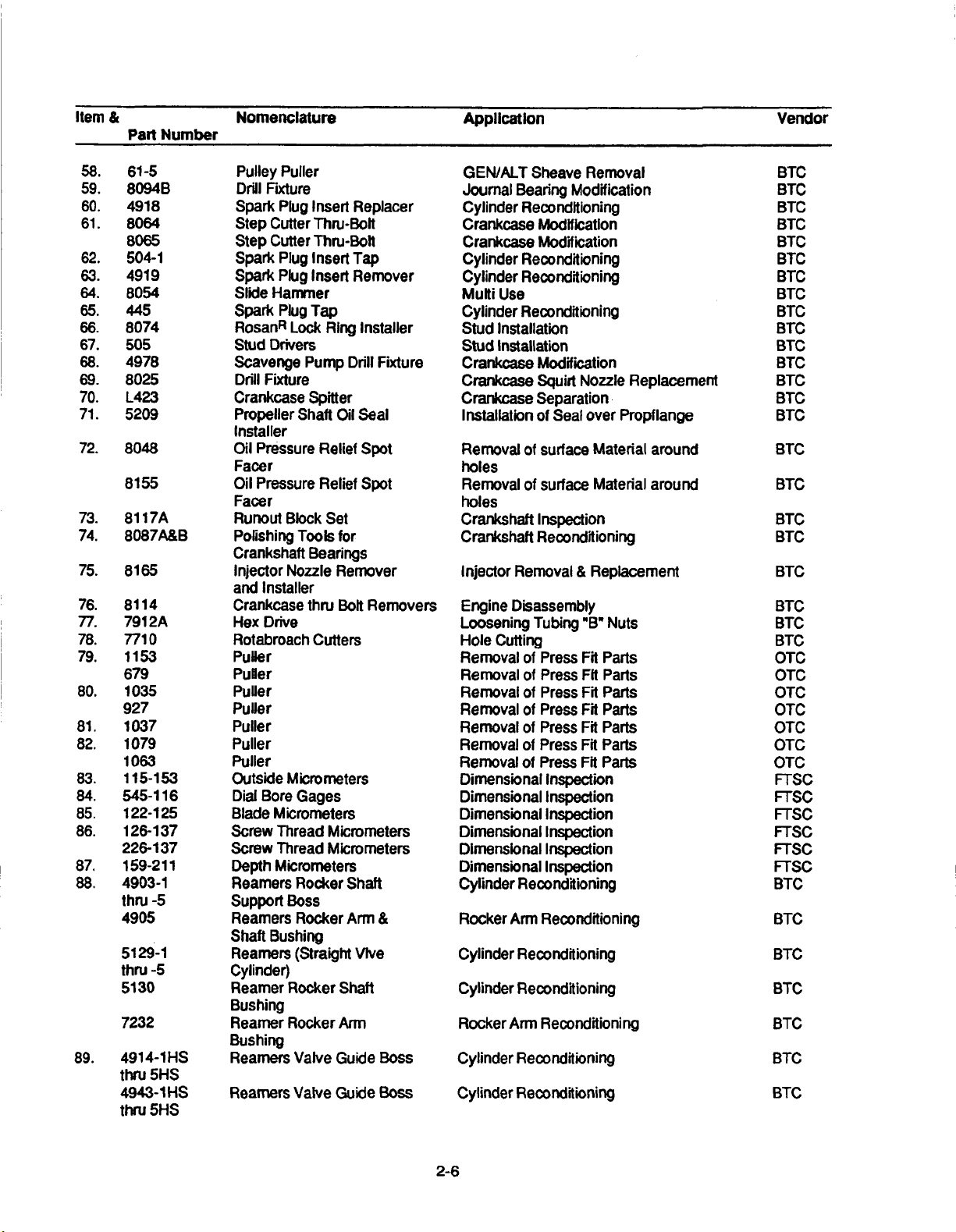

Item

&

Nomenclature

Application

Vendor

Part

Number

58.

61-5

59.

8094B

60.

4918

61.

8084

8065

62.

504-1

63.

4919

64.

8054

65.

445

66.

8074

67.

505

68.

4978

69.

8025

70.

L423

71.

5209

72.

8048

8155

73.

74.

8117A

8087A&B

75.

8165

76.

8114

77.

7912A

78.

7710

79.

1153

679

80.

1035

927

81.

1037

82.

1079

1063

83.

115-153

84.

545-116

85.

122-125

86.

126-137

226-137

87.

159-211

88.

4903-1

thru

-5

4905

5129-1

thru

-5

5130

7232

89.

4914-1H-S

thru 5HS

4943-1HS

thru 5HS

Pulley

Puller

Drill

Fixture

Spark

Plug

Insert

Replacer

Step

Cutter

Thru-Bolt

Step

Cutter

Thru-Bolt

Spark

Plug

Insert Tap

Spark

Plug

Insert Remover

Slide

Hammer

Spark

Plug

Tap

RosanR

Lock Ring

Installer

Stud

Drivers

Scavenge

Pump

Drill

Fixture

Drill

Fixture

Crankcase Spitter

Propeller

Shaft

Oil

Seal

Installer

Oil

Pressure

Relief Spot

Facer

Oil

Pressure

Relief

Spot

Facer

Runout

Block

Set

Poilshing Tools

for

Crankshaft

Bearings

Injector

Nozzle Remover

and

Installer

Crankcase

thru

Bolt

Removers

Hex Drive

Rotabroach Cutters

Puller

Puler

Puiler

Puller

Puller

Puller

Puller

Outside Micrometers

Dial

Bore

Gages

Blade

Micrometers

Screw

Thread

Micrometers

Screw

Thread

Micrometers

Depth

Micrometers

Reamers

Rocker

Shaft

Support

Boss

Reamers

Rocker

Arm

&

Shaft

Bushing

Reamers

(Straight

VIve

Cylinder)

Reamer Rocker

Shaft

Bushing

Reamer

Rocker

Arm

Bushing

Reamers

Valve

Guide

Boss

Reamers

Valve

Guide

Boss

GEN/ALT

Sheave Removal

Journal

Bearing

Modification

Cylinder

Reconditioning

Crankcase

Modification

Crankcase

Modification

Cylinder

Reconditioning

Cylinder Reconditioning

Multi

Use

Cylinder

Reconditioning

Stud

Installation

Stud

Installation

Crankcase

Modification

Crankcase

Squirt

Nozzle

Replacement

Crankcase

Separation

Installation

of Seal

over Propf

lange

Removal

of

surface Material

around

holes

Removal

of

surface

Material

around

holes

Crankshaft

Inspection

Crankshaft Reconditioning

Injector

Removal

&

Replacement

Engine

Disassembly

Loosening

Tubing

"B*

Nuts

Hole

Cutting

Removal

of

Press

Fit

Parts

Removal

of

Press

Fit

Parts

Removal

of

Press

Fit

Parts

Removal

of

Press

Fit

Parts

Removal

of

Press

Fit

Parts

Removal

of

Press

Fit

Parts

Removal

of Press

Fit

Parts

Dimensional Inspection

Dimensional Inspection

Dimensional

Inspection

Dimensional

Inspection

Dimensional

Inspection

Dimensional Inspection

Cylinder

Reconditioning

Rocker

Arm

Reconditioning

Cylinder

Reconditioning

Cylinder

Reconditioning

Rocker

Arm

Reconditioni

ng

Cylinder

Reconditioning

Cylinder

Reconditioning

2-6

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

OTC

OTC

OTC

OTC

OTC

OTC

OTC

FTSC

FTSC

FTSC

FTSC,

FTSC

FTSC

BTC

BTC

BTC

BTC

BTC

BTC

BTC

This manual suits for next models

4

Table of contents

Other Teledyne Continental Motors Engine manuals