TempMaster LS-1628 User manual

Quick Start Guide for Equipment Touch and

LS-1628 Unit Controller, Standard 3.1.5 Program

Introduction

This start-up guide will guide you through the

necessary procedures to start-up the unit equipped

with an LS-1628 controller. Before turning on the

controller, be sure all wiring is completed and in

the proper location. All input connections (i.e. SAT

sensor) wire into the grey terminals located on the

bottom of the controller. All output connections

wire into the blue terminals located on top of the

controller. Refer to the wiring diagram included with

the unit for the connections specific to this unit.

If installing a zone or room sensor, wire to TB5

terminal blocks, these will be factory wired to the

controller’s Rnet port located on bottom-left of the

controller. Refer to the wiring diagram included with

the unit for the connections specific to this unit.

Figure 1: LS-1628 controller

Form Number: TPM54-SU2 (321) New Release

Issue Date: 2021-03-16

Figure 2: Equipment touch

The equipment touch will be prewired by the factory

and mounted to the electric panel.

The equipment touch 2 (EQ2) is powered by 24

VDC, a DC power supply is provided and wired

into the grey connector shown in Figure 2. The

green and white wires run to TB 5 Rnet + and Rnet -

connections.

Note: DO NOT CONNECT old equipment touch

(EQ1) or ET1 Kits to this connection, it could

damage the controller, EQ1 or ET1 tablet.

The controller can now be turned on by the switch

on the upper left-hand side of the controller.

Once turned on, the controller will go through

a built-in start-up diagnostic, which can take

approximately 10 seconds to complete. After this,

the sensors and controls will become fully available

and the EQ2 display will upload and configure the

display to show the Home screen.

Note: This takes about 5 minutes to complete.

If nothing is touched or pushed on the Home

screen for 5 minutes, the Standby screen will

appear as below.

Note: The EQ2 screen timeout is set to a

standard setting of 2 minutes, this can be

adjusted, see .

Figure 3: Start-up diagnostic

The Standby screen shows the program name,

version number, date of revision issue, and the

current operational condition/mode of the unit (i.e.

UNOCCUPIED/SCHEDULE is the initial condition).

Press the continue button on the keypad to go to

the Home screen.

Figure 4: Standy screen

Equipment touch notes

First thing to note is the new EQ2 operates just like

a tablet or smart phone, the screen has a timeout

setting (the standard setting is 2 minutes, but is

adjustable to 10 minutes), when not used for the

allotted time the screen will timeout and turn off,

to wake screen simply touch anywhere on screen.

This is a Touch screen device so you will touch the

objects for the links, changing parameters, and

even to scroll by use of the slide bars on the right or

bottom of the screen.

Note: When scrolling and touching the screen

the new EQ2 has a ZOOM function that will

activate if the screen is touched three (3) times

in rapid succession, to return to normal view,

tap 3 times again in rapid succession. All menu

items can be accessed by slide bar, holding an

arrow, or placing your finger on the slide and

moving it. If a line is too long a slide bar will

appear on the bottom of the screen.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program2

Password enter screen

There are 3 levels of passwords used in the

program, User, Admin and Factory passwords. User

passwords are not used often as most of those

screens are for READ OUT sensors and unit data.

Most changes will require an ADMIN PASSWORD

because these are specific configuration and are not

meant to be changed unless authorization has been

given. Once an ADMIN password has been entered

ALL screens and buttons below that level will not

need a password to be re-entered unless it requires

a Factory password. Factory password protected

changes that must be performed by an authorize

service tech, please contact the manufacturer's

technical service representative if assistance is

required. The password will timeout after 5 min of

screen inactivity and need to be reentered, when

this happens you will be brought back to the Unit

Status screen.

Note: You will need to switch the keyboard

input to numbers to enter the password.

Figure 5: Enter password

Table 1: Reference table for main screens.

Navigation

button Description Password Reference

Unit status Main settings and modification screen None

Tech settings Occupancy control, SF min setting, enable settings Admin

Misc. setup BAS, ModStat, config Admin

Calibration Allows manual +/- of sensor readings – used for testing of unit and sensor

calibration Admin

Unit config Shows unit information, serial number, operational configuration, factory

options Admin

Setpoints/DB Adjustment to “adjustable” setpoints.

Note: Some setpoints/DBs are not adjustable from factory Admin

Settings, controls, and options

Procedures for setting up the date and time,

schedule of occupancy, modifying parameters of

operation, and selectable options, such as adding

zone sensor and safety switches. For specific

operational information for this unit, refer to

the unit specific Sequence of Operations provided

separately.

The controller will be pre-configured from the

factory with the necessary options for the unit to

operate properly. However, some items may need

to be modified in the field as required. This can be

achieved in the field through the EQ2 display.

Unit status screen

From the Unit status screen, most of the status

screens can be accessed. Also, the alarm reset will

appear on the home screen if the controller is in an

alarm state. Once alarm is reset, the Reset Alarm

text will hide itself.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 3

Figure 6: Unit status screen

All screens will have the top two lines which includes

a home, previous, and an alarm link. These links

on the Unit Status screen are followed by the date

and time. The next line will have the operational

condition/mode of the unit. This screen will have

links depending on the options of the unit, such

as ECW (Energy Wheel), Econ (Economizer), EF

Fan (Exhaust Fan), HP1 and HP2 (Heat Pump)

not shown, see Sequence of Operation for specific

configuration. Below are two status screens.

You can use this screens to test your Sequence

of Operation on the unit. The Supply fan status

screen shows the supply fan (SF) status is turned

On and the UO9 light will be On. The SF_APS is the

feedback from the Air Proven Switch or a current

sensor. The SF MOD is the percentage output of

the VFD. Minimum is the lowest speed the SF can

run (default is 50% or 30 Hz.). The second screen is

for Cooling 1 status. On the left side of the screen

are different status points. C1 EN will light when

the ZAT is 1°F above the Clg1 EN SP. Y1 will light

when the compressor 1 command or UO10 is turned

On. CMP1 will light when the current sensor closes

for compressor 1. HPS1 and LPS1 should always

have the light on. FRZ1 will light when the DXLAT1

sensor is below 38°F. Clg Mode will be on, when

OAT is above 55°F and there is demand for cooling

or dehumidification. Min off and on are 5 minute

timers. When the compressor starts or stops it

must remain or be off for 5 minutes. They will start

at 5 minutes and count down. These timers meet

Copelands requirement of 6 starts an hour. There

are two of the status screens for this unit. The

rest of the status screen are similar by using the

Sequence of Operation, then you can check the status

of unit.

Figure 7: Unit status screen 1

Figure 8: Unit status screen 2

Tech settings screen

The Tech Settings screen can be accessed by

selecting the Setup link from the Unit Status

screen. The Tech Settings screen includes

navigating links for Unit Config screen, Tech

Setup screen, Schedule screen, Calibration

screen, etc. Here is where you will be able to add

and/or calibrate sensors and access screens for

occupancy control and settings. Just like the Unit

Status screen, the Tech Settings screen will have

additional links such as DPT, AMS, Reset (ZAT/SAT),

based on unit configuration.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program4

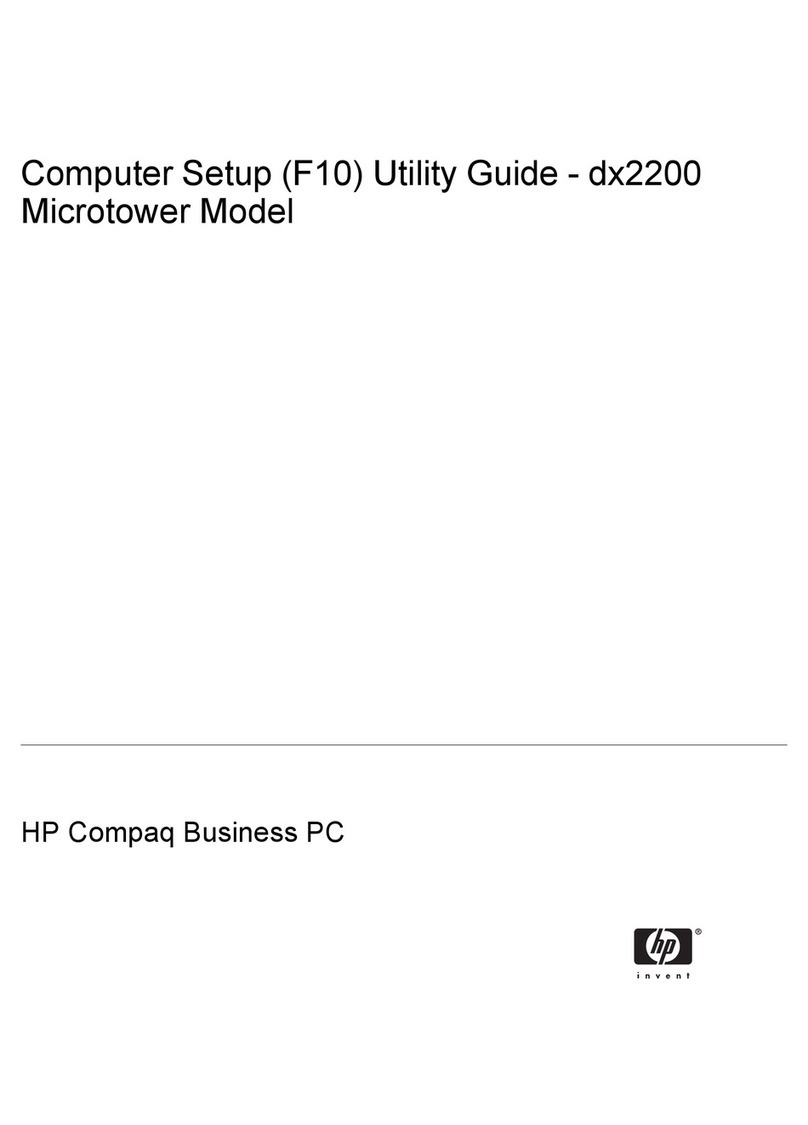

Figure 9: Tech settings screen

Note:

• A: Back to Unit status screen.

• B: Shows model and program version,

optical sensor enable options.

• C: Allows calibration of all installed sensors

for temp and humidity.

• D: Allows manual inputs of adjustable

setpoints and deadbands.

• E: Occupancy control, shut down settings,

supports.

• F: Schedule is used to setup an internal

schedule on the controller.

• G: Screen title.

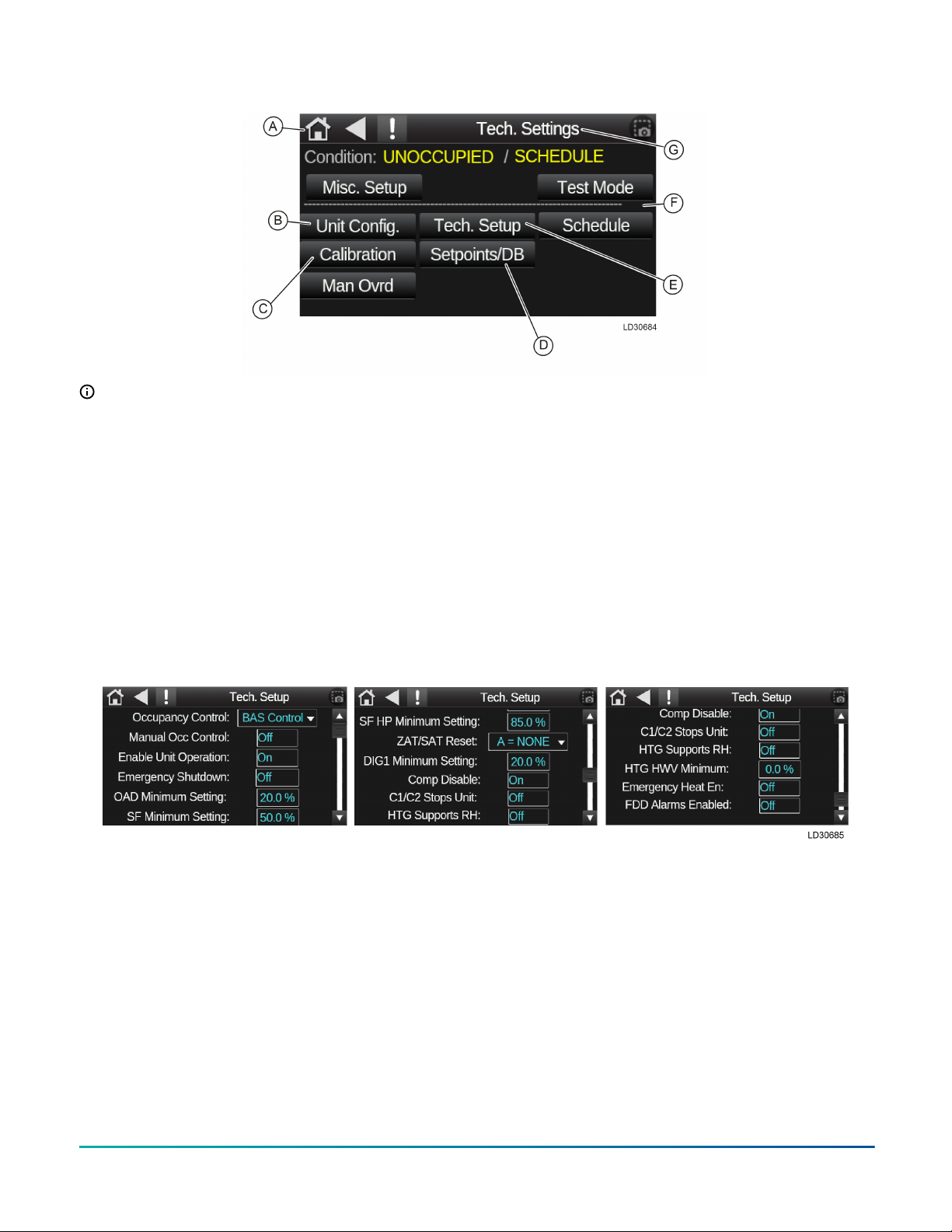

Tech setup screen

Tech setup allows for unit override controls and

certain operational parameters. Parameters that

can adjust/changed in tech setup are occupancy

control, unit enable supply fan minimum run

settings, ZAT/SAT reset on/off, emergency heat

enable and many more.

Please refer to specific unit sequence of operation

for specific run conditions and set points.

Figure 10: Tech setup screen

Unit configuration screen

To access the Unit configuration screen, select

the Unit Config link on the Tech Settings screen.

The Unit configuration screen you can select

options for miscellaneous controls that are FACTORY

options. This screen also displays the factory S/

N and unit configuration, zone sensor set up

(optional), night set back options can be enabled

and miscellaneous options A and B (COS, SD, CFI).

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 5

Figure 11: Unit configuration screen

Note:

• A: Unit configuration by factory selected

options.

• B: Factory serial number (unit serial

number).

• C: Optional, can add a zone sensor if

needed.

The following four charts show all avaibable options

for the four selectable drop-down menus. These

options can be added to the unit or may have come

from the factory.

Figure 12: ZAT sensor options

Figure 13: Option A

Figure 14: Option B

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program6

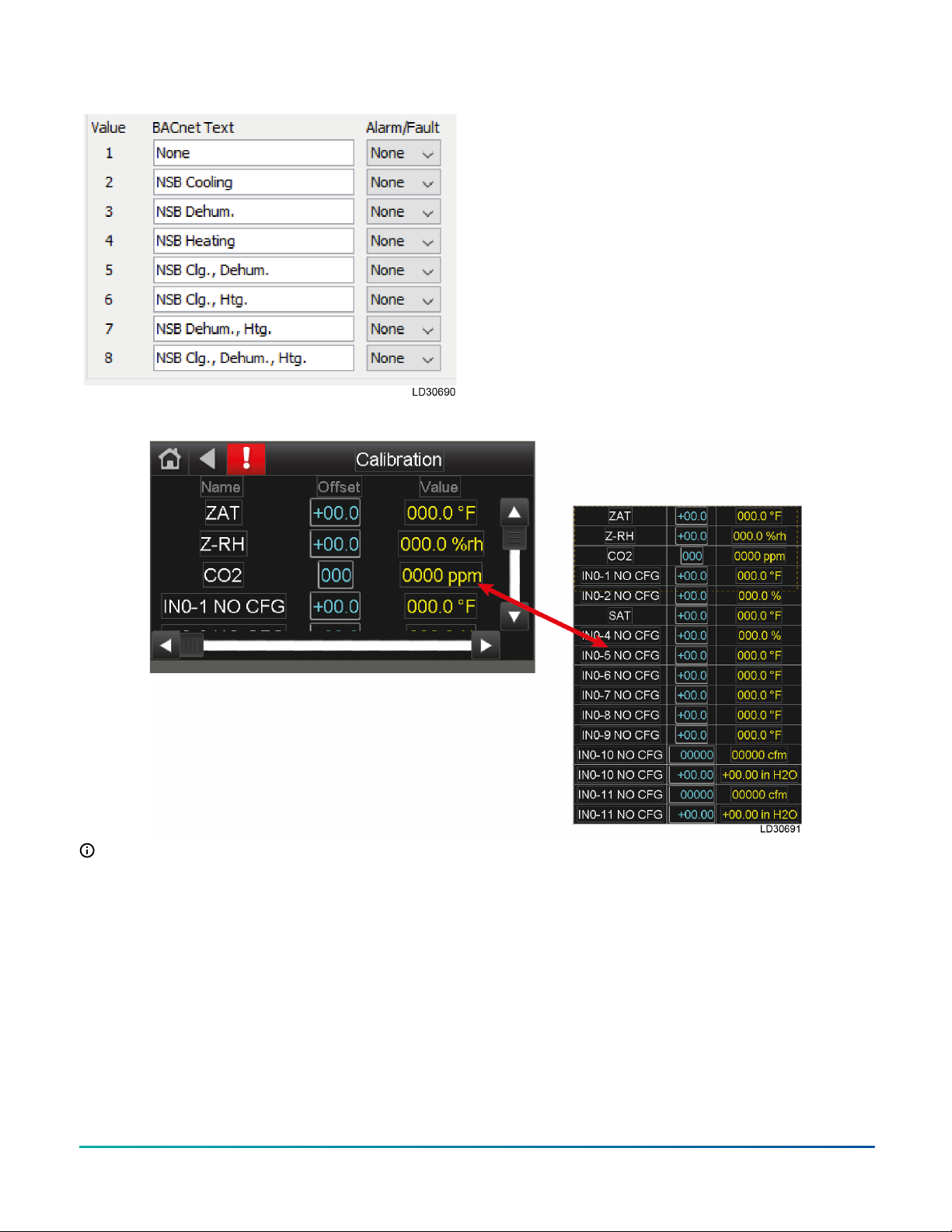

Figure 15: NSB options Calibration screen: control sensor

readouts and manual adjustments

Use the Calibration screen to see all sensor values

and to apply an offset. The value shown represents

the current value + the offset given. This screen is

used for testing purposes to enable an operational

state or to calibrate a sensor reading.

Figure 16: Calibration screen

Note: The Calibration screen displays the

current value + offset. If the offset is zero, the

value is current sensor reading.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 7

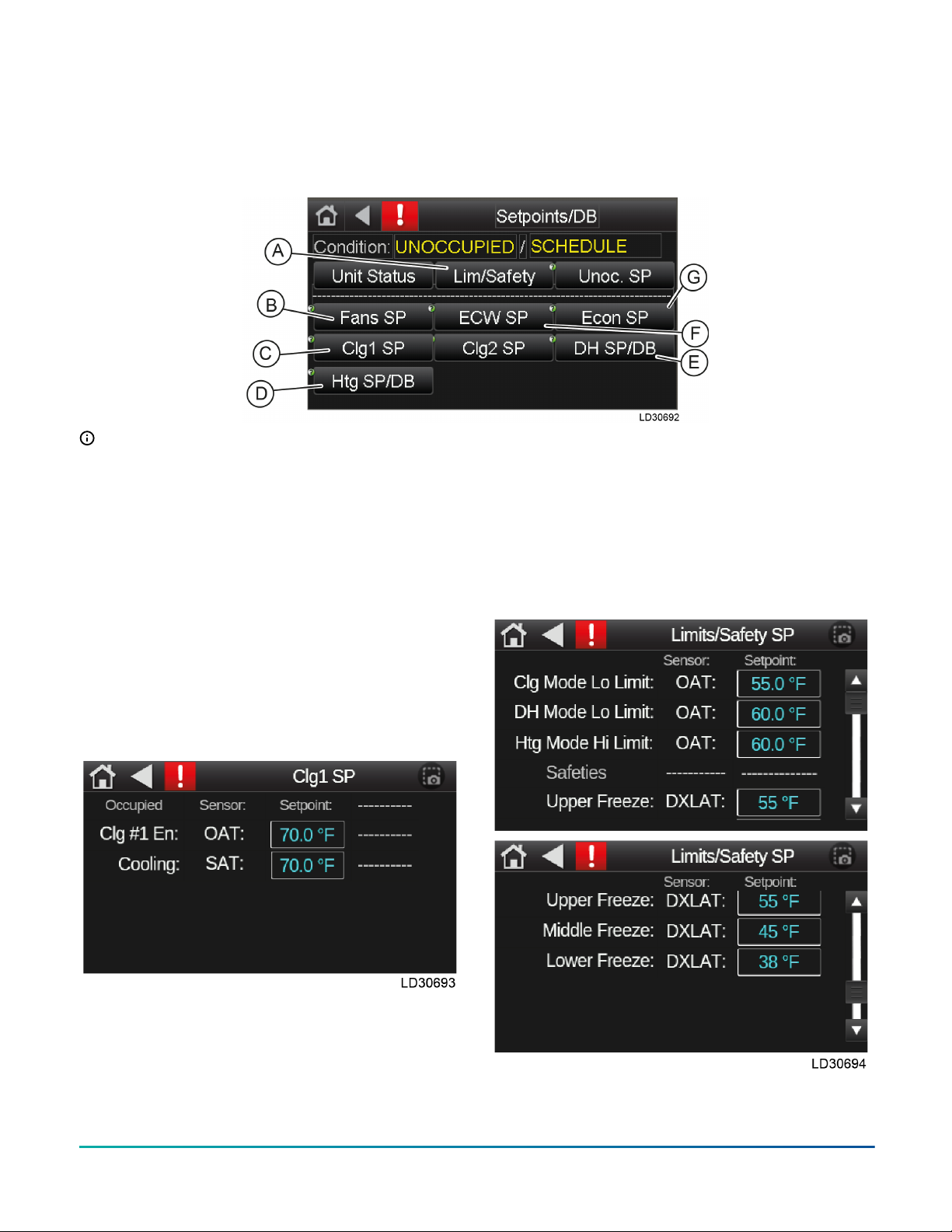

Setpoint and deadband screen

The Setpoints/DB screen allows you to adjust any

setpoints that need to be adjusted through field

test and balancing. These setpoint come preset to

a factory setting during the initial program unless

requested otherwise. Admin password is required to

access and change any setpoints.

Figure 17: Setpoint and deadband screen

Note:

• A: Limits and safeties

• B: Supply and exhaust fans setpoints and

deadbands

• C: Cooling setpoints (Clg1 SP and Clg2 SP)

• D: Heating setpoint and deadband

• E: Dehumidification setpoint and

deadband

• F: Energy wheel setpoint and deadband

• G: Economizer setpoint

See for an example of the setpoint screens available

from the Setpoints/DB screen.

Figure 18: Cooling 1 setpoint

These setpoints are all adjustable, the sensor is NOT

adjustable and is for information only.

Limits and safety setpoints

The Limits/Safety SP screen allows you to see the

lower and upper limits of the deadbands. These

deadbands are editable and the standard values are

set from the factory. An admin password is required

to access the Limits/Safety SP screen.

The sensor tag is not adjustable and for information

purposes only. The sensors are set from factory and

can only be changed or modified when instructed

to do so by technical service. If you have any

questions, please call technical service.

Figure 19: Limits and safety setpoints

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program8

Default limits: all values are degrees Fahrenheit

• Cooling mode Lo Limit: 40° to 65°

• Dehumidification mode Lo Limit: 55° to 90°

• Heating mode Upper Limit: 40° to 70°

• Compressor disable OAT: 0° to 50°

• Upper freeze protection: 28° to 55°

• Middle freeze protection: 28° to 55°

• Lower freeze protection: 28° to 55°

• ECW defrost WExAT: 0° to 20,000°

Occupancy control

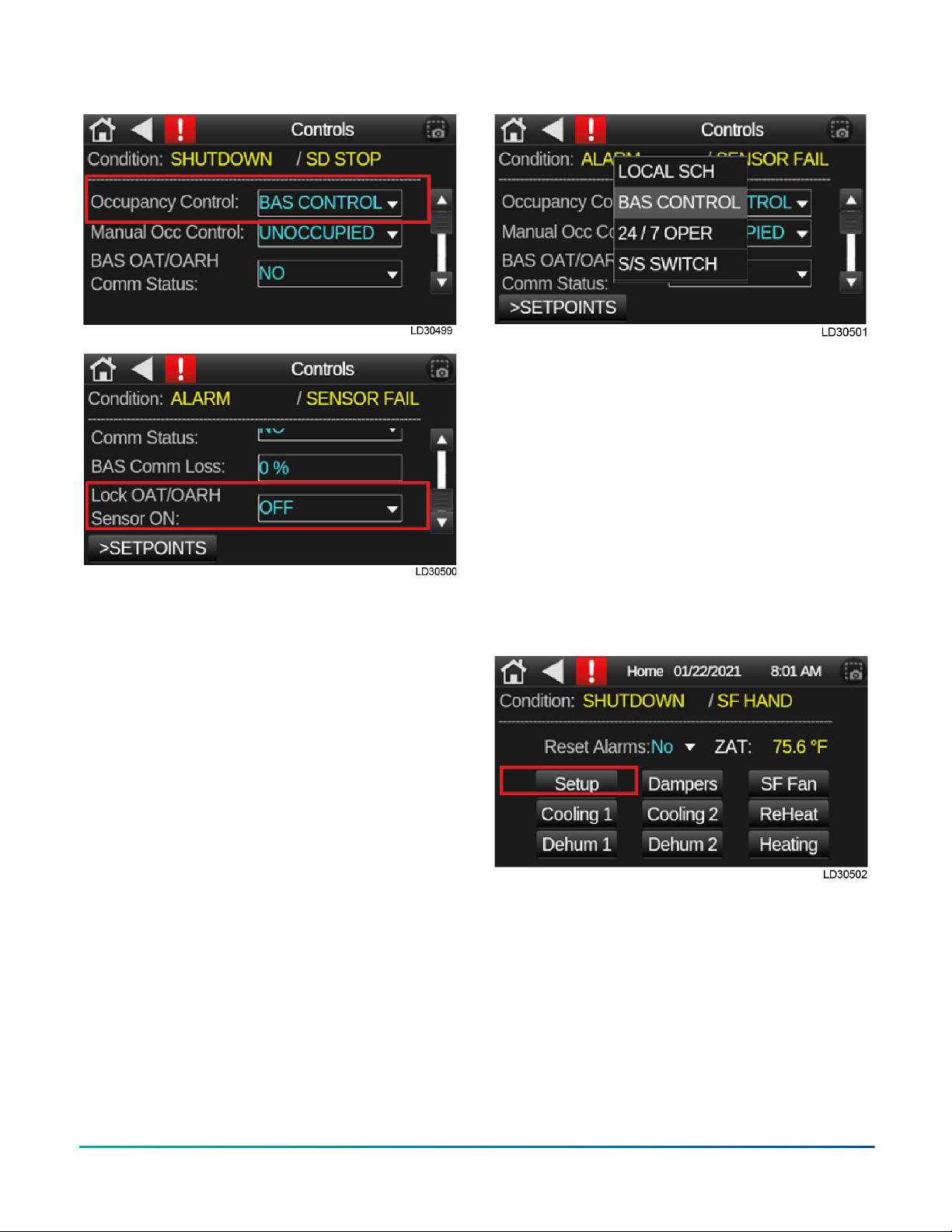

Press the Occupancy Control drop down menu

option, the Occupancy Control parameter dictates

where the unit control for occupied mode of the unit

originates, all modes can be set in the field and/or

overridden by the BAS.

Figure 20: Occupancy control

•Local schedule – internal schedule on the

controller.

•BAS control – building automated system

controls unit enable by writing to manual occ

control point, occ enable.

•24/7 operation – runs continuously, unit does

not have an unoccupied mode unless the

occupancy enable is changed.

•S/S switch – on/off signal control, could be a

switch or a digital input (DI) (UI12, option A

selected in ET2)

•CO2 occupancy – CO2 sensor enabled control.

When the CO2 level reaches 300 ppm, the unit

will be placed in occupied mode.

Note: This will require a CO2 zone (space)

sensor for reading space CO2 and enabled

in Config screen on ET2.

Setting a schedule

There is no default schedule for the LOCAL SCH option. Change the schedule to the desired hours. To edit

the schedule, select the Schedule button on the Setup Status screen.

1. Click the Add Schedule button in upper right corner.

2. Enter a name for the schedule – example here is named Addison Schedule.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 9

3. Select schedule type – you can choose On schedule - occupied or Off schedule - Unoccupied.

4. Select time and date – we recommend weekly schedules. Leave the Date Range to NO. Make sure to set

the time to the hours for occupied schedule unless otherwise stated by customer.

5. Click Save Schedule button on bottom of screen. Then press OK button.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program10

6. Confirm schedule is correctly input and saved

by verifying the monthly screen. There are

green bars in all days where schedule is active.

For example, in the following figures, the

schedule is set for Monday through Friday

every week. By clicking the drop-down option

where the word Monthly is shown, you can see

the schedule in weekly view or daily.

Misc status screen

The Misc Setup screen can be accessed by selecting

the Misc Setup link from the Unit Status” screen.

The “Misc Setup” screen includes navigating

buttons for “BAS setup” and “Modstat.” The “BAS

setup” button allow you to set up communication

with BAS as well as network device information.

“Archive” will allow for backup and restore functions

of the installed unit specific program.

Figure 21: Misc status screen

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 11

Config status screen

This screen will show you the unit type, the Model

number, the Serial number of the unit and the

program code string and version number. This

screen also has buttons for Sensors and Options,

both allow for modification of controlling and field

installed sensors options including ZAT/RH sensor,

condensate overflow, clogged filter and smoke

detector.

Figure 22: Config status screen

Changing settings

Note: The last value or command will set the

point. When a BAS system is connected to the

unit, the BAS may continually write to the point.

If you change a value or condition the BAS may

overwrite your command. Disconnecting the

BAS input wire will generate a BAS comm lost

alarm and change the OAT/OARH reading to

the unit supplied sensor.

All settings can be changed using the following

method.

1. Press the button for the desired screen.

Note: Some screens will require a USER/

ADMIN password to access. Please contact

your local Johnson Controls service

branch.

2. Enter the password and press the Log in

button.

Note: You will need to switch the keyboard

input to numbers to enter the password.

3. Change the state of a two-position point or

multi-stat point by pressing the desired button.

A drop-down menu will give you your choices.

4. Press the button of your desired choice. The

select choice will appear on your button. You

may need to scroll by using the slide bar.

5. For a value press on the value, a second

window will open, press on the value and a

keypad will appear.

6. Now enter the desired value and press the OK

button.

Figure 23: Change password

Settings

The program will default to the factory download

or last archive. Start on the home screen, press the

SETUP button. Press the Controls button and you

will be prompted to enter an admin password. Then

the following screen will appear with the default

values. The first line has Occupancy Control set

for the default setting BAS CONTROL. You can use

the second line to place the unit into unoccupied/

occupied mode. The Lock OAT/OARH Sensor ON:

is set for the default of Off. The default values are

OAT of 60°F and OARH of 50%. These two read/

writable points will be updated by the BAS with a

local temperature and humidity readings. These

neutral temp and humidity will give time to check

the damper and supply fan control, see Sequence

of Operations. Testing of the unit can be achieved

by using the calibrate screen and adjusting your

temperature or humidity values.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program12

Figure 24: Settings

Occupancy control

Press the Occupancy Control drop down menu

option, The Occupancy Control parameter dictates

where the control of the Occupied Mode of the unit

originates, all modes can be set in the field and/

or overridden by the BAS. The occupancy control

options are below:

1. LOCAL SCH: Select if the Controllers schedule is

to be used.

2. BAS CONTROL: Select if the BAS is used for unit

control and enable.

3. 24 / 7 Operation: Select if unit will run in 24/7

Occupied Mode.

4. S/S Switch: Select if occupancy control is from a

separate unit controller binary input (UI-12).

5. CO2 Control: Select if occupancy control is

based upon CO2 levels.

6. Clock Ovrd: Select to override scheduled

unoccupied condition and place unit in

occupied mode for a set period of time

(adjustable; 30 minutes default).

7. Manual Ovrd: Select to manually force

Occupied or Unoccupied Mode.

Figure 25: Occupancy control

Settings before startup

From the Home screen, select the Setup button,

then select the Setpoints/DB button to pull up

the setpoints screen. From the Setpoints/DB

screen you can access fan, cooling, heating and

dehumidification set points. Also, the limits and

safeties are accessible thru the Setpoints/DB

screen.

One thing that should be done before startup

begins is select the Fan SP (default is 3900) and set

the SFAMS Air Flow set point to the desired CFM.

For a value press on the value, a second window will

open, press on the value and a keypad will appear.

Now enter the desired value and press the OK

button.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 13

Start-up

Let's get started on the startup of the unit. The best

way to check the unit out is to follow the Sequence of

Operations.

1. All sensor readings should display a good

value. A sensor reading -60.2 or 296 has an

open circuit or is shorted respectively. The

condition on the second line will display

“ALARM/ SENSOR FAIL” or “SAT FAIL’. By

selecting the alarm key (red square with

an exclamation point on top line) the new

screen will display the failed sensor. If there

are no failures navigate to the Calibration

screen by press the Setup link on the Home

screen. Now press the calibration link to

display the Calibration screen. Show all

points. Remember the unit will receive the

OAT/OARH readings from the BAS system.

However, you should check the local OAT/OARH

sensor by navigating to the Control screen

and turning on “Lock OAT/OARH sensor ON”.

Return to the Calibrate screen and check the

OAT/OARH reading. Turn this option off after

verifying the readings. Correct the sensor

before proceeding. The SF AMS reading will be

checked after the supply fan is running.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program14

2. Place the unit in the occupied mode. From the

Home screen select Setup button, the select

the Controls button to navigate to the controls

screen. Change the MANUAL OCC. CONTROL to

OCCUPIED. Since the Occupancy Control is set

to BAS CONTROL, you can check the damper

and supply fan operation. The Damper and

Fans screen will show their status.

3. Damper status: From the Home screen press

the damper link. On the screen you will see

OA DAMPER twice, the first is the command to

open the damper and UO14 on the controller

will light up. The second OA damper is a

feedback from the actuator that the damper

has opened xx%. The Smoke detector status

will display normal/alarm. If the status is

showing an alarm, then the condition line will

display SHUTDOWN/SD STOP. Once the smoke

detector is restored, the unit will restart.

4. Fan screen: The SF Status is the command to

start the fan, then the status shows started

or on the UO09 on the controller will light up.

The SF-APS will show “on” when the air proven

switch or the current sensor contact closes. The

next three points are for the modulation of the

supply fan speed. The supply fan will modulate

to maintain the setpoint (Default is 3900 cfm).

The SF setpoint may need to be adjusted (check

with your TAB contractor). In some cases,

the unit is set to run as a constant air volume

(CAV). Check with the TAB contractor for the

desired percentage. To set the unit for CAV

press the setup link on the home screen. Press

the Man Ovrd link for the manual override

screen. Set the percentage to the required

value and turn the output to on. The last

status is the 2-minute countdown timer on SF

shutdown (see Sequence of Operations).

5. Cooling 1 status: The next step in the sequence

of operations will be to start compressor #1.

Go to your Calibration screen and add 12°F

to the OAT. The SOO states the compressor

will start when the OAT is 1°F above the OAT

cooling setpoint of 70°F. The CLG #1 will turn

to on when this condition is true. If the Y1 does

not turn to “on” check the Min OFF countdown

timer. If the timer is zero, the HPS1 and LPS1

status are both on, then Y1 will turn on and

UO10 on the controller will light up. Comp #1

is the feedback for the compressor #1 using a

current sensor.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 15

The next three points are for the modulation of

compressor #1. The compressor will modulate

to maintain the DXLAT SP (Default is 55°F).

Note: If the units for the C1 MOD shows 35 to

60 Hz, then the unit has a Bitzer compressor.

A Copeland Digital Compressor will display

the units as 0-100%. The next line will give

you the status of the purge cycle and when

the next purge will happen. The purge will

be on startup of the compressor and every

hour. During the purge cycle the condition

line will show OCCUPIED/PURGE#1. The next

two lines will display the freeze protection

status and the min off and min on timers. The

freeze protection has the DXLAT reading and

C1 FRZ status (see Sequence of Operations). The

min OFF and min ON 5-minutes countdown

timer are triggered by the compressor’s

current sensor. These timers can restrict the

compressor from shutting down or starting. If

you think the compressor should be starting

or stopping check these timers. The last line

shows the status for the 10 minute countdown

timer for the heating mode change over to

cooling mode. On the very bottom of the

screen are links to other screens.

6. Reheat (HGRH) screen: The reheat displays

that reheat is included in the unit. When RH

status is on then UO12 will light. The next three

points are for the modulation of reheat. The

modulating reheat will modulate to maintain

the SAT SP (default is 70°F).

7. Cooling 2 status: The first line has qualifiers

for compressor #2 to start (see Sequence of

Operations). Demand SP is set to 95% or 59Hz,

the 10 minute countdown timer, and the SAT

cooling setpoint plus 3°F must all be satisfied to

turn on compressor #2. Go to your Calibration

screen and add enough to the offset so the SAT

above 73°F. The sequence of operation states

that the compressor will start when the SAT

is 3°F above the SAT cooling setpoint of 70°F.

The CLG #2 will turn to on when this condition

is true. If the Y2 does not turn to on check the

min OFF countdown timer. If the timer is zero,

the HPS2 and LPS2 status are both on, then

Y2 will turn on and UO11 on the controller will

light up.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program16

Comp #2 is the feedback for the compressor

#2 using a current sensor. The next line will

give you the status of the purge cycle and when

the next purge will happen. The purge will

be on startup of the compressor and every

hour. During the purge cycle the condition line

will show OCCUPIED/PURGE#2. The next two

lines will display the freeze protection status

and the min off and min on timers. The freeze

protection has the DXLAT reading and C2 FRZ

status (see SOO). The min OFF and min ON 5

minutes countdown timer are triggered by the

compressor’s current sensor. These timers can

restrict the compressor from shutting down or

starting. If you think the compressor should

be starting or stopping check these timers. On

the very bottom of the screen are links to other

screens

8. Dehumidification #1 screen: The first line has

the status of the OAT and the dehum lower

limit setpoint (see SOO). The OAT must be

above the lower limit setpoint and the OADP

must be above the SADP setpoint of 51°F to

enable dehum #1. When Dehum1 shows on,

then the condition line will display OCCUPIED/

DEHUM.

On the second line you have the status of the

sub-cooling coil (see Sequence of Operations).

Sub-cooling will turn on anytime we are in the

dehum mode and a compressor is running.

When the unit is running in the dehum mode

the compressor will modulate to maintain the

SADP SP of 51°F. On the very bottom of the

screen are links to other screens.

9. Dehumidification #2 screen: The SADP must be

2°above the SADP setpoint of 51°F to enable

dehum #2. When Dehum2 shows “on”. On the

very bottom of the screen are links to other

screens.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 17

10. Heating Screen: The next step in the SOO will

be to start heating. Go to your Calibration

screen and subtract enough temperature to

the OAT to be below 54. You may need to wait

for the heating mode to turn on. The cooling

to heating switchover is a 10 minute timer. The

OAT must be below the high limit setpoint, the

OAT must be below the OAT heating setpoint

of 54°F to enable heating. When HTG shows on,

then the condition line will display OCCUPIED/

HEATING. The next three points are for the

modulation of heater. The heater will modulate

to maintain the SAT SP (default is 70°F). The

last line shows the status for the 10 minute

countdown timer for the cooling mode change

over to heating mode. On the very bottom of

the screen the type of heat is displayed.

You have completed the startup of the 100%

Outside Air unit. Before you leave make sure

all offsets you made in the Calibration screen

are set to zero. The LS1628u does not require an

Archive to save change made in the field. The

Archive is down automatically.

BAS and communicaton specific

screens

Module status screen: network

information and device data

Module Status will allow you to get all the network

and system information for the controller. This

screen will help with trouble shooting any network

issues, show all shut down time stamps and any

system controller errors. On the new EQ2 does an

ALL-IN-ONE report when selected.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program18

Figure 26: Module status screen

BACnet device

From the Home screen, press the Setup button,

then press the Misc. Status button to get to the

Misc. Status screen. Press the BAS Setup button to

enter the BAS Setup screen. Select Communication

menu option, this will open the communication

screen and allow you to enter BAS information.

The BACnet Device Instance being utilized in the

field will be unique for each unit. The Autogenerate

Device ID should be set to no. The rotary switch

on the controller, located in the upper left corner,

need to be set to the proper protocol (1=MSTP,

2=ARCnet) contact the FMOC for correct BACnet

Device Instance number and protocol. The BACnet

Device instance could already be populated always

check to verify correct number.

Network router and IP screens

The router and IP network number can be checked

and manually changed by using the related menus.

To access the Router screen, select Router on the

BAS screen. To access the IP screen select IP on the

BAS screen.

Quick Start Guide for Equipment Touch and LS-1628 Unit Controller, Standard 3.1.5 Program 19

The rotary switch on the controller, located in the

upper left corner, needs to be set to the proper

protocol (1=MSTP, 2=ARCnet, 3=Modbus). Contact

your BMS engineer for information of which

protocol is being used.

1. On the Router screen make sure to change

PORT S1 value to specific network number for

communication protocol.

2. On the IP screen make sure to set the IP

Network to 0 if not already.

Safety switches

•High pressure switch (HPS1): If HPS1 is open,

compressor #1 will turn off and the controller

will issue an alarm. After manually resetting

HPS1, the HPS1 alarm will reset. Following

a minimum time off delay, compressor #1

will turn on. If the controller records 3 high

pressure start/restart failure incidents within

1 hour, compressor #1 is locked out and the

controller will issue an alarm. The compressor

lock-out can be reset in the EQ2 display pad or

by cycling the power of the controller. Refer to

the IOM for more information.

• For systems with two circuits, this is the same

for compressor #2, Y2 and HPS2.

•Low pressure switch (LPS1): If LPS1 is open

after the LPS1 by-pass time, the controller

will issue an alarm and compressor #1 turns

off. After 30 seconds (fixed), the LPS1 alarm

will reset. Following the minimum time-off

delay, the compressor #1 will turn on. If the

controller records 3 low pressure start/restart

failure incidents within 1 hour, compressor #1

is locked out and the controller will issue an

alarm. The compressor lock-out can be reset

in the EQ2 display pad or by cycling the power

of the controller. Refer to the IOM for more

information.

• For systems with two circuits, this is the same

for compressor #2, Y2 and LPS2.

Safety shutdowns

•Smoke detector (optional): When a smoke

detector (SD) is provided, it is wired directly

to the controller. If smoke is detected, the

controller will shut down the unit. The alarm

can be reset in the EQ2 display pad or by

cycling the power of the controller.

• If a compressor fails to start 3 times in an

hour due to high pressure switch lock out. The

alarm can be reset in the EQ2 display pad or by

cycling the power of the controller.

• If a compressor fails to start 3 times in an

hour due to low pressure switch lock out. The

alarm can be reset in the EQ2 display pad or by

cycling the power of the controller.

• If a compressor fails to start 3 times in an hour

due to DX LAT or suction line temperature lock

out. The alarm can be reset in the EQ2 display

pad or by cycling the power of the controller.

If the controller detects an SAT sensor failure. The

alarm can be reset in the EQ2 display pad or by

cycling the power of the controller.

TEMPMASTER® IS A REGISTERED TRADEMARK OF JOHNSON CONTROLS © 2021 Johnson Controls. All rights reserved. Subject to change

without notice. 100 JCI Way, York, Pennsylvania USA 17406-8469.

Table of contents