Teledyne Photometrics PRIME 95B User manual

1

Prime 95BTM Scientific CMOS User Manual

Prime 95B Manual

i

Prime 95BTM Scientific CMOS User Manual

© Copyright 2019 Teledyne Photometrics

3440 East Britannia Drive

Tucson, Arizona 85706

Tel: +1 520.889.9933

Fax: +1 520.295.0299

All rights reserved. No part of this publication may be reproduced by any means without the written permission of Teledyne

Photometrics.

Acrobat and Reader are registered trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Teledyne Photometrics and PVCAM are registered trademarks of Teledyne Technologies.

Prime and Prime 95B are trademarks of Teledyne Photometrics.

Intel Core is a trademark of Intel Corporation in the U.S. and/or other countries.

Windows is a registered trademark of Microsoft Corporation in the United States and/or other countries.

All other brand and product names are the trademarks of their respective owners and manufacturers.

The information in this publication is believed to be accurate as of the publication release date. However, Teledyne

Photometrics does not assume any responsibility for any consequences including any damages resulting from the use

thereof. The information contained herein is subject to change without notice. Revision of this publication may be issued to

incorporate such change.

ii

Prime 95BTM Scientific CMOS User Manual

LIMITED WARRANTY

Teledyne Photometrics (“Teledyne Photometrics,” “us,” “we,” “our”) makes the following limited warranties. These limited

warranties extend to the original purchaser (“You”, “you”) only and no other purchaser or transferee. We have complete

control over all warranties and may alter or terminate any or all warranties at any time we deem necessary.

Basic Limited Two (2) Year Warranty

Teledyne Photometrics warrants this product against substantial defects in materials and/or workmanship for a period of

up to two (2) years after shipment. During this period, Teledyne Photometrics will repair the product or, at its sole option,

repair or replace any defective part without charge to you. You must deliver the entire product to the Teledyne Photometrics

factory or, at our option, to a factory-authorized service center. You are responsible for the shipping costs to return the

product. International customers should contact their local Teledyne Photometrics-authorized representative/distributor for

repair information and assistance, or visit our technical support page at www.photometrics.com.

Limited One (1) Year Warranty on Refurbished or Discontinued Products

Teledyne Photometrics warrants, with the exception of the CMOS or CCD image sensor device (which carries NO

WARRANTIES EXPRESS OR IMPLIED), this product against defects in materials or workmanship for a period of up to one

(1) year after shipment. During this period, Teledyne Photometrics will repair or replace, at its sole option, any defective

parts, without charge to you. You must deliver the entire product to the Teledyne Photometrics factory or, at our option, a

factory-authorized service center. You are responsible for the shipping costs to return the product to Teledyne Photometrics.

International customers should contact their local Teledyne Photometrics representative/distributor for repair information

and assistance or visit our technical support page at www.photometrics.com

Normal Wear Item Disclaimer

Teledyne Photometrics does not warrant certain items against defect due to normal wear and tear. These items include

internal and external shutters, cables, and connectors. These items carry no warranty, expressed or implied.

Software Limited Warranty

Teledyne Photometrics warrants all of our manufactured software discs or memory devices to be free from substantial

defects in materials and/or workmanship under normal use for a period of one (1) year from shipment. Teledyne Photometrics

does not warrant that the function of the software will meet your requirements or that operation will be uninterrupted or

error free. You assume responsibility for selecting the software to achieve your intended results and for the use and results

obtained from the software. In addition, during the one (1) year limited warranty, the original purchaser is entitled to receive

free version upgrades. Version upgrades supplied free of charge will be in the form of a download from the Internet. Those

customers who do not have access to the Internet may obtain the version upgrades on a CD ROM or USB memory device

from our factory for an incidental shipping and handling charge.

iii

Prime 95BTM Scientific CMOS User Manual

Owner’s Manual and Troubleshooting

You should read the owner’s manual thoroughly before operating this product. In the unlikely event that you should

encounter diculty operating this product, refer to the owner’s manual. If the problem persists, please contact the Teledyne

Photometrics technical support sta or an authorized service representative.

Your Responsibility

The above Limited Warranties are subject to the following terms and conditions:

You must retain your bill of sale (invoice) and present it upon request for service and repairs or provide other proof of

purchase satisfactory to Teledyne Photometrics.

You must notify the Teledyne Photometrics factory service center within thirty (30) days after you have taken delivery of

a product or part that you believe to be defective. With the exception of customers who claim a “technical issue” with the

operation of the product or part, all invoices must be paid in full in accordance with the terms of sale. Failure to pay invoices

when due may result in the interruption and/or cancellation of your two (2) year limited warranty and/or any other warranty,

expressed or implied.

All warranty service must be made by the Teledyne Photometrics factory or, at our option, an authorized service center.

Before products or parts can be returned for service you must contact the Teledyne Photometrics factory and receive a

return authorization number (RMA). Products or parts returned for service without a return authorization evidenced by an

RMA will be sent back freight collect.

These warranties are eective only if purchased from the Teledyne Photometrics factory or one of our authorized

manufacturer’s representatives or distributors.

Unless specified in the original purchase agreement, Teledyne Photometrics is not responsible for installation, setup, or

disassembly at the customer’s location.

Warranties extend only to defects in materials or workmanship as limited above and do not extend to any product or part

which has:

• been lost or discarded by you;

• been damaged as a result of misuse, improper installation, faulty or inadequate maintenance, or failure to follow

instructions furnished by us;

• had serial numbers removed, altered, defaced, or rendered illegible;

• been subjected to improper or unauthorized repair; or

• been damaged due to fire, flood, radiation, or other “acts of God” or other contingencies beyond the control of

Teledyne Photometrics.

iv

Prime 95BTM Scientific CMOS User Manual

After the warranty period has expired, you may contact the Teledyne Photometrics factory or a Teledyne Photometrics-

authorized representative for repair information and/or extended warranty plans.

Physically damaged units or units that have been modified are not acceptable for repair in or out of warranty and will be

returned as received.

All warranties implied by state law or non-U.S. laws, including the implied warranties of merchantability and fitness for a

particular purpose, are expressly limited to the duration of the limited warranties set forth above. With the exception of

any warranties implied by state law or non-U.S. laws, as hereby limited, the forgoing warranty is exclusive and in lieu of all

other warranties, guarantees, agreements, and similar obligations of manufacturer or seller with respect to the repair or

replacement of any parts. In no event shall Teledyne Photometrics’ liability exceed the cost of the repair or replacement of

the defective product or part.

This limited warranty gives you specific legal rights and you may also have other rights that may vary from state to state and

from country to country. Some states and countries do not allow limitations on how long an implied warranty lasts, when an

action may be brought, or the exclusion or limitation of incidental or consequential damages, so the above provisions may

not apply to you.

When contacting us for technical support or service assistance, please refer to the Teledyne Photometrics factory of

purchase, contact your authorized Teledyne Photometrics representative or reseller, or visit our technical support page at.

www.photometrics.com.

U. S. Government Restricted Rights

The software and documentation are provided with Restricted Rights. Use, duplication, or disclosure by the Government is

subject to restrictions as set forth in subparagraph (c)(1)(ii) of the Rights in Technical Data and Computer Software clause

at DFARS 252.227-7013 or subparagraphs (c)(1) and (2) of the Commercial Computer Software-Restricted Rights at 48 CFR

52.227-19, as applicable. Contractor/manufacturer is Teledyne Photometrics, 3440 East Britannia Drive, Tucson, AZ 85706.

This license is eective until terminated. It will terminate upon the conditions set forth above or if you fail to comply with

any term hereof. Upon termination, you agree that the software and accompanying materials, and all copies thereof, will

be destroyed. This agreement is governed by the laws of the State of Arizona. You acknowledge that you have read this

agreement, you understand it, you agree to be bound by its terms, and that this is the complete and exclusive statement of

the agreement between you and Teledyne Photometrics regarding the software.

v

Prime 95BTM Scientific CMOS User Manual

vi

Prime 95BTM Scientific CMOS User Manual

Table of Contents

Chapter 1 - Overview 1

About This Manual 1

Precautions 1

Environmental Requirement 2

Storage Requirements 2

Microscopes, Lenses, and Tripods 2

Repairs 2

Cleaning 2

Chapter 2 - System Installation 3

Introduction 3

Getting to Know Prime 4

Software Compatibility Requirements 4

Host Computer Requirements 5

Software Installation 5

Installing the PCI Express Interface Card 5

Connecting Prime to PCI Express Bus 8

Connecting Prime with USB 3.0 9

Chapter 3 - Theory of Operation 10

Introduction 10

CMOS Image Sensor Structure 10

Gain Combining and Bit-Depth 11

Rolling and Global Shutter Readout 12

Digital Binning 13

Sensor Clearing 13

Bias Oset 13

Pixel Noise Filters 14

Signal Processing 15

Denoising (PrimeEnhanceTM)16

Localization Microscopy (PrimeLocateTM)17

Chapter 4 - Operating Features 18

Introduction 18

Gain States 18

vii

Prime 95BTM Scientific CMOS User Manual

Bias Oset Setting 18

Clearing Mode Selection 18

Single and Multiple Regions of Interest 19

Device Synchronization (Triggering) 20

Trigger Modes 21

Expose Out Behaviors 22

Multiple Output Triggers 26

SMART Streaming 26

Advanced Features 28

Time Stamps 29

Chapter 5 - Troubleshooting 30

System Does Not Boot Normally 30

New Hardware Found Dialog Box Does Not Appear 30

Images Not Displayed 31

Camera Running Too Warm 31

PVCAM Error Message Appears 31

Lengthy Pauses During Imaging 31

Camera Hand with ROIs 31

Chapter 6 - Basic Specifications 32

Prime 95B Front, Side, Rear Views 32

Camera Weight 32

Power Supply Specifications 33

Liquid Cooling Setup Instructions 34

INDEX 35

1

Prime 95BTM Scientific CMOS User Manual

1

Chapter 1 - Overview

This Prime 95B Scientific CMOS Camera User Manual is divided into five chapters.

Teledyne Photometrics recommends you read this entire manual before

operating the camera to ensure proper use. The chapter contents are briefly

described below.

Note: The information in these chapters applies only to the Prime 95B camera

and is currently not applicable to any other Teledyne Photometrics camera.

• System Installation — Instructions for connecting the Prime 95B

camera to a computer via the PCI Express interface card or the USB3.0

bus.

• Theory of Operation — A basic overview of Scientific CMOS camera

technology as used in the Prime 95B camera.

• Operating Features — Prime 95B features and how to optimize them

for speed and sensitivity, and how to use the dierent trigger modes.

• Troubleshooting — Answers to common camera system questions.

• Basic Specifications — Specifications for Prime 95B system

components.

The CMOS sensor and other system electronics are extremely sensitive to

electrostatic discharge (ESD). To avoid permanently damaging the system, please

observe the following precautions:

• If using high-voltage equipment (such as an arc lamp) with the camera

system, turn the camera power on last and when powering down,

power the camera o first.

• Never connect or disconnect any cable while the system is powered

on.

• The camera’s power should be switched o before disconnecting any

camera system cables. However it is not necessary to power o the

computer to detach the cables.

• Use caution when triggering high-current switching devices (such as

an arc lamp) near the system. The image sensor can be permanently

damaged by transient voltage spikes. If electrically noisy devices are

present, an isolated, conditioned power line or dedicated isolation

transformer is highly recommended.

• Always leave one inch of space around the camera for airflow.

• Do not operate the camera without cooling (air or liquid).

• Never open the camera. There are no user-serviceable parts inside the

Prime 95B camera. Opening the camera voids the warranty.

• Use only the PCI Express interface card, cables and power supply

designated for this camera system. Using non-Prime cables, PCI

Express interface cards or power supplies may result in unexpected

errors or

permanent damage to the system.

• Do not use a C-mount lens with optics that extend behind the lens

flange.

About This Manual

Precautions

2

Prime 95BTM Scientific CMOS User Manual

The Prime 95B camera system should be operated in a clean, dry environment.

The camera system’s ambient operating temperature is 0°C to 30°C with 80%

relative humidity, non-condensing.

Store the Prime 95B camera system in its original containers. To protect the

system from excessive heat, cold and moisture, store at an ambient temperature

between -20°C and 60°C with a relative humidity of 0% to 90%, non-condensing.

The camera has a standard threaded video mount and can be mounted to

any microscope that accepts a standard C-mount adapter. The camera is also

available in a configuration compatible with F-mount adapters. The camera also

allows you to install any lens that is compatible with a standard threaded video

mount as long as its optics do not extend behind the flange of the lens. Prime

can be mounted to optical tables, tripods and copy stands using the eight ¼-20

threaded attachment points located near the camera front and rear on all sides

(see figure 1)

Please save the original packing materials so you can safely ship the camera

to another location or return it for repairs if necessary. The Prime 95B camera

system contains no user-serviceable parts. Repairs must be done by Teledyne

Photometrics. Should the camera system require repairs, please contact Teledyne

Photometrics Customer Service.

Note: Do not open the camera. Opening the Prime 95B camera voids the

warranty.

Clean exterior surfaces of the camera with a dry, lint-free cloth. To remove

stains, contact Teledyne Photometrics Customer Service. To clean the camera’s

imaging window, use only a filtered compressed-air source. Hand-held cans are

not recommended as they may spray propellant onto the window. Do not touch

the window.

Environmental Requirements

Storage Requirements

Microscopes, Lenses, and

Tripods

Repairs

Cleaning

3

Prime 95BTM Scientific CMOS User Manual

Carefully review the Precautions section in the previous chapter before

performing any of the procedures outlined in this chapter. Again, use only a

Prime 95B PCI Express data cable and Prime PCI Express interface card with the

camera. Using a dierent cable or interface card may result in in unexpected

errors or permanent damage to the system.

The Prime 95B camera system includes the following hardware components:

• Prime 95B Scientific CMOS

• PCI Express (PCIe) interface card

• PCI Express data cable

• USB 3.0 SuperSpeed A to B data cable

• A 12V/12A power supply with international power cord set

• I/O to 8 BNC trigger break out cable, part number CBL-IO-8-BNC

• USB memory device containing PVCAM library and drivers

• Quick Installation Guide

Prime 95B system components are linked by the PCI Express or USB3.0 data cable

and controlled by the host computer system. All of these hardware components

should be included with the shipment. Keep all the original packing materials so

you can safely ship the camera to another location or return it for service.

If you have any diculty with any step of the instructions, contact Teledyne

Photometrics Customer Service.

Introduction

Chapter 2 – System Installation

4

Prime 95BTM Scientific CMOS User Manual

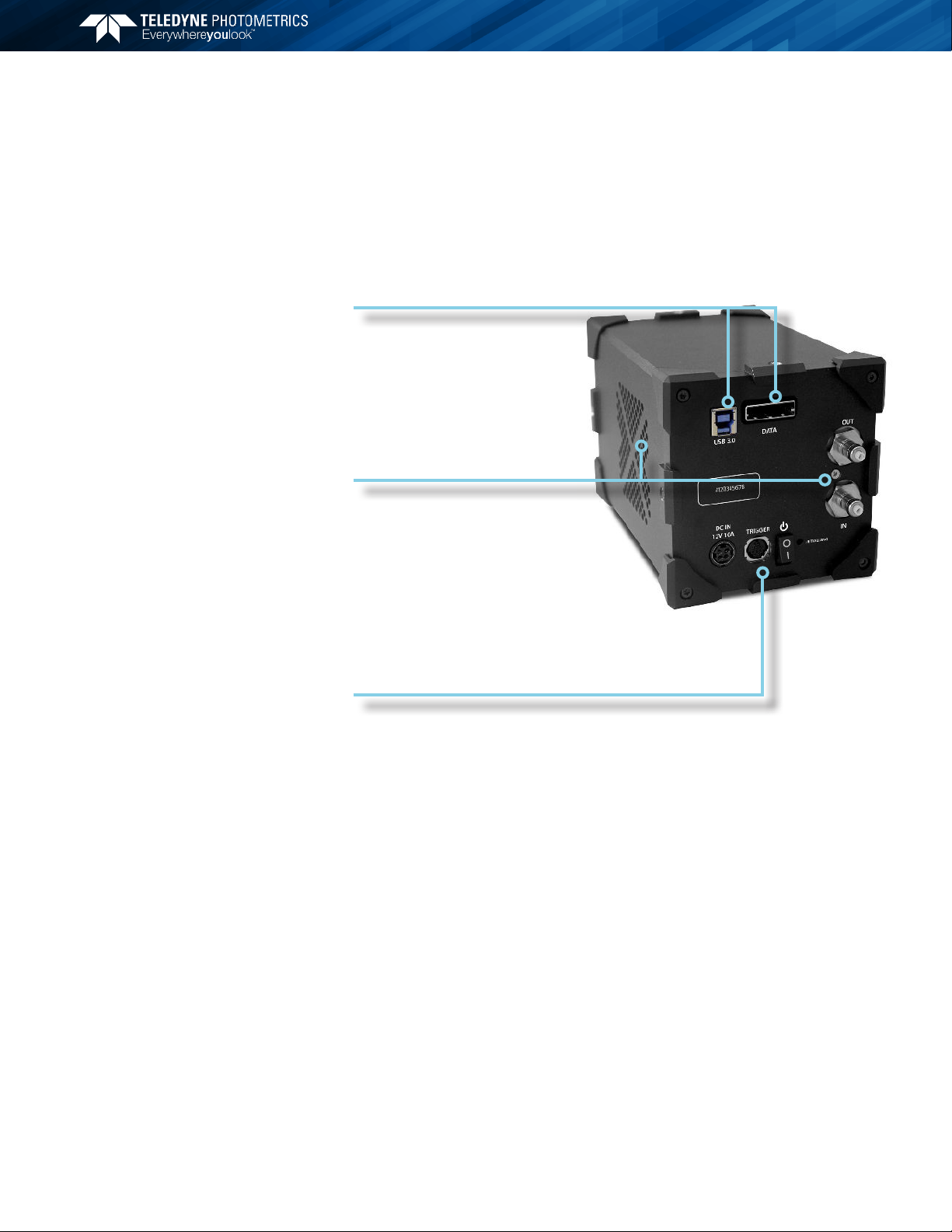

Highlights of the Prime 95B camera are shown below: The Prime 95B package

includes the PVCAM drivers designed to allow you to use this camera with a

variety of third party imaging software - To see a list of supported software, visit

the Teledyne Photometrics website.

Figure 1

• USB3.0: Lower Speed Data Connection.

• DATA : High Speed PCI-Express Connection.

• Out/In: Liquid Cooling Connections.

• Initializing: LED blinking indicates the camera is booting up.

• Power Switch: Turns the camera on and o.

• Trigger: Hirose HR10A-10R-10S for use with Teledyne Photometrics’

trigger to BNC break out cable CBL-IO-8-BNC.

• DC IN: Connection to external 12V 10A DC power supply.

Unless there is a preferred version specified by a third party software provider, the

latest version of PVCAM is recommended for use with Prime 95B.

Getting to Know Prime 95B

Software Compatibility

Requirements

16-bit Data

°° 41 fps

12-bit Data

°° 80 fps

Forced Air Cooling

°° -20°C Cooling

°° Selectable Fan Speed

Liquid Cooling

°° -25°C Cooling

°° Leak-proof, quick-disconnect ports

Eective Global Shutter

Up to four selectable expose-out lines

Convenient Interfaces

Multiple Cooling Options

Advanced Application Triggers

5

Prime 95BTM Scientific CMOS User Manual

The host computer (PC) for Prime must meet the following minimum requirements:

• Windows 7/8/10 64-bit operating system

• 2.0 GHz or faster Intel processor: either Xeon or Core i7

• 8+ GB RAM

• 250+ GB serial ATA (SATA) HDD and/or >512 GB solid state drive (SSD)

for high-speed imaging and storage

• 512+ MB slot-based ATI/NVIDIA video graphics card (i.e., not an

“onboard/integrated graphics” adapter)

• USB port for use with the USB memory device or Internet access to

obtain the PVCAM library and interface drivers

• USB3.0 port for use with the Prime USB3.0 interface

• An open PCI-Express 4x (4 lane) interface slot or higher for use with the

Prime PCIe interface card

An appropriate Installation Guide is included as an insert with the camera. This

guide provides step-by-step instructions for installing the camera interface

software for Windows-based computers. Additional instructions are included for

installing a PCI Express interface card in the computer.

The Teledyne Photometrics USB memory device contains the following files:

• Manuals Directory — contains user manuals in PDF format.

• Customer Case Studies — application examples

• Imaging Software – a copy of Open Imaging’s FOSS Application,

Micromanager

• Technical Notes – detailed background on advanced features

• For a 64-bit Windows OS, install the PVCam driver.

• Follow the Installation Guide insert for the version of Windows being

used. Reboot the computer when the installation is complete.

As CMOS cameras have developed, the amount of data generated from these

products has exceeded the current capabilities of USB interfaces. The Prime

CMOS camera platform provides both USB 3.0 for convenience and a PCI-

Express interface to ensure that the camera is capable of sustaining the required

bandwidth of the camera.

The data rate of the Prime 95B camera is sustainable through both the USB 3.0

and PCI-Express interfaces.

Host Computer Requirements

Software Installation

Installing the PCI Express

Interface Card

6

Prime 95BTM Scientific CMOS User Manual

TIP: PCI Express is a high speed peripheral data bus used by the computer to

communicate with video cards, high speed Solid State Drives, and image frame

grabbers. The PCI Express interface card is simply an adapter between the

computer’s internal PCIe bus and the camera.

While this has benefits in cost, reliability, simplicity, and performance, it is

important that the camera is powered on for 30 seconds before starting the

PC. This will ensure that as the computer goes through the boot process, it

discovers the camera on the PCIe bus.

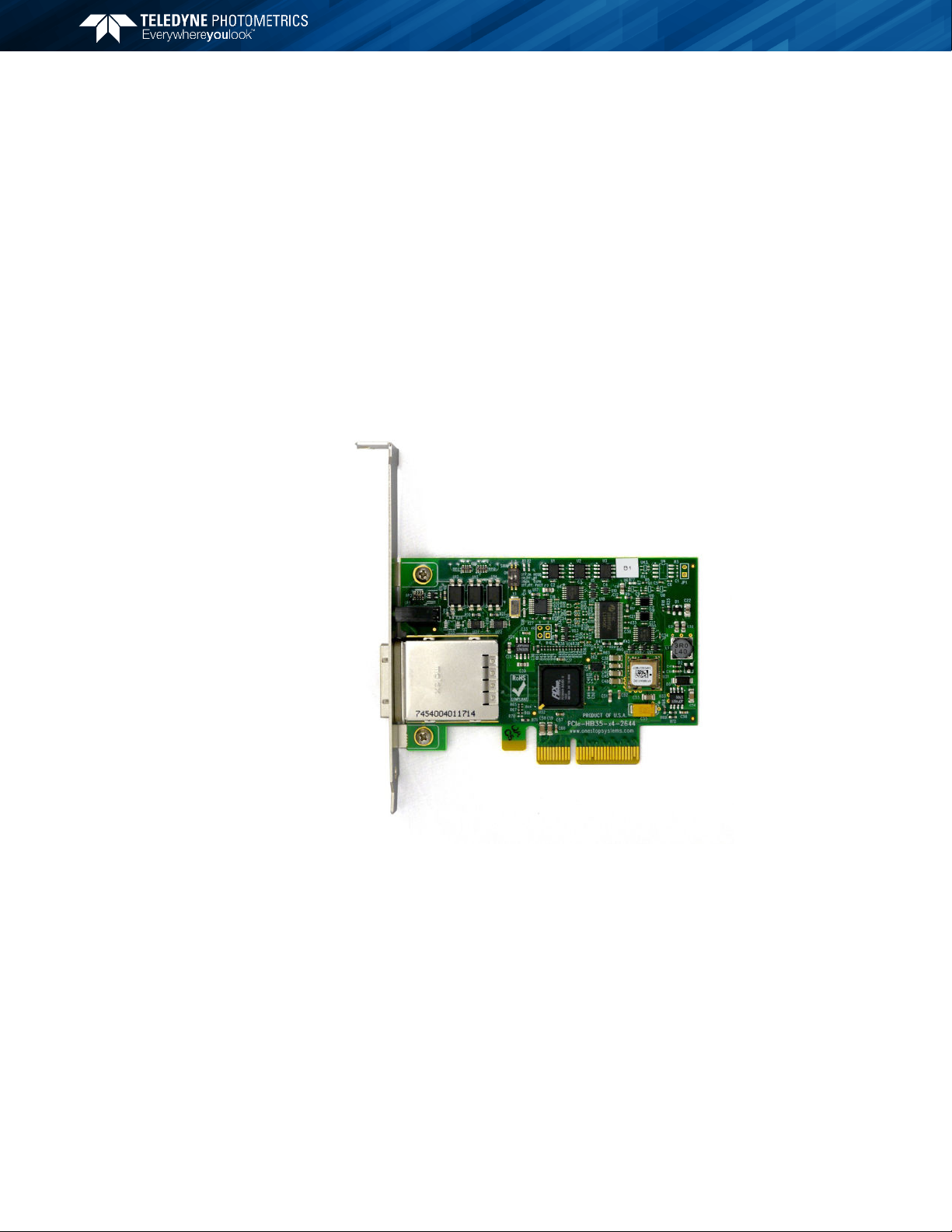

Install the High Speed PCI Express Interface

Figure 2

Note: The model of PCIe card shipped with the camera may dier from the one

shown in the photo.

Warning: Do not use the PCIe interface supplied with the QImaging optiMOS

sCMOS camera with the Teledyne Photometrics Prime 95B camera. While they

have a common cable and connector, they are not compatible.

7

Prime 95BTM Scientific CMOS User Manual

Before attempting to operate the camera, first install this interface card into the

PC with the following steps:

1. Shut down the PC

2. Unplug the PC from power mains and ensure the camera is turned o

3. Open the side of the computer to access the PCI and PCIe slots

Figure 3

4. Locate an available 4 channel or higher PCIe slot (marked x4). Refer to

the PC’s documentation to locate a suitable slot.

Tip: The PC may have motherboard slot information on the side cover

Figure 4

5. Holding the Prime PCIe card and (being careful not to touch the board

components or PCIe bridge pins) insert it with the proper orientation into the

open slot. The card should slide into place with minimal resistance and snap

when fully inserted.

8

Prime 95BTM Scientific CMOS User Manual

The Prime 95B camera data cable is a quick insertion, quick release cable that

works with the interface card and camera. Either end of the cable can be plugged

into either device, and in any order.

Figure 5

The connector can only be inserted with the correct orientation, do not force

the connector. If the connector does not insert, simply turn the connector over

and retry.

With the cable connected on both ends of the camera, it is ready to power on

the computer.

1. Verify that the power switch on the side of the camera is in the o

position.

2. Connect the power supply to the Power connector on the rear of the

camera.

3. Plug the power cord into the power supply and then into a suitable

wall outlet.

4. Switch on the camera (power switch on the side of camera).

5. Wait 30 seconds before powering on the PC

Tip: The power supply and connector used by the Prime 95B camera is a

common type. However, Teledyne Photometrics carefully selects power

supplies for optimum noise performance, EMI compliance and stability. Do not

swap power supplies with other lab equipment even though they may meet the

connector, voltage and ampere requirements of the Prime.

Connecting Prime

to the PCIe Bus

9

Prime 95BTM Scientific CMOS User Manual

Prime’s USB3.0 interface is ubiquitous and easy to use. To use the interface, the

PC must have an open USB3.0 port. Prime is not USB2.0 compatible. USB3.0

ports are usually indicated by the SuperSpeed+ logo and are typically blue in

color.

Tip: USB devices sharing the same bus as the Prime 95B contend for available

bandwidth, potentially causing the camera to drop frame rate. For this reason,

Teledyne Photometrics recommends isolating the camera to its own USB3.0

root hub as shown in the Windows Device Manager.

A method for creating an independent root hub in computers with many USB

devices is to install a PCI Express based USB3.0 interface card for use with

the camera. In this case Teledyne Photometrics recommends using the PCIe

interface described above.

It is not recommended to connect to the Prime 95B external USB3.0 hubs.

Figure 6

Note that the ends of the USB3.0 cable are dierent between the camera and

PC, and require a specific orientation. The camera has a “Type B” connector

and the computer will have a “Type A” connector. Do not force insertion when

connecting the cable – if significant resistance is encountered stop, reexamine

the connection, and if correct, retry.

With the cable connected on both ends, you are now ready to power on the

computer:

1. With the camera o, connect the USB3.0 cable between camera

andhost computer.

2. Power the camera on.

3. Wait 30 seconds before launching the application. An LED on the rear

of the camera will stop blinking when the camera is initialized and

ready to communicate.

Connecting Prime

with USB 3.0

10

Prime 95BTM Scientific CMOS User Manual

Backside illuminated scientific CMOS (BSI Scientific CMOS) sensors are a recent

development in image sensor technology. BSI CMOS sensors are able to provide

the highest levels of sensitivity with a near perfect 95% quantum eciency (QE).

This QE coupled with large pixel CMOS sensors which have high frame rates,

high pixel counts, and low electronic noise provide the most complete low-light

scientific imaging solution.

A major dierence between traditional CCD sensors and CMOS sensors is the

location where charge-to-voltage conversion of accumulated photoelectrons

takes place. CCD sensors transfer the pixels accumulated signal in charge packets

in “bucket brigade” fashion across the sensor to a common output node where

charge is converted to a voltage. The voltage is then sampled using o-chip

Analog-to-Digital Converters (ADC) and transferred to the PC as digital grey

values.

While providing excellent quantitative photometry and very high image quality,

the large number of transfers and sequential digitization of pixels results in low

frame rates. This speed penalty increases with the number of pixels to be digitized.

CMOS sensors leverage many of the same analog signal concepts used in CCDs,

but places the output node circuitry inside each pixel. This eliminates the charge

transfer process. To read the signal from a given row, the accumulated charge is

converted to a voltage inside the pixel, then each pixel in the row is connected to

the appropriate column voltage bus, where the on-chip ADCs covert the voltages

to an 11-bit or 12-bit grey value. (Thus far, the on-chip ADCs available on CMOS

sensors have limited dynamic range.)

The parallel digitization of all pixels in a row provides CMOS devices with a

tremendous speed advantage. Imagine a CCD with 1200x1200 pixels – and

each pixel’s voltage is measured in 1 µsec. To read a single row, 1200 voltage

measurements are performed in serial fashion taking slightly longer than 1 ms,

and when repeated for 1200 rows, the entire image takes over 1 second to be

digitized.

On a CMOS device – the entire 1200 voltage conversions needed to digitize a row

happen in parallel.

Introduction

CMOS Image

Sensor Structure

Chapter 3 – Theory of Operation

11

Prime 95BTM Scientific CMOS User Manual

If the time to digitize a pixel remains at 1 µs – the time to read the entire frame

is now 1.2 ms. In practice, the time saving is split between faster frame rates and

slowing the rate of pixel measurement to reduce electronic noise. For example,

if the time to measure a pixel was increased to 10 µsec to lower noise, the image

sensor can still be read in 12.5 ms (for a maximum 80fps).

Of course, there are many challenges to obtaining the same analog performance

from each of the Prime 95B’s 1.4 million pixels, whereas a CCD has a single,

common output node resulting in a uniform response. The most common

problems are pixel-to-pixel non uniformity in gain and oset, random

telegraph noise (RTN), and defective pixels with abnormal noise or dark current

characteristics (hot pixels).

Often solutions to these challenges are found in the digital domain, where Prime

95B’s advanced real time signal processing corrects each pixel for gain and oset

variation using calibration at the factory. To address RTN and other pixel defects,

real-time digital filters are used. These corrections are described further in this

manual.

As discussed in the previous sections, the column ADCs present in scientific

CMOS devices have limited dynamic range. This is addressed by making two

measurements of the accumulated charge in each pixel – the first with very high

sensitivity but limited to a maximum signal of approximately 1000 electrons, and

the second with reduced sensitivity but capable of measuring signals up to the

pixel’s 80,000 electron full well capacity.

Combining the two measurements into a single 16-bit value is the function of

the digital “gain combiner.” This mathematical operation is performed on the

cameras FPGA. The result is a single gain of approximately 1.2 e-/ADU.

In practice, the Prime 95B oers both a combined ADC 16-bit output as well as a

12-bit single ADC output. The combined gain takes two measurements of a pixel

for the combined ADC 16-bit output. The 12-bit mode is able to sample 2 rows

simultaneously as only a single sample is required resulting in a 2X increase in

frame rate.

Since the 12-bit mode does not have the flexibility in dynamic range provided

by gain-combining, multiple gain states are provided so that acquisition can be

optimized for the required performance. These gain states are:

• Full Well - Provides maximum full-well capacity with a gain conversion

factor of ~2e-/ADU

• Balanced - Provides the best balance between read noise and full-well

capacity with a gain conversion factor of ~1e-/ADU

• Sensitivity - Provides the highest levels of sensitivity with a gain

conversion factor of ~0.5e-/ADU

Gain Combining

and Bit-Depth

12

Prime 95BTM Scientific CMOS User Manual

Rolling Shutter and Global Shutter are the two primary operating modes of CMOS

image sensors. In Global Shutter readout, a global charge clearing mechanism

begins the exposure period for all pixels. Each pixel accumulates signal charge

until the exposure period ends. At this point, the accumulated charge is transferred

and converted to a voltage in the pixels output node, ending the exposure.

The strength of the Global Shutter approach is that all pixels are exposed at the

same instant in time – an important attribute when imaging fast moving objects.

The downside of this approach is the sensor has two phases, an active image

accumulation phase and a subsequent readout phase. As the phases are not

overlapped in time, the maximum achievable frame rate is lower.

In Rolling shutter readout, exposure and readout are overlapped. This is

accomplished by reading one row, while exposing all of the other rows (The row

being digitized “rolls” through the sensor).

For Prime 95B, the time to digitize a single row is 20µs, and consequently the

delay between the start of exposure between two adjacent rows is approximately

9.6µs. Digitizing 1200 rows of pixels, the time delay from the top to the middle of

the sensor is approximately 24 ms. Since readout and exposure are overlapped,

the sensor achieves the maximum frame rate of 41fps. In the 12-bit mode, as

two rows are read out simultaneously, the row time is eectively halved to 10µs,

providing an increase maximum frame rate of 80fps.

The graphic below depicts the time delay between each row of pixels in a rolling

shutter readout mode with a CMOS camera.

Figure 7: Rolling Shutter Exposure Row by Row Exposure Start/End Oset

The downside of Rolling Shutter readout is that changes in the scene on similar

time scales is distorted, as each row samples the image at dierent times. This is

the well known “rubber band” eect – but can appear in fluorescence microscopy

as shaded illumination when rapidly changing wavelengths.

To maintain the benefit of Rolling Shutter readout and eliminate rolling shutter

artifacts, external illumination can be gated on when all rows are being

simultaneously exposed, and o during the readout phase. This external triggering

mode used in combination with high speed light sources (lasers, LEDs) achieves

a pseudo global shutter eect. This triggering mode is described in the device

synchronization section of this manual.

Rolling and Global

Shutter Readout

Table of contents

Other Teledyne Photometrics Digital Camera manuals

Popular Digital Camera manuals by other brands

Pentax

Pentax ZOOM 105-R operating manual

Olympus

Olympus E620 - Evolt 12.3MP Live MOS Digital SLR... instruction manual

Samsung

Samsung Vluu PL20 Manual Del Usuario

Samsung

Samsung BL103 - 10.2 Mega Pixels Digital Camera Manual de usuario

V-TAC

V-TAC VT-5157 Installation instruction

Sony

Sony Cyber-Shot DSC-RX10M4 Help guide