TelliQ TQ12 ver 2 User guide

Title Author Date Reg.no Revision

Mounting instructions for TQ12 ver 2 Patrik Abrahamsson 2018-04-24 TQ-18-196 2

Production tracker Reviewed by

Joel Verpers

TQ12 ver 2 Production tracker

Mounting instruction

Contact TelliQ Customer Center after each installation for function

control and configuration of the unit in the TelliQ web-system.

+46 589 123 70

Page 1 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- TQ12 Production Tracker

- Delivery from TelliQ

Unit

TQ12 ver 2 Production tracker

Changes since former version

●Black wire connects to GROUND

●Blue wire connects to 1WIRE POWER

●Unit has 3 DIN, 2 DOUT and 1 AIN

●Unit has 10 wires

Relay

(Accessories)

RFID reader

(Accessories)

- Mounting materials

Mounting materials and tools shall be provided by the installer.

When installing TQ12 you will need:

●Cable ties or double-sided tape

●Terminal block

●Fuse Holder

●Fuse 2-3A

●Cables for extension( depends on installation)

- Important to know before installing the TQ12 Production Tracker

TQ12 Production tracker is suitable for installation on construction machines. The unit must be installed differently depending on whether

the machine's main power switch located on the battery positive or negative side, as well as the function desired by the device. Electrical

wiring is divided into the following scenarios:

●Main power switch on negative side (main power switch is located on the machine negative side)

o Installation for collecting positioning and production data (running hours, etc.)

●Main power switch on positive side (main power switch is located on the machine positive side)

o Installation for collecting positioning and production data (running hours, etc.)

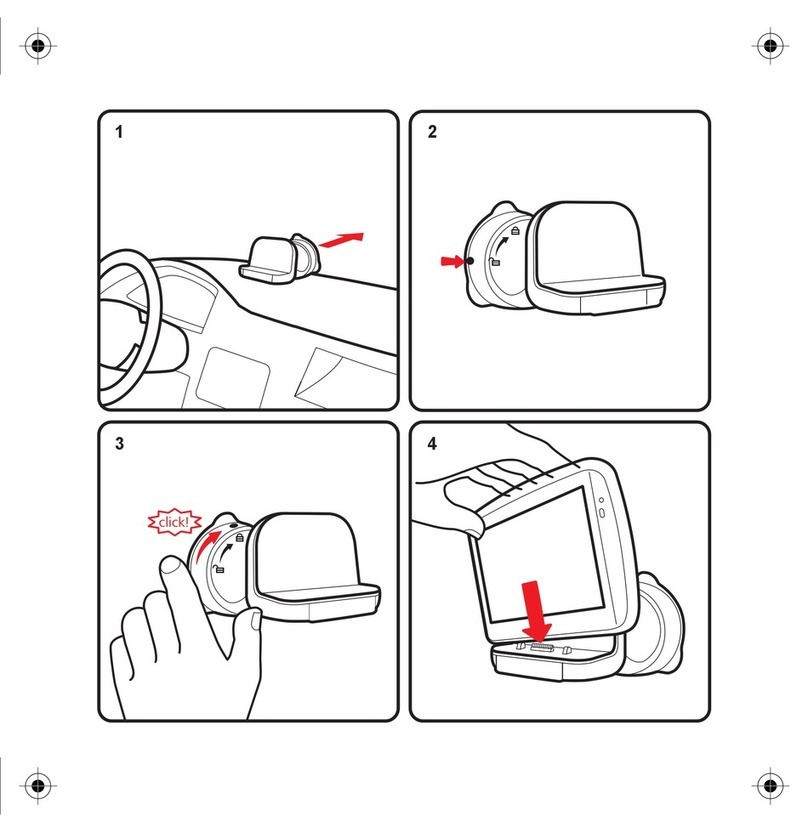

- Mounting recommendations

The unit should be placed in an area where there are no disturbing elements (i. e. metal) over or besides the unit. The unit has built-in

antennas, which makes the location of the unit important for achieving good coverage to the sky.

The unit should be mounted as horizontal as possible, do not tilt the device more than 30 degrees, to ensure proper operation.

The unit needs an undisturbed view to the sky for full functionality and connectivity.

Fasten the unit firmly using cable ties in the dedicated holes on the unit’s enclosure. Make the machine powerless by disconnecting the

battery before connecting the unit to the machine.

Note if the main power switch is placed on the battery's negative side or the positive side.

Page 2 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- Main power switch on negative side

The following scenario must be used if the machine's main power switch is located on

the negative battery side.

- Installation for collecting positioning and production data

This scenario should be used when the unit shall collect the machine's running and

production hours, and alarms. When the main switch is turned off the unit has limited

possibility to send data. The unit is equipped with a back-up battery, fully charged and in good condition it can send positions for some

hours after the main power switch is turned off. In this scenario, the unit draws no power from the battery when the main power switch is

turned off.

●Red wire connects to battery + at a suitable location. Use a 2 or 3 A fuse to protect the unit. The power must be constant when

machine is running

●Black wire is connected to ground. NOTE! Shall not be installed before the machine's main power switch!

●Yellow wire is connected to the signal when the engine is turned on, such as the ignition. The signal should be 7.5-30 VDC.

●Optional, White/Green wire is connected to the signal that is high when the machine produces. The signal should be 2.5-30 VDC.

●Optional, White wire is connected to the alarm (2.5-30 VDC).

●The other wires are used for TelliQ accessories.

Page 3 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- Installation with relay to collect production data and constant positioning

This scenario should be used when the unit shall collect the machine's running and production hours, and alarms. This scenario also

supports constant positioning, which means that the device can send in position after the main switch has been turned off.

This is done by connecting the digital inputs (running hours, production hours and alarms) through relays that break when the main power

switch is turned off. The relay should be NO (normally opened) or alternating 1 pole (12-24VDC).

Suitable relays can be ordered from TelliQ AB.

NOTE! If the unit is installed as described below without relay, running and production hours will be counted when the main switch is off

and provide incorrect data in the TelliQ system and increase the power consumption of the machine's battery.

●Red wire connects to battery + at a suitable location. Use a 2 or 3 A fuse to protect the unit. The power must be constant when

machine is running

●Black wire connected to battery - not chassis GND.

●Yellow wire is connected to the signal when the engine is switched on (hour counter), such as the ignition by relay as shown in the

picture below. The signal should be 7.5-30 VDC.

●Optional, White/Green wire is connected to the signal that is high when the machine produces. The signal should be 2.5-30 VDC.

●Optional, White wire is connected to the alarm (2.5-30 VDC).

●The other wires are used for TelliQ accessories.

NOTE! The unit consumes < 6mA when the machine is not in use

Page 4 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- Main power switch on positive side

The following scenario is used when the main power switch is located on

the battery positive side.

- Installation for collecting production data and constant positioning

This scenario should be used when the unit shall collect the machine's running and production hours, and alarms. This scenario also

supports constant positioning, which means that the device can send in position after the main switch has been turned off.

●Red wire connects to battery + at a suitable location, before the main switch. Use a 2 or 3 A fuse to protect the unit. The power must

be constant when machine is running

●Black wire is connected to ground.

●Yellow wire is connected to the signal when the engine is turned on, such as the ignition. The signal should be 7.5-30 VDC.

●Optional, White/Green wire is connected to the signal that is high when the machine produces. The signal should be 2.5-30 VDC.

●Optional, White wire is connected to the alarm (2.5-30 VDC).

●The other wires are used for TelliQ accessories.

NOTE! The unit consumes < 6mA when the machine is not in use

Page 5 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- Installation for collecting positioning and production data

This scenario should be used when the unit shall collect the machine's running and production hours, and alarms. When the main switch is

turned off the unit has limited possibility to send data. The unit is equipped with a back-up battery, fully charged and in good condition it

can send positions for some hours after the main power switch is turned off. In this scenario, the unit draws no power from the battery

when the main power switch is turned off.

●Red wire connects to battery + at a suitable location, after the main switch. Use a 2 or 3 A fuse to protect the unit. The power must be

constant when machine is running

●Black wire is connected to ground.

●Yellow wire is connected to the signal when the engine is turned on, such as the ignition. The signal should be 7.5-30 VDC.

●Optional, White/Green wire is connected to the signal that is high when the machine produces. The signal should be 2.5-30 VDC.

●Optional, White wire is connected to the alarm (2.5-30 VDC).

●The other wires are used for TelliQ accessories.

Page 6 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- RFID installation (Optional)

RFID cable wiring:

Wire color Description Connects to

YELLOW VCC Battery + 10-30 VDC

BLACK GND Battery - (ground)

WHITE 1WIRE DATA TQ12 GREEN

BROWN Red LED TQ12 VIOLET

GREEN Green LED N/A in standard application

- GNSS and connectivity

On the opposite side of the cable there are two LED indicators, marked with "Navigate" and "Status". See how the status is read below:

Navigate LED

Status LED

Behavior

Description

Behavior

Description

Permanently on

No GPS fix

Blinking every second

Normal mode

Blinking every second

Normal mode, GPS is working

Blinking every two seconds

Deep sleep mode

Off

Causes:

Blinking fast for a short time

Modem activity

Unit is powerless

Blinking fast constantly

Unit is booting

Unit is in deep sleep mode

Off

Causes:

GNSS module is short circuited

Unit is powerless

Device is not working or

Unit firmware is being flashed

It can take up to 5 minutes before the unit has a connection to the TelliQ Back Office.

- Function control

If all steps above have been completed, wait at least 5 minutes then contact TelliQ Customer Center. Prepare by getting the machines

current running hours, the TQ12 IMEI number, vehicle manufacturer and an identification name/number of the machine before contacting

TelliQ Customer Center.

- Support/Back office

TelliQ Support is to be contacted after each installation. This is making a functionality check and to configure the machine correctly in the

TelliQ web-system. The support can also be contacted if something is missing in the delivery or for help with installation on telephone

The Support is open between 08:00-17:00 CET

Please visit www.telliq.com for more information.

Page 7 (8)

Mounting instructions for TQ12 ver 2 Production tracker

- Technical information

Main cable wiring:

Wire color Description Connects to

RED VCC Battery + 10-30 VDC

BLACK GND Battery - (ground)

YELLOW DIN1 Engine signal + 7,5-30 VDC, can also connect to ignition

WHITE/GREEN DIN2 Optional connection to producing signal + 2,5-30 VDC

WHITE DIN3 Optional connection to detect alarms, + 2,5-30 VDC

GREY AIN1 N/A in standard application

WHITE/ORANGE DOUT1 N/A in standard application

VIOLET DOUT2 N/A in standard application

GREEN 1WIRE DATA N/A in standard application

BLUE 1WIRE POWER N/A in standard application

GSM - Quad-band module with internal antenna

GNSS - 50 channel receiver with internal antenna

Power supply: 6 - 30 VDC Operational temperature: -25C - +55C

2W Max Storage temperature : -40C - +70C

Power consumption: 207 mA MAX Storage relative humidity: 5 – 95%

Normal 27,3 mA

Backup battery: NiMH 400 mAh

If the machine will not be used for a long time, we recommend that the battery is disconnected to not affect

the battery life time or cause starting problems.

Page 8 (8)

Table of contents