Temptek PTK Series User manual

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-6352 fax: 317-881-1277

Service Department fax: 317-885-8683

www.Temptek.com

E-mail: [email protected]

I.O.M. #129 updated 09/30/2019

INSTRUCTION MANUAL • INSTALLATION • OPERATION • MAINTENANCE

Model:

Serial Number :

INSTRUCTION MANUAL

TOUGH TANK ‘PPT’

for TOWER WATER SYSTEMS

and CHILLED WATER SYSTEMS

With Checkmate Controller

COVERING

INSTALLATION

OPERATION

MAINTENANCE

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, IN 46142

317-887-0729 fax: 317-881-1277

Service Department fax: 317-885-8683

www.Temptek.com

E-mail: [email protected]

Page: 3

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

TABLE OF CONTENTS

1.0 GENERAL 4

1.1 Safety 5

1.2 Efciency 5

1.3 Component Placement 5

2.0 INSTALLATION 7

2.1 Installation Drawings 8

2.2 Pump Base To Tank Mating Instructions 8

2.3 Plant Water Distribution 8

2.4 Water Treatment 8

2.5 Vacuum Breakers 9

2.6 Process Connections 9

2.7 Water Supply Connection 10

2.8 DrainAndOverowConnections 10

2.9 Electrical Connection 10

2.10 Probe Installation 11

3.0 OPERATIONS 12

3.1 General 13

3.2 Start Up/Operations Procedure 13

3.3 Instrument And Controls 16

4.0 MAINTENANCE 19

4.1 Preventive Maintenance 19

4.2 Pump Seal Service 20

4.3 Solenoid Valve Service 23

4.4 Instrument Calibration 24

5.0 ELECTRICAL

5.1 Electrical 26

6.0 APPENDIX 27

6.1 Typical Press Drop 28

6.2 Checkmate Second Set Point Guide 29

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 4

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

1.0 GENERAL

1.1 Safety

1.2 Efciency

1.3 Component Placement

Page: 5

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

1.1 SAFETY

A. It is important to become thoroughly familiar with this manual and the operating

characteristic of the equipment.

B. Several important references are made to safety considerations in this manual. It is the

owner’sresponsibilitytoassureproperoperatortraining,installation,operation,and

maintenance of the equipment.

C. Observe all warning and safety placards applied to the unit. Failure to observe warnings

can result in serious injury or death.

1.2 EFFICIENCY

A. Longtermefciencyofoperationislargelydeterminedbypropermaintenanceofthe

mechanical parts of the unit and the water quality.

B. TheFactoryacceptsnoresponsibilityforinefcientoperationordamagecausedby

improperinstallationoftheunitorforeignmaterialsintheprocessuid.

C. A water treatment system must be part of any pump tank system installation. The

servicesofaprofessionalqualiedwatertreatmentcompanyisrequiredtopreventscale,

corrosion, bacterial and biological growth.

The Factory highly recommends the services of a competent water treatment specialist

be obtained and his recommendations be followed. The Factory accepts no responsibility

forinefcientoperation,ordamagecausedbyforeignmaterialsorfailuretouseadequate

water treatment.

1.3 COMPONENT PLACEMENT

A. The TTK polyethylene pump tank station is designed to circulate temperature stabilized

uidthroughtheprocessresultinginprocesstemperaturecontrol.

B. Theabilityoftheequipmenttodothisissignicantlyaffectedbythemethodof

installation. The picture on the following page will give the reader an overview to the

major components of the unit.

C. If any questions arise, please contact The Factory Sales Representative or Service

Department.

D. TTKpumptanksystemsaredesignedforaspecicduty.Thecongurationofyour

system may differ from those in this manual. Contact the factory for additional

informationaboutyourspecicsystem.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 6

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

Service Lid

Alarm

Process Pump

Tower/Evaporator Pump

CheckmateTM Control Panel

Polyethylene Reservoir

Control Console

Polyethylene Tank

Sight Glass

Temperature Gauges

Alarm Beacon

Drain Valve

Pump Assembly

Pressure Gauges

Electrical Cabinet

CheckmateTM Control Panel

Page: 7

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

2.0 INSTALLATION

2.1 Installation Drawings

2.2 Pump Base To Tank Mating Instructions

2.3 Plant Water Distribution

2.4 Water Treatment

2.5 Vacuum Breakers

2.6 Process Connections

2.7 Water Supply Connection

2.8 DrainAndOverowConnection

2.9 Electrical Connection

2.10 Probe Installation

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 8

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

2.1 INSTALLATION DRAWINGS

A. A number of typical drawings have been provided within this manual and with the unit. It

is necessary to review all drawings supplied to assure proper installation.

B. Contactthefactoryfortheelectricaldiagramthatisspecictoyourunit.

C. You will need the unit serial number when contacting the factory.

2.2 PUMP BASE TO TANK MATING INSTRUCTIONS

A. The following instructions detail the mating of the pump base to the polyethylene tank.

Refer to the drawing on the next page.

B. Unless otherwise noted, all necessary parts have been supplied by the factory.

C. Optional standby pump, alarm automatic water make-up and control console are shown

in the drawing. Not all systems are supplied with these options.

D. Pleasenotethatthecontrolconsoleisshown‘offbase’fordrawingpurpose’sonly.

E. Pump discharge manifold and sight glass are not shown in the drawing.

F. Mate the pump base to the tank.

2.3 PLANT WATER DISTRIBUTION

A. Please note that all material used in the installation should be rated for 150°F and 200 psi

minimum. Also note that the materials should have the equivalent diameter or larger of

their process connections.

B. Plant water distribution system design is critical to maximum performance of the system.

Careful attention should be paid to the pipe sizing, length of runs, number of elbows, tees

andvalving,asspecied.Normally,themostsuccessfulinstallationsarethosewhich

insuremaximumowsandminimumpressuredrops.

C. All water distribution piping should be properly braced to prevent sway and undue stress.

Brace all pipes to assure no excess loads or strains are applied to the unit. Insulate all

pipes to control excessive condensation and to help maintain set temperature to the

process (on chilled water systems).

2.4 WATER TREATMENT

A. A water treatment system must be part of any cooling tower or chilled water

system installation. The services of a professional qualied water treatment

company is required. A water treatment system typically consists of a plan to

control scaling, corrosion and biological growth. Failure to control the quality of

the water can result in premature unit failure, fouling of plant wide heat transfer

surfaces and biological growth that can cause sickness and even death.

B. Keeping the water in a cooling tower or chilled water system clean has benet

by reducing scale and fouling and ensuring that the cooling process is operating

Page: 9

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

efciently. Fouling can lead to a loss of plant performance.

C. The Manufacturer assumes no responsibility for equipment failures or other results from

untreated or improperly treated water.

D. Legionella. Cooling towers must be treated for and protected from Legionella. Follow

ASHRAE Standard 188P and/or CTI Guidelines WTB-14B, and /or OSHA Guidelines

Section III Chapter 7 and/or the recommendation of your professional water treatment

expert to prevent Legionella in your tower. Failure to prevent Legionella may result in

sickness or death.

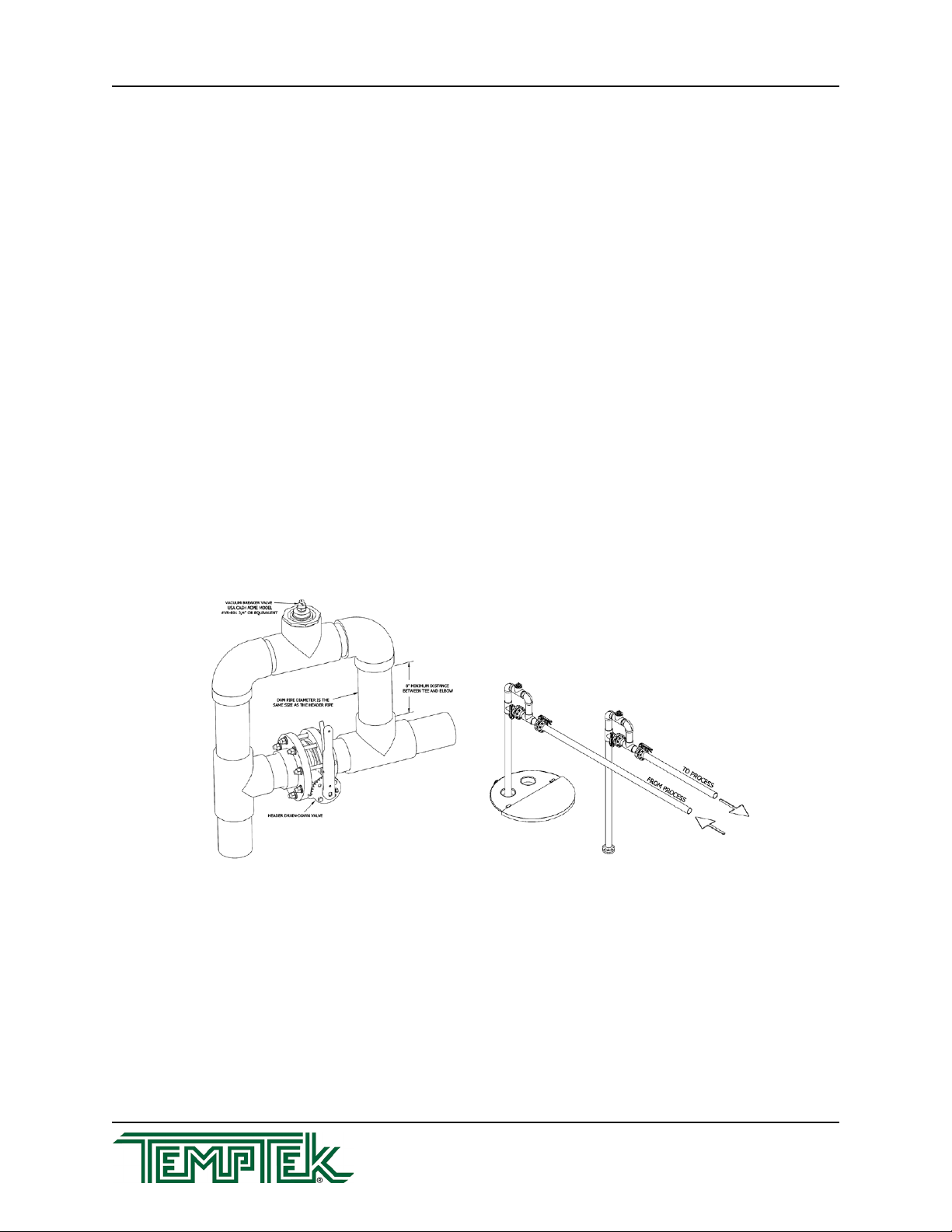

2.5 VACUUM BREAKERS

A. Vacuum breakers are required in all systems where overhead piping is used. Vacuum

breakerskeepthemainheadersystemfullofuidandpreventtankoverowduringshut

down periods.

B. The purpose of the vacuum breaker/anti-siphon (also called a drain-back dam) is to retain

water in the header system during shut-down periods and to allow for air purge which

eliminates shock to plumbing during start-up.

C. Itisnecessarytoinstallvacuumbreakersinthe‘supply’and‘return’lines.Thevacuum

breaker must be installed at the highest point in the system, nearest to the tanks to

bemosteffective.Anipplelengthof8inchesminimumisrequiredtocreatesufcient

vacuum to open the Cash Acme model VR-801.

2.6 PROCESS CONNECTIONS

A. Connect equipment process pump discharge port to main header supply line.

B. Connect equipment chiller or tower pump discharge port to chiller to tower cell inlet.

C. Install return line from the chiller or tower cell into the back 1/3 section of the cold tank

throughtheprovideopening.Returnlinefromtowerisgravityinducedowandslopingof

thispipeiscriticaltoproperowrates(minimum10%slope).

Typical Vacuum Breaker System

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 10

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

D. Install‘fromprocess”lineintotheback1/3sectionofthehotsideofthetankthroughthe

provided opening.

E. Note: all lines returning to the tank should extend below the water level, approximately

1.5 feet from the bottom of the tank.

F. Note: on a single pump system, the return line will connect directly to the chiller or tower

cell inlet. The line exiting out of the chiller or tower cell should be installed into the back

1/3 section of the cold side of the tank through the provided opening.

2.7 WATER MAKE-UP SUPPLY CONNECTION

A. Connecttheunit’s‘WATERSUPPLY’porttotheplant’scitywaterorwellwatersupply.

B. The factory recommend minimum operating water supply pressure requirement is

identiedontheunit’sdatapate.Thisisnormally20psi.

C. For units with electric automatic water make-up the water supply connection is located on

the reservoir. The make-up solenoid valve provides the water supply connection.

D. For units with mechanical automatic water make-up the water supply connection is

locatedonthereservoir.Abulk-headttingattachedtoaoatvalvelocatedinsidethe

tank provides the water supply connection.

E. Localcodesnormallyrequireabackowpreventiondevicebeinstalledinthewater

make-up line (customer supplied).

2.8 DRAIN AND OVERFLOW CONNECTIONS

A. Connectthedrainandoverowportstotheplant’sdrainagesystem.Thisisnormallya

sanitary sewer. Consult local codes.

2.9 ELECTRICAL CONNECTION

A. Electricalpowersupplyrequirementsareidentiedontheequipmentdataplate.

B. VERIFYTHATTHEAVAILABLEVOLTAGESUPPLYISTHESAMEASTHEUNIT’S

VOLTAGE REQUIREMENTS.

WARNING:Donotconnecttheunittoavoltagesupplysourcenotequaltotheunit’s

voltagerequirementsasspeciedontheunit’sdataplate.Useofincorrectvoltagewill

voidtheunit’swarrantyandcauseasignicanthazardthatmayresultinseriouspersonal

injury and unit damage.

C. For units with the optional central control console... a customer supplied four conductor

cable is required for connection to a customer supplied fused disconnecting means. The

fuseddisconnectingmeansshallbesizedandinstalledaccordingtotheunit’spower

supply requirements and local electrical codes. Connect the power cable to the terminal

L-1,L-2,L-3andthegroundlug(seegure2.9A).Somemodelsmayrequireapower

supply entry hole be made in the electrical cabinet.

D. For units without the optional central control console separate high voltage power with

customer supplied disconnecting means is required at each motor starter. Select a four

Page: 11

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

conductorcableratedforthemotor’spowerrequirementsandinstallaccordingtolocal

codes. Some motor starters may require a separate 110 volt line be installed.

E. GENERAL

1. Makecertainallgroundconnectionstotheunitareproperlyafxed.

2. Make certain power conductor, disconnecting means, and fusing are properly

sizedaccordingtotheunit’spowersupplyrequirements.

3. Makecertainallelectricalconnectionsaretightlyafxed.Anyloosewiring

connections must be tighten before engaging the power supply.

4. Make certain no moisture or standing water is present inside the electrical

cabinet.

2.10 PROBE INSTALLATION

A. For systems with the Checkmate control panel, two probes are shipped inside the

electrical cabinet and must be installed into the return distribution piping. These probes

are encased in a threaded bulb well.

B. P2 - From Process Probe: Install this probe into the from process return piping.

C. P4 - Tower/Evaporator Out Probe: Install this probe into the return line from the tower or

evaporator piping.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 12

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

3.0 OPERATIONS

3.1 General

3.2 Start Up/Operations Procedure

3.3 Instruments And Controls

Page: 13

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

3.1 GENERAL

A. Failuretofollowthefactoryrequiredoperationproceduresmayadverselyaffecttheunit’s

ability to adequately distribute process water and may create a hazardous operating

condition which may result in unit damage and serious operator injury.

B. The operator must verify that all plumbing and electrical connections are in accordance to

section 2 of this manual and local codes.

C. The Operations segment of this manual is outlined below:

3.2 Start-up/operations procedure - follow this segment to start the unit after the

initialinstallation.Thissectionincludesinformationonsystemll,electricmotor

phasing(pumprotation)andprocessowadjustments.

3.3 Instrument and controls - follow this segment to start up and operate the

instrument and controls. This section includes feature explanations of PTS and

CPTS instruments.

3.2 START UP / OPERATIONS

A. System Checks

1. Before operating the pump tank station, verify the unit piping installation and unit

electrical installation is correct as outlined in section 2 of this manual.

2. System should be leak checked prior to pump tank system operation.

B. System Fill

1. All systems have automatic make-up. Some have mechanical and some system

useaoatswitchthatactivatesanelectricsolenoidvalve.

2. For units with electric automatic water make-up. Turn on plant water supply

to the tank and activate power supply to the tank. The water make-up solenoid

willopenandbeginllingthetank.Note: if electrical service is not connected the

tankwillnotll,manuallyllthetankuntilthewaterlevelisevenwiththelocation

of the external level switch tank.

3. For units with mechanical water make-up... turn on the plant water supply to

thetank.Thetankwilllluntilthewaterlevelreachesthemake-upoat.

4. For all units...whenthewaterlevelhasnearlyreachedthetopofthebafe,the

unit is ready to start.

C. Valve Placement

1. Opento100%thesuctionvalvesontheprocessandtower/evaporatorpumps.

2. Opento50%thedischargevalvesontheprocessandtower/evaporatorpumps.

3. Opento100%themain‘to’and‘from’processheadervalves.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 14

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

4. Openasmanyprocessconnectionvalvesaspossibletoestablishawaterow

path.

D. Motor Rotation for Process Pump.

1. Activate the electrical power to the unit.

2. Turntheprocesspump‘on’momentarilyandthen‘off’again.Observetheshaftof

each motor. As the shaft slows to a stop, its rotation can be determined. Correct

rotation is clockwise when viewed from the rear of the motor.

3. If rotation for a motor is incorrect, disconnect power and reverse any two wires at

themotor’sstarterblock.

E. Motor Rotation For Tower / Evaporator Pump and Tower Fan

1. Activate the electrical power to the unit.

2. For tower system applications. It may be necessary to lower the setpoint on

the Checkmate control instrument.

3. Turnthepumporfan‘on’momentarily,then‘off’again.Observetheshaftofthe

motor. As the shaft slows to a stop, its rotation can be determined. For pump

motors, correct rotation is clockwise when viewed from the rear of the motor.

As for the cooling towers, correct rotation is counter clockwise or air should be

drawn from the bottom of the tower and out the top. For other tower cells, check

the tower cell manual for instructions on correct rotation.

4. If rotation for a motor is incorrect, disconnect power and reverse any two wires at

themotor’sstarterblock.

F. Pump Flow Adjustments

1. Whenstartingacentrifugalpump,itisimportanttoproperlysettheowrateto

prevent overloading of the pump motor. The following example is the start up

procedure for a two pump system.

2. Fully open the suction valves to the process and tower/evaporator pump. Note:

never allow the pumps to operate ‘dry’, as this can cause shaft seal failure.

3. Close the discharge valves of the process and tower/evaporator pumps. Note:

acentrifugalpumpcanbeoperatedwithnoowwithoutdamage,althoughthis

should not be for an extended period of time. Internal friction will cause the water

in the pump case to overheat.

4. Place an amp meter on one leg of the process pump wires at the motor starter.

Start the motor. Slowly open the discharge valve, allowing the process piping to

llwithwater.Afterowisestablished,continuetoopenthedischargevalve.The

ampdrawwillincreaseastheowincrease.Oncetherun-loadamprating,as

listed on the motor data tag, is reached, leave the valve in that position.

Page: 15

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

5. Note...ininitialstartup,thewaterusepointsmaynotbesufcienttofullyload

the motor. As you add use points, you should recheck the amp draw on the motor

and adjust the discharge valve as needed to prevent overloading the motor.

6. Repeat the procedure with the tower/evaporator pump.

7. On tower systems... the back pressure is very low on most tower cells. The

discharge valve may only be open one or two notches at full load.

8. Note... never operate a centrifugal pump without water in the case. Also, never

operate a centrifugal pump without checking for proper amp draw.

9. Note... always operate a centrifugal pump with the suction valve fully open.

Adjust the amp draw with the discharge valve starting from a closed position.

Starting from a wide open position can give a false reading and result in motor

overload.

10. Note... if during operations, the motor overload trips, the overloads will need to

be manually reset to restart operations. Once the pump is restarted, check for

excessive motor amps at the motor start block and throttle back the discharge

valve as needed.

G. Pump Tank Cycle

1. Two pump operation... the pump tank set is divided into two sections by a

bafe.Thesectionsarereferredtoasthe‘hotside’andthe‘coldside’.The

‘processpump’suctionisconnectedtothecoldsideandpumpswaterthrough

the distribution system. The water removes heat from the processes and returns

tothehotsideofthetank.The‘evaporatorpump’or‘towerpump’receiveswater

from the hot side of pumps the water through the chiller(s) or tower(s) and returns

the cooled water to the cold side of the tank.

2. One pump operation... the process pump suction is connected to the tank and

pumps water through the distribution system. The water removes heat from the

processes and passes through the chiller(s) or tower(s). The cooled water then

returns to the tank.

3. Standby pump operation... standby pumps are supplied as an option. If

installed on the system, they are supplied valved and wired such that switching

to back-up will take only a few minutes. A valve orientation guide is provided in

section 8 of this manual.

H. Valve Orientation for Normal and Standby Pump Operation

1. Refer to the following chart for proper position of the valves for normal and

standby operations:

I. Temperature and Pressure Gauges

1. Pressure gauges.The‘toprocess’pressuregaugesismountedonthe

dischargesideofthe‘toprocess’pumpandindicatespressuretothedistribution

system.The‘tower/evaporator’pressuregaugeismountedonthedischargeside

of the tower/evaporator pump and indicates pressure to the tower cell or chiller

evaporator.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 16

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

2. Temperature gauges. On systems without the digital annunciator display,

temperature gauges are mounted on both sides of the tank. On systems with the

Checkmate display, temperature is indicated on the digital display window.

3.3 INSTRUMENT AND CONTROLS

A. Instrument and Control Operation

1. Determinepowerissuppliedtotheunit,(notetheilluminated‘power’led).Moving

the power switch to the On position will activate the system.

2. Each motor has a Top OperatorTMswitchoron/offoperatorwhichmustbe‘on’

for the pump to activate. These switches allow for selecting primary or standby

pumpsasneeded.Toturnoffaselectedpumpsimplyswitch‘off’thepump.

Moving the power switch to the Off position will activate the system and will

deactivateallpumpsthathavebeenswitched‘on’bytheirindividualtoggles.

3. Each pump is controlled by dedicated motor starters. To activate the pump, move

the power switch to the On position. To deactivate the pump move the power

switch to the Off position.

B. CHECKMATETM Control Panel

1. The CheckmateTM control panel is divided into two sections: the Top OperatorsTM

and the CheckmateTM instrument control.

2. The CheckmateTM control panel is mounted to the central control console cabinet

door on most installations.

Master Start / Stop

Emergency Stop

Process Pump On / Off

Standby Pump On / Off

CheckmateTM Instrument

Display Panel

Operator Controls

Tower Fan On / Off

Alarm Enable / Disable

Tower Pump On / Off

Page: 17

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

3. Top OperatorsTM are provided for pump, fan control, and system start and stop.

4. An emergency stop operator is provided for emergency system shut down.

C. Top Operator for Pump Control

1. Tostartthepumpturntheswitchto“ON”.

2. Tostopthepumpturntheswitchto“OFF”.

3. Normalpumpoperationisindicatedbythe“GREEN”light.

Overloadconditionisindicatedbya“RED”light.

D. Top Operator for Tower Fan Control

1. Tostartthefanturntheswitchto“ON”.

2. Tostopthepumpturntheswitchto“OFF”.

3. Toautocontrolthetowerfanturntheswitchto“AUTO”.

The fan will be controlled by the system instrument.

4. Normalfanoperationisindicatedbythe“GREEN”light.

Overloadconditionisindicatedbya“RED”light.

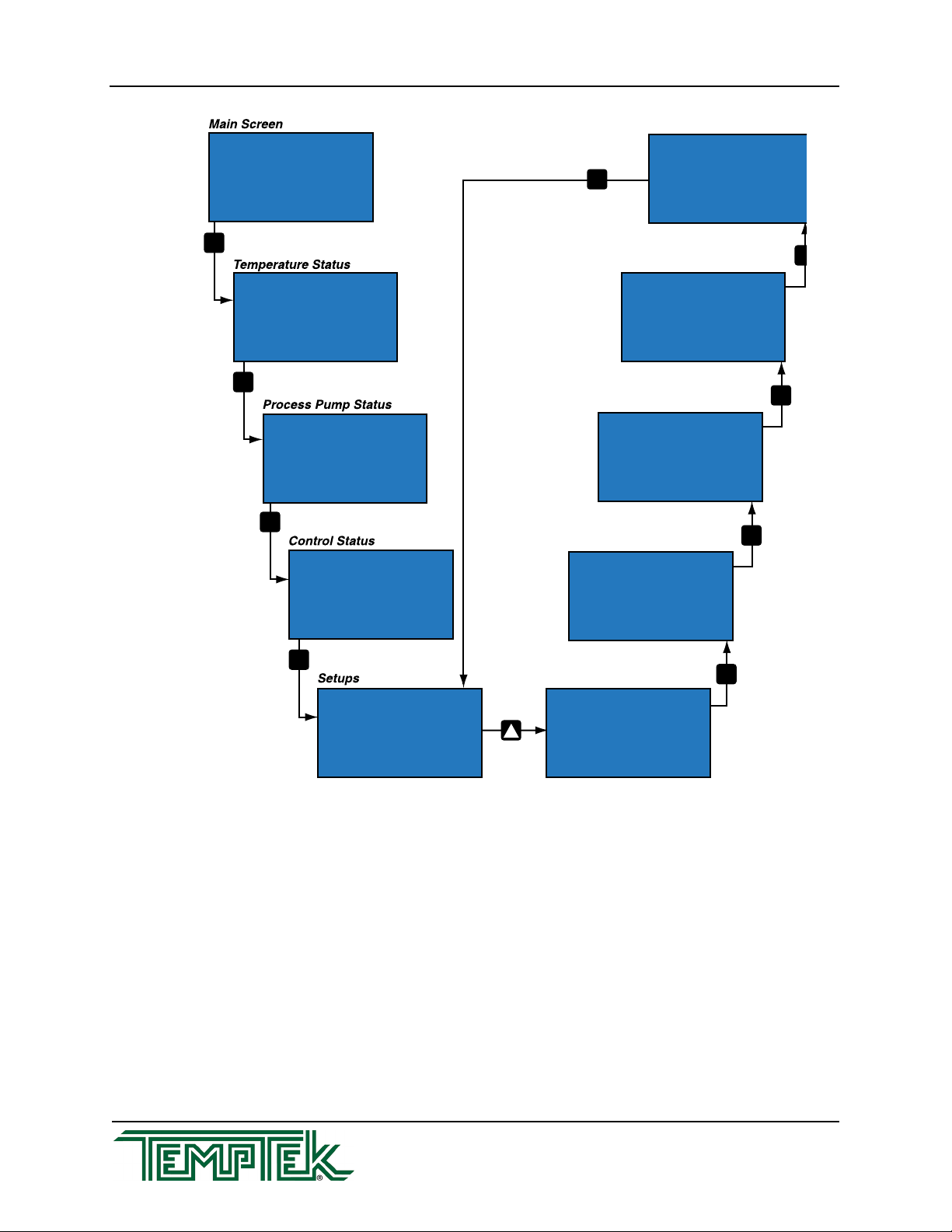

E. CheckmateTM Instrument Operation

1. Systeminformationisdisplayedinthecenterscreen.Usethe“SELECT”button

toscrollthroughthedifferentscreens.Usethe“UP”or“DOWN”arrowbuttonsto

set different operational parameters.

2. MAIN SCREEN. Displays the current To Process temperature in °F. The setpoint

temperature is also displayed.

3. TEMPERATURE STATUS SCREEN. Displays the From Process, To Process

and From Tower temperatures. On chilled water installations, there is a From

Chiller display instead of the From Tower display (as shown in the photo).

4. PROCESS PUMP STATUS SCREEN. Displays the on / off status of the process

pumps.

5. CONTROL STATUS SCREEN. Display the on / off status of the fans and process

pumps.

6. SETUP SCREENS. The operator can select this screen to enter the Setpoint

Temperature, the Hi Alarm and Low Alarm values. The Hi Alarm value is the

number of degree above the setpoint when the alarm will sound. The Lo Alarm

temperature is the number of degrees below the setpoint when the alarm will

sound.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 18

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

F. Alarm system operation

1. The audible / visual alarm system is an optional component. If installed, there is a

visual and audible alarm beacon mounted on the control cabinet (typical).

2. Low pump pressure...the‘toprocess’pressurefallsbelowthepressureswitch

setting. The default is 40 PSI to open the contacts and 20 PSI to close the

contacts and trigger the alarm).

Causes of low pump pressure are: pump not operating due to tripped

overloads; impeller damaged or some internal pump obstruction; excessive

gpm.

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

Setpoints

Config 1

Delays

Communication

System Config

SEL

SYSTEM CONFIG

ADRESS 1

RATE 1

COMMUNICATION

PRESSURE 15

LEVEL 4

DELAYS

OUTPUT 1 PUMP

CONFIGURE 1

OUTPUT 2 FAN

OUTPUT 3 FAN

OUTPUT 4

OUTPUT 5

OUTPUT 6

PROCESS 84

ALT SP 40

HI ALARM 20

LO ALARM 20

SETPOINTS

PRESS TO ENTER

SETUP ACCESS

PROCESS

STATUS

84 94

TO FROM

TOWER 94

84

PUMP 1

PROCESS PUMPS

ON 17

PUMP 2 OFF 13

1 PUMP

OUTPUTS

ON 17

2 FAN ON 17

3 FAN ON 17

4 ON 17

5 ON 17

6 ON 17

84

SETPOINT 84

°F

RANGE 1 to 99

TYPE 1

1 - PTS

2 - CPTS

Page: 19

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

3. Low water level... the low water level alarm can be adjusted from 1 - 30 minutes.

If you set to 0, the alarm is disable.

Possible causes: defective makeup solenoid, defective level switch,

makeup water supply insufcient.

4.0 MAINTENANCE

4.1 PREVENTIVE MAINTENANCE

A. The following is a guide to preventive maintenance. The frequency of maintenance will

varywitheachapplication,installationconditions,owrates,hoursofuseandoperating

temperatures.

B. Preventive maintenance:

1. Lubricate all motors. Note: some motors are supplied with sealed bearings.

2. Tighten all wire terminations.

3. Clean and check motor starter and contactor contacts.

4. Check safety switch settings (ie. alarm thermostat).

5. Check all motors for correct amperage.

6. Clean water make-up solenoid valve.

7. Cleanandushunit.

PTK Series Polyethylene Pump Tank Station with Checkmate Control System

Page: 20

TEMPTEK, INC.

525 East Stop 18 Road Greenwood, Indiana 46142

317-887-6352 Fax: 317-881-1277

Email: [email protected]

4.2 PUMP SEAL REPLACEMENT

A. The unit pump seal is a carbon/niresist shaft

seal assembly including a stationary member,

rotatingmemberandtensionspring(gure

4.2A).

B. The operator can determine the pump seal is

leakingwhenuidisidentiedleakingfrom

the pump case adapter.

C. Generally, a pump seal will leak due to

inadequateunitpressure,excessiveowandpooruidquality.

D. The operator should follow this procedure to replace the pump seal:

1. Disengageprocessoperations.Theoperatormustbecertainprocessuid

pressureisrelieved(pressuregaugereads“0”)andwatersystemowisshutoff

and all pressure relieved.

2. Disengage main power supply. The operator must verify the Power light on the

display is off.

3. Close the suction and discharge valves.

4. Drain pump. The pump can be drained by using the drain plug located on the

pump case.

5. Locate and remove the three motor wire leads from the motor wiring terminals.

The operator should note the wire terminal locations to ensure correct rewiring.

Thepowercordshouldberemovedfromthemotorhousing(gure4.2B).

6. Locate and remove the pump casing bolts. These bolts secure the motor and

motoradaptertothepumpcasing(gure4.2C).

7. Separate the motor and motor adapter from the pump casing to expose the pump

impeller(gure4.2D).Removethemotorandmotoradapterfromtheunitand

place on a workbench to continue the procedure.

8. Locate and remove the dust cap from motor end to expose slotted motor shaft.

Motor leads Figure 4.2B

Figure 4.2A

Impeller Figure 4.2DPump casing bolts Figure 4.2C

Table of contents

Popular Water System manuals by other brands

Everpure

Everpure QL1 Single Head EV9256-17Q Specification sheet

Everpure

Everpure Exubera Installation, use and maintenance handbook

Spectra Watermakers

Spectra Watermakers VENTURA 150 MPC-5000 owner's manual

EINHELL

EINHELL RG-WW 6536 operating instructions

Mi-T-M

Mi-T-M WTR Series Operator's manual

ZeroWater

ZeroWater Filter Bottle owner's manual

Greenfield

Greenfield ATLAS installation guide

Mueller

Mueller Hydro-Guard HG-6 Operating instructions manual

HoMedics

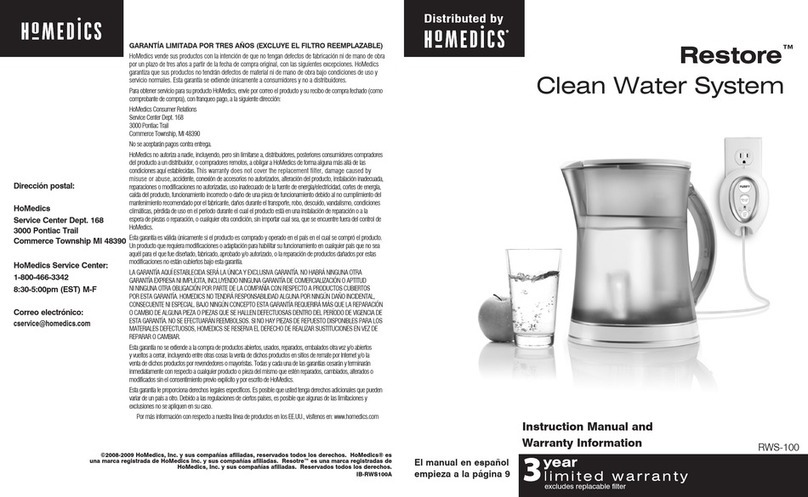

HoMedics Restore IB-RWS100A instruction manual

Wolf

Wolf FWS-2-60(L) installation manual

Balboa

Balboa Wavezone3NE Installation Instructions and Maintenance Manual

Judo

Judo Bioquell PURE Installation and operating instructions