TENTECH MPK254 User manual

Formato: 137mm x 190mm

P. 17

P. 03

Manual de uso

Micro-ohmímetro digital

Digital micro-ohmmeter User guide

www.tentech.com

3

MPK-254

Digital micro-ohmmeter

User’s guide

GF-2045

© 2016 TENTECH. All rights reserved.

4

Safety Precautions

•This equipment should be operated only by qualified and duly trained people,

closely observing the corresponding safety regulations and instructions

contained in the present User guide.

•It should be checked that the item to be measured is voltage free.

•Before starting with the measurements, be sure that the battery is well charged

and that the line voltage is between specified limits.

•Do not connect or disconnect the test leads during the measurement.

•There are no adjustable parts or parts that can be replaced by the user within the

equipment. Taking out the Control Panel in order to have an access to the

internal parts may be dangerous as there are high voltages inside, capable of

causing fatal accidents.

•Cleaning of this instrument should be carried out using a soft cleaning liquid,

after verifying that it doesn't attack the plastic parts used in the case and in the

Control Panel of this equipment.

This equipment should be used only by a trained and competent

person, strictly applying suitable safety rules.

Used symbols

Caution, refer to User Guide.

Equipment complies with current EU Directives.

The rubbish bin with a line through it means that in the European Union,

the product must undergo selective disposal for the recycling of electric

and electronic material, in compliance with Directive WEEE 2002/96/EC.

5

Index

1. Description......................................................................................................... 6

1.1. Operating principle...................................................................................... 6

2. Control panel ..................................................................................................... 7

3. Power supply ..................................................................................................... 8

3.1. Battery condition ......................................................................................... 8

3.2. Battery charger ........................................................................................... 8

4. Measurement..................................................................................................... 9

5. Messages ........................................................................................................ 10

6. Some notes about accuracy............................................................................. 12

7. RS232 output................................................................................................... 13

8. Cleaning .......................................................................................................... 13

9. Replacement fuse............................................................................................ 13

10. Technical specifications ................................................................................. 14

11. Warranty........................................................................................................ 16

6

1. Description

The MPK-254 micro-ohmmeter is a portable, microprocessor controlled

instrument, used to accurately measure very low contact resistances of

breakers and switches, busbars, transformers and engines windings, etc,

with test currents from 1 mA to 5 A.

•Kelvin architecture (four-terminal method).

•Digital reading, alphanumeric display.

•Up to 4½ digits readings.

•Powered by rechargeable battery.

•1 µresolution.

•200 maximum reading.

1.1. Operating principle

This device uses the Kelvin Bridge architecture, with four terminals,

avoiding testing leads resistance to cause error during measurement. The

operator may choose test current and the reading is obtained by

comparison through internal high-stability standards. The result appears

in the alphanumeric display that is very easy to read.

7

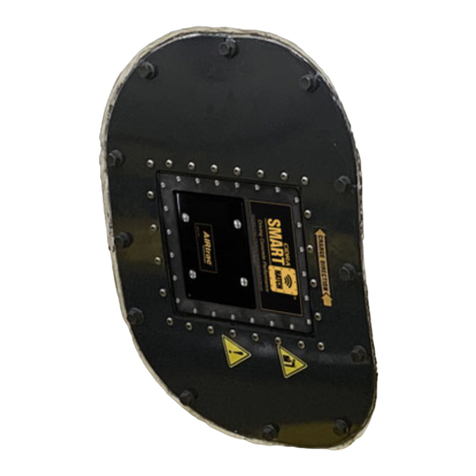

2. Control panel

5

4

32

1

6

7

89

Fuse.

Power cord connector.

On/Off switch.

Battery charge indicator.

Current terminal (C+).

Potential terminal (P+).

Potential terminal (P-).

Current terminal (C-).

RS232 data output.

Alphanumeric display. Shows both

the measured resistance value and

messages to the operator.

Start key.

Stop key.

Hold key. It retains the last

measurement in the display.

Battery key. To measure the battery

charge condition.

Test current control.

Range and test current selector.

On led.

8

3. Power supply

Internal battery powered, rechargeable, 12 V - 7 Ah.

At the end of the useful life, the battery has to be recy

cled or disposed of

properly in order to take care of the environment.

3.1. Battery condition

The charge condition of the battery can be verified before or during the

resistance measurement. In order to achieve that, the operator has to

press the battery key while the equipment is turned on. The bargraph

shows remaining charge as a percentile value. If during measurement the

charge of the battery achieves a critical level, the display will show the

BAT message notifying that the charge level is low. After a few minutes

the measurement will be automatically interrupted in order to preserve the

battery from a deep discharge that is prejudicial for its expected useful

life.

3.2. Battery charger

The built-in battery charger is always active when the equipment is

connected to the mains supply, even if the On/Off switch is turned off.

Charging procedure:

•Check that the On/Off switch is in Off.

•Connect the equipment to the mains supply.

•The battery charge indicator will keep on lightning with a red light

up to completing the charge. At that point, it will change to a green light,

being like this up to the equipment disconnection from the mains supply.

If the ON/OFFswitch was pressed, the display will indicate

CHARGING BAT.

9

4. Measurement

It should be checked that the item to be measured is voltage free.

1. Before turning the equipment On, connect the test leads to the item to

be measured and to the front panel terminals.

5

4

32

1

6

7

89

R

The alligator clamps in the drawing are only for illustration.

2. Using the test current selector , choose the range and the current

to be used.

3. Switch the equipment On using the On/Off .

4. The PRESS START message will appear showing that measurement

can be started. Press the Start key. Depending on the position of

the test current control the LOW CURRENT message will turn

up.

5. Turning the test current control clockwise increases the current.

Adjust this control until obtaining the desired value or until the current

indicator (bargraph) indicates 100%. The bargraph will show the test

current value as a percentage of the nominal value selected by using

the test current selector .

10

6. The lowest current for measuring is 10% of the nominal value. It is

important to consider that the measurement errors increase while test

current decreases. The equipment accuracy is specified for test

currents higher than 80%.

7. The display will show the resistance value measured and the

corresponding unit ([ohms], m[milli-ohms] or µ[micro-ohms]).

8. The value can be retained in the display by pressing the hold key.

Pressing this key again, the value will be released.

9. Press the Stop key in order to finish the measurement. Do not turn

Off the equipment without pressing the Stop key before.

10. Finally, when finishing measurements, turn the equipment Off using

the On/Off switch.

Precaution:

Do not connect or disconnect the test leads during the

measurement.

5. Messages

TENTECH MPK-254

When turning the equipment On using the On/Off switch, this

introductory message appears for a while.

WAIT...

This message appears each time the equipment needs to adjust any

parameter in order to optimize the readings.

PRESS START

The equipment is ready to start a measurement, thus the operator has to

press the Start key.

11

LOW CURRENT

It shows that the test current is not enough to carry out the reading. It

appears at the beginning of each test and it keeps on being there up to

the operator rotates the test current control clockwise, as necessary

for the test current to be higher than 10 % of the nominal current in the

range. The inappropriate connection of the cables may cause a difficult

circulation of test current. If this message keeps on being displayed,

please check that the current cables are connected appropriately.

OVERRANGE

It indicates that the measured resistance is higher than the maximum

value readable in the selected range.

H

Indicates that the value is the one retained in the display when pressing

the hold key.

BAT

It shows that the battery is quite discharged. It is necessary the battery to

be recharged.

CHARGING BAT

It appears when the equipment is connected to mains supply and the

ON/OFswitch, is ON.

12

6. Some notes about accuracy

In order to obtain the specified accuracy, the operator has to adjust the

test current to a value higher than the 80% of the nominal value. If it were

necessary, it is possible to use a lower current, but by doing this the

accuracy will be affected.

MPK-254 has an auto-compensation system that automatically eliminates

the error produced by internal offset. Thus, it is not necessary to carry out

measurements by reversing the polarity in order to compute the average

value. Nevertheless, if the operator suspect that there is a difference of

temperature between the contact points that would can generate

thermoelectric voltages, it is necessary to carry out two measurements by

reversing the current cables and so, the circulation sense of the current

through the resistance under measurement. The resistance value to be

measured will be the average between the values in one sense and in the

contrary (direct and inverse current).

13

7. RS232 output

The equipment has an RS232 data output in the control panel that can

be used to register measurements in a serial printer or data collector. The

outputs are the following ones:

Pin 2: Rx ; Pin 3: Tx ; Pin 5: Gnd;

Rate: 4800 bps

8 bits - no parity - 1 stop bit (8,n,1)

Note: In order to assure the compatibility with most printers available in

the market, the resistance units are shown with the following symbols:

uR = micro-ohm

mR = milli-ohm

R = ohm

8. Cleaning

The panel, terminals and connectors of the equipment must stay dry and

clean. Cleaning should be made using a wet cloth in water and a soft

detergent or isopropyl alcohol (be sure that the products to be used for

cleaning does not affect plastic).

9. Replacement fuse

To check the instrument fuse , remove it with a screw driver. If the fuse

is ruptured replace it by another with the following specifications:

Fuse Schurter, model SPT 5x20 (Time-lag) 5A/250V. High breaking capacity.

14

10. Technical specifications

Test currents :

1 mA - 10 mA - 100 mA - 1 A - 5 A.

Each current may be continuously adjustable from

0 to 100%.

Resistance ranges :

0 - 20 m@ 5 A.

0 - 600 m@ 5 A.

0 - 200 m@ 1 A.

0 - 2000 m@ 100 mA.

0 - 20 @ 10 mA.

0 - 200 @ 1 mA.

Resolution :

1 µ@ 5 A.

Output voltage :

Up to 10 Vd.c. @ 1 A (open circuit).

Measurement principle :

Four-terminal, Kelvin-type.

Basic accuracy :

± 0.2% of reading ± 2 digits.

Advanced features :

Digital direct reading of very low resistances in the

alphanumerical display, with up to 4½ digits. Very

fast and accurate measurements.

Serial data output :

RS232 @ 4800 bps. Suitable for data collection in

an external serial printer, computer or data-logger.

Environmental protection :

IP54 (with closed lid).

Safety class :

Meets the requirements of IEC 61010-1.

Power supply :

Rechargeable battery 12 V - 7 Ah.

Built-in battery charger :

220-240 V~ mains supply.

Operating temperature

range :

-5°C to 50°C.

Storage temperature range

:

-25°C to 65°C.

Humidity range :

95% RH (non condensing).

Weight :

Approx. 8

.7 kg (including accessories).

15

Dimensions :

378 x 308 x 175 mm.

Accessories :

2 Combined current and potential leads (1.8 m).

1 Communication cable (RS232).

1 Power cord.

1 User guide.

1 Carrying bag.

Subject to technical change without notice.

16

11. Warranty

TENTECH warrants the products for one year from date of shipment.

We will repair, without charge, any defects due to faulty materials or

workmanship. For warranty repair information, contact us or visit our

webpage www.tentech.com. This warranty does not apply to

accessories or damage caused where repairs have been made or

attempted by others. For the accessories and batteries the period of

warranty is six months.

TENTECH’ warranty obligation is limited, at TENTECH’ option, to free of

charge repair or replacement of the defective product within the warranty

period, or to refund of the purchase price.

Any costs for transportation to manufactures facility is the responsibility of the

customer. The manufacturer assumes no risk for damage in transit.

If TENTECH determines that the failure was caused by misuse, alteration,

accident or abnormal condition or handling, you will be charged for the

repair and transportation.

The manufacturer does not take any responsibility for any eventual

damage due to the use or impossibility to the use of the equipment

such as the loss of memory data, accidents in the field, loss of

profit, etc.

17

MPK-254

Micro-ohmímetro digital

Manual de uso

© 2016 TENTECH. Todos los derechos reservados.

18

Precauciones de Seguridad

•Estos equipos deben ser operados únicamente por personas calificadas,

debidamente entrenadas, respetando rigurosamente las normas de seguridad

pertinentes y las indicaciones contenidas en el actual manual de uso.

•Se debe verificar que el elemento a medir no esté energizado.

•Antes de comenzar las mediciones se debe verificar que la batería esté con

carga y que la tensión de línea está entre los límites especificados.

•No conecte o desconecte las puntas de prueba durante una medición.

•No existen partes ajustables o reemplazables por el usuario en el interior del

equipo. Retirar la tapa para acceder a su interior es peligroso, porque existen

tensiones elevadas, capaces de provocar accidentes fatales.

•La limpieza de este instrumento se debe realizar empleando un líquido limpiador

suave, verificando previamente que no ataca los materiales plásticos utilizados.

Este equipo debe ser operado únicamente por personas calificadas,

aplicando rigurosamente las normas de seguridad pertinentes.

Símbolos utilizados en el equipo

Atención, referirse al manual de uso.

El equipo está conforme con las directrices actuales de la U.E.

El contenedor de basura tachado significa que, en la Unión Europea, el

producto deberá ser objeto de una recogida selectiva de los residuos

para el reciclado de los aparatos eléctricos y electrónicos de

conformidad con la directiva WEEE 2002/96/CE.

19

Índice

1. Descripción...................................................................................................... 20

1.1. Principio de funcionamiento ...................................................................... 20

2. Función de los controles del panel................................................................... 21

3. Alimentación.................................................................................................... 22

3.1. Estado de carga de la batería ................................................................... 22

3.2. Cargador de batería.................................................................................. 22

4. Operando el equipo ......................................................................................... 23

5. Mensajes del display........................................................................................ 25

6. Consideraciones acerca de la exactitud........................................................... 26

7. Salida RS232................................................................................................... 26

8. Limpieza .......................................................................................................... 27

9. Cambio de fusible............................................................................................ 27

10. Especificaciones técnicas .............................................................................. 28

11. Término de Garantía...................................................................................... 30

20

1. Descripción

El micro-ohmímetro digital MPK-254 es un instrumento portátil,

controlado por microprocesador, destinado a medir con alta precisión

resistencias muy bajas de contacto de disyuntores, llaves, barras

conductoras, bobinados de transformadores y motores, etc., con

corrientes de prueba desde 1 mA hasta 5 A. Entre sus principales

características se destacan las siguientes:

•Controlado por microprocesador.

•Utiliza el método de los 4 terminales.

•Lectura digital, en display alfanumérico.

•Indicación de hasta 4½ dígitos.

•Batería recargable.

•Resolución de 1 µ.

•Lectura máxima de 200 .

•Salida de datos RS232.

1.1. Principio de funcionamiento

Utiliza la arquitectura del Puente de Kelvin, de cuatro terminales, evitando

que la resistencia propia de los cables de prueba introduzcan errores en

las mediciones. La corriente de prueba es seleccionable por el operador y

la indicación se obtiene por comparación con patrones internos de alta

estabilidad. El resultado es presentado en un visor alfanumérico de fácil

lectura.

21

2. Función de los controles del panel

5

4

32

1

6

7

89

Fusible.

Entrada de tensión de red.

On/Off - Llave de encendido.

Led indicador de carga de batería.

Borne positivo de corriente (C+).

Borne positivo de potencial (P+).

Borne negativo de potencial (P-).

Borne negativo de corriente (C-).

Salida RS232

Display alfanumérico, indicada el

valor de resistencia bajo ensayo y

avisos al usuario.

Start - Tecla de inicio del ensayo.

Stop - Tecla para finalizar el ensayo.

Hold - Mantiene congelada en el

display la última medición.

Battery -

Tecla pulsadora para medir

el estado de la batería.

Test current - Control de ajuste de

corriente.

Selector de rangos y de

corrientes.

On -Led de encendido.

Table of contents

Languages: