Telme GEL 20 User manual

Z15.013

0198 V02 ING GEL

OPERATING INSTRUCTIONS

GEL 20

Ice cream freezer

English

Ice cream freezer

2

3

Dear customer,

we congratulate you for choosing a high quality product

which will surely satisfy your expectations.

With our thanks for choosing us,

we kindly invite you to examine the present operating

instructions manual before operating your new device.

SUMMARY

WARNING:

GENERAL/MECHANICAL DANGEROUS

DANGER VOLTAGE

A TEXT IN UPPER-CASE, IDENTIFIED BY ONE OF THE SYMBOLS ABOVE, CONTAINS INSTRUC-

TIONS THAT, IF NOT FOLLOWED, MAY CAUSE HARM TO PEOPLE.

A text in lower-case, identified by this symbol, contains instructions that, if not followed, could cause

damages or malfunctions to the device, or falls in its quality.

1 IMPORTANT SAFETY SUGGESTIONS AND

PRECAUTIONS ...................................................... 4

2 SAFETY DEVICES ................................................. 5

2.1 Lid's magnetic sensor ..................................... 5

2.2 Extraction door's grill ....................................... 5

3 TECHNICAL DATA ................................................. 6

3.1 Technical data plate and EC marking .............. 6

3.2 Acoustic pressure level ................................... 6

4 CARRYING AND UNPACKING .............................. 6

4.1 Transportation of the packed machine

(floor models) .................................................. 7

4.2 Unpacking ...................................................... 7

5 INSTALLATION ...................................................... 8

5.1 Placing and check of the parts ....................... 8

5.2 Machine’s parts reassembling ......................... 8

5.3 Electrical connection ...................................... 9

5.4 Initial functional test ...................................... 10

6 MACHINE’S OPERATION ..................................... 11

6.1 Warnings ....................................................... 11

6.2 Controls and indicators .................................. 11

6.3 Production .................................................... 12

7 WASHING AND SANITIZING ............................... 14

7.1 Rinse only ..................................................... 14

7.2 Disassembling of the parts ............................ 15

7.3 Washing ....................................................... 15

7.4 Reassembly .................................................. 16

7.5 Adjusting blades ............................................ 17

7.6 Sanitization ................................................... 17

8 MAINTENANCE .................................................... 17

8.1 Maintenance during the components

disassembling ............................................... 18

8.2 Check of safety devices ............................... 18

8.3 Yearly maintenance ...................................... 18

9 PERIODS OF INACTIVITY ................................... 19

10 MALFUNCTIONS ................................................. 19

English

Ice cream freezer

4

1IMPORTANT SAFETY SUGGESTIONS AND PRECAUTIONS

CAREFULLY READ THE INSTRUCTIONS CONTAINED IN THE PRESENT OPERATING

INSTRUCTIONS MANUAL BEFORE INSTALLING AND OPERATING THIS MACHINE. THESE

INSTRUCTIONS HAVE BEEN DRAFTED FOR THE SAFETY OF INSTALLATION, OPERATION AND

MAINTENANCE OF THIS MACHINE.

»–› The present manual of Operating Instructions, placed on the machine in the packing and supplied with the Technical

Handbook, the EC’s conformity certification and the electrical tests schedule, is an essential part of the ice-cream

freezer (also referred to as, in the present manual of operating instructions, simply with the term, machine) and must

be preserved for any future consultation.

»–› The Technical Handbook must always be given, together with the machine, to the Assistance Service’s personnel or to

the technicians to whom you will eventually request assistance.

»–› In case of selling or transferring to other user, all the above mentioned documentation must be handed to the new user,

so that he can be informed of the operation and relative technical information and safety instructions.

ALWAYS STOP THE MACHINE BY TURNING THE BEATER'S

SWITCH [24] (AS SHOWN) BEFORE INTRODUCING YOUR

HANDS OR ANY OBJECT INSIDE THE REFRIGERATING CYLIN-

DER.

DONOT INSERT YOUR FINGERS OR ANY OBJECT THROUGH

THE GRILLS, LOOPHOLES OR DRAIN HOLES.

DONOT REMOVE OR HIDE, FOR ANY REASON, ANY LABEL APPLIED ON THE MACHINE.

NEVER OPEN THE PROTECTING PANELS. THE MACHINE DOES NOT CONTAIN, IN ITS INSIDE,

PARTS WHICH CAN BE OPERATED BY THE USER.

THE USER MUST NOT EXECUTE OPERATIONS WHICH ARE NOT CLEARLY CONTAINED IN THE

PRESENT USER’SMANUAL. ANY OPERATION WHICH REQUIRES TOOLS NOT GIVEN IN THE

MACHINE’SEQUIPMENT IS TO BE CARRIED OUT ONLY BY THE ASSISTANCE SERVICE OR BY

TECHNICALLY AUTHORISED PERSONNEL.

»–› Always turn power supply off before undertaking any operation requiring access to the machine’s moving parts

(beater, cylinder or extracting door).

»–› Any modifying of the electrical supply must be exclusively performed by professionally qualified and certified person-

nel.

»–› Any use of the machine that is not for the production of ice-cream, sorbet, ice-cream cake or crushed-ice, is to be

considered improper.

»–› The machine has been made to be operated by adults, prohibit children to play with it.

»–› Modifying, or attempting to modify this machine, can be dangerous and would void any type of warranty.

»–› Always use original spare parts.

It is important to adopt the following precautions to avoid damages at the cylinder, at the beater

or any other mechanical part:

• Do not drop them and do not expose them to bumps;

• do not operate the machine dry, with a bad quality mixture or in a quantity lower or higher to that recommended: while

inside the cylinder, the ice-cream lubricates the cylinder’s sides as well as cooling down the beater, thus stabilizing its

temperature;

English

Operating instructions

5

• The beater and the cylinder are have been assembled with precision: therefore they are sensitive to changes of

temperature, which could cause breakdowns or damages to the machine's mechanical parts due to thermal dilatation.

NEVER expose to abrupt temperature changes the parts subject to refrigeration: DO NOT pour water in the cylinder

immediately after ice-cream has been produced.

• For the above reason, in the event that you have turned on the refrigerator without inserting the beater in the cylinder

first, wait for the cylinder to reach room temperature, then proceed to install the beater.

»–› In the event of the use of the machine being no longer required, deactivate the machine by severing the electric cable

(after unplugging it from wall socket). In addition, follow these recommendations:

- avoid dispersing the freezing gas and the oil contained in the machine;

- carry out the draining and/or recycling according to the local provisions of the law currently in force on this matter.

2SAFETY DEVICES

DONOT ALTER THE SAFETY DEVICES AND DO NOT UTILIZE THE MACHINE IF THE SAFETY

DEVICES ARE DAMAGED OR MALFUNCTIONING.

THE MANUFACTURER IS NOT RESPONSIBLE FOR POSSIBLE DAMAGES CAUSED TO PEOPLE

OR OBJECTS BY THE ALTERING OR BYPASSING SUCH DEVICES OR RELATIVE CIRCUITS.

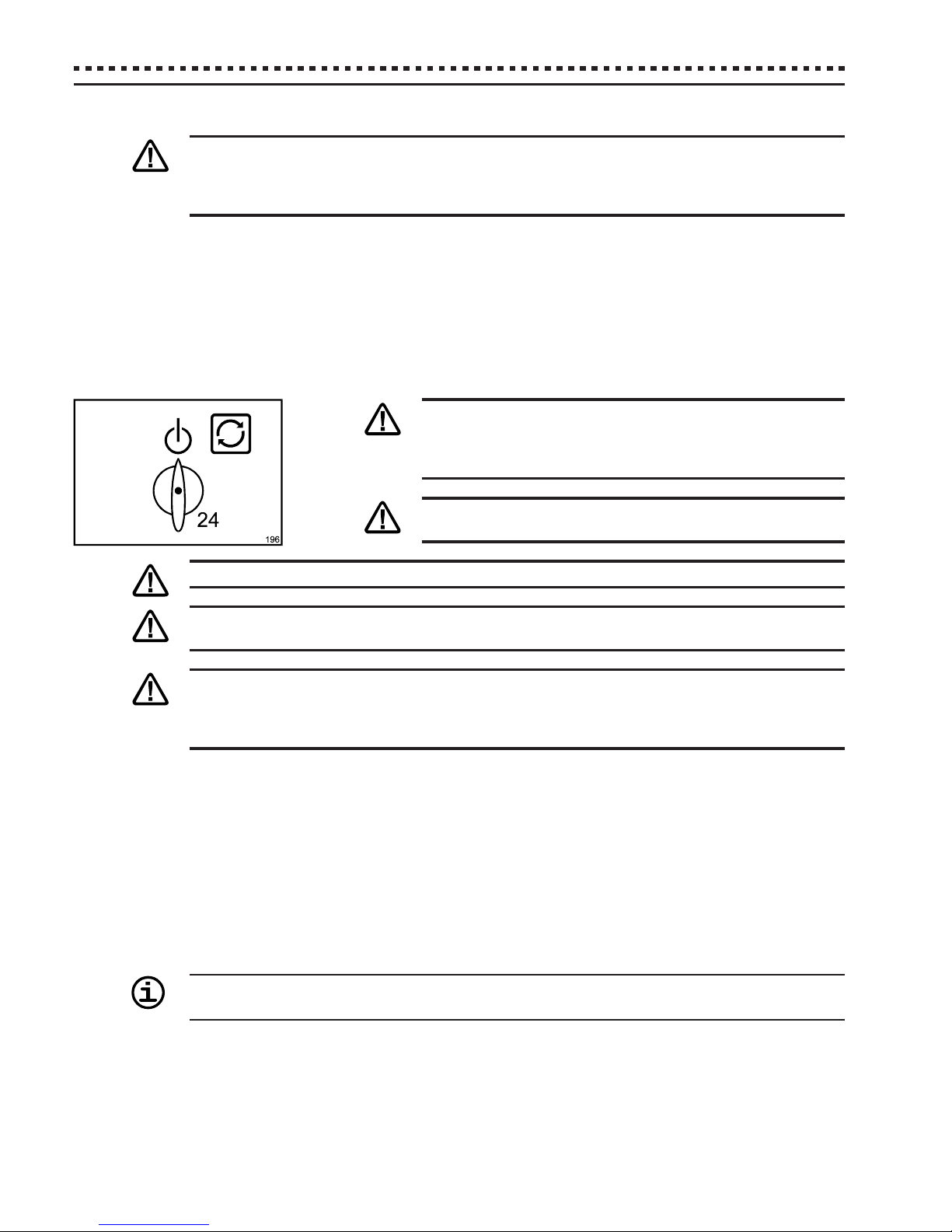

2.1 Lid's magnetic sensor

This safety device, featuring an approved type magnet [1] and a magnetic contact [2]

avoids accidents caused by the accidental starting of the beater when the lid is open.

In consequence the device can't operate when the lid is open, and if it is opened

during its functioning the beater immediately stops.

In any case the lid's magnetic sensor MUST NOT be considered a control to be used

for the normal stop of the device.

DURING THE NORMAL USE, THE DEVICE MUST BE STOPPED ONLY

BY USING THE BUTTONS ON THE CONTROL KEYPAD, AND NOT BY

OPENING THE LID.

The magnet [1] and the magnetic contact [2] must be assembled as follows: the grooves [3] and the stencilled semicircle [5]

on the bottom of the magnet [1] must coincide with the grooves [4] (marked by a white line down the side) and the stencilled

semicircle [6] on top of the magnetic contact [2]. The device will not work unless all parts have been correctly

assembled in accordance with these instructions.

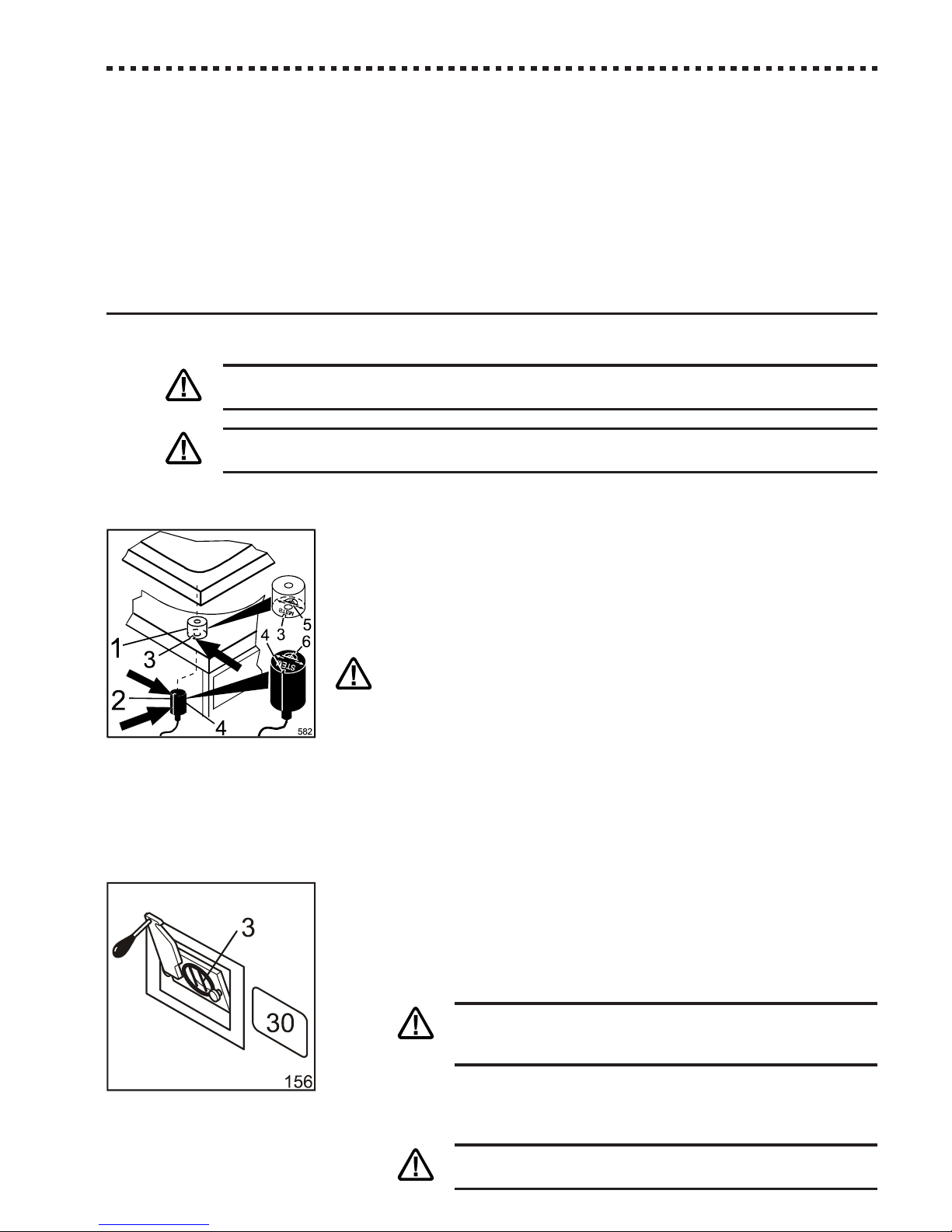

2.2 Extraction door's grill

In large-sized models, supplied with extraction door, a fixed protection grill [3] prevents,

as far as possible, fingers or objects from being ACCIDENTALLY inserted in the chute.

In order to insure normal operation it is not possible to adjust the fixed grill as to prevent

fingers and objects from being VOLUNTARILY inserted through the extraction chute

(according to Machines Directive 89/392/CEE and ensuing modifications, Appendix

I, Art. 1.1.2.b, 3rd paragraph).

RESIDUAL HAZARD: DONOT FOR ANY REASON INSERT

FINGERS OR OBJECTS THROUGH THE GRILL OF THE

EXTRACTION DOOR WHEN THE MACHINE IS IN FUNCTION.

The user is warned of the above RESIDUAL HAZARD (89/392/CEE and ensuing

modifications, Appendix. 1, Art. 1.1.2.b, 3rd paragraph and 1.7.2) by a plate [30]

affixed next to the extraction chute.

DONOT HANDLE OR REMOVE THE GRILL [3] FROM ITS SET-

TING IN THE EXTRACTION DOOR!

English

Ice cream freezer

6

3TECHNICAL DATA

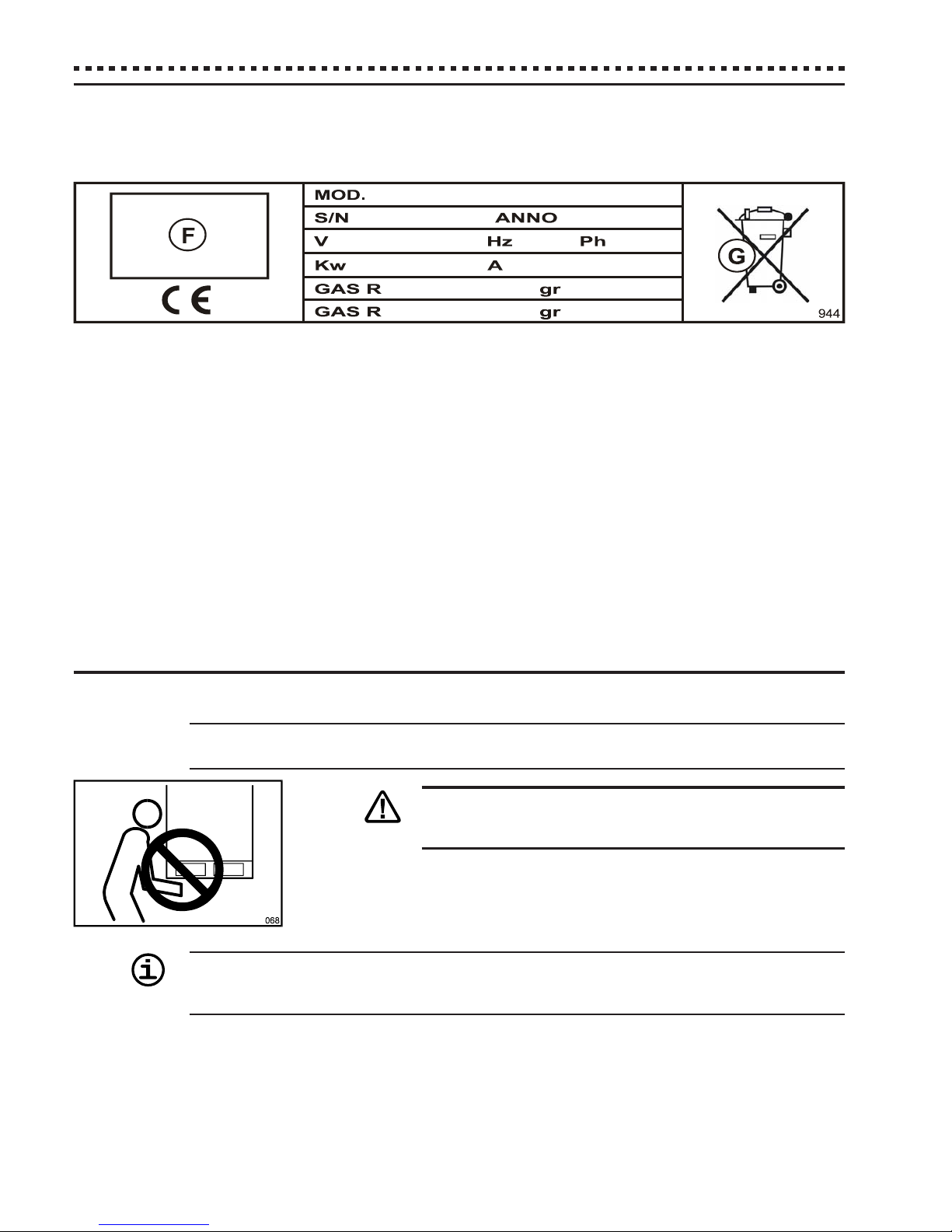

3.1 Technical data plate and EC marking

The technical data plate and CE marking must not be removed. It is located on the back part of the device and identifies:

- the name and address of the manufacturer [F];

- the designation of the model [MOD] and the relative series number [S/N];

- the type and quantity of freezing gas contained [GAS];

- the year of construction [ANNO];

- the values of voltage and frequency [V], and the power [Hz] and current [Ph] consumption;

- the CE marking [9];

- dismantle symbol [G];

3.2 Acoustic pressure level

The average equivalent continuous acoustic pressure level of this machine is quoted in the Technical Handbook (Technical

Data section). This data has been measured at 1 meter from the surface of the machine and at 1.60 meters from ground-

level, during the machine’s functioning.

4CARRYING AND UNPACKING

Note: We suggest you to let the Assistance Service or qualified technicians carry out the transportation,

unpacking and installation.

TOLIFT THE MACHINE ALWAYS USE AN ADEQUATE LIFTING

DEVICE. ATTEMPTING TO LIFT IT MANUALLY IS DANGEROUS

AND CAN DAMAGE YOUR HEALTH.

The machine’s weight specifications, both inclusive of packaging and net, can be

found in both the supplied documents and on the packaging itself.

To prevent the oil contained in the compressor to flow into the refrigerating circuit, it is neces-

sary to always keep the machine in upright position, both during carrying and during the instal-

lation and operation. Always follow the instructions on the packing.

English

Operating instructions

7

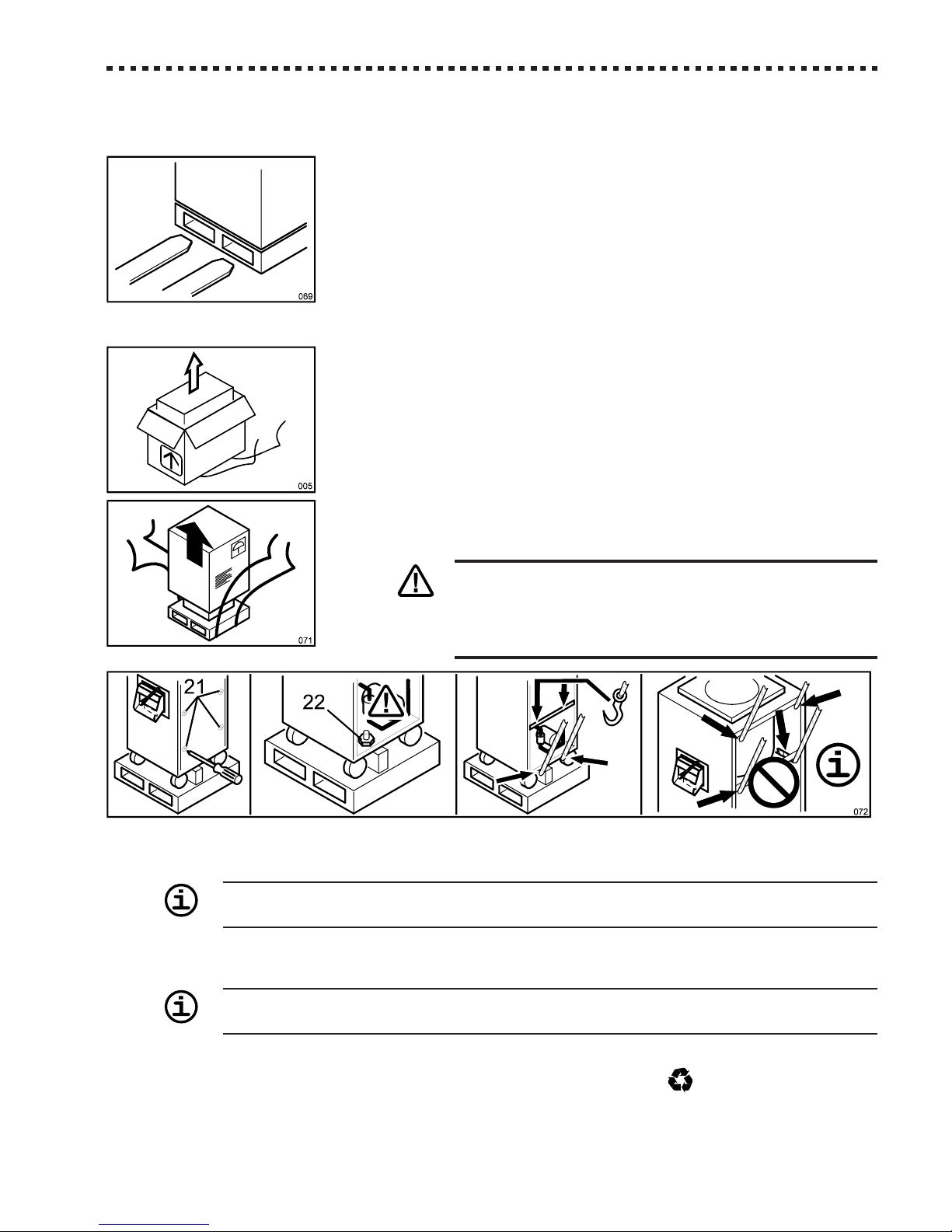

4.1 Transportation of the packed machine

(floor models)

The packing has been projected to assure at the machine the highest protection.

It is therefore suggested to transport the machine while it is packed as near as possible

at the place where it will be installed.

To carry the packed machine, use an elevator, or a bench trolley, inserting its forks in

the basement’s holes.

4.2 Unpacking

Unpack the machine and carefully check it. In case of doubt, do not use it, and call the

Seller.

Bench top models:

- cut holding straps, open box from the top, remove protection packaging material

and remove machine from the box.

Floor models:

- cut the straps and remove the cardboard box from the top;

THE OPENING OF THE LATERAL PANEL IS ONLY ALLOWED

TO THE ASSISTANCE SERVICE OR TO QUALIFIED

TECHNICIANS AND MUST BE MADE BEFORE CONNECTING

IT. MAKE SURE NOT TO DAMAGE THE INTERNAL PARTS OF

THE MACHINE.

- Remove both the lateral panels unscrewing the relevant fixing screws [21];

- Find and unscrew the bolts [22] which fix the machine’s frame at the packing’s basement;

The outlet of the supply cable is placed on the machine’s lower side. During the lifting make sure

not to damage it.

- Lift the machine from the basement, possibly working on the lower side, near the wheels, and however, only on the

frame’s carrying parts. Remove the basement, and lean the machine on the floor avoiding bumps;

DO NOT insert objects, ropes or brackets for the lifting THROUGH the machine, since these

could damage the inside parts.

- Re-close the lateral panels;

- Replace or move the packing, which is produced with entirely recyclable materials ( ).

English

Ice cream freezer

8

5INSTALLATION

THE INSTALLATION MUST BE CARRIED OUT ONLY BY THE ASSISTANCE SERVICE OR BY TECH-

NICALLY AUTHORISED PERSONNEL AND IN COMPLIANCE WITH THE LAWS IN FORCE, ALWAYS

FOLLOWING INSTRUCTIONS OF THE MANUFACTURER.

5.1 Placing and check of the parts

Place the machine on a flat and steady surface.

Install the machine away from any source of heat, avoiding a direct exposition to sun

radiation and making sure that air can freely circulate around each side of the ma-

chine itself.

The machines with AIR CONDENSING need at least a 50 cm

free space in front of the condenser’s grill, to assure the re-

frigerating plant correct functioning. Further information are

reported on the Technical Book (Technical Data section).

Check that the following items are all included in the package:

- lid [5];

- beater [6], correctly fixed inside the cylinder with its knob [7] and supplied with adjustable blades [31] (1…3 according

to the model);

- drain plug [4] (not in large-sized models which are supplied with extraction door [14]);

Also check that the following items are included:

- spare part kit [11], tube-brush [12] and ice-cream blade [13];

- only in large-sized models, basin support [10], knobs [16], the lever [8] and the extraction door chute [9];

- all the technical documentation (in addition to this handbook): the Technical Handbook, the EC’s Conformity Certifi-

cation and Electrical Test’s Schedule.

5.2 Machine’s parts reassembling

THE REASSEMBLING MUST BE MADE BEFORE CONNECTING THE MACHINE TO THE

ELECTRICAL SUPPLY SYSTEM.

- Screw the lever [8] in the extraction door [14];

- if the chute [9] is supplied disassembled, install it under the extraction door [14] by hooking it to the hinges [26];

- install the basin support [10] by fixing it to the front panel with knobs [16].

English

Operating instructions

9

5.3 Electrical connection

THE SUPPLY’SVOLTAGE REQUIRED BY THE MACHINE IS HIGH, SO, IT IS PARTICULARLY DAN-

GEROUS. THE WORKS ON THE SUPPLY’SELECTRICAL CIRCUITS MUST BE MADE

WORKMANLIKE BY QUALIFIED STAFF.

THE ELECTRICAL SAFETY OF THIS MACHINE IS REACHED

ONLY WHEN THE SAME IS CORRECTLY CONNECTED, BY

QUALIFIED AND CERTIFIED PERSONNEL, TO AN EFFICIENT

EARTHING SYSTEM, MADE AS PROVIDED FOR IN FORCE

SAFETY REGULATIONS.

The manufacturer must not be considered responsible for eventual damages

caused by an inadequate electric plant or earthing.

All the machine’s electrical features required for the system’s proportioning are re-

ported on the Technical Data Plate and on the Technical Handbook.

FOR THE PREPARATION OF THE ELECTRICAL PLANT WHICH

SUPPLIES THE MACHINE, IT IS COMPULSORY TO FOLLOW

THE PRESCRIPTIVE STANDARDS IN FORCE. IN PARTICULAR:

- The electrical capacity of the plant must exactly match the supply’s voltage and frequency required by the machine;

- the current capacity of the plant must be suitable for the machine’s input;

- the plant must end with a standard socket (3-pole socket for monophasic 1N input and 5-pole socket for triphasic 3N –

3F input) with electrical and mechanical suitable characteristics. The electrical socket’s poles must be marked with

appropriate letters (phase R or phases R-S-T + neutral N + earth); the earth pole must be properly recognizable;

- the electrical socket must prevent, through appropriate mechanical measures, the plug’s wrong connection;

- the electrical socket must have, above or annexed, a knife switch, conformed to the in force safety laws, with an

associated safety breaker positioned near the machine, in a place easily reachable by the operator. It must also be

protected by fuses, above or annexed, with characteristics suited at the current absorbed by the machine.

A WRONG CONNECTION ON THE EARTH TERMINAL MAY CAUSE SERIOUS DANGER.

A plug (3-pole plug for monophasic 1N input and 5-pole plug for triphasic 3N – 3F

input) must be connected to the end of the input cable. This must be suited to the power

supply socket.

The machine’s power supply cable is composed by coloured wires, and eventually

marked with appropriate bands, which must be connected to the relevant plug’s termi-

nals, as shown in the following table.

FAULTY WIRING INSIDE THE PLUG MAY BE DANGEROUS

AND CAUSE DAMAGE TO THE MACHINE. FOR THE

CONNECTION, ONLY ADDRESS YOURSELVES TO QUALIFIED

AND AUTHORIZED TECHNICIANS.

Kind Wire Wire marking band Code marked near

of supply colour (only 3N – 3F) plug’s terminal

EARTH GREEN/YELLOW None PE or

Phase R (3N – 3F) BLACK R or L1

Phase S (3N – 3F) BROWN S or L2

Phase T (3N – 3F) BLACK T or L3

NEUTRAL BRIGHT or SKY BLUE N

Phase (1N) BROWN — L

Before operating machine the initial functional test is required (ref. Par. 5.4).

English

Ice cream freezer

10

5.4 Initial functional test

At the end of the installation, and before utilising the machine, it is indispensable to let a qualified

technician check the correct connection, by performing the following procedure.

- Before starting, check that the socket's Main Switch is in the position “0”;

- check that Beater's Switch [24] on the machine is in the STOP position (centre) and that Principal Switch [23] (if

applicable) is on OFF position;

- plug in and turn socket's Main Switch to position “1”;

- turn Principal Switch [23] (if applicable) to ON position: its indicator lamp should light up;

Remove the beater from the cylinder before carrying on the check, to avoid letting it function

dry. ATTENTION: Follow the directions reported on Par. 7.2 - Disassembly of parts.

ALWAYS STOP THE MACHINE BY TURNING THE BEATER'SSWITCH [24] BEFORE INTRODUCING

YOUR HANDS OR ANY OBJECT INSIDE THE REFRIGERATING CYLINDER.

- Open the lid, unscrew the fixing knob [7], pull out the beater [6] from the cylinder, then close the lid.

Note: large-sized models do not operate when tie lid is open.

- turn Beater's Switch [24] to BEATING position and check beater's shaft by looking through the lid. If it turns

CLOCKWISE the machine is correctly connected and ready to be used;

Note: do not unnecessarily start the refrigerator.

- TRIPHASIC INPUT MODELS ONLY: If the rotation is COUNTERCLOCKWISE, the connection to the triphase

power supply is wrong, and must be changed proceeding as follows:

- stop machine by turning Beater's Switch [24] to STOP position (centre) and

turn Principal Switch [23] to OFF;

TURN THE SOCKET’SBREAKER TO THE “0” POSITION, THEN

UNPLUG MACHINE;

- Open the plug’s shell and invert TWO of the THREE conductors connected at the

phases (R-S, R-T or S-T);

- Close the plug’s shell, plug in the machine and repeat the test.

English

Operating instructions

11

6MACHINE’SOPERATION

6.1 Warnings

WHEN USING THE MACHINE, AS WITH ALL ELECTRICAL DEVICES, ESSENTIAL RULES MUST

BE COMPLIED WITH, PARTICULARLY:

- never touch it if your feet or hands are wet;

- never operate it while barefoot;

- never pull the supply cable to disconnect it from the mains network;

- avoid liquids to penetrate in the machine, for example during its cleaning;

- forbid children and unable people to operate it.

In case of failure and/or malfunctioning of the machine - and every time you notice damages, mainly at the supply cable or

at the safety devices - turn off the power supply. Contact qualified and certified personnel for assistance.

NEVER operate the machine in DRY conditions or with an amount of mixture other than the one

recommended.

NOT RESPECTING THESE RULES, IN ADDITION TO VOIDING ANY FORM OF WARRANTY, CAN

SERIOUSLY COMPROMISE THE SAFETY, PERFORMANCES AND FUNCTIONING OF THE SAME

MACHINE.

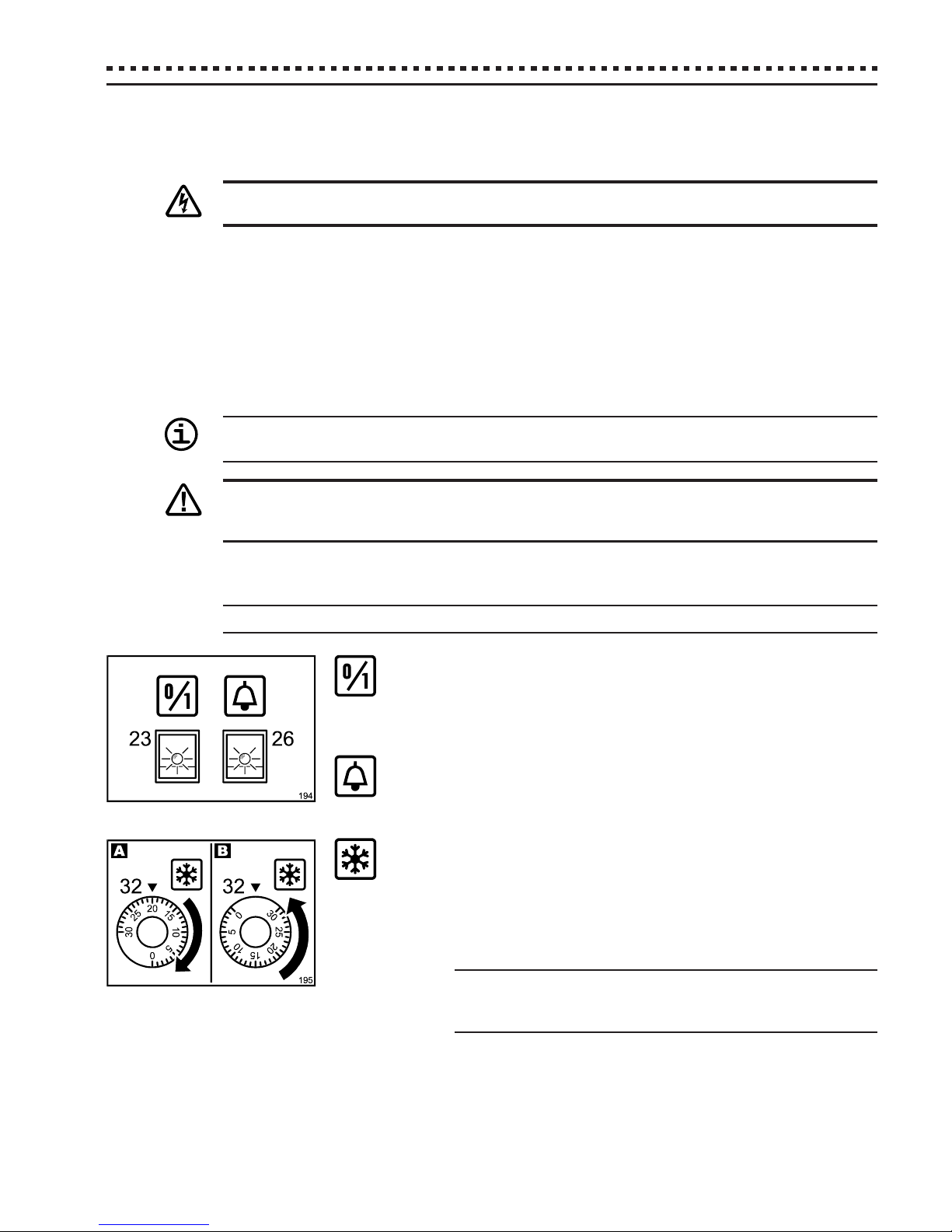

6.2 Controls and indicators

Note: Those controls and functions with [X] next to them, may not be available on small-sized models.

[X] Principal Switch [23]

When ON, machine is ready to operate: indicator light goes on and controls are ena-

bled.

[X] Bell switch [26]

When ON, indicator light goes on and end-of-refrigeration alarm is enabled.

Refrigeration Timer [32]

By turning knob CLOCKWISE [A] refrigerating system is activated for the required

time. The knob turns backwards to starting position showing remaining refrigerating

time. The knob can also be manually turned in both directions in order to reduce or

increase refrigerating time or to switch refrigerator off [B].

Note: It is recommended to set refrigerating time as soon as beater is

operating, usually 10…20 minutes according to machine model,

mixture type and quantity.

English

Ice cream freezer

12

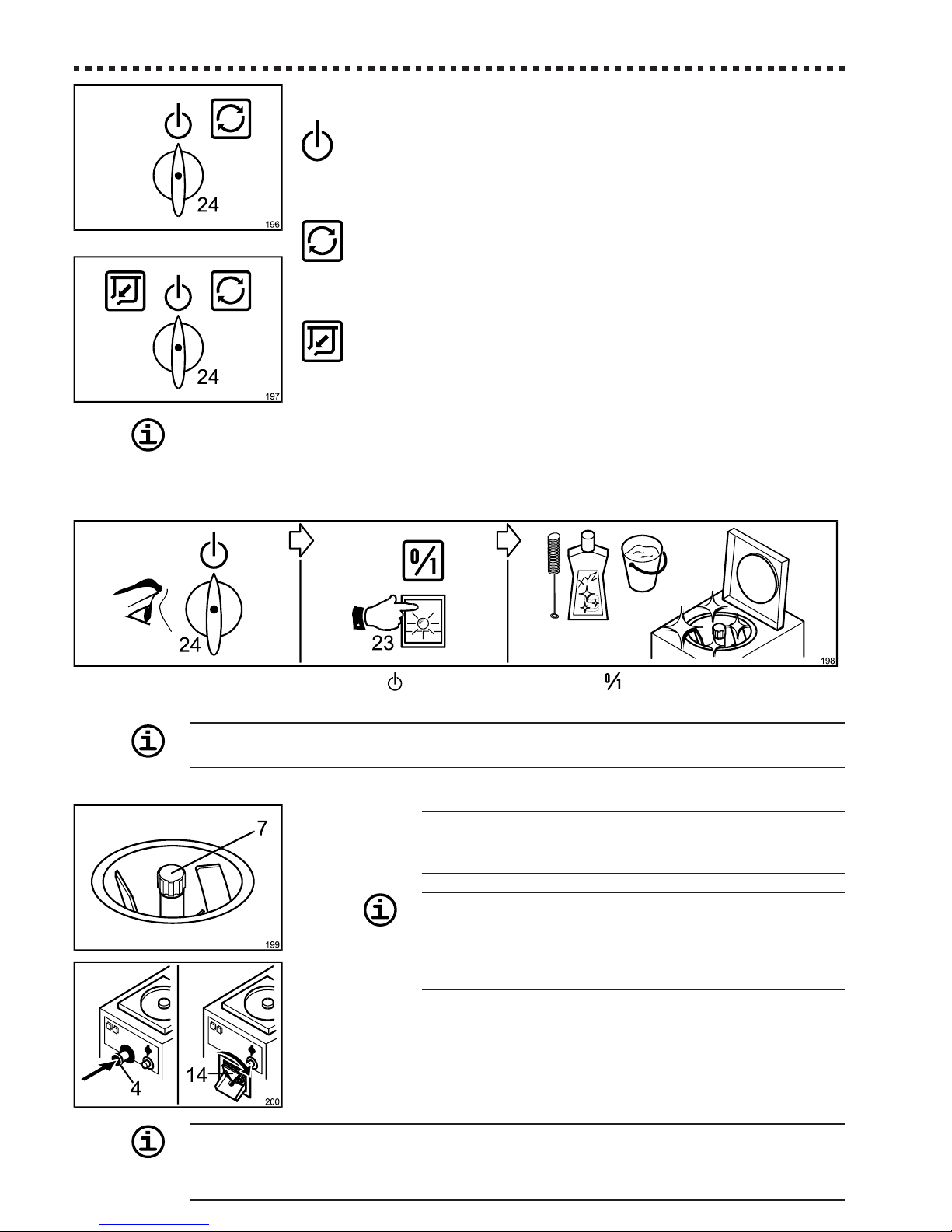

Beater's Switch [24]

STOP position (centre)

When knob is in the above position, the beater is not moving and the refrigerator is off,

independently from the Timer.

BEATING position (right)

By turning the knob to the above position the beater starts rotating clockwise and, when

setting refrigerating time, the refrigerator turns on.

[X] EXTRACTION position (left)

This is only available on models supplied with extraction door. It allows the ice-cream to

come out from the door by quickly rotating the beater COUNTERCLOCKWISE.

To avoid excessive mechanical stress, before commanding the extraction, it is necessary to

OPEN THE EXTRACTION DOOR.

6.3 Production

- Check that Beater's Switch [24] is on STOP (centre). Turn Principal Switch [23] (if applicable) to turn machine

on;

Do not start beater before pouring any mixture in the cylinder. The beater must not operate in

dry conditions, to avoid damage.

- before starting production, the machine must be thoroughly cleaned and sanitized (see Section 7).

Note: if more than one consecutive production cycle is required, a rinse

between cycles is sufficient (ref. Par. 7.1), alternatively start with

light-coloured mixtures and conclude with dark-coloured mixtures.

Before operating beater, ALWAYS check that beater's fixing

knob [7] is FIRMLY TIGHTENED and the gasket is intact and

clear of any fat. Should the knob accidentally come loose and

fall into the cylinder while operating, this would cause serious

damage to the machine.

- check that drain plug [4] is firmly in place or extraction door [14] is firmly closed,

then pour mixture in the cylinder. Only use suitable, perfectly preserved mixtures

(for ice-cream, sorbet or crushed-ice) and in the correct amount. The maximum

and minimum amounts are indicated in the Technical Handbook, in the “Technical

Data” section.

Unsuitable mixture or insufficient amount of it can cause the formation of ice, and cause dam-

ages or irregular functioning at the cylinder and beater, while an excessive quantity of mixture

can forbid the correct whipping, in addition to causing an excessive stress at the motor and

beater and overflows of product.

English

Operating instructions

13

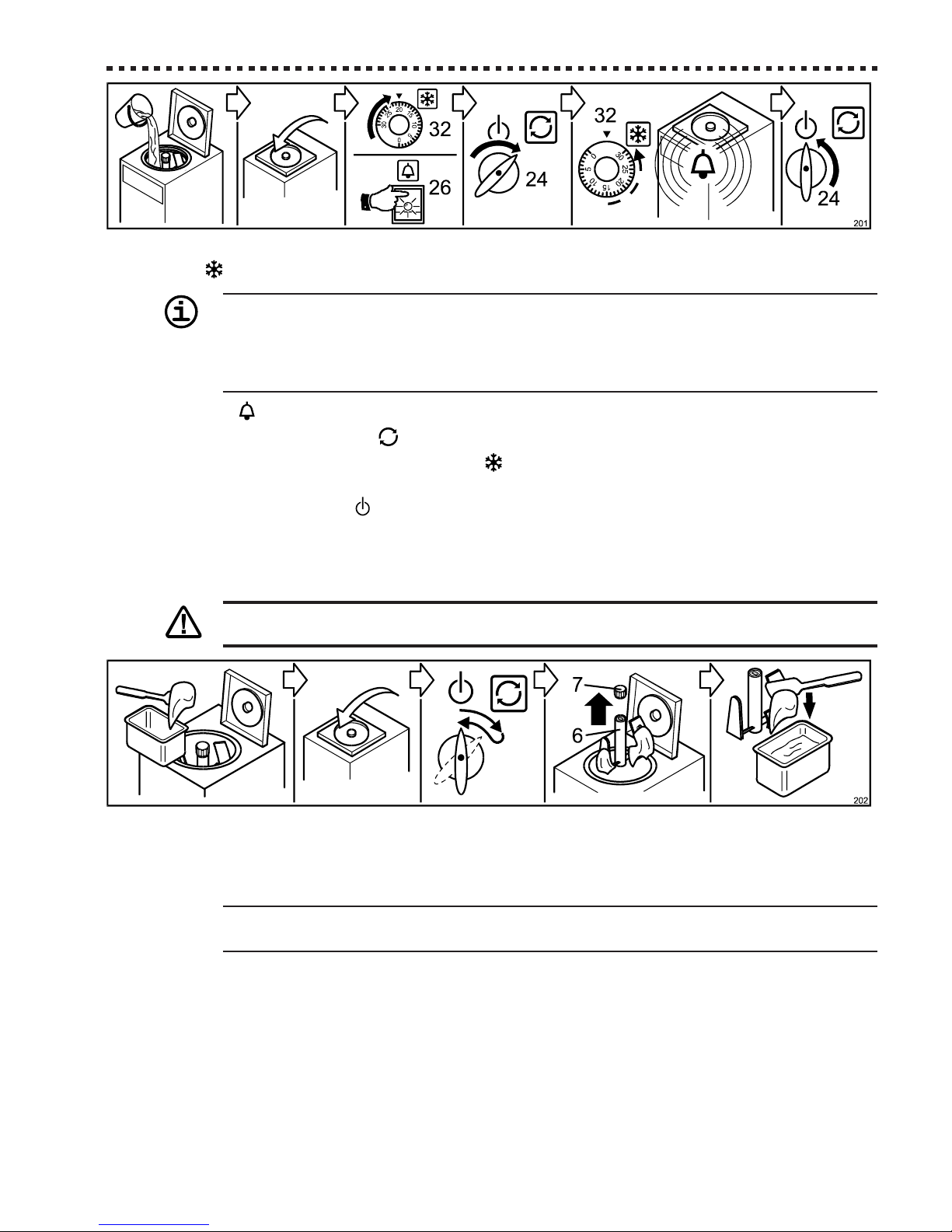

- close cylinder's lid;

- turn Timer [32] and read clock (in minute) to set refrigerating time according to mixture type and quantity;

The product's required thickness can be achieved by carrying out a few trial cycles. We suggest

to start with a short time (6…10 minutes) and to increase it by one minute at a time, according to

machine model, mixture type and quantity to be whipped. It is important to note that the first

production cycle will require 1…2 minutes longer than the following cycles, the machine's parts

having been kept at room temperature.

- turn Bell Switch [26] to ON to activate alarm when whipping cycle is completed (indicator light will turn on);

- turn Beater's Switch [24] to BEATING (right);

- wait for completion of cycle, which is when Timer knob [32] is again on starting position and the alarm rings (when

available);

- turn Beater's Switch [24] to STOP (centre).

At the end of the production cycle, the product is ready to be extracted:

Models WITHOUT extraction door:

ALWAYS STOP THE MACHINE BY TURNING THE BEATER'SSWITCH BEFORE INTRODUCING

YOUR HANDS OR ANY OBJECT INSIDE THE REFRIGERATING CYLINDER.

- open lid and remove as much as possible of the product using the supplied ice-cream blade;

- close the lid and spin beater for a short time: this will allow any remaining product to be collected on the beater's

blades. Open lid and remove as much as possible of the product. This can be repeated a few times, until cylinder is

completely empty.

Note: by opening the lid and unscrewing fixing knob [7], the beater [6] can be removed and the product wiped

from the blades.

English

Ice cream freezer

14

Models WITH extraction door:

- place a suitable basin on the basin support;

- FIRST completely open the door, THEN turn Beater's Switch [24] to EXTRACTION (left). Scoop product out into the

basin;

- stop beater by turning Switch [24] to STOP (centre);

- open lid and remove any ice-cream left on the beater's blades, this will be collected at the bottom of the cylinder;

- turn switch again to EXTRACTION as to eject any remaining product;

- if needed the above procedure can be repeated;

- stop beater and close extraction door.

FATS CONTAINED IN ICE-CREAM MIXTURES ARE POTENTIAL BACTERIA BREEDING GROUNDS.

ITIS RECOMMENDED, ON COMPLETION OF THE PRODUCTION CYCLE(S) TO THOROUGHLY

DISASSEMBLE, WASH AND SANITIZE ANY PARTS OF THE MACHINE WHICH COME INTO

CONTACT WITH THE PRODUCT.

7WASHING AND SANITIZING

7.1 Rinse only

To remove ice-cream residues of a dark colour or containing hard pieces such as dry fruit or granules a quick rinse

between cycles is available.

Wait the cylinder to reach the right temperature to avoid freezing rinsing water.

Note: During rinsing, the machine may make a louder noise. This is due to the lack of lubrication usually

provided by mixture or ice-cream.

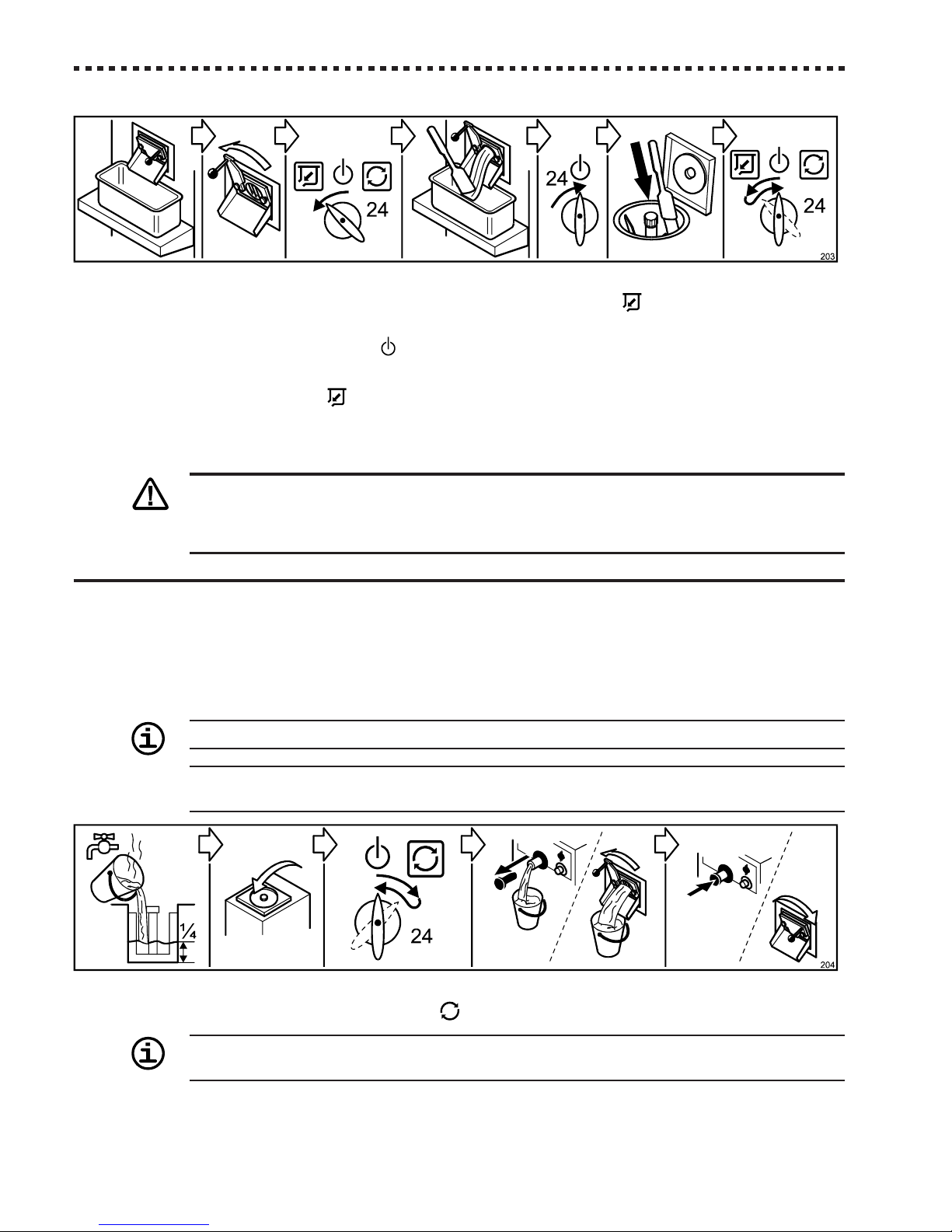

- pour warm water in the cylinder up to 1/4 of its capacity;

- close the lid and turn beater switch [24] to BEATING (right) spin for a short time;

Do not operate cylinder for long periods of time. Lack of lubrication usually provided by mixture

or ice-cream may damage either the beater or the cylinder.

English

Operating instructions

15

Check that Timer knob is turned counterclockwise (start-

ing position) to avoid starting refrigerator unnecessarily.

CAUTION: DO NOT TURN Beater Switch to EXTRACTION

(left) as this would cause water to be suddenly ejected out of

the cylinder.

- stop beater, put a container under the cylinder drain (or extraction door) and open

it to let water out of the cylinder.

7.2 Disassembling of the parts

To make washing and sanitization easier, all parts coming into contact with the product can be easily and quickly disassem-

bled directly by the user.

THESE OPERATIONS MUST BE CARRIED OUT ONLY AFTER DISCONNECTING MACHINE FROM

MAIN POWER!

- Carry out rinsing operations (ref. Par. 7.1) in order to easily reach machine's

parts;

- remove lid [5] (if necessary remove hinge pin [25]);

- remove drain plug [4];

- unscrew counterclockwise fixing knob [7] and remove beater [6];

RESIDUAL HAZARD: BEATER'SBLADE ARE SHARP ALONG

BOTTOM AND EXTERNAL SIDE EDGES. ITIS RECOMMENDED

TO USE SUITABLE PROTECTIVE GLOVES AND TO HANDLE

THE BEATER ONLY BY HOLDING THE CENTRAL HUB AND

NOT THE BLADES.

- remove basin support [10] (if applicable) by unscrewing knobs [16];

- unhook chute [9] (if applicable) from hinges [26] and remove it;

- for a thorough wash, separate blades [31] (take care not to loose screws).

7.3 Washing

THESE OPERATIONS MUST BE CARRIED OUT ONLY AFTER DISCONNECTING MACHINE FROM

MAIN POWER!

DONOT ALLOW WATER OR ANY OTHER LIQUID INSIDE THE

MACHINE.

TOCLEAN CONTROLS ON FRONT PANEL ONLY USE ADRY

CLOTH OR ONE SLIGHTLY DAMP WITH DETERGENT. NEVER

USE WATER OR ANY LIQUIDS!

All parts coming into contact with the product must be carefully washed and sanitized to comply with health regulations

currently in force.

English

Ice cream freezer

16

1) Separately wash all those parts which can be dismantled by the user following instructions in Par. 7.2. Only

use warm water and food compatible detergent, followed by a cool rinse.

Note: For a long life of the machine we suggest not to use too hot water, solvents, abrasive detergents, or

rough sponges, in particular on the plastic parts.

2) Thoroughly wash all those parts of the machine which are fixed:

- cylinder drain (or extraction door) using the supplied tube-brush;

- top and inside of the cylinder;

- front panel and its components, taking care as to avoid letting water into electric controls.

7.4 Reassembly

THESE OPERATIONS MUST BE CARRIED OUT ONLY AFTER DISCONNECTING MACHINE FROM

MAIN POWER!

- Assemble blades [31] on beater's supports [6] partially screwing screws [36].

Blades will be subsequently adjusted.

Carefully place beater into the cylinder, taking care to keep it

vertical without dropping it.

- The slot on the beater's hub [27] goes into the shaft clutch [28];

- FIRMLY tighten beater's fixing knob [7];

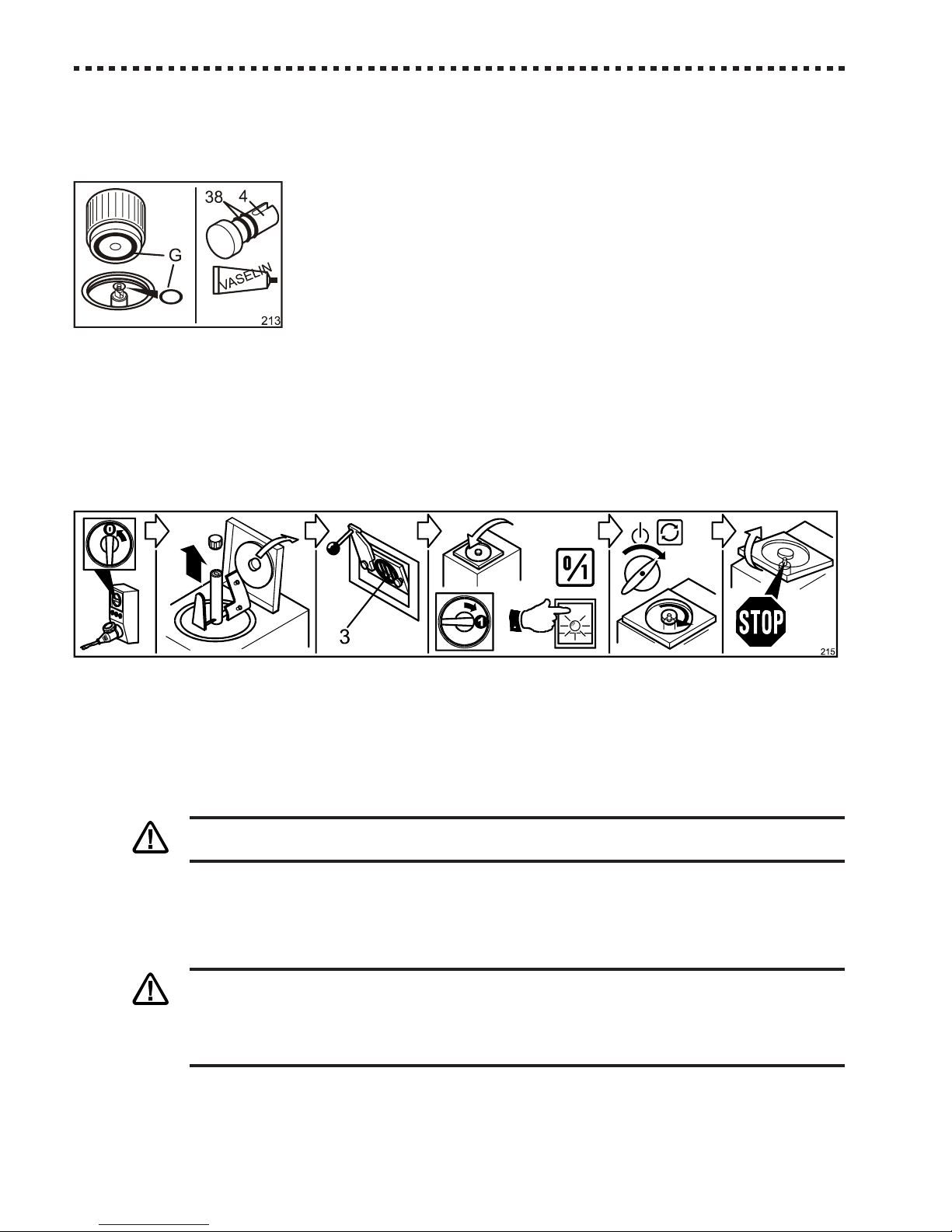

Before tightening knob [7], always check that the gasket [G] is

in perfect conditions and in place, an that is clear of any fat as

to prevent knob from accidentally coming loose. Should the

knob fall into the cylinder during production cycle, it would

cause serious damage to the machine.

Note: Gaskets must be periodically replaced (ref. Par. 8.1).

- put lid in place. If supplied with hinges, insert pin [25];

English

Operating instructions

17

Models WITHOUT extraction door:

- put drain plug [4] in. The slot [37] has to be facing downwards, otherwise the plug

will not go in. Should it prove hard to insert, lubricate gasket [38] with food compat-

ible lubricant;

Models WITH extraction door:

- fix chute [9] under the door [14] hooking it on hinges [26];

- fix basin support [10] on the front panel with knobs [16].

7.5 Adjusting blades

THESE OPERATIONS MUST BE CARRIED OUT ONLY AFTER DISCONNECTING MACHINE FROM

MAIN POWER!

Blades must be adjusted whenever they are replaced on the beater.

An incorrect or lack of adjustment of the blades could cause

the formation of ice on the cylinder inner walls, or excessive

wearing of the blades and mechanical stress of the beater.

- Once the beater is in place, push blade [31] outwards by hand so that scraping

edge is perfectly in line with and matches the cylinder inner surface. At the same

time, tighten fixing screws [36];

- in case of models supplied with more than one scraping blade, repeat operations

for all blades, placing them evenly.

7.6 Sanitization

Sanitization is an operation similar to rinsing (ref. Par. 7.1). However, this must to be carried out with a solution of warm

water and food compatible disinfectant.

To correctly dose, follow disinfectant's instruction for use. If required, in the final stage of sanitizing, rinse with water only.

On completion of sanitization, close lid and neither touch with your hands, nor wipe with cloths

or paper towels any part of the machine which will come into contact with food.

Check that there is no more water inside the cylinder. If needed, briefly spin the beater to drain any remaining water.

8MAINTENANCE

The machine requires a very limited maintenance. Periodically, we suggest to:

- check the good conditions of the machine's parts;

- check that electric power cable is not damaged;

- Try the efficiency of the safety devices (ref. Par. 8.2).

It is then useful to maintain the external panels clean and the surrounding area. Dust, paper fragments or other small objects

may penetrate in the machine through the ventilation loopholes (in particular if equipped with air condensation and rapidly

compromise its correct functioning.

The inside parts, to which the user MUST NOT accede, must be checked by the Assistance Service (ref. Par. 8.3)

English

Ice cream freezer

18

8.1 Maintenance during the components disassembling

Check the integrity of gaskets and substitute those that are deteriorated.

Use exclusively original, compatible with food, rubber gaskets. The spare bag contains a complete series of gaskets

approved by the manufacturer.

- To correctly replace the gaskets it is necessary to:

- remove the old gaskets by using a sharp tool, possibly non-metallic, paying atten-

tion not to scratch the seating of the gaskets themselves;

- clean the seatings and the gaskets [G] from any kind of grease before inserting

the new gaskets;

- LUBRICATE gaskets [38] and their seats in the drain plug [4] with food compatible

fat.

Check that the plastic blades' scraping edges do not show any dents, scratches or wear marks which cannot be mended by

adjusting. Should this be the case, replace blades.

A yearly preventive replacement of all wearing parts and all gaskets is recommended. We suggest you to always keep a

spare supply: to order it, reference to the Spares Section contained in the Technical Handbook.

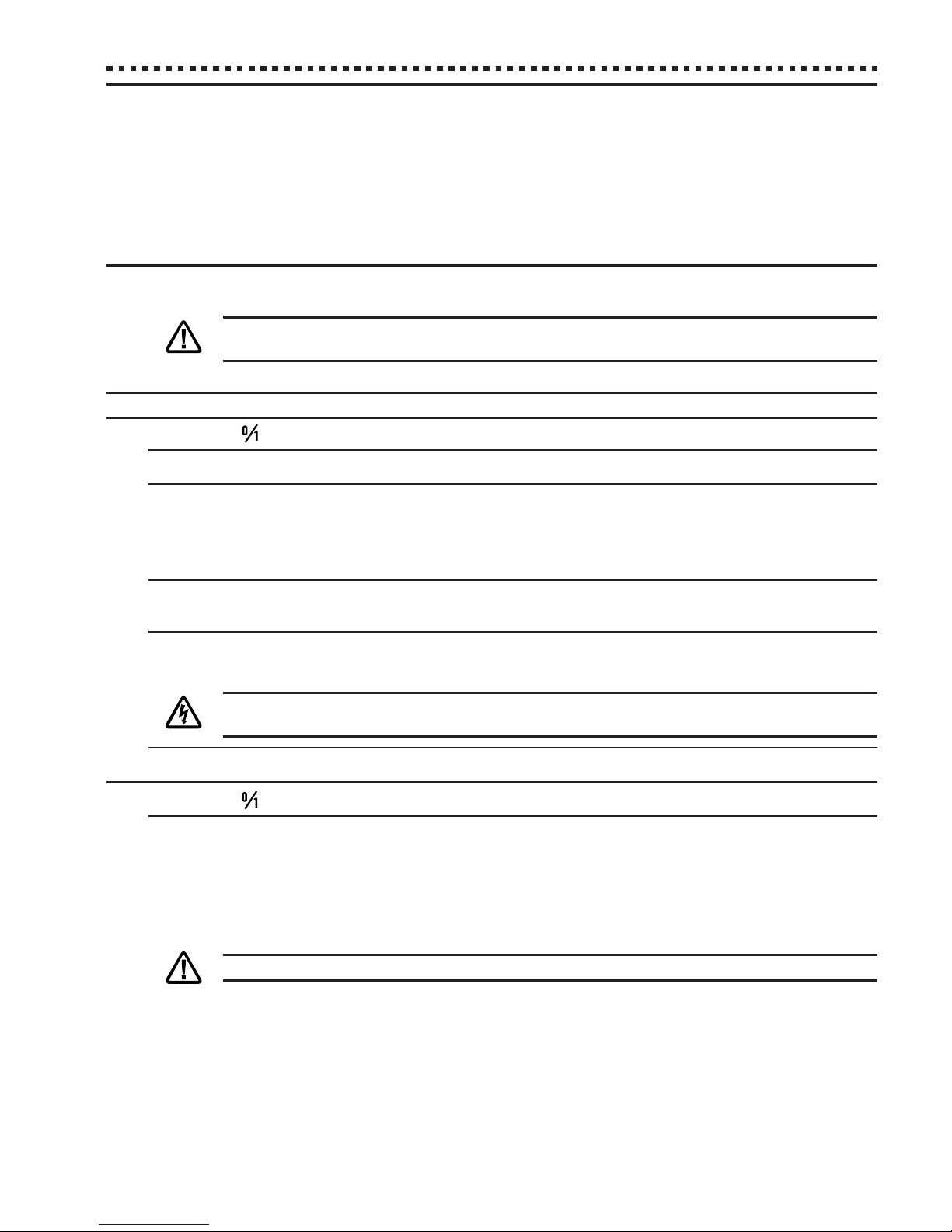

8.2 Check of safety devices

Every three months, check that all safety devices on your machine are in perfect working order:

- open the lid and remove the beater;

- check that the protection grill [3] is well fixed and not damaged;

- close lid and supply the machine;

- turn beating on (beater's shaft will start). Then open the lid. Provided that the lid’s magnetic contact is correctly

working, the beater’s shaft will stop immediately and the Display will show “oo” (two small squares).

If the machine’s functioning is as described, the safety devices are efficient.

THE MACHINE MUST NOT BE USED IF ONE OR MORE OF THE SAFETY DEVICES SHOULD

RESULT DAMAGED OR MALFUNCTIONING!

8.3 Yearly maintenance

Periodically (basing yourself on the environmental conditions in which the machine operates) and in any case once every

year, make sure to have a general checkup.

THE CHECK-UP MUST BE MADE BY THE AUTHORISED ASSISTANCE SERVICE, OR, IN ANY

CASE, BY TECHNICALLY AUTHORISED PERSONNEL WITH ADEQUATE TOOL. THE MAINTENANCE

OPERATIONS RESERVED TO THE SERVICE ASSISTANCE CAN BE DANGEROUS IF CARRIED

OUT BY NON-PROFESSIONALS, THEREFORE, FOR HIS OWN SAFETY, THE USER MUST NEVER

CARRY THEM OUT.

English

Operating instructions

19

9PERIODS OF INACTIVITY

If long periods of inactivity are foreseen, proceed as follows:

- wash up completely the machine (see Section 7);

- switch off the power breaker and unplug the machine;

- if the machine will be stored in a different place, group all the documentation, together with the present manual, and

enclose it at the machine (i.e. in the cylinder).

10 MALFUNCTIONS

WERECOMMEND YOU TO CALL IMMEDIATELY THE ASSISTANCE SERVICE IF AMALFUNCTION

DIFFERENT FROM THOSE HERE DESCRIBED IS FOUND.

The machine does not work or stops working …

… Principal Switch is ON but its indicator light DOES NOT TURN ON.

Cause: The plug is not correctly plugged.

Cause: The plug is defective. A qualified technician should substitute it.

Power in the socket is missing. Check that the breakers, the omnipolar switches and the differentials

(lifesavers) on the electric plant are closed. If they aren’t, before closing them, make sure that no one is

making electrical maintenance.

Cause: A protective fuse of the electric plant is cut down. Find and remove cause of overload and replace fuses

with ones of suitable capacity.

Cause: The supply cable is defective. FIRST turn off switch / knife switch above the socket to remove power

supply from it, then unplug the machine and call Assistance Service.

DONOT TOUCH THE DAMAGED ELECTRICAL CABLES BEFORE HAVING CUT DOWN THE ELEC-

TRICAL SUPPLY!

Cause: Principal Switch is faulty. Call Assistance Service for a replacement.

… Principal Switch is ON and its indicator light IS ON but machine does not work.

Models with lid's magnetic contact:

Cause: The lid is not correctly closed or tends to open;

The product lifts the lid due to an excessive quantity or an excessive volume increase. Use a smaller

amount of mixture or more suitable ingredients.

The lid’s magnet is damaged. Call the Assistance Service.

THE MAGNET AND ITS CONTACT ARE IMPORTANT SAFETY DEVICES!

English

Ice cream freezer

20

Cause: The Beater’s back up relay switches off, following overuse or mechanical overload. Check that the

eventual product in the cylinder is not excessively dense and that there are no other causes of mechani-

cal stress. Stop the machine, wait a few minutes and try again. If the inconvenient should not be eliminated,

or should frequently repeat, call the assistance service.

Note: it may be necessary to wait up to 30 minutes for the thermal protections to cool down.

Cause: Break down of inside parts or at the electronic controls. Call the Assistance Service.

The machine causes repeated releases of the mains electrical protections or the interruption of

mains fuses.

Cause: The capacity of the electrical plant is not sufficient to feed the machine.

The electrical characteristics of protections and fuses are not adequate.

Inside breakdown of the machine. Call the assistance service.

The refrigeration is insufficient or disactivates in an anomalous way.

Cause: The compressor’s back up relay switches off, following excessive stress (REPEATEDLY STARTING TO

BE AVOIDED, high pressure, overheating). Stop the machine, wait a feu minutes and start again. If the

inconvenient shall repeat or frequently repeat, call the assistance service.

Refrigerating system or control circuit are faulty. Call Assistance Service.

Cause: Obstacles are placed at the air conditioning’s opening, at a distance lower than that described. Restore

the minimal distance reported in the Technical Handbook.

The room temperature is too high and condensation is inadequate.

The air condensator is dirty. Request the cleaning at the Assistance Service.

The condensator’s fan is broken. Call the Assistance Service.

Unusual noises.

The noisiness comes, mainly, from the cylinder, when the beating is activated.

Cause: Beater's blades are not correctly adjusted. Proceed as describes in Par. 7.5 - Adjusting blades.

A layer of ice has developed between the beater and the cylinder: the mixture is not idoneous, or is not

sufficient.

Beater's blades may be damaged or worn. Check that the plastic blades' scraping edges do not show

any dents, scratches or wear marks which cannot be mended by adjusting. Should this be the case,

replace blades.

The beater and/or the cylinder are damaged or excessively worn. Call the Assistance Service.

Cause: The beater and/or the cylinder have gone through a sudden temperature change, and stress mechani-

cally. Stop the machine and wait a few minutes.

The noisiness DOES NOT come from the cylinder, or is also present when the beating is not activated.

Cause: Inside break down. Call the Assistance Service.

Table of contents

Other Telme Freezer manuals

Popular Freezer manuals by other brands

Blue Star

Blue Star CHFSD60DHSW user manual

Port A Cool

Port A Cool cyclone 3000 owner's manual

HIGH ONE

HIGH ONE CF 98 F W742C Instructions for use

Master cool

Master cool MCP SERIES Installation and operating manual

Scan Cool

Scan Cool Classic SCL510 user manual

OEM Tools

OEM Tools 23976 Operating instructions and parts manual