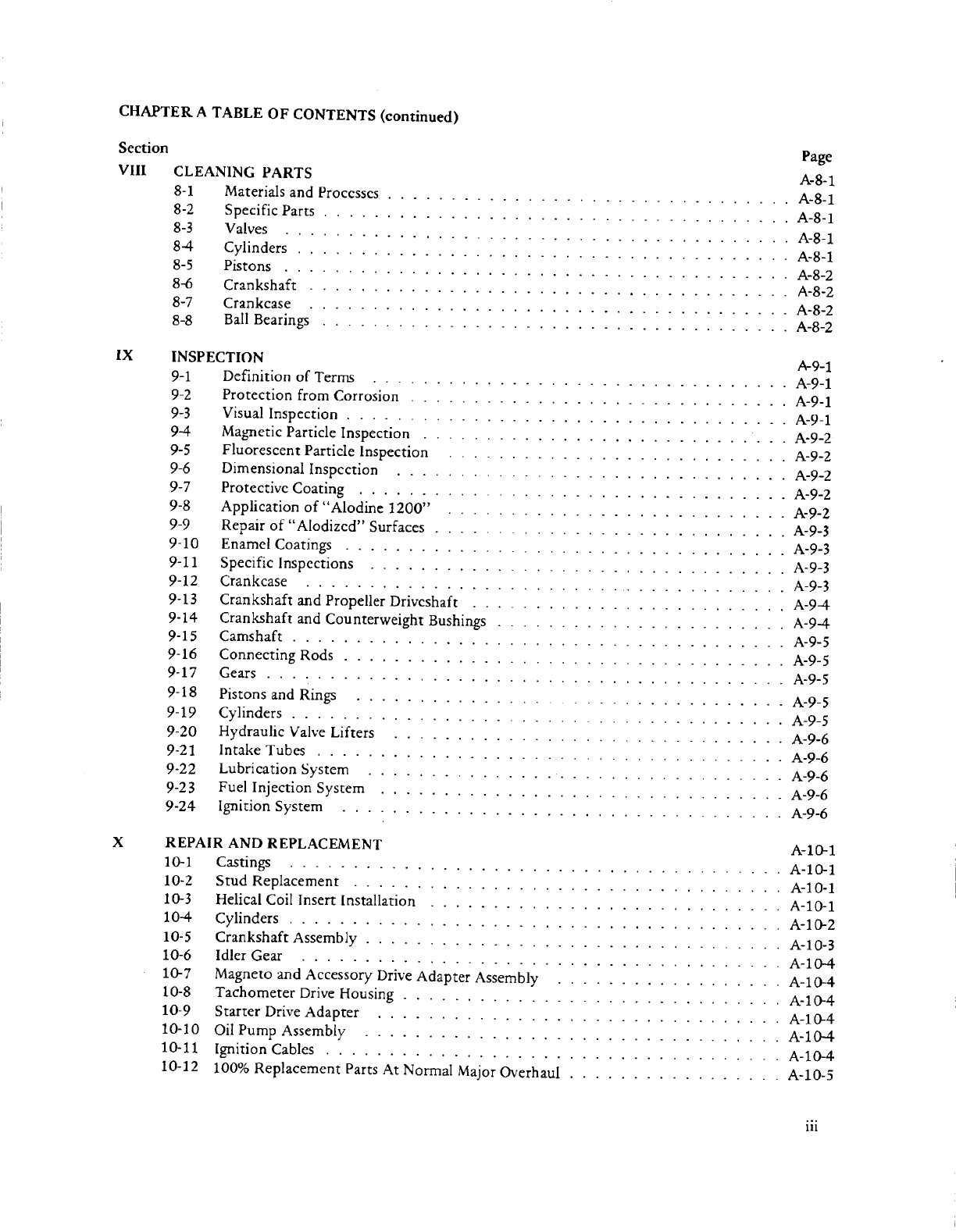

CHAPTER

A

TABLE OF

CONTENTS

(continued)

Section

Page

VIII

CLEANING

PARTS

A-8-1

8

1

Materials

and

Processes.

...............................

A-8-1

8-2

Specific Parts.

....................................

A-8-1

8-3

Valves.

.......................................

A-8-1

8-4

Cylinders. ......................................

A-8-1

8-5

Pistons. .......................................

A-8-2

8-6

Crankshaft.

.....................................

A-8-2

8-7

Crankcase.

.....................................

A-8-2

8-8

Ball

Bearings.

...................................

A-8-2

IX

INSPECTION

A-9-1

9-1

Definition of

Terms

.. .. ... ..... .. .. .. .. .... . ... . .. ..

A 9-

9-2

Protection

from

Corrosion. .............................

A-9-1

9-3

Visual

Inspection. ..................................

A-9-1

9-4

Magnetic

Particle

Inspection.

............................

A-9-2

9-5

Fluorescent

Particle

Inspection.

..........................

A-9-2

9-6

Dimensional Inspcction. ...........................

A-9-2

9-7

Protective Coating.

.................................

A-9-2

9-8

Application

of "Alodine

1200".............................A-9-2

9-9

Repair

of

"Alodized"

Surfaces

. . . .

........................

A-9-3

9-10

Enamel

Coatings.

..................................

A-9-3

9-11

Specific

Inspections.

................................

A-9-3

9-12

Crankcase.

.....................................

A-9-3

9-13

Crankshaft

and

Propeller

Driveshaft.

........................

A-94

9-14

Crankshaft

and

Counterweight

Bushings.

...................... A-94

9-15

Camshaft.

......................................

A-9-5

9-16

Connecting

Rods.

..................................

A-9-5

9-17

Gears.

........................................

A-9-5

9-18

Pistons

and

Rings.

.............. .................

A-9-5

9-19 Cylinders. ......................................

A-9-5

9-20

Hydraulic

Valve

Lifters.

..............................

A-9-6

9-21

Intake

Tubes.

....................................

A-9-6

9-22

Lubrication

System.

................................

A-9-6

9-2

3

Fuel

Injection

System.

...............................

A-9-6

9-24

Ignition

System.

.................................

A-9-6

X

REPAIR

AND REPLACEMENT

A-10-1

10-1

Castings.

......................................

A-1b-1

10-2

Stud Replacement.

.................................

A-10-1

10-3

Helical

Coil

Insert

Installation.

...........................

A-10-1

104

Cylinders. ......................................

A-10-2

10-5

Crankshaft

Assembly.

................................

A-10-3

10-6

Idler

Gear.

.....................................

A-104

10-7

Magneto

and

Accessory

Drive

Adapter

Assembly.

.................

A-

10-4

10-8

Tachometer

Drive

Housing.

.............................

A-

10-4

10-9

Starter

Drive

Adapter.

...............................

A-1

0-4

10-10

Oil

Pump Assembly.

................................

A-1O0-4

10-11

Ignition

Cables.

...................................

A-10-4

10-12

100%

Replacement

Parts

At

Normal

Major

Overhaul.

................

A-10-5

iii