X45 AIR COMPRESSOR

PRESSURE MEASURING &

SETTING PROCEDURE

Test Procedure

Proheat has an improved Air compressor pressure settings

procedure based on supply voltage to the heater.

1. Run heater until warm to the touch. This ensures the heater

components are up to normal operating temperature.

2. Switch heater off.

3.

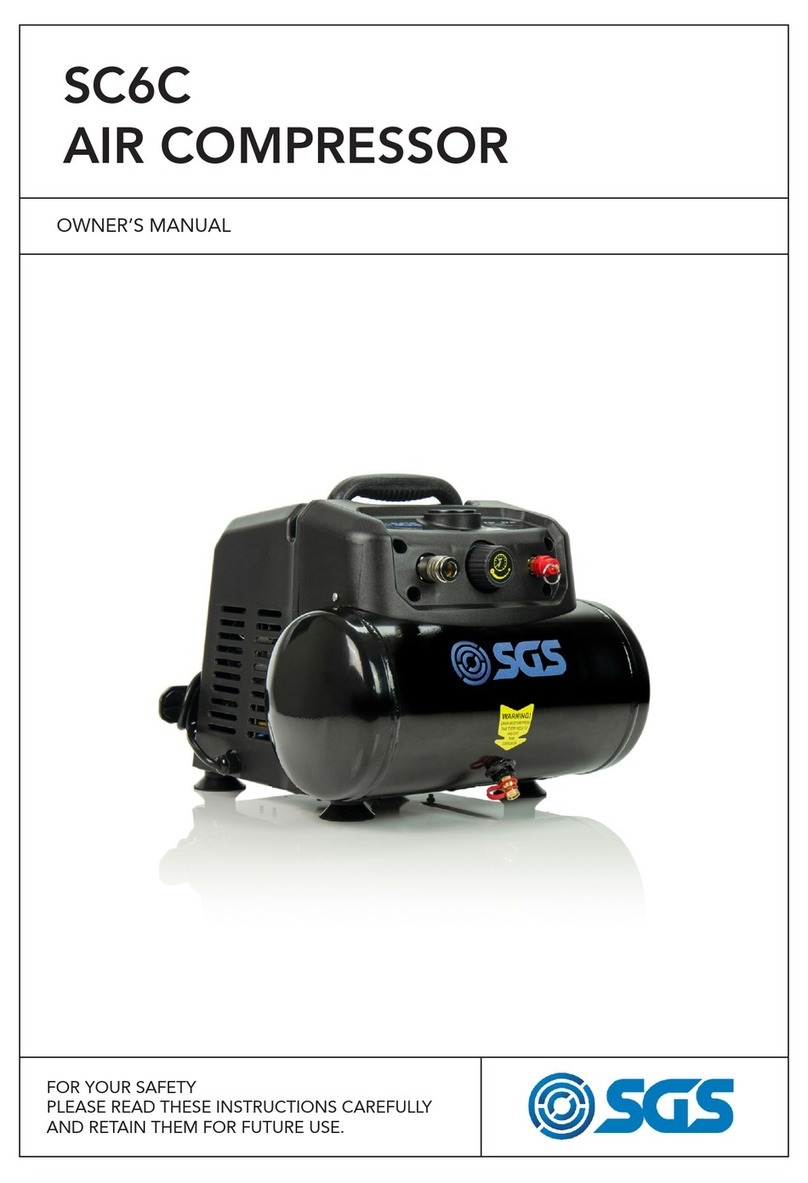

Install the calibrated Pressure Gauge Tool PK0060 in-line as

shown in Figure A.

Calibrate gauge before each use see

www.proheat.com/PDFs/990614.pdf

NOTICE

Altitude Correction is needed above

3000 Feet (see inset on charts).

DO NOT adjust air pressure when

above 6000 Feet.

NOTICE

Remove Pressure Gauge when finished

with measuring & setting procedure.

NOTICE

HOSE TO NOZZLE

AIR INLET

PRESSURE

GAUGE TOOL

PK0060

4. Locate the rubber boot on the positive end of the ignition coil

and peel it back to expose the positive terminal.

5. Select the DC Volts range of a multimeter and connect as per

Figure B. The positive lead of the multimeter should be

attached to the positive coil lead. The negative lead of the

multimeter should be attached to the heater chassis at the

PROHEAT ground boss.

6. With the heater running in full output (flame on and ignition is

off) read the voltage and refer to the 12 or 24 volt chart

(Figure C and D) for the correct Air Pressure Reading.

7. The reading must be within the range of the shaded area as

shown in Figures C and D.

Figure A. Pressure Gauge Tool PK0060.

Shock hazard due to high secondary

coil voltage.

WARNING

© 2011 Teleflex Canada Limited Partnership 3831 No. 6 Road, Richmond, B.C. Canada V6V 1P6 Fax: 604-270-7172 Web: www.proheat.com

SERVICE BULLETIN

Copy Part# SB0060, Rev. A, 04/2011 Page 1 of 3

THERMAL SYSTEMS