Teledyne Continental Motors CONTINENTAL L/TSIO-360-RB User manual

L/TSIO-360-RB

FORM X30645 CHANGE 2

CONTINENTAL®AIRCRAFT ENGINE

MAINTENANCE

MANUAL

TECHNICAL PORTIONS APPROVED BY THE FAA

© 2008 TELEDYNE CONTINENTAL MOTORS INCORPORATED APRIL 2008

Supersedure Notice

The contents of this manual are in the original format issued in October 1996, except as noted in the List of Effective

Pages below. Previous versions, dated prior to October 1996 are obsolete.

Effective Changes for this Manual

0 ................................1 Oct 1996

1 ................................1 Oct 1998

2 ................................1 Apr 2008

List of Effective Pages

Document Title: L/TSIO-360-RB Maintenance Manual

Publication Number: X30645 Initial Publication Date: 1 Oct 1996

Page ...................Change Page ...................Change Page................... Change Page...................Change

Cover .........................2 7-3 thru 7-4.................2 15-1 thru 15-2.............0 21-1 thru 21-5............ 0

Ii thru iii.......................2 8-1 thru 8-4.................0 15-3............................1 21-6 thru 21-7............ 1

iv thru viii....................1 9-1 thru 9-6.................0 15-4............................0 21-8........................... 0

1-1 thru 1-12 ..............2 10-1 thru 10-2.............0 16-1 thru 16-2.............0 22-1 thru 22-2............ 0

2-1 thru 2-3 ................0 11-1 thru 11-6.............0 16-3............................1 22-3........................... 1

2-4..............................1 11-7............................1 16-4............................0 22-4........................... 0

2-5- thru 2-6...............0 11-8 thru 11-10...........0 17-1thru 17-3..............0 22-5 thru 22-7............ 1

3-1 thru 3-6 ................0 11-11..........................1 17-4............................1 22-8...........................0

4-1 thru 4-2 ................0 11-12..........................0 17-5 thru 17-8.............0 23-1 thru 23-7............ 0

5-1 thru 5-17 ..............0 12-1 thru 12-4.............0 18-1 thru 18-3.............0 23-8........................... 1

5-18............................1 12-5 thru 12-6.............1 18-4............................1 23-9 thru 23-12.......... 0

5-19............................0 12-7 thru 12-14...........0 19-1 thru 19-9.............0

5-20............................1 13-1 thru 13-6.............0 19-10 thru 19-12.........1

6-1 thru 6-9 ................0 13-7 thru 13-10...........1 19-13 thru 19-14.........0

6-10 thru 6-10 ............1 14-1 thru 14-2.............0 20-1............................1

6-11 thru 6-12 ............0 14-3............................1 20-2 thru 20-7.............0

7-1 thru 7-2 ................0 14-4............................0 20-8 thru 20-20...........1

Published and printed in the U.S.A. by Teledyne Continental Motors.

Available exclusively from the publisher: P.O. Box 90, Mobile, AL 36601

Copyright © 2008 by Teledyne Continental Motors. All rights reserved. This material may not be reprinted, republished, broadcast, or otherwise

altered without the publisher’s written permission. This manual is provided without express, statutory, or implied warranties. The publisher will

not be held liable for any damages caused by or alleged to be caused by use, misuse, abuse or misinterpretation of the contents. Content is

subject to change without notice. Other products and companies mentioned herein may be trademarks of the respective owners.

ii

Change 2 1 Apr 2008

CURRENT

STATUS

OF

PAGES

AS

OF:

OCTOBER

1998

See "Manual Revisions,"in the introductionsection for distribution procedure.

THE ORIGINAL DATE

OF

THIS PUBLICATION IS OCTOBER

1996.

INSERT LATEST PAGES;

DESTROYSUPERSEDEDPAGES.

WARNING

If the user of this manual

is

uncertain whether all current revisions have been

incorporated into the manual, contact Teledyne Continental Motors. Do not

perform any operation, maintenance, installation

or

other operation until the

manual

is

confirmedcurrent.

OCTOBER

1998

iii

WARN

Use

only

parts

meetingthe engine

type

design.

Replacement Parts

Beware of replacement parts, materials and accessories that may be sold as aircraft quality but

whose origin and quality are not known. These parts may be deceptively advertised as "unused,"

"like new," or "remanufactured," and purchasersare often unaware that they are not eligible for use

on certificated aircraft. The hazards involved in installing these types of parts on your aircraft are

obvious.

Know

Your

Supplier

Many original parts and components are copied and the copies are sold at discounted prices for

installationon U.S. certified aircraft. An original manufacturer'spart is often usedas aguideto make

duplicatesthat appear to be as good as the original, butthere are many unknowns about the quality

of design, materials, and workmanship. Other factors that go into quality parts are the degree of

heat treating and plating,and inspections,tests, and calibrations. Unfortunately, a cheaply produced

part that looked"as goodas the original" is usuallyfound out too late.

FederalAviation Regulations FAR 43.13 and FAR

145.57

specify performance rules for replacement

of parts and materials used in the maintenance and alteration of United States certificated aircraft.

FAR

91.403,

FAR

121.363, FAR 123.45, and FAR 135.143

(a)

holdsthe ownertoperator responsible

for the continuedairworthinessof the aircraft, and that includes the quality of replacement parts.

Identiwing

Approved

Parts

Approved serviceable replacementparts are identified

by:

1.

Federal Aviation Administration (FAA) Form 8130-3 Airworthiness Approval Tag. An

Airworthiness Approval Tag identifies a part or group of parts that have been approved by an

authorized

FAA

representative.

2.

FAA Technical Standard Order (TSO) number and identification mark indicatingthat the part or

appliance was manufactured in accordancewiththe requirementsof FAR

21

Subpart

0.

3.

FAA Parts Manufacturer Approval (PMA) symbol with the manufacturer's name, part number,

make and model of the type certified product on which the part can legally be installed stamped

on the part. An FAA/PMA is issued under FAR 21.305. Make and model information may be on

a tag attachedto the part.

4.

Shippingticket, invoice, or other document which verifies that the part was manufactured by a

facility that was holding an FAA Approved Production Inspection System Certificate issued

under FAR 21 Subpart F, or by a manufacturer holding an FAA Production Certificate issued

under FAR 21 Subpart

G.

5.

Certificate of aiworthiness for export issued

by

governments in countries other than the United

States ofAmerica under the provisions of FAR 21 Subpart

N.

It's

Your

Responsibility

The ownertoperatoris responsiblefor the continuedai~lorthinessof the aircraft. Inaccordancewith

FAR, certification of materials, parts and appliances for return to service for use on aircraft is the

responsibilityof the personlagency who signs the approval. To insure the continued safe operation

of your aircraft, you must exercise great care when inspecting, testing, and determining the

acceptability of

all

parts and materials.

A

very important part of this is verifying the origin

of

all

materials,parts,and accessoriesthat are used on your aircraft.

iv

OCTOBER

4998

I

Notice

to

all

users

This manual does not contain maintenance information for supplemental type certificated

components or systems. This manual contains information on engines, components and systems

I

designed,tested and certifiedby TCM in accordance with the pertinenttype design data.

The following publication contains maintenance information only.

All

personnel involved with these

functions must thoroughly read and understandthe information provided; these instructions inform

of the procedures necessary to operate, maintain and install an engine and they must be followed

carefully.

This manual contains no warranties, either expressed or implied.

PublicationFormat

This publication is formatted for practical use and ease of reference. Due to the large volume of

information necessary for maintenance, chapters are independently numbered. For example,

chapter

1

begins on page

1;

chapter

2

begins again with page

1,

etc. To locate information easily,

usethe PublicationTable of Contents and the Chapter Contents provided at each division.

WARNING

The Operator and Installation manual, Maintenance, manual, Overhaul manual,

Service Documents and the Parts Catalog constitute the instructions for Continued

Airworthiness prepared byTCM as approved bythe

FAA,

pursuantto FAR Part33. As

required by

FAR

§

43.13, each person performing overhaul, maintenance, alteration

or preventive maintenance on the engine or accessories must use the methods,

techniques and practices prescribed inthe lnstructions for Continued Airworthiness.

Failure to comply with the lnstructions for Continued Ai~lorthinessmay result in

engine malfunction, engine failure, injury or death.

The Mechanic

Prior to performing, maintenance, alteration, overhaul or preventive maintenance the mechanic

must meet requirements of FAR

65

and must follow

FAR

Parts

43,

91

and

145

as applicable. Use

this manual in conjunction with Teledyne Continental Motors (TCM) service documents, related

publications,accessory manufacturer'sinstructions,FAR and FAAAdvisory Circulars.

OCTOBER

1998

v

Notes,

Cautions

and Warnings

...

NOTE...

Special interest information

which

may facilitate performance

of

a procedure or operation of

equipment.

CAUTION

...

Used to emphasize certain information or instructions which if disregardedmay result in damage

to

engine or accessories.

WARNING

Used

to

provide warning with respect to information andlor instructions which

if

disregarded

will

endanger personnel andlor severely damage the engine resulting in

subsequent engine malfunctionor

failure.

Notes, cautions and warnings do not impose undue restrictions.

They

are inserted to obtain

maximum safety, efficiency and pelformance. Abuse, misuse or neglect of equipment can cause

eventual engine malfunction or failure.

vi

OCTOBER

1998

Publication Table Of Content

COVER

PAGES

PAGE

...

Status Page

...................................................................................................................

111

......................................................................................................................

WARNING

iv

.........................................................................................................

Notice

To

All Users

v

Notes, Cautions andWarnings

.......................................................................................

vi

Chapter Index

..........................................................................................................................

CHAPTER PAGE

............................................................................................................

1 Introduction 1-3

...............................................................................................

2 Tools (Maintenance) 2-1

3 Approved Products

............................................................................................

3-1

4 Airworthiness Limitations

........................................................................................

4-1

5

Time LimitslOperationalInspection/Troubleshooting

.............................................

5-1

6

UnpackingiDe-inhibitingllnstallation

&

Test

...........................................................

6-1

....................................................................................................

7

Servicing. Fluids 7-1

8

Engine Preservationand Storage

..........................................................................

8-1

................................................................................................

9 Standard Practices 9-1

Engine Maintenance

...........................................................................................

10-1

ExhaustSystem

....................................................................................................

11-1

IgnitionSystem

.....................................................................................................

12-1

Fuel Injection System

..........................................................................................

13-1

InductionSystem

.............................................................................................

14-1

Air ConditioningSystem

........................................................................................

15-1

16 ElectricalChargingSystem

...............................................................................

16-1

17 Starter

&

StarterAdapter

........................................................................................

17-1

18 Accessory Case

..................................................................................................

18-1

19 LubricationSystem

............................................................................................

19-1

20 CylinderAssembly

..............................................................................................

20-1

21 Crankcase

........................................................................................................

21-1

..................................................................................................

22 EngineDriveTrain 22-1

................................................................

23 Post MaintenanceAdjustmentAnd Test

23-1

OCTOBER

1998

vii

t

NTENTIONALLY

LEFT

BLANK

viii

OCTOBER

1998

CHAPTER 1

1-1. Introduction ....................................................................................................................1-3

1-2. Scope.............................................................................................................................1-3

1-3. Definition of Terms.........................................................................................................1-3

1-4. Manual Revisions...........................................................................................................1-3

1-5. Revision/Change Distribution.........................................................................................1-4

1-6. Related Publications.......................................................................................................1-4

1-7. Service Documents........................................................................................................1-5

1-8. Service Reports and Inquiries ........................................................................................1-5

1-9. Suggestions and Corrections .........................................................................................1-6

1-10. TCM Contact Information...............................................................................................1-6

1-11. Engine Model Description ..............................................................................................1-7

1-12. Engine Design Features.................................................................................................1-7

1-13. General ........................................................................................................................1-10

1-14. Engine Specifications...................................................................................................1-10

1-15. Operating Limits...........................................................................................................1-11

LIST OF ILLUSTRATIONS

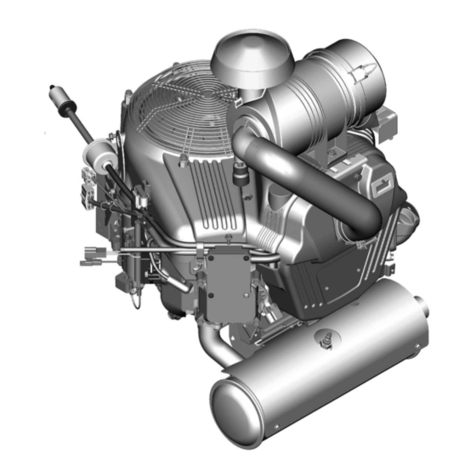

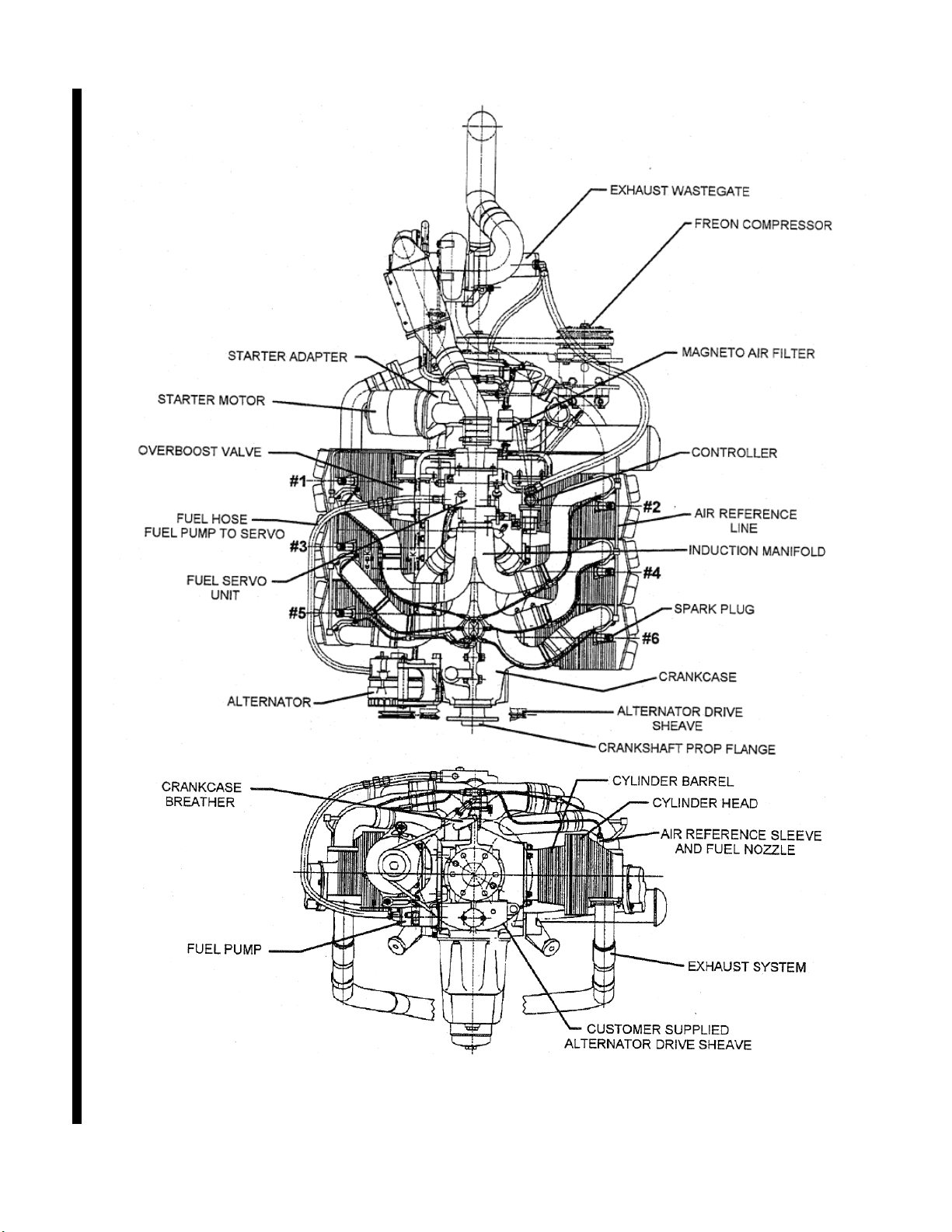

Figure 1-1. L/TSIO-360-RB Top and Front View ..........................................................................1-8

Figure 1-2. L/TSIO-360-RB Side and Aft View .............................................................................1-9

1-1

Change 2

1-2

Change 2

INTENTIONALLY

LEFT

BLANK

1-1. INTRODUCTION

This maintenance manual and the publications listed in Section 1-6 contain the information

necessary to install, operate and maintain TSIO-360-RB or LTSIO-360-RB engines.

For a list of chapters contained in the manual, refer to the Chapter index on page vii. Each

chapter begins with a table of contents on the first page. Pages in the manual are numbered

consecutively by chapter; each chapter starts with page 1.

1-2. SCOPE

WARNING

Instructions in TCM manuals are applicable only to engines and parts

supplied by TCM. TCM Instructions for Continued Airworthiness should

not be used for non-TCM parts.

This publication contains information necessary to perform scheduled maintenance, adjust

and test L/TSIO-360-RB engines in their original, type certified configuration.

Installation of non-TCM parts on a TCM engine constitutes a deviation from TCM type-

design criteria. TCM has not participated in design, test, or certification of any non-TCM

parts. TCM does not provide product manufacturing specifications to aftermarket parts

manufacturers and accepts no liability for the suitability, durability, longevity, or safety of

such parts installed on TCM engines. Installation of non-TCM parts on a TCM engine must

be performed using Instructions for Continued Airworthiness prepared by the manufacturer

and approved by the FAA for the subject installation.

1-3. DEFINITION OF TERMS

In this manual, the terms front, rear, left and right refer to the engine as viewed by a pilot

sitting in the crew compartment. The accessory end is at the rear and the propeller is at the

front of the engine. Cylinders are numbered from the rear, with odd numbers on the right

and even numbers on the left.

1-4. MANUAL REVISIONS

The instructions in this manual represent the best and most complete information available

at the time of publication. Product or process improvements may trigger changes to existing

product design specifications or procedures contained in publications. As new technical

information becomes available, TCM will deliver the updated information to the customer in

the most expedient manner.

WARNING

New information may be contained in Teledyne Continental Motors

service documents. Service documents applicable to engines and

accessories within the scope of this manual must be complied with as

defined in these documents. This manual, and the manuals identified in

Section 1-6 constitute the Instructions for Continued Airworthiness

(ICAs) prepared by Teledyne Continental Motors and approved by the

Federal Aviation Administration (FAA).

1-3

Change 2

Teledyne Continental Motors releases publication changes in the form of either change

pages or complete publication revisions, depending upon the extent of change. Service

documents may supplement or replace technical information contained in one publication or

an entire series of publications. Such service documents represent a change to the

published ICA until the individual publications incorporate the latest technical information.

1-5. REVISION/CHANGE DISTRIBUTION

Document updates are available via TCMLINK upon notification of FAA document approval.

TCM notifies engine owners of technical publication changes free of charge. TCM notifies

current TCMLINK service subscribers as publications are updated. Current TCMLINK

service subscribers receive a complete publication library on CD delivered quarterly. Current

printed publication subscribers receive printed changes and revisions as they are released.

1-6. RELATED PUBLICATIONS

The following manuals contain additional information regarding operation, maintenance and

overhaul of L/TSIO-360-RB engines:

1. L/TSIO-360-RB Overhaul Manual, Form X 30596A Supplement 1.

2. Operation and Installation Manual, X30644.

3. Starter Service Instructions, Form X30592.

4. TCM Ignition Systems Master Service Manual, Form X40000.

5. TCM Aircraft Engine Service Documents.

For TCM product pricing information, request a TCM Publication Pricing Index from your

local TCM distributor or TCMLINK.com Powerstore.

6. Slick Ignition Systems Master Service Manual Index and Order Form No. F-1100. Order

through:

Slick Aircraft Products, Unison Industries

530 Blackhawk Park Avenue

Rockford, IL 61104

ATTN: Subscription Department

USA

Phone: (815) 965-4700

www.unisonindustries.com

7. Precision Fuel System Manual, Form 15-895, Index of Manuals, Bulletins and Service

Information Letters. Order through:

Precision Airmotive LLC

14800 40th Avenue NE

Marysville, WA 98271

USA

Phone: (360) 651-8282

www.precisionairmotive.com

8. American Society for Testing and Materials (ASTM). Order through:

ASTM International

PO Box C700

West Conshohocken, PA 19428-2959

USA

Phone: (610) 832-9555

www.astm.org

1-4

Change 2

1-7. SERVICE DOCUMENTS

Six categories of Service Documents may be issued by TCM ranging from mandatory

(Category 1) to informational (Category 6). Definitions of the categories are listed below:

NOTE: Upon FAA approval, TCM service documents are published and available on

TCMLINK. Service Documents which contain updates to the Instructions for

Continued Airworthiness must be inserted in the affected manual until such time the

manual is revised to include the Service Document instructions or the Service

Document is cancelled or superseded. The Service Document cover page shall list

specific engine manuals affected by the Service Document’s changes to the

Instructions for Continued Airworthiness.

Category 1: Mandatory Service Bulletin (MSB)

Used to identify and correct a known or suspected safety hazard which has been incorporated in

whole or in part into an Airworthiness Directive (AD) issued by the FAA or have been issued at

the direction of the FAA by the manufacturer requiring compliance with an already-issued AD (or

an equivalent issued by another country’s airworthiness authority). May contain updates to

TCM’s Instructions for Continued Airworthiness to address a safety issue.

Category 2: Critical Service Bulletin (CSB)

This category identifies a condition that threatens continued safe operation of an aircraft,

persons or property on the ground unless some specific action (inspection, repair, replacement,

etc.) is taken by the owner or operator. Documents in this category are candidates for

incorporation into an FAA Airworthiness Directive. May contain updates to TCM’s Instructions for

Continued Airworthiness to address a safety issue.

Category 3: Service Bulletin (SB)

Information which the product manufacturer believes may improve the inherent safety of an

aircraft or aircraft component; this category includes the most recent updates to Instructions

for Continued Airworthiness.

Category 4: Service Information Directive (SID)

The manufacturer directs the owner/operator/mechanic in the use of a product to enhance

safety, maintenance or economy. May contain updates to TCM’s Instructions for Continued

Airworthiness in the form of maintenance procedures or specifications.

Category 5: Service Information Letter (SIL)

This category includes all information (not included in categories 1 through 4) that may be useful

to the owner/operator/technician. May contain updates to TCM’s Instructions for Continued

Airworthiness for optional component installations, which are not covered in the Applicable

Operator, Maintenance, or Overhaul Manuals.

Category 6: Special Service Instruction (SSI)

This category is used to address an issue limited to specific model and/or serial number

engines. TCM will distribute SSI notification directly to the affected engine’s owners. SSIs will not

be included in the general service document set but will be made available through TCM

Customer Service to owners of the affected engines only. An SSI may contain updates to the

Instructions for Continued Airworthiness applicable to the listed engines.

1-5

Change 2

1-8. SERVICE REPORTS AND INQUIRIES

If for any reason you have an inquiry or require technical assistance, contact your local TCM

distributor or TCM field representative. TCM service bulletins are available through your

distributor or from TCMLINK.

1-9. SUGGESTIONS AND CORRECTIONS

Teledyne Continental Motors solicits and encourages user comments regarding suggested

changes to this manual. Direct recommended changes or questions to the attention of

“Publications” at the TCM address listed under “TCM Contact Information.”

Notify TCM Customer Service immediately, using our toll-free number, if you discover

incorrect information which adversely affects safety.

1-10. TCM CONTACT INFORMATION

Teledyne Continental Motors is available to answer technical questions and encourages

suggestions regarding products, parts, or service. If customers have an inquiry or require

technical assistance, they should contact their local TCM distributor or TCM field

representative. To contact TCM, refer to the contact information below:

1-6

Change 2

Teledyne Continental Motors, Inc.

P. O. Box 90

Mobile, AL 36601

Customer Service Phone Number: 888-826-5465 toll free within the U.S.

International: 1-251-438-3411

Internet Address: http://www.tcmlink.com

1-11. ENGINE MODEL DESCRIPTION

Horizontally Opposed Cylinders

Left Hand Rotation

TS I O- 360 -RB1

Specification Number

Model Identifier

Cubic Inch Displacement

Turbo-Supercharged

Fuel Injected

B

Shipping Designation

L

Horizontally Opposed Cylinders

Left Hand Rotation

TS I O- 360 -RB1

Specification Number

Model Identifier

Cubic Inch Displacement

Turbo-Supercharged

Fuel Injected

B

Shipping Designation

L

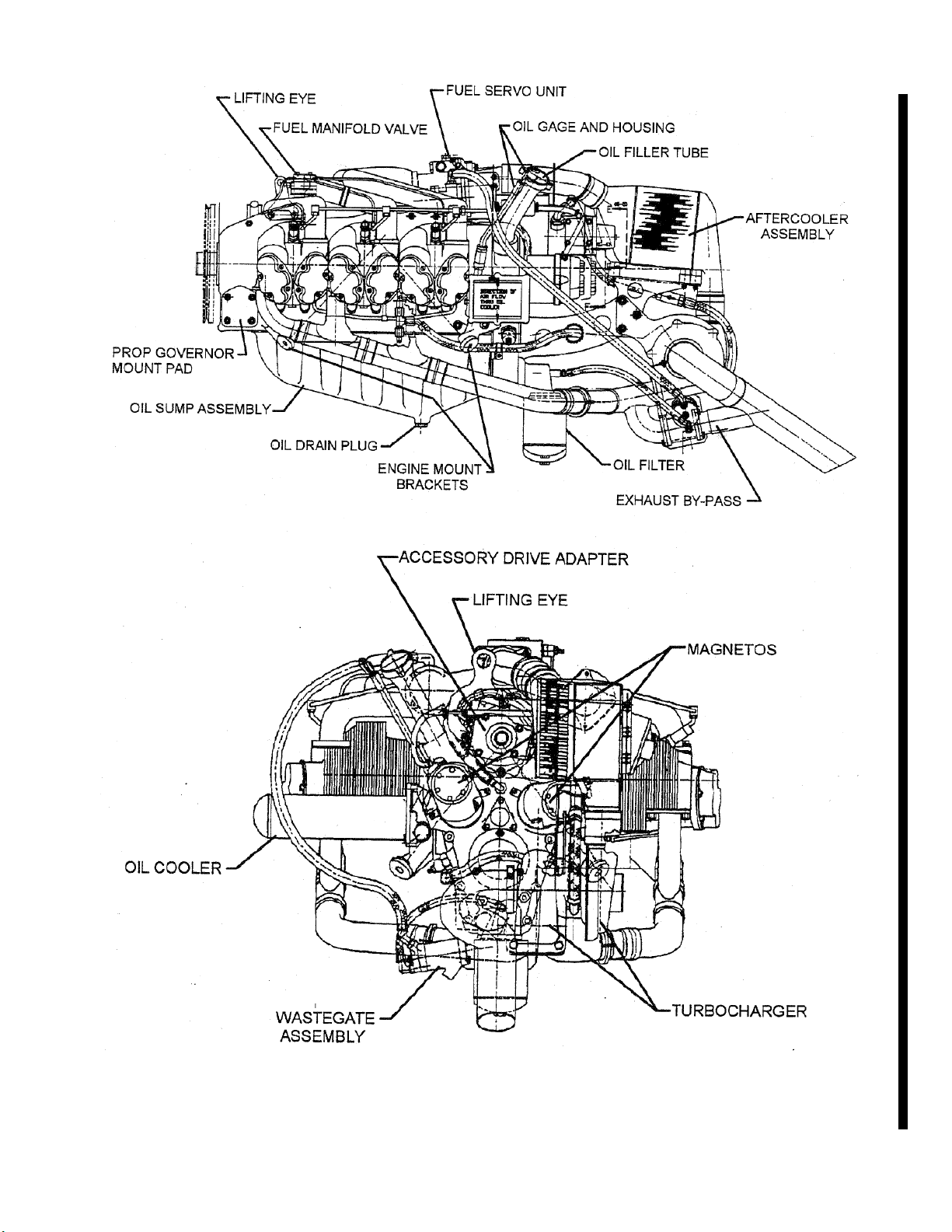

1-12. ENGINE DESIGN FEATURES

L/TSIO-360-RB series engines are air-cooled, with six horizontally opposed, incline valve,

cylinders. Cylinder displacement of 360 cubic inches is achieved with a 4.4 inch bore and

3.875 inch stroke. L/TSIO-360-RB engines are fuel injected and turbocharged. The

crankshaft is equipped with pendulum type counterweight dampers to suppress torsional

vibrations.

L/TSIO-360-RB series engines have a dowelled, six bolt hole configuration propeller flange.

A mounting pad is provided to utilize a hydraulic controlled governor for a constant speed

propeller. The engine is designed with a wet-sump and a positive displacement oil pump.

When properly adjusted, under normal conditions, desired oil pressure is maintained by a

pressure relief valve. Engine cranking is accomplished by a geared, right angle driven

starter adapter and a direct current starter motor.

The L/TSIO360-RB incorporates provisions for a belt-driven alternator mounted on the front

of the 1-3-5 side of the crankcase. The engine is equipped with two independent, gear

driven magnetos mounted on the accessory case. The exhaust and turbocharger systems

are supplied with the engine.

NOTE: Figures depicted in this publication are for illustration purposes only,

Illustrations represent the most common system configurations available for the

engine model and are not drawn to scale. They are not intended to be accurately

detailed illustrations of any specific engine model, part, or equipment. Detailed

illustrations of each engine model specification may be found in the TCMLINK online

parts catalogs.

1-7

Change 2

1-8

Change 2

Figure 1-1. L/TSIO-360-RB Top and Front View

1-9

Change 2

Figure 1-2. L/TSIO-360-RB Side and Aft View

1-13. GENERAL

Operating limits and specifications listed in this section apply to the L/TSIO-360-RB aircraft

engine model. Consult the L/TSIO-360-RB Operation and Installation Manual, Form X30644

for additional operating specifications.

For L/TSIO-360-RB time between overhaul (TBO), see Section XX or the latest TCM Time

between Overhaul Service Bulletin. TCM aircraft accessories are subject to the same

overhaul requirements as the engine, with criteria for service and longevity outlined in

applicable service manuals and service documents, unless otherwise specified.

1-14. ENGINE SPECIFICATIONS

Model: L/TSIO-360-RB

Brake Horsepower

Rated maximum Continuous Operation..........................................................................220

Cylinders

Arrangement.........................................................horizontally opposed individual cylinders

Compression ratio .........................................................................................................7.5:1

Firing Order

TSIO-360-RB...................................................................................................... 1-6-3-2-5-4

L/TSIO-360-RB................................................................................................... 1-4-5-2-3-6

Number of cylinders.............................................................................................................6

Bore (inches) ................................................................................................................4.438

Stroke (inches) .............................................................................................................3.875

Piston Displacement (cubic inches) ................................................................................360

Fuel

Fuel Control System...................................................................................Precision RSA-5

Minimum Fuel Grade............................................................................ Refer to Section 7-3

Ignition Timing

Right magneto, degrees BTC.....................................................................................22°±1°

Left magneto, degrees BTC .......................................................................................22°±1°

Spark Plug........................................................................................................TCM 630049

1-10

Change 2

Champion RHM38E

Spark plug gap ................................................................Use manufacturer’s specified gap

Oil

TCM Approved Oils.............................................................................. Refer to Section 7-2

Below 40° Ambient (Sea Level)...........................TCM Approved SAE 30 or Multi Viscosity

Above 40° Ambient (Sea Level)..........................TCM Approved SAE 50 or Multi Viscosity

Sump Capacity (US Quarts..............................................................................................8.0

Oil Consumption Formula......................................................................... 0.006 X %Powe

r

NOTE: One quart = 1.875 pounds 100

Engine Direction of Rotation

TSIO-360-RB........................................................................................................ Clockwise

LTSIO-360-RB..........................................................................................Counterclockwise

TSIO-360 Accessory Drive Ratios

Drive rations for LTSIO-360-RB engines are the same as TSIO-360 except the direction of

rotation is reversed.

CAUTION…A removable oil transfer plug conducts oil pressure from the propeller governor

through the crankshaft to the propeller hub. When a test club or fixed propeller is used for

testing purposes, the propeller governor cover must have an internal grooved surface to

allow the circulating oil to lubricate the front main bearings. The governor pad is not used if a

propeller governor is installed.

Accessory Direction of Rotation Drive Ratio

Magneto Clockwise 1.5:1

Starter Clockwise 24.73:1

Propeller Governor1Clockwise 1:1

Fuel injection Pump Counterclockwise 1:1

Freon Compressor2Clockwise 1.545:1

Accessory Drive Pad3Counterclockwise 1.545:1

1 Drive is a modified AND 20010; supplied with a cover plate

2 Ration is for six inch diameter driven sheave

3 Drive is a modified AND 20000; supplied with a cover plate

1-15. OPERATING LIMITS

Rated Maximum Continuous Operation...............................................220 HP@2600 RPM

Recommended Minimum for Idle.....................................................................700 ±25 RPM

Manifold Pressure (in. Hg).................................................................................... 38.0 PSIA

Oil Pressure

Minimum (Idle)............................................................................................................10 PSI

Maximum (Cold Oil)..................................................................................................100 PSI

Normal Operation..................................................................................................30-60 PSI

Oil Temperature

Minimum for Takeoff...................................................................................................100° F

Maximum Limit............................................................................................................240° F

Turbocharger Inlet Temperature

Maximum Continuous...............................................................................................1650° F

Maximum, 60 seconds..............................................................................................1700° F

Cylinder Head Temperature*

Recommended Maximum Operating Temperature....................................................420° F

Limit............................................................................................................................480° F

1-11

Change 2

1-12

Change 2

INTENTIONALLY

LEFT

BLANK

Table of contents

Other Teledyne Continental Motors Engine manuals

Popular Engine manuals by other brands

Power Tec

Power Tec 25A owner's manual

Vanguard

Vanguard 610000 Operator's manual

Oriental motor

Oriental motor FPW Series operating manual

Oriental motor

Oriental motor BLF Series operating manual

woodmizer

woodmizer D42 Safety, Operation, Maintenance & Parts Manual

UDI R/C

UDI R/C UD1609 operating instructions