Section 4 — Refrigerant Management

System

4.1 Suction and Interstage Piping.................23

Section 5 — Electrical Specifications

5.1 Thermal Protection................................. 25

5.2 Screw Compressor Motor Protection......26

5.3 Circuit Breaker Tables.............................27

Section 6 — Motor and Discharge

Temperature Control

6.1 Carlyle Electronic Module (CEM).............29

6.2 Discharge Temperature Control.............. 29

6.3 Motor Cooling Control............................29

Section 7 — Subcooler Selection and

Performance Data Adjustment

7.1 Subcooler Selection................................30

7.2 Subcooling Correction............................30

7.3 Superheat Correction............................. 30

7.4 Carlyle Software..................................... 30

Section 8 — 05T Open Drive Application

Information

8.1 General Information................................31

8.2 Compressor Dimensions........................ 31

8.3 Compressor C-Flange............................ 31

8.4 Compressor Coupling............................ 31

8.5 Overall Dimensions.................................31

8.6 Carlyle Electronic Module....................... 36

8.7 Motor Selection......................................36

8.8 Performance Factors..............................37

Section 9 — Start-Up Procedure

9.1 Oil Charging Procedure.......................... 38

9.2 Testing the Control Circuit...................... 38

9.3 Pre-Start-Up Check List.........................38

9.4 Start-Up Worksheet................................39

Section 10 — Accessory

Part Numbers............................................... 40

Appendix A LonCEM — Electronic

Module

Appendix B Original CEM — Electronic

Module

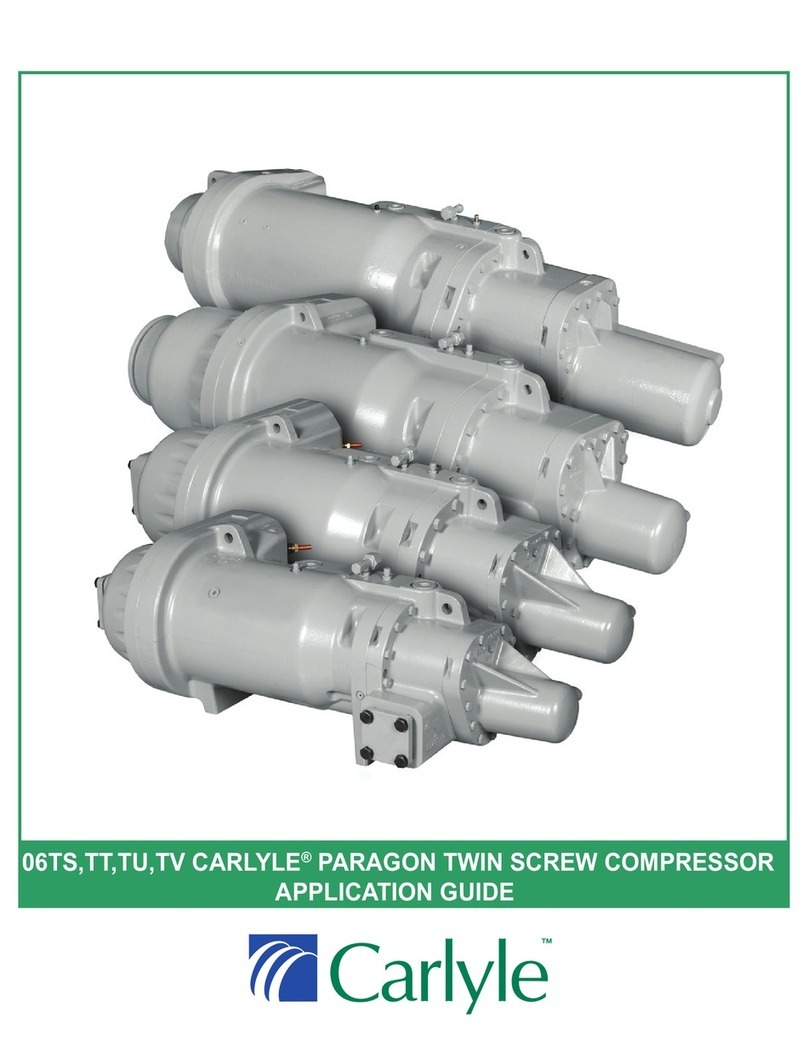

Introduction

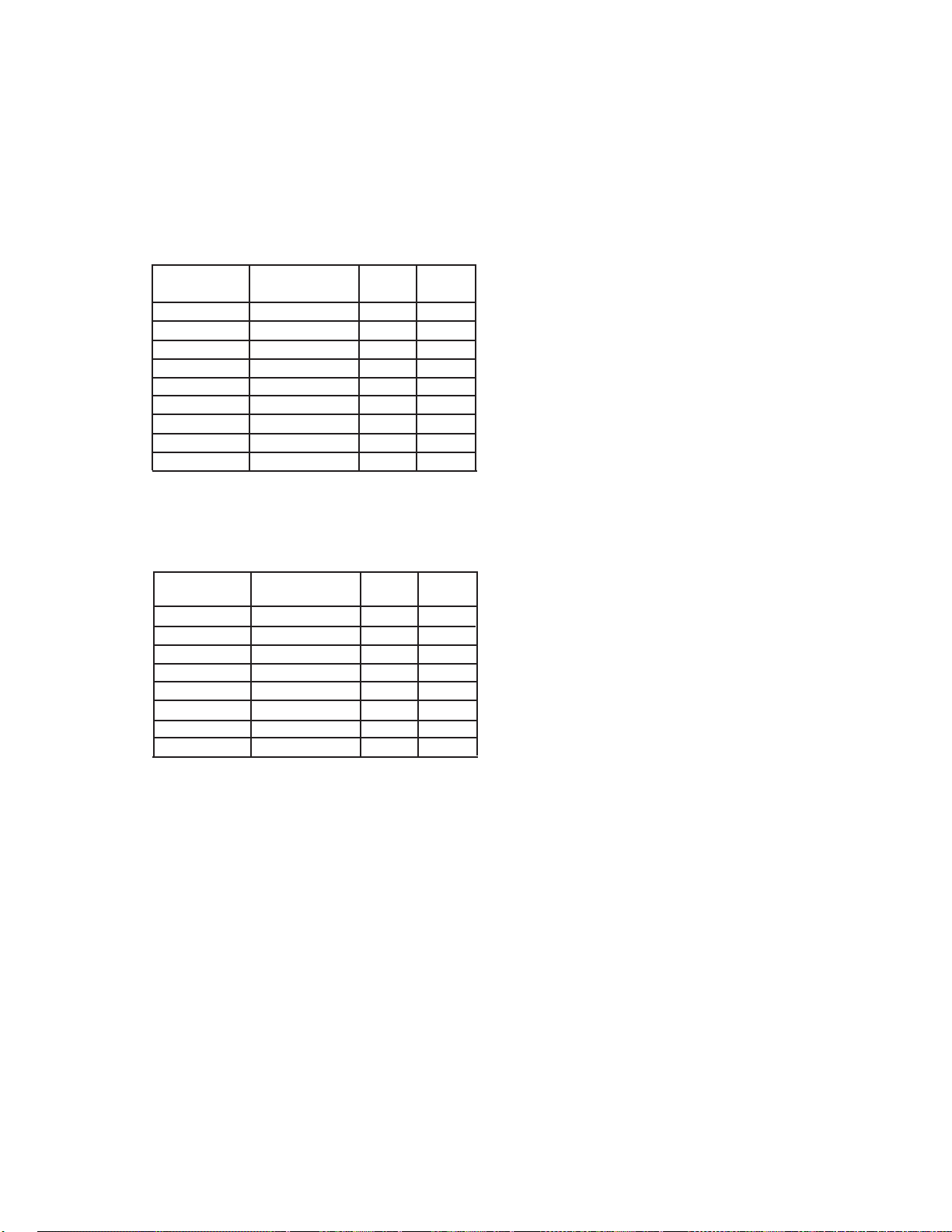

Summary of Control Points...............................1

06T Model Number Significance.......................2

Compressor Physical Dimensions.....................2

Section 1 — General Information

1.1 Certification..............................................4

1.2 Screw Compressor Size (Displacement)...4

1.3 Compressor Mounting..............................4

1.4 Oil Type....................................................4

1.5 Ambient Conditions..................................5

1.6 Installation Environment............................5

1.7 Pressure Relief Valve................................5

1.8 Discharge Check Valve............................5

1.9 Compressor Inlet Screens........................5

1.10 Service Valves..........................................5

1.11 Condenser Pressure Control....................5

Section 2 — Operating Specifications

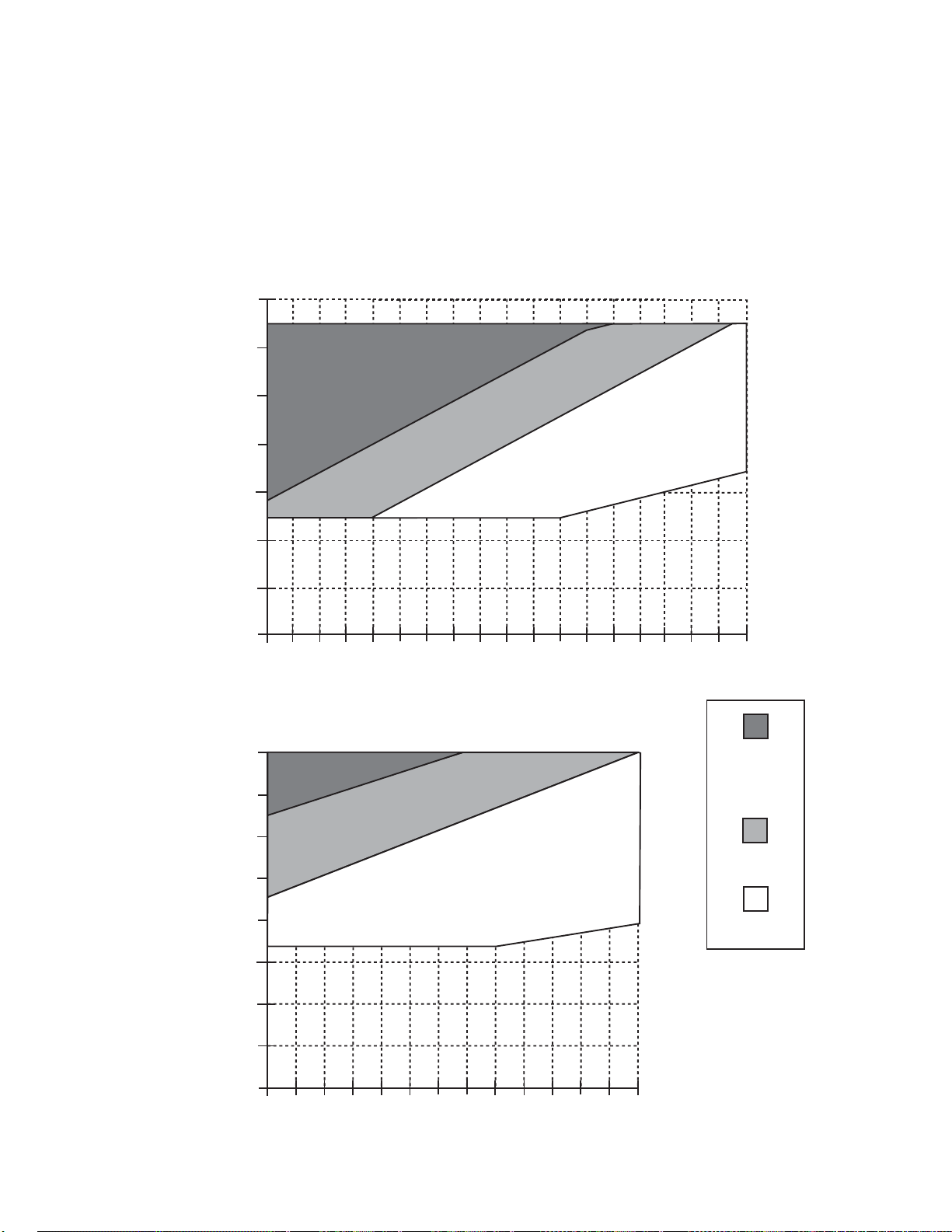

2.1 Operational Envelopes.............................6

2.2 Vapor Temperature Limits........................ 7

2.3 Minimum Oil Pressure Differential.............7

2.4 Operating Speed Ranges.........................7

2.5 Inverters and Refrigerants........................8

2.6 Compressor Cycling................................ 8

2.7 Mechanical Unloading..............................9

2.8 High Discharge Pressure Control.............9

2.9 Low Suction Pressure Cut Out.................9

2.10 Volume Index (Vi) Control....................... 9

2.11 Reverse Rotation Protection....................10

2.12 Mufflers...................................................10

Section 3 — Oil Management System

3.1 Oil Separator...........................................11

3.2 Piping Configuration................................12

3.3 System Oil Charge..................................12

3.4 Oil Level Switch...................................... 12

3.5 Oil Pressure Protection........................... 13

3.6 Oil Solenoids...........................................13

3.7 Oil Cooling Systems................................14

3.8 Oil Cooler Selection.................................16

3.9 Oil Filter...................................................20

3.10 Oil Sump Heaters................................... 20

3.11 Oil Sight Glass........................................20

3.12 Oil System Schematics...........................21

3.13 Oil Line Manifold Selection Table.............22

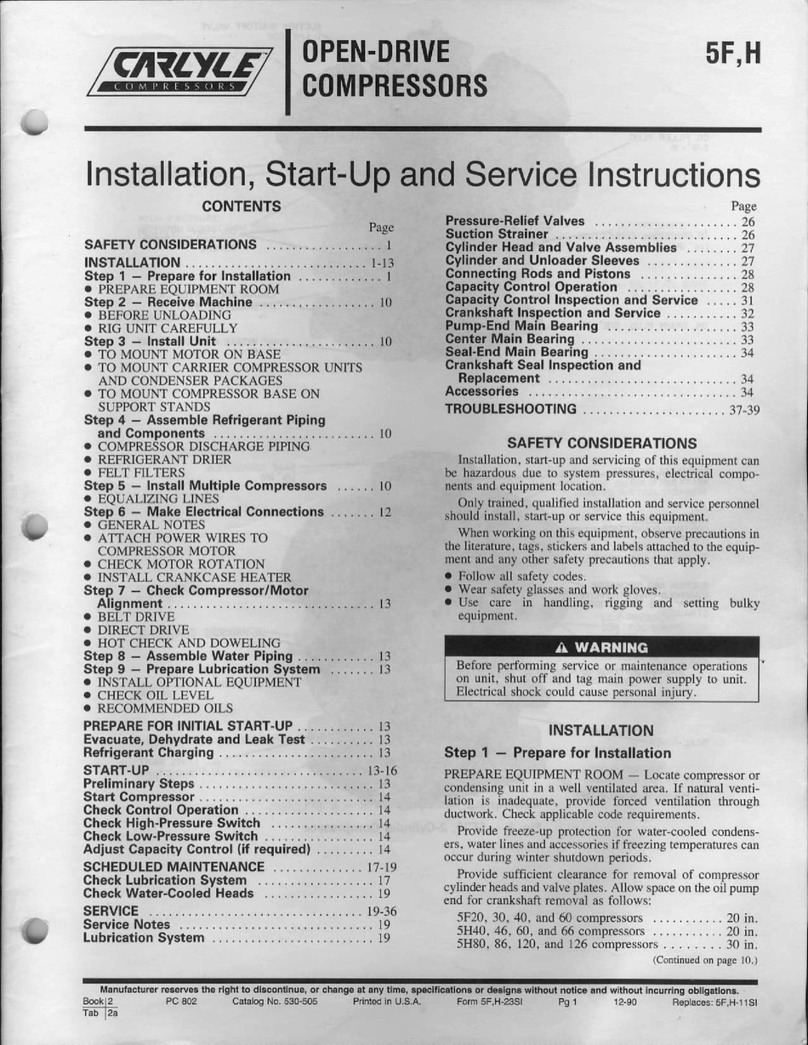

Contents