Tenco M2R User manual

Pagina 1

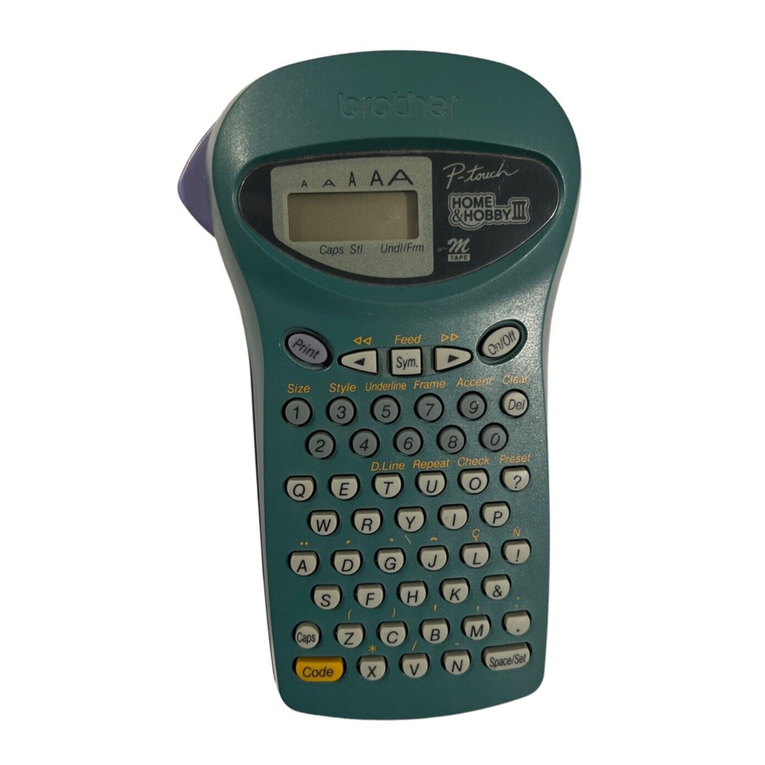

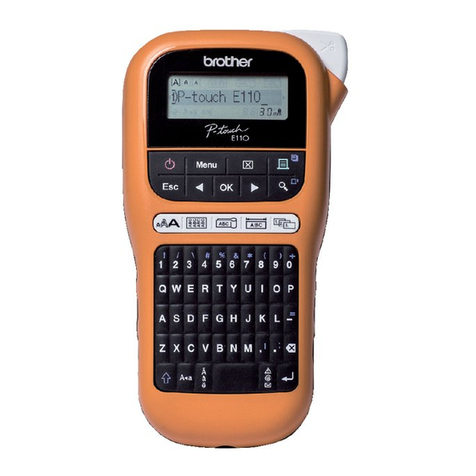

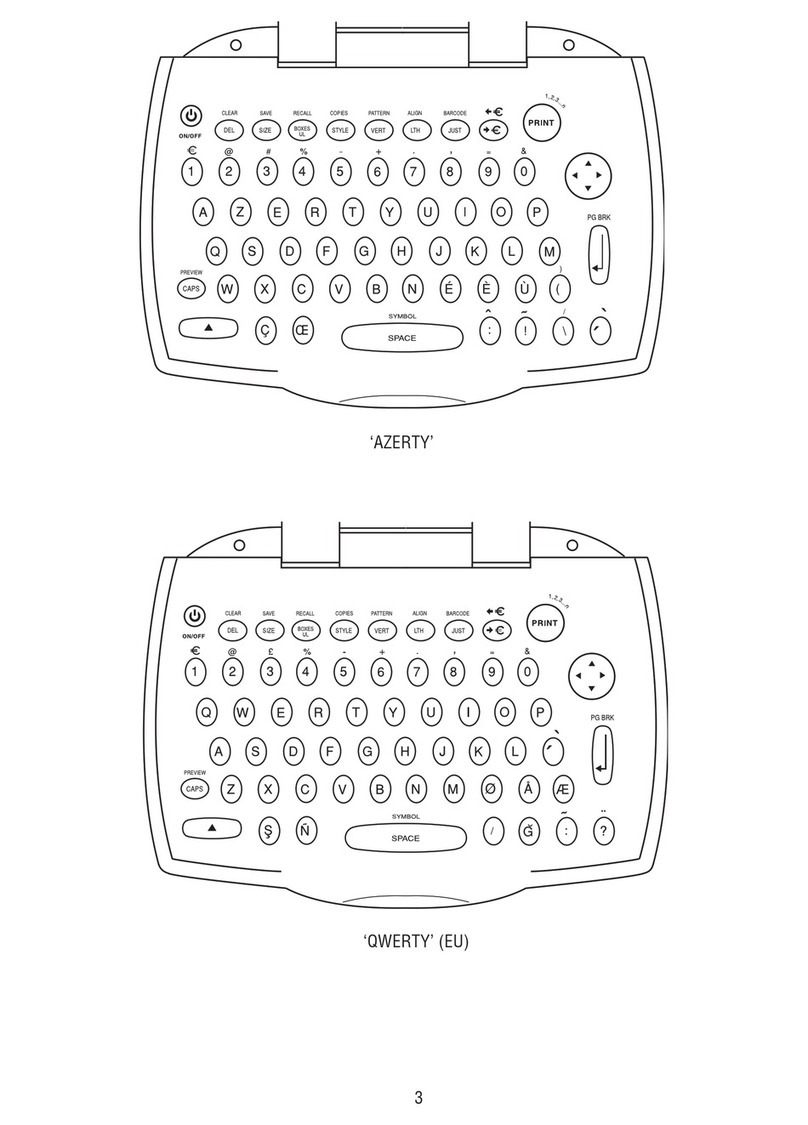

Control panel M2R, 900-1201-200 / 2016

Chart 7.1 Display buttons

01

Decreasing button

02

Increasing button

03

SELECTION button

04

ARROW DOWN button

05

ARROW UP button

06

EMERGENCY button

07

START button

Picture 1 Display

1

3

2

5

4

7

6

Pagina 2

CAPITOLO 8

COMMISSIONING

8.01 Starting and stopping the machine

8.01.01 PRELIMINARIES OPERATION AND STARTING

For turning the machine ON:

-Turn the general ON

-Release the emergency button ref. 6, pic 1.

8.01.02STOPPING THE MACHINE

It is possible to immediately stop the machine during the work cycle by pressing the EMEREGENCY

button. In this condition all the moving parts stop immediately independently from the machine status.

Once releasing the EMERGENCY button it is necessary to remove the bottle and have a ¾ mm portion of

label protruding from the blade.

Pagina 3

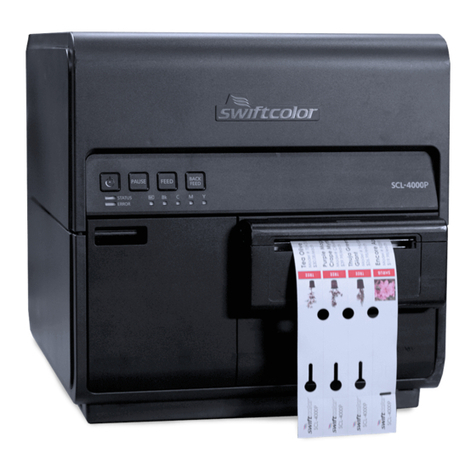

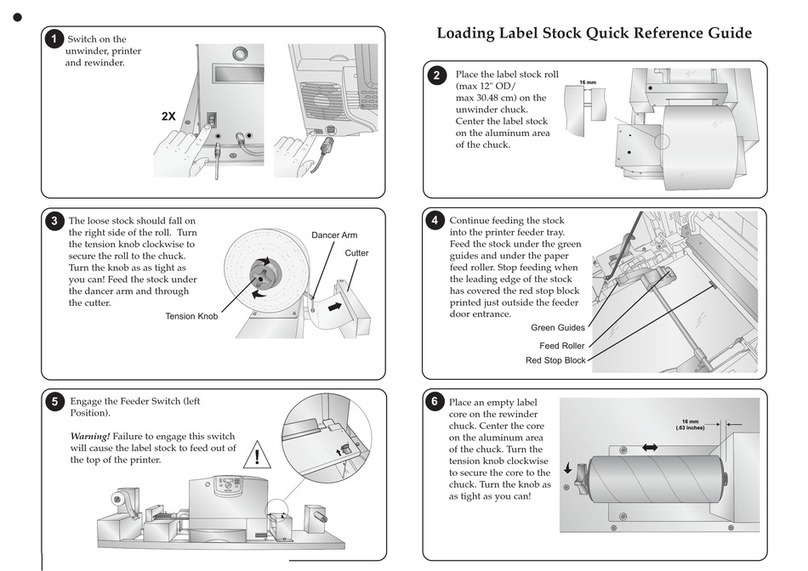

8.02 Main MENU

Turning the machine ON, the following is the main page shown on the display.

Use the buttons ARROW UP/DOWN (ref. 4 and 5) for moving the cursor thorough the display sections.

Use the SEL button for entering on a parameter to modify.

Use the buttons +/- (ref. 1 e 3) for enable / disable the functions and increasing / decreasing a value.

T1

T7

T2

T8

T3

T9

T10

T4

T5

T6

Pagina 4

NOTE: if no label is selected the cycle starts and stops almost immediately.

ATTENTION: When the bottle counter reaches “0” the machine stops. For starting again press SEL

For visualizing the cursor, press SEL once or the UP/DOWN button.

8.02.01 FUNCTION P, PARAMETER T1

This funcion is used for selecting a program from 0 to 19. PARAMETER T1.

Move the cursor in correspondence of the letter P, press <SEL> and select the program number with the

<+/-> buttons. For saving and exit press <SEL>. For each programs it is possible to set values and

parameters related to a particular bottle or label format, as explained in the following sections.

8.02.02 FUNCTION Q, PARAMETER T2

This function enable / disable the cycle for square bottles. This function can be linked to a program

number.

When the asterisk on the right of the letter Q is present, the square bottle cycle is active.

8.02.03 FUNCTION B(BOTTLE COUNTER), PARAMETER T3

For setting a new value move the cursor in correspondence ot the letter B, then press <SEL>, and act on

the <+> button until reaching the required value. Save and exit by pressing the <SEL> button.

For each processed bottle the value decreases. Once the counter goes at “0” the machine stops. For

continuing production set again a positive value.

Pagina 5

8.02.04 FUNCTION SP (SPOT DETECTION), PARAMETER T4

This function activates the detection of a reference on the bottle (usually a notch on the bottom). The T4

value shown on the right of “SP”shows the minimum width of the reference to detect. The machine must

be equipped with a dedicated photocell.

For activating this function, it is necessary to set a positive value.

For modifying this value, move the cursor in correspondence of the parameter. Press <SEL> for entering,

and use the <+/-> button until reaching the desired value. Save and exit by pressing <SEL>.

If the value is “0” the function is disabled.

8.02.05 FUNCTION P: PRINTING UNIT ENABLING, PARAMETER T5

This function activates the printing unit (if installed on the machine).

For activating this function move the cursor in correspondence of the parameter P. Press <SEL> and use

the ‘+’button in order to enable the function. An asterisk must appear. Save and exit by pressing <SEL>.

8.02.06 HOT FOIL PRINTER TEMPERATURE, PARAMETER T6

This values are related to the hot foil printing unit. The number on the left is the temperature detected by

the sensor. The number on the right is the required working temperature. If the printing unit is active but

the temperature hasn’t been reached, the wording BASSA TEMPERATURA is shown on the display.

8.02.11 SX: ENABLING THE LEFT LABELLING STATION, PARAMETER T7

On the row of the wording “SX”, there are a series of values that manage the functioning of the left

labelling station.

For enabling the left labelling station, move the cursor in correspondence of the parameter SX. Press

<SEL> for entering and use the button ‘+’until the asterisk appears. Save and exit by pressing <SEL>.

FRONT AND BACK LABEL APPLICATION

Enabling this function the machine applies two labels on a round container for each cycle. For achieving

this condition the display must show two asterisks on the right of the wording SX.

For activating this function, move the cursor in correspondence of the SX parameter, press <SEL> and

press the button ‘+’ until two asterisks appear. Save and exit by pressing <SEL>.

NOTE: When the square bottle cycle is active just one label for each cycle is applied. It is not possible to

apply two labels for each cycle. In this case, the second asterisk on the SX function, with printing unit

enabled, manages the printer functioning. With one asterisk the printer work on every label applied. With

two asterisks the printer works alternately (one label is printed over two).

On the picture above the machine is set on square bottle cycle with the printer working alternately.

Pagina 6

8.02.12 FUNCTION T8

This vaule determines the bottle rotation time, before the first bottle is defoiled. When working with square

bottle, this value determines the delay of label application from the cycle start. This value allows to obtain

the correct centering and positioning of the label on a square bottle.

For modifying this value, move the cursor in correspondence of the parameter. Press <SEL> for entering,

and use the <+/-> button until reaching the desired value. Save and exit by pressing <SEL>.

8.02.13FUNCTION T9 (JUST WITH FRONT AND BACK LABEL APPLICATION ON ROUND

CONTAINER)

This value determines the delay of the second label application. It is used for obtaining a correct centering

of front and back label. By increasing the value, the delay increases as well. The value can be recorded

and related to a program number.

For modifying this value, move the cursor in correspondence of the parameter. Press <SEL> for entering,

and use the <+/-> button until reaching the desired value. Save and exit by pressing <SEL>.

8.02.14 PORTION OF LABEL PROTRUDING FROM THE BLADE:PARAMETER T10

This function determines the portion of label protruding from the blade. We suggest to have a ¾ mm

portion of label protruding.

For modifying this value, move the cursor in correspondence of the parameter. Press <SEL> for entering,

and use the <+/-> button until reaching the desired value. Save and exit by pressing <SEL>.

T8

T9

T10

Other manuals for M2R

1

This manual suits for next models

1

Table of contents

Other Tenco Label Maker manuals