Temp-Heat THP-750 Manual

Installation and Service Manual

1-800-836-7432

Temporary

Heating

Cooling

Dehumidifying

Ventilating

For your safety,

do not use this heater in a

space where gasoline or

other liquids having

flammable vapors are

stored or used.

This manual is the property of the

owner. Leave with the unit when

set-up and start-up are complete.

THP-750

Gas, Direct-Fired Temporary Heater

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Rating Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Control Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Fuel Supply System — Bulk-Tank System . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Natural-Gas Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Set-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Preliminary Start-Up Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Control Vestibule Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Start-Up Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Shut-Down Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Short-Term . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Long-Term or Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Wiring Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Control Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Ignition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Airflow Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Setting Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

To Check Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3

TEMP-HEAT

®

This heater is designed and approved for use as a construction heater under ANSI Z83.7-1990.

We cannot anticipate every use which may be made of our heaters. Check with your local fire safety

authority if you have questions about applications.

Other standards govern the use of fuel gases and heat-producing products in specific applications.

Your local authority can advise you about these.

Warning

General Hazard Warning

Failure to comply with the precautions provided with this heater can result in death,

serious bodily injury and property loss or damage from hazards of fire, explosion,

burn, asphyxiation, carbon monoxide poisoning, and electrical shock.

Only persons who can understand and follow the instructions should use or service

this heater.

If you need assistance or heater information such as an instructions manual, labels,

etc., contact the manufacturer.

Fire, burn, inhalation and explosion hazard.

Keep solid combustibles, such as building materials, paper or cardboard, a safe

distance away from the heater as recommended by the instructions.

Never use the heater in spaces which do or may contain volatile or airborne

combustibles, or products such as gasoline, solvents, paint thinner, dust particles

or unknown chemicals.

Warning

Warning Not for home or recreational vehicle use.

THP-750 Installation and Service Manual

Introduction

The following recommendations are not intended to supplement requirements of federal, state, or local

codes having jurisdiction over the application and operation of this heater.

This instruction booklet contains the necessary information, instructions, and guidelines to achieve

maximum efficiency and safety from the TEMP-HEAT construction heater. Please read all instructions

before attempting the set-up and operation of this heater.

The THP-Series Heaters are direct-fired, fresh-air heaters used to provide temporary heat for buildings

under construction, alteration, or repair. The area of fresh air required for safe operation must be equal to

the area of the unit’s intake grill. THP-Series heaters draw fresh, outside air through the unit’s intake

and discharge tempered air controlled by a remote thermostat. The heaters generate 85° F to 170° F

discharge temperatures with models ranging from 300,000 BTU/hour to 4,500,000 BTU/hour operating

on natural gas or propane gas vapor.

Equipment with these characteristics are preferred for enclosed areas because they generate lower mois-

ture and contaminant levels while controlling ventilation and air distribution.

Most models are equipped with a remote thermostat and an adjustable, automatic burner control. This

combination prevents extreme temperature fluctuations that occur when ON/OFF burner controls are

selected.

5

TEMP-HEAT

®

Rating Information

snoitacificepStinU 057-PHT noitallatsniroodtuororoodniroF

MFC 000,4

ruoH/UTB muminim

mumixam

002,34

000,057

erusserPtelnI gispmuminim

saGlarutaN gispmumixam

2/1

*4

erusserPtelnI gispmuminim

enaporP gispmumixam

5

01

stnemeriuqeRlacirtcelE

spma/esahp/ztreh/egatlov

5.71/1/06/032

01/3/06/032

5/3/06/064

snoisnemiD ni,hxwxl 56x33x86

thgieW sbl056

morfecnatsidmuminiM ni,roolf

slairetamelbitsubmoc ni,pot

ni,sedis

tf,egrahcsid

0

6

6

01

snoitidnoCtneibmA muminim F

mumixam F

04-

021

tcatnoc,saglarutanisp-4revoerusserptelniroF* TAEH-PMET .

THP-750 Installation and Service Manual

Control Functions

hctiwSwolfriA nacnoitingierofebtneserpsitinuhguorhtwolfriareporptahtseifireV

.ecalpekat

rotalugeRegatS-t

sriF telniseilppusdna,erusserpetaidemretninaoterusserpknatsecudeR

.rotalugeregats-dnocesaoterusserp

lort

noCytefaS-emalF .eruliafemalffotneveehtniretaehehtnwodstuhsdnaemalfsesneS

timiLerutarepmeT-hgiH ehtnisev

lavsagsesolcdnalortnocytefas-emalfottiucriccirtcelesnepO

.noitidnocgnitaehrevonafotneve

timiLerutarepme

T-woL ehtotniriagnizeerfgnigrahcsidfoytilibissopehttsniagastcetorP

04tates-erP.etingiotsliafrenrubehttneveehtnignidliub siht,F

spordtinuehthguorhterutarepmetehtfinwodrewolbehtstuhslortnoc

.tnioptessihtwoleb

e

vlaVsaGlaunaM nwod-tuhs,mret-trohsroF.retaehtaylppusleufffostuhsyllaunaM

.ylno

hctiwSssapyBlaunaM ehtfipu

-tratsgnirudrewolbehtfonwod-tuhscitamotuaehtsedir-revO

04ehtwolebsitinuehthguorhterutarepmet -woLehtfognittesF

.lortnoctimiLerutarepmeT

evlaVlortnoCgnitaludoM .tatsomrehtetomerehtybdellortnocrenrubehtotylppu

ssagsetalugeR

evlaVtoliP.tinugnitratsnehwtolipnoitingiehtotleufseilppuS

rotalugeRegatS-dnoceS .erusserpre

nrubotslevelegats-tsrifmorferusserpteltuoehtsecudeR

kcolretnIretratS .noitisopdesolcyllamronehtnidegagn

esiretrats-rotomsevorP

tatsomrehTniatniamoterif-hgihot-wolmorfretaehehtselcycyllacitamotuA

.erutarepmetm

oorderised

7

TEMP-HEAT

®

Fuel Supply System — Bulk-Tank System

• Installation must comply with all state and local codes or, in the absence of local codes, with the

standard for the Storage and Handling of Liquified Petroleum Gases, ANSI/NFPA 58.

• Locate fuel tanks according to the minimum distances shown in the Rating Information

Table on page 5.

• The vapor-supply fuel line from the tank or vaporizer must have a first-stage regulator located

at the tank or vaporizer to reduce the tank pressure to the 10-psi needed to supply unit.

• A vaporizer may be necessary, especially on multiple-heater installations where adequate storage

supply is not attainable or practicable.

• Vaporizers must be no closer than 10-ft from a container.

• Locate vaporizers at a minimum of 15-ft from fuel-transfer valves.

Typical Vaporizer Installation — Algas 40/40 Vaporizer

union

hand valve

tee

tank fill

vapor service valve

POL connector NOTE: left-hand thread

reducer

union and UL approved 350 psi gas hose

to temporary heating unit when a vaporizer is not used

Liquid inlet line to vaporizer

must be schedule 80 black iron pipe

or copper tubing of adequate size.

Contact state or local authorities governing

the installation of vaporizers.

tee

globe valve

union

elbow

street elbow

first-stage regulator

elbow

gauge tee

tee

shut-off valve

reducer

dripleg

to temporary heating unit

first-stage regulator

yticapaCegarotShcaEyticapaCegarotShcaE yticapaCegarotShcaE yticapaCegarotShcaEyticapaCegarotShcaE dnuorGevoba ecnatsiDmuminiMecnatsiDmuminiM ecnatsiDmuminiM ecnatsiDmuminiMecnatsiDmuminiM gnidliuBmorf

knatlag-005,eno tf-01

sknatlag-0001,owtroeno tf-52

eromrolag-1002 tf-05

THP-750 Installation and Service Manual

Natural Gas Installations

• See Rating Information Table on page 5 for proper inlet pressure.

• Gas meter and supply system must be able to supply the minimum supply pressures as specified

in the Rating Information Table on page 5.

• Follow all federal, state, and local codes governing temporary-gas connections.

• Leak test all gas connections using a 1:3 solution of soap and water.

9

TEMP-HEAT

®

Set-Up

• Block heater’s wheels to prevent movement.

• Keep fresh-air intake and heated-air discharge clear of obstruction.

• Provide clearance to allow access to vestibule, blower, and motor compartments.

• Heater must be level and in compliance with minimum-clearance and minimum-distance require-

ments for combustible materials. See Rating Information Table on page 5.

• Position heater to draw 100% fresh outside air through its intake grill.

• Do not use or operate the heater in the presence of combustible vapors of liquids.

• Maintain a maximum voltage differential of plus or minus 10% while unit is running.

• Protect the hose from traffic, building materials, and contact with hot surfaces both during use

and while in storage.

• Do not move, handle, or service heater while hot, running, or connected to power supply.

• Check for gas leaks and proper functioning during installation, periodically, or when relocating.

Typical Heater Installation

from gas supply

meter

pressure gauge

regulator

manual shut-off valve

pressure gauge

regulator

discharge-air

hood extension

THP-750 Installation and Service Manual

Preliminary Start-Up Steps

• Check for proper fuel-supply application, connections, and pressure.

• Purge gas line of air, as necessary.

• Leak test all gas connections with a 1:3 solution of soap and water.

•Do not operate unit if leaks are present.

• Determine that unit is drawing 100% fresh outside air through its intake grill.

• Check for proper electrical connections and supply voltage.

• Check that the intake and discharge of unit are free from obstructions.

• Reset flame-safety control by pressing reset button on control.

• Reset motor overload.

• Check control settings:

high-temperature limit switch: 240° F

low-temperature limit switch: 40° F

THP-750 Switch Panel

low-temperature light

flame relay light

blower switch

burner switch

11

TEMP-HEAT

®

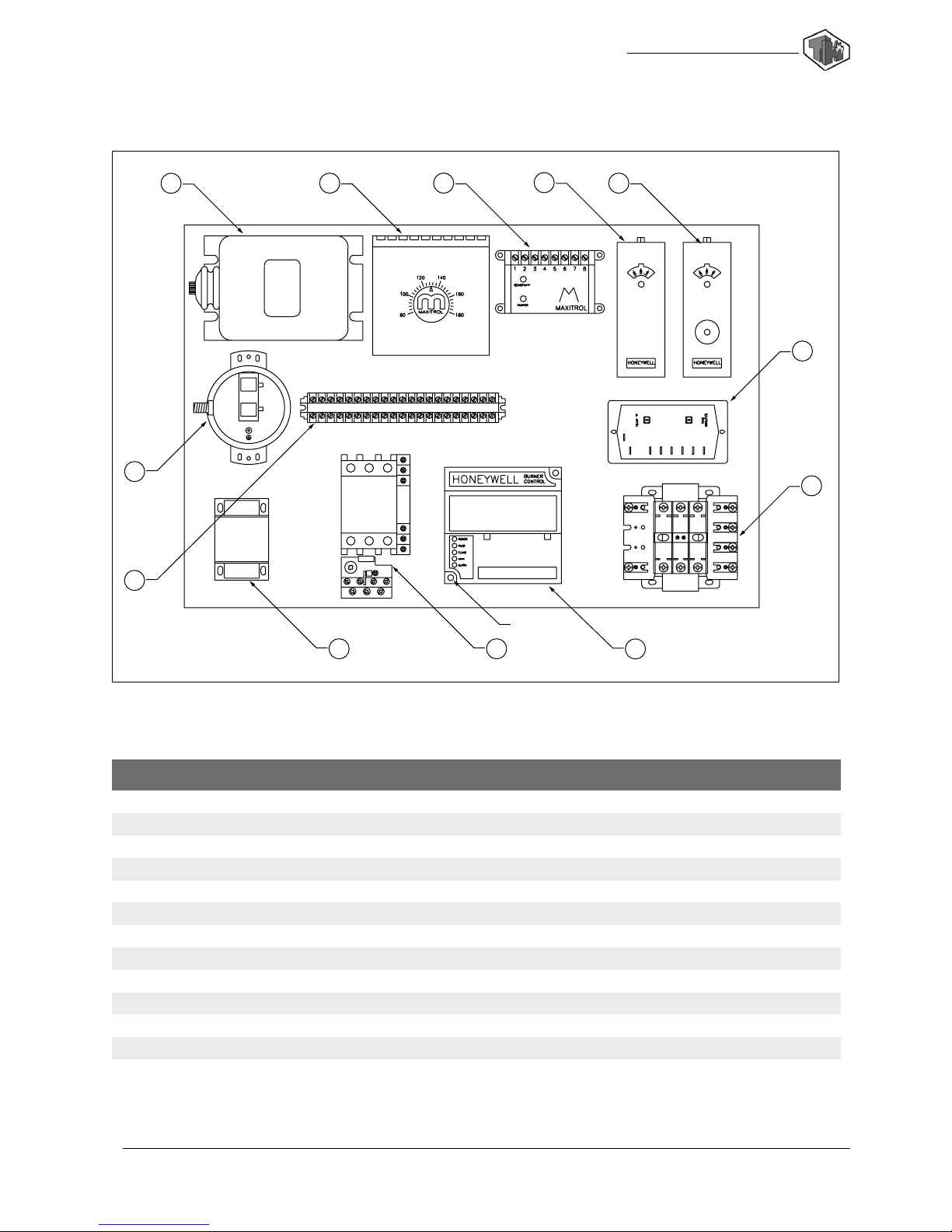

THP-750 Vestibule Layout

Control Vestibule Layout

123

45

6

7

8

910

11

12

reset

rebmuNmet

I

noitpircseD

1remrofsnartnoitingi

2 rotceleserutarepmetegrahcsid

3reifilpma

4 hctiwstimilerutarepmet-hgih

5hctiwstimilerutarepmet-hgih,teser-launam

6 hctiwstimilerutarepmet-wol

7remrofsnartrewop

8 lortnocytefas-emalf

9daolrevoretrats-rotomdnaretratsrotom

01 remrofsnartV-42

11pirtslanimret

21 hctiwswolfria

THP-750 Installation and Service Manual

Start Up Steps

1. Connect power supply. See Rating Information Table on page 5 for electrical requirements.

2. Confirm heater is set up for fuel being supplied. See Rating Information Table on page 5 for proper

gas-inlet pressures.

3. Plug remote thermostat into thermostat jack on heater. Mount in an area away from the discharge-air

stream and set at highest setting.

4. Open fuel-supply valve at tank slowly.

5. Open manual gas valve at heater.

6. Reset Flame-Safety control.

7. Check control settings:

high-temperature limit switch: 240° F

low-temperature limit switch: 40° F

8. Turn main disconnect to the ON position.

9. Turn blower and burner switches to the ON position.

For units equipped with electronic low-temperature limit control:

allows unit to run for 3-min. If discharge-sensor bulb located in the discharge-air stream does

not reach the 40° F minimum temperature, the unit shuts down, and the low-temperature bulb

glows.

To reset: turn blower and burner switches OFF. Reset the Flame-Safety Control and turn

switches back to ON.

Do not attempt to light the pilot manually.

10. Observe flame at both high- and low-fire ranges.

High Fire high-fire flame produces a discharge temperature approximating

160° F with flame extending 14-in beyond burner.

Low Fire low-fire flame produces a discharge temperature between 85° and 90° F.

11. Set remote thermostat to the desired room temperature.

13

TEMP-HEAT

®

Shut Down Steps

Short-Term Shut Down

• Turn burner switch to OFF position.

• Wait 30-sec.

• Turn blower switch to OFF position.

• Look to see that flame is extinguished.

Extended Shut-down or Disconnection of Unit

• With unit running, close vapor-fuel supply valve at vaporizer.

Caution: Do not close liquid supply valve while vaporizer is ON. See vaporizer for proper

operation of vaporizer. Contact your gas company for further information on safe handling

of propane vaporizers.

• Allow heater to run until flame-safety light goes ON, indicating that all gas has been burned

from gas lines.

Caution: Check to see that pilot light on vaporizer is extinguished before disconnecting gas lines.

• Turn burner switch OFF.

• Continue running blower until no flame exists in the base of the burner.

• Turn the blower switch OFF.

• Turn power OFF at source and disconnect electrical lines.

• Disconnect propane-vapor line from heater.

• Contact gas company to disconnect vaporizer.

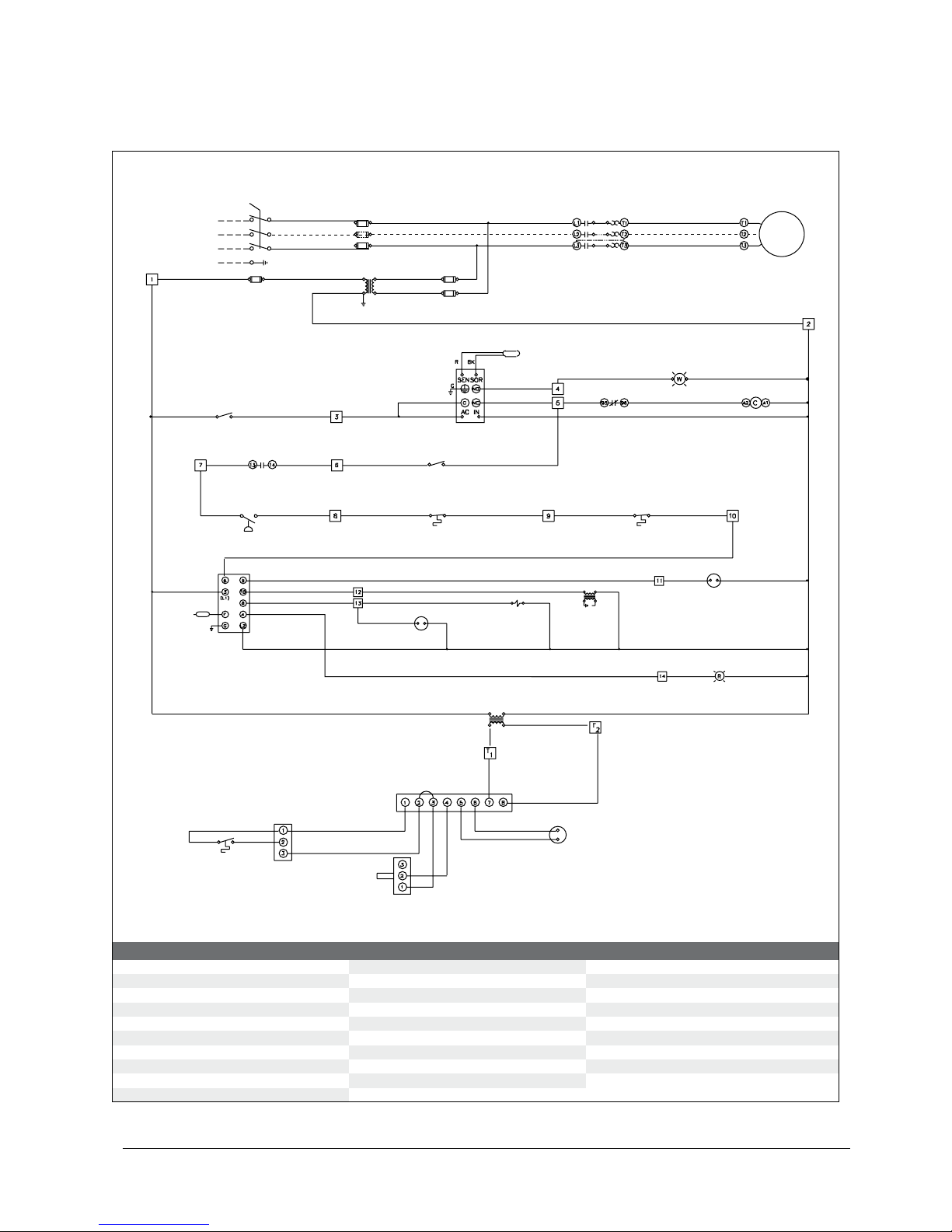

noitacifitnedItnenopmoC

10-MA reifilpma 20-NS doremalf40-SThctiwstimilerutarepmet-hgih

10-UF esufniam 10-TS retratsrotom 50-ST timilerutarepmet-hgihtenibac

20-UFesuflortnoc 50-WS hctiwsrewolb70-SThctiwstimilerutarepmet-wol

10-IL thgilerutarepmet-wol 60-WS hctiwsrenrub 80-ST erutarepmetegrahcsid-etomer

20-IL thgilteser-renrub 70-WS hctiwstrats-rewolb11-STtatsomrehtedirrevo-moor

10-TM rotomrewolb-ylppus 80-WS hctiwspots-rewolb 10-AV evlavsag-niam

10-LO daolrevoretrats 20-RT remrofsnartegatlov-wol20-AVevlavsag-niamdnoces

10-SP hctiwswolf-ria30-RTremrofsnartnoitingi 30-AV evlavsag-tolip

70-ER yalerytefas-emalf 10-ST rosnesria-egrahcsid50-AVevlavsag-gnitaludom

10-NS rosneserutarepmet-wol

230/460 VOLT

60 HERTZ

3 PHASE

POWER SUPPLY

L1

L2

L3

FU-01

FU-01

FU-01

BK

BK

BK

BK

BK

ST-01 OL-01

TS-07

TR-01 FU-03

FU-03

BK BK

BK

BK

BK

W

Y

BR

O

Y

OBL

BK R OYBL

ADD JUMPER FOR

SINGLE PHASE

SN-01

R

BR

SW-07

TS-04 TS-05

BK

BL Y

W

W

R

W

BK

BK

OR

BK

VA-01 VA-03 TR-03

VA-02

LI-02

TR-02

120V

24V BR

TS-08

AM-01

TS-01

VA-05

TS-11

BR

BK

RG YBLRO

BL

BK

RE-07

MT-01

FU-03

BK R

SW-05

ST-01OL-01

LI-01

W

W

W

W

W

W

W

Y

BR

Y

G

SN-02

BR

R

PS-01

ST-01

120V 230/460V

G

THP-750 Installation and Service Manual

Wiring Sequence of Operation

15

TEMP-HEAT

®

to 6

5

to 10

9

to 6

10

to 13

8

to 12

10

When the main safety switch, SW-01 is turned ON, power is supplied:

— to the line side of the motor starter, ST-01,

— to the primary side of the power transformer, TR-01, and

— from the secondary side of the power transformer to the FU-02 control fuse, located

on the transformer.

Terminal 1 receives 120-V power from the FU-02 control fuse.

Terminal 2 is neutral.

Terminal 3 receives power from Terminal 1 through the blower switch, SW-07

or the blower auxillary switch SW-05.

Terminal 5 receives power from Terminal 3 through the low-temperature limit

control, TS-07.

Note: the low-temperature limit control is a timed thermostat that allows the heater

to run for 3-min. If the discharge sensor bulb, located in the discharge-air stream,

does not meet the 40° F minimum temperature setting of the control, the unit shuts

down and the low-temperature alarm light, LI-01, glows.

To Reset: turn blower switch OFF, wait 45-sec and turn back ON.

Terminal 6 receives power from Terminal 5 through the burner switch, SW-06.

Terminal 7 receives power from Terminal 6 through the supply-fan motor starter.

With proper air flow through unit, Terminal 7 supplies power to Terminal 8 through

the airflow switch, PS-01.

Terminal 9 receives power from Terminal 8 through the high-temperature limit

switch, TS-04.

Terminal 10 receives power from Terminal 9 through the cabinet high-temperature

switch, TS-05.

Terminal 10 supplies power to Terminal 6 within the flame-safety control,

RE-07. Internal circuitry energizes Terminal’s 4, 8, 9 and 10 within the control.

Terminal 8 of the flame-safety control supplies power to Terminal 13, energizing the

pilot-gas valve, VA-03 and the main-gas valve, VA-01.

Note: if pilot flame is not present, the flame-safety control locks out, and the control

must be reset.

Terminal 10 of the flame-safety control supplies power to Terminal 12, energizing the

ignition transformer, TR-03.

Terminal 9 of the flame-safety control supplies power to Terminal 11, energizing the

second-main gas valve, VA-02

to 5

3

to

to

1

F2

2

13

to 11

9

to 7

6

to 8

7

to 9

8

THP-750 Installation and Service Manual

Troubleshooting

melbor

P

esuaCelbaborP ydemeR

etarepotonseodrewolBonroetauqedanI

tneserpegatlov

ebtsumV-064ot-032.tinuotylppusrewopkcehC

.5egapnoelbaTnoitamrofnIgnitaRkcehC.elbaliava

nwolbroesoolesuF .20-UF,esuflortnockcehC

tonhctiwsrewolB

noitisopNOni

.NOnruT

deppirtdaolrevorotoM .teseR

evitcefedhctiwsrewolBtaV-511rofkcehc,noitisopNOehtnihctiwshtiW

.tneserptonsiegatlovfihctiwsecalpeR.3lanimreT

nwodstuhstinU

ytefasemalfno

.lortnocnonottubtesersserP

timilerutarepmet-woL

gnittesreporptatonhctiws

nim-3:remiT

04:erutarepmeT F

dnaFF

Osehctiwsrewolbdnarenrubnrut:teseRoT

.NOkcabneht

erutarepmet-wolevitcefeD

hctiwstimil

taV-511rofkcehC.snoitcennocgniriwkcehC

.hctiwsecalper,tneserpsiegatlovonfI.5lanimreT

daolrevoretratS

evi

tcefed

.ecalpeR

rotomevitcefeD rotommorfsnoitcennocdnanoitidnocgniriwkcehC

dnaegatlovreporpgniviecersirotomfI.rotomotretrats

dnaevitcefedsirotomeht,noitidnocdoognisigniriw

.decalperebtsum

renrub,snurrewolB

etingitonseod

tonhctiwsrenruB

noitisopNOni

.NOnruT

hctiwsrenrubevitcefeD taegatlovkcehc,noitisopNOehtnihctiwsrenrubhtiW

tondna5lanimreTtatneserperaV-511fI.5lanimreT

.evitcefedsihctiwsrenrubeht,6lanimreTta

wolfriatneiciffusnI .snoitcurtsborofegrahcsiddnaekatnis'tinukcehC

.noitareporeporprofrotomdnaedalbnaftcepsnI

nosnoitcurtsniehtotgnidroccalortnocwolfriatsujdA

.91egap

.snoitcurtsboroftcepsnidnagnibutwolfriaevomeR

.gnibuttcennoceR

,8lanimreTtatontub7lanimreTtatneserpsiegatlovfI

.hctiwswolfriaehtecalper

timilerutarepmet-hgiH

tnemtsujdafotuohctiws

tuhsotseunitnoctinufI.hctiwsnonottubtesersserP

sihctiwstimilehtro,derifrevorehtiesitinueht,nwod

tcatnoC.evitcefed .TAEH-PMET

-hgihelbatsujdA

hctiwstimilerutarepmet

gnittesreporptaton

042tateS sitinueht,nwodtuhsotseunitnoctinufI.F

tcatnoC.evitcefedsihctiwstimilehtroderifrevorehtie

.TAEH-PMET

17

TEMP-HEAT

®

melbor

P

esuaCelbaborP ydemeR

renrub,snurrewolB

etingitonseod

lortnocytefas-emalF

tuokcol

tcerroctonseodgnitteserfI.lortnocnotesersserP

.lortnocytefasemalfecalper,melborp

evitcefedevlavsaG sagmorfdnaotnoitidnocdnasnoitcennocgniriwkcehC

siegatlovdnanoitidnocdoognisigniriwfI.sevlav

.tnemecalpe

rdeenyamsevlaveht,tneserp

ylppusleuFnoitamrofnIgnitaReeS.tinuotylppussagmrifnoC

.serusserpylppussagtelni

rof5egapnoelbaT

.esohsagmorfriadeelB

dorkrapsnoitingI

deppagylreporpmi

.91egapnonwohssapagni-8/1niatniaM

.dedeensadorkrapsecalpeR

seod,setingirenruB

tilyatston

evitcefeddorkrap

S dor-krapskcehC.FFOsehctiwsrenrubdnarewolbnruT

rotalusninialecroptcepsniylluferaC.noitidnocdnapag

.yrassecenfiecalpeR.erutsiomroskcarcrof

wolfriatneiciffusnI .snoitcurtsborofegrahcsiddnaekatnis'tinukcehC

.noitareporeporprofrotomdnaedalbnaftcepsnI

nosnoitcurtsniehtotgnidroccalortnocwolfriatsujdA

.91egap

.snoitcurtsboroftcepsnidnagnibutwolfriaevomeR

.gnibuttcennoce

R

,8lanimreTtatontub7lanimreTtatneserpsiegatlovfI

.hctiwswolfriaehtecalper

renrub,snurrewolB

seodtinutub,

setingi

erifhgihreviledton

ylppusleuFnoitamrofnIgnitaReeS.tinuotylppussagmrifnoC

.erusserpylppussagtelnirof5egapnoelbaT

tatsomrehtetomeR nokcajtatsomrehtotniylerucestatsomrehtetomergulP

ria-roodniehtnahtrehgiherutarepmetatateS.retaeh

.eruta

repmet

THP-750 Installation and Service Manual

Control Adjustments

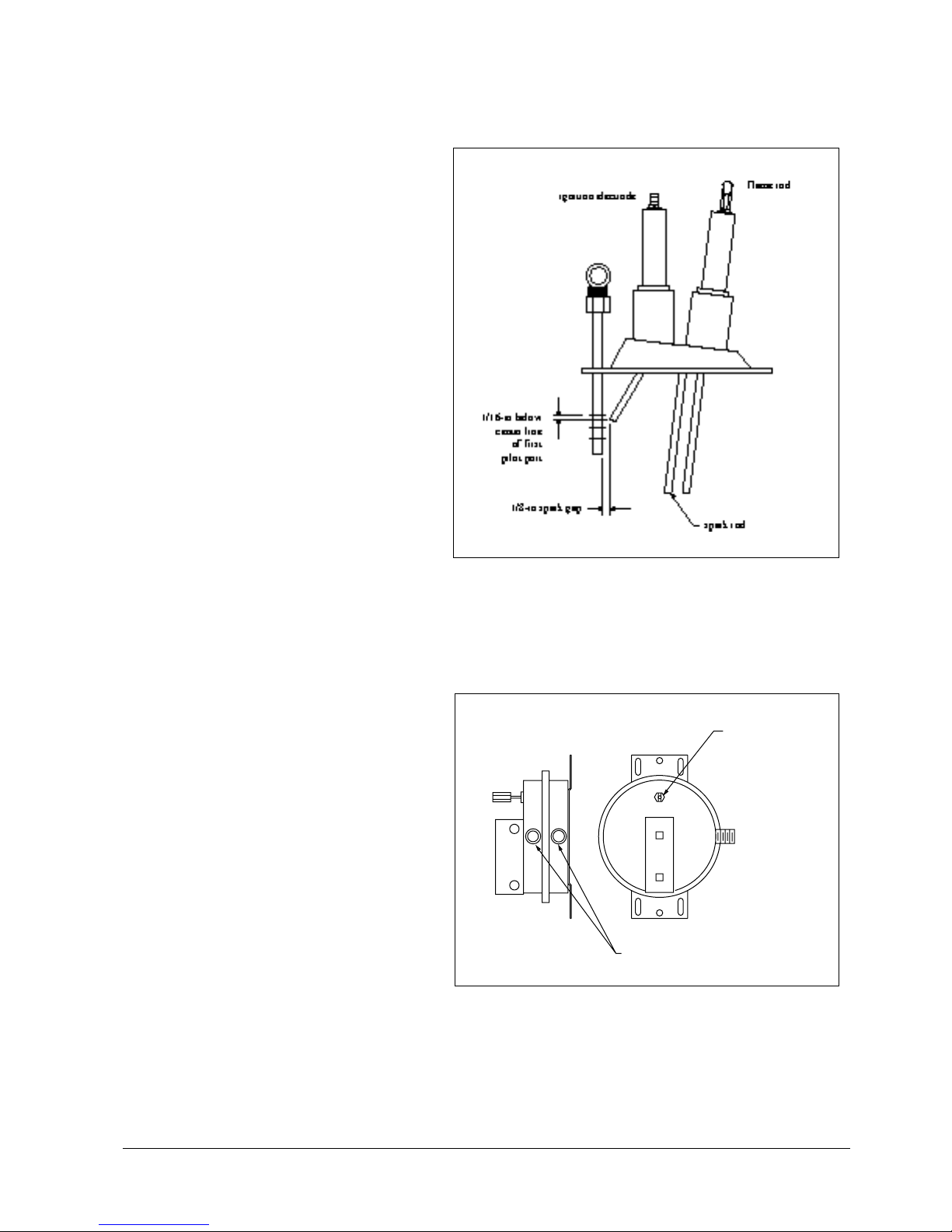

Ignition

1. Clean and dry electrodes.

2. Check porcelain insulators for cracks or

moisture. Replace if necessary.

3. Adjust as shown.

4. Secure ignition leads.

5. Replace spark electrode if defective.

Air-Flow Control

Setting control

1. Turn ON/OFF switch to ON.

2. With unit operating at high-fire, turn

adjusting screw clockwise until burner

goes OFF.

3. Turn adjusting screw counter-clockwise

1/2 turn at a time until burner re-ignites.

To check setting

1. Set remote thermostat on highest setting.

2. Observe that when operating on high-fire,

the switch does not break contact.

Ignition Assembly

Airflow Control

adjusting screw

airflow tube connections

19

TEMP-HEAT

®

One Rupp Plaza

3700 West Preserve Boulevard

Burnsville, Minnesota 55337-7746

1-800-836-7432

Boston, MA 800-666-8133 fax 508-624-0036

Chicago, IL 800-283-2843 fax 847-931-7704

Cleveland, OH 800-443-3301 fax 330-721-7742

Columbus, OH 800-444-3481 fax 614-471-1933

Denver, CO 800-577-7053 fax 303-783-8579

Detroit, MI 800-678-1488 fax 248-526-9527

Duluth, MN 888-539-5438 fax 218-722-6701

Minneapolis, MN 800-836-7432 fax 612-707-5104

Newark, DE 800-232-7419 fax 302-369-8022

Watertown, WI 800-558-9209 fax 920-261-4523

RUPP Industries manufactures, sells and rents commercial, industrial

and construction equipment. Our employees — our most valuable

asset, are dedicated to finding innovative solutions that fulfill our

customers’ product and service requirements.

0123.9901 © RUPP Industries, Inc. 1999 Printed in USA

Table of contents