Index page

1 Safety advices ..................................................................... 4.......

1.1 Important Warnings .............................................................. 4.......

1.2 Danger Indications ............................................................... 4.......

1.3 Symbol descriptions .............................................................. 5.......

2 Introduction ........................................................................ 6.......

2.1 General informations ............................................................. 6

.......

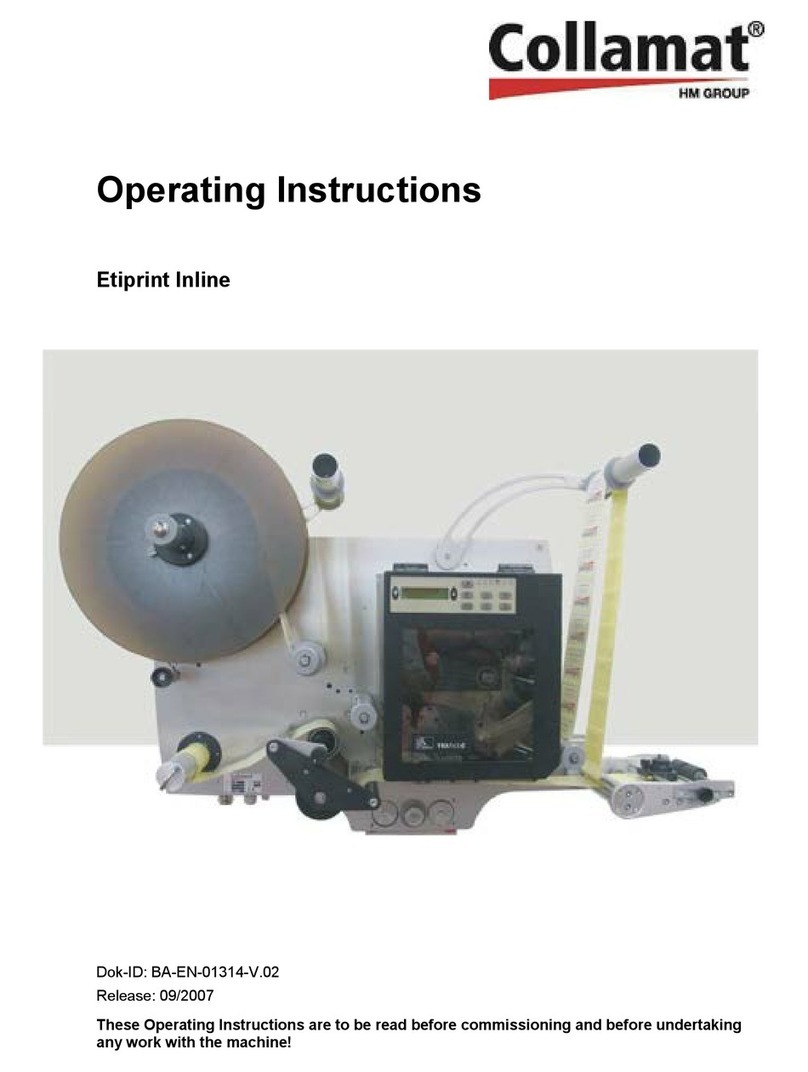

2.2 The labeler C6600 ................................................................ 6

.......

2.2.1 Prevention of accidents ......................................................... 7

.......

2.2.2 Noise suppression .............................................................. 7.......

2.2.3 Mechanical stability ............................................................. 7.......

2.3 Assembly parts ................................................................... 8.......

3 Mechanical adjustments ............................................................ 9.......

3.1 Traction unit ...................................................................... 9.......

3.1.1 Threading the labelweb ......................................................... 9.......

3.1.2 Adjustment of rewinder coupling force .......................................... 9.......

3.1.3 Readjustment of paper brake ................................................... 10

......

3.1.4 Longitudinal adjustment on the module rail ...................................... 10

......

3.2 Flap adapter ...................................................................... 11......

3.2.1 Inclination adjustment of flap adapter ........................................... 11......

3.2.2 Adjustment of the pressure roller of the flap adapter ............................ 11......

3.3 Adjustment of the optical label scanner ........................................... 12

......

3.4 Adjustment of the mechanical label scanner ...................................... 13......

4 Technical description ............................................................... 14......

4.1 Dispenser board .................................................................. 14......

4.1.1 Power supply ................................................................... 14

......

4.1.2 Motordriver ..................................................................... 14......

4.1.3 Controller ....................................................................... 14......

4.2 Signals and connection diagrams ................................................. 15......

4.2.1 Inputs .......................................................................... 16......

4.2.2 Outputs ........................................................................ 16

......

4.2.3 Isolated outputs ................................................................ 17......

4.2.4 Open-Collector-outputs ......................................................... 17

......

4.2.5 Currentsource-output ........................................................... 18......

4.3 Connection diagrams BUS X101, X102 ........................................... 19

......

4.4 Transformer wiring ............................................................... 19......

4.5 Connection of the mains input .................................................... 20......

4.6 Grounding of the labeler .......................................................... 20......

4.7 Connection of the mains output ................................................... 21......

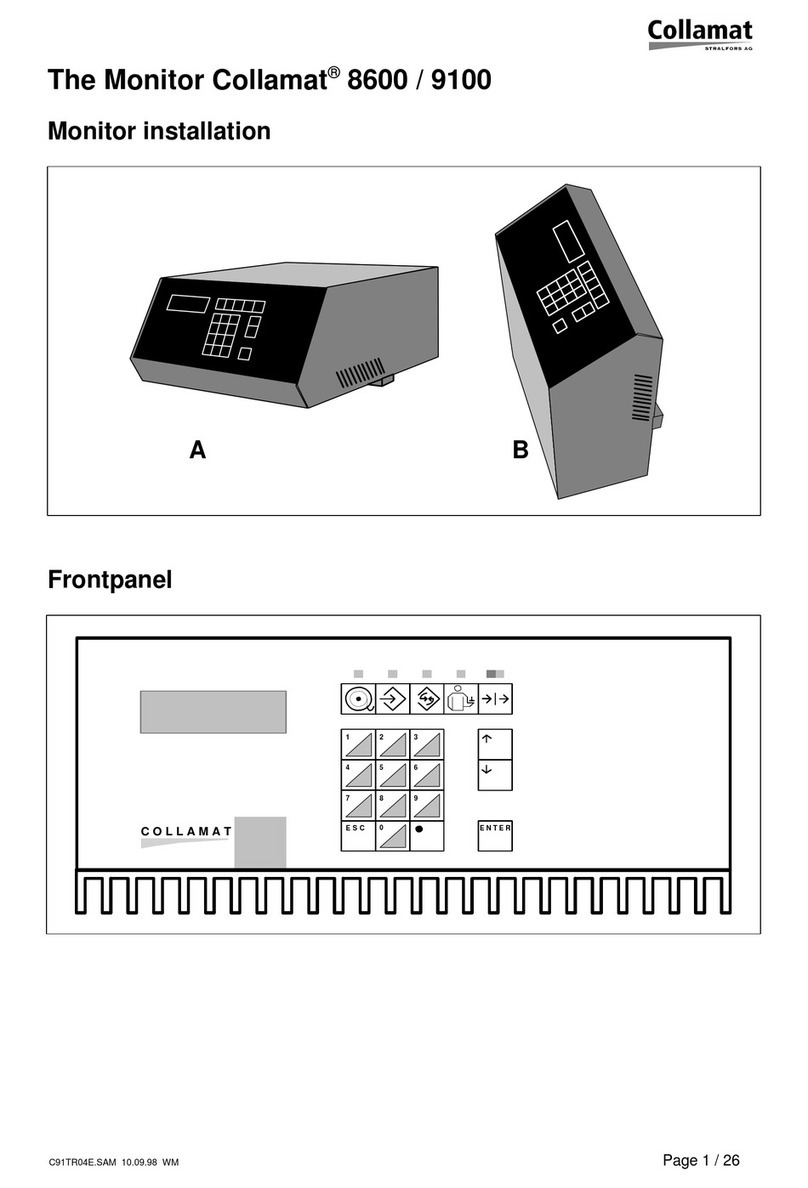

4.8 Connection of the frontpanel ...................................................... 21

......

5999.525-01F 13.01. 2010 PS page 1/ 56