PPA-TF2Z064EN

Page 1 of 2

Instruction Manual

Compact Manometer

PPA100 / PPA101 / PPA102

The intended use of this product is for pressure measurement.

1 Safety Instructions

These safety instructions are intended to prevent hazardous situations

and/or equipment damage. These instructions indicate the level of

potential hazard with the labels of “Caution,” “Warning” or “Danger.”

They are all important notes for safety and must be followed in addition

to International Standards (ISO/IEC)*1), and other safety regulations.

*1) ISO 4414: Pneumatic fluid power - General rules relating to systems.

ISO 4413: Hydraulic fluid power - General rules relating to systems.

IEC 60204-1: Safety of machinery - Electrical equipment of machines.

(Part 1: General requirements)

ISO 10218-1: Robots and robotic devices - Safety requirements for

industrial robots - Part 1: Robots.

•Refer to product catalogue, Operation Manual and Handling

Precautions for SMC Products for additional information.

•Keep this manual in a safe place for future reference.

Caution indicates a hazard with a low level of risk which, if

not avoided, could result in minor or moderate injury.

Warning indicates a hazard with a medium level of risk

which, if not avoided, could result in death or serious injury.

Danger indicates a hazard with a high level of risk which, if

not avoided, will result in death or serious injury.

Warning

•Always ensure compliance with relevant safety laws and

standards.

•All work must be carried out in a safe manner by a qualified person in

compliance with applicable national regulations.

•Refer to the operation manual or catalogue on the SMC website (URL:

https://www.smcworld.com) for further Safety Instructions.

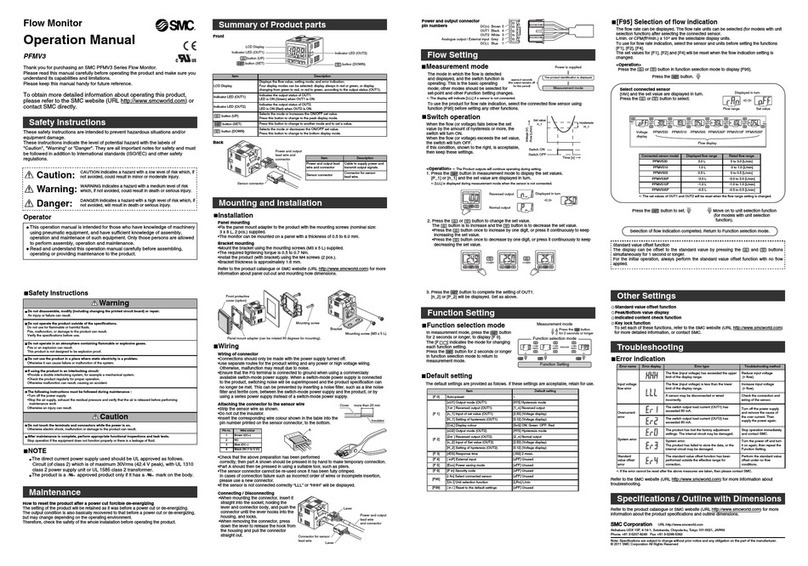

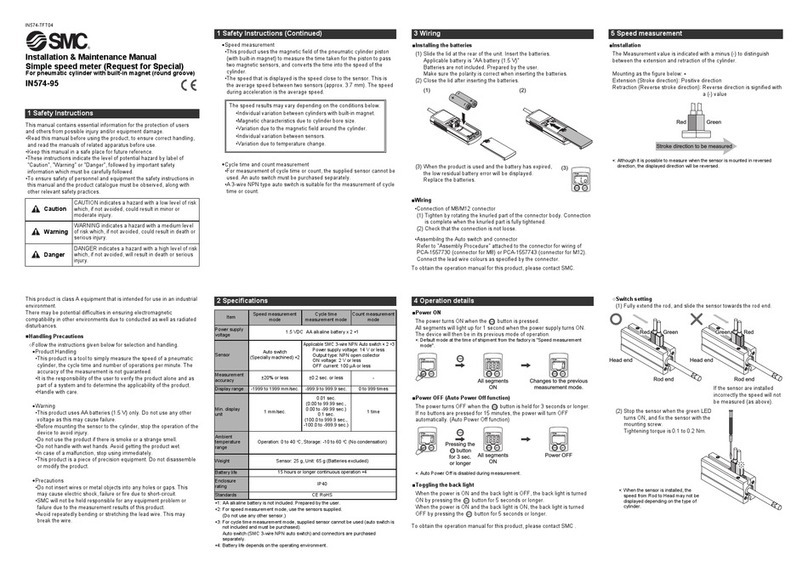

2 Specifications

2.1 General specifications

Model

Rated pressure range

3 digit LCD with backlight

Pressure display

discrimination

1/100

Minimum

display

unit

Error display

Over pressure, Memory data error,

Change battery sign

Function

Peak / bottom display, backlight, Auto power

OFF, Zero clear, Units display switching

Air, Non-corrosive gases, non-flammable gas

3 VDC, Type AA dry cell x 2 pcs.

Battery life

12 months continuous operation

(without backlight, at 25°C)

Temperature

characteristics

±3% F.S. (0 to 50°C with 25°C standard)

Operating

temperature range

0 to 50°C (no condensation)

35 to 85% RH (no condensation)

100 g (Unit: 50 g, Battery: 50 g)

*1) Batteries (manganese R6 or alkaline LR6) not included.

*2) For the type without the unit switching function are fixed to SI units

(kPa or MPa.

*3) With regard to the compatibility condition for EMC, the pressure

display value variation is ±15% F.S. or less.

Warning

Special products (-X) might have specifications different from those

shown in this section. Contact SMC for specific drawings.

3 Installation

3.1 Installation Warning

•Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment Warning

•Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

•Do not use in an explosive atmosphere.

•Do not expose to direct sunlight. Use a suitable protective cover.

•Do not install in a location subject to vibration or impact in excess of

the product’s specifications.

•Do not operate in a location exposed to radiant heat that would result

in temperatures in excess of the product’s specifications.

3 Installation (continued)

3.3 Piping Caution

•Before connecting piping be sure to clean up chips, cutting oil, dust etc.

•When installing piping or fittings, ensure sealant material does not

enter inside the port. When using seal tape, leave 1 thread exposed

on the end of the pipe/fitting.

•Tighten fittings to the specified tightening torque.

3.4 Lubrication Caution

•SMC products have been lubricated for life at manufacture, and do not

require lubrication in service.

•If a lubricant is to be used in the system, refer to catalogue for details.

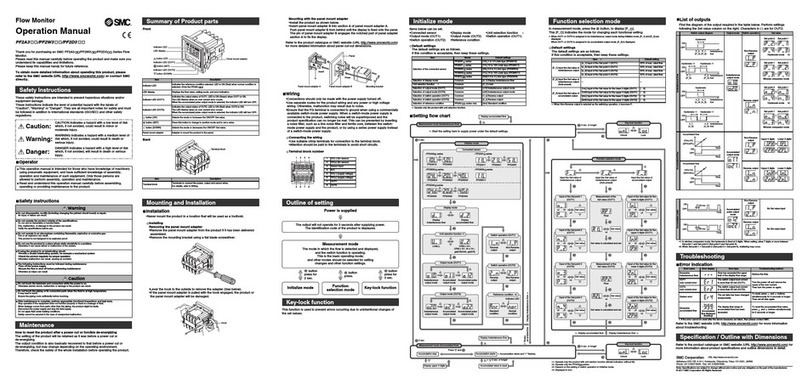

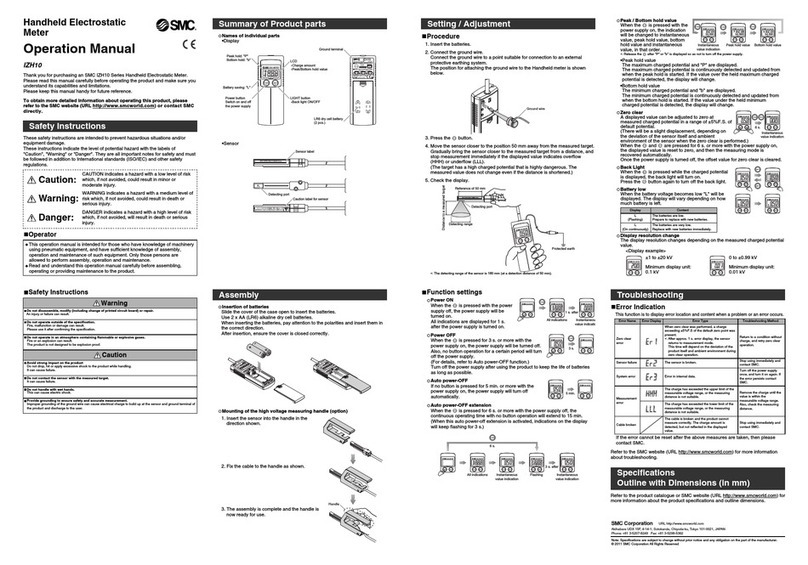

4 Settings

4.1 Initial Setting

Perform initial setting when using for the first time and after changing the

batteries, as the unit will display a memory data error.

1. Confirmation of display

When power is applied, if there is nothing on the

display, proceed to step 2.

If “Err” Is displayed on the LCD, switch the power

OFF and ON again. The display should clear.

Proceed to step 2.

2. Press and hold the POWER button for 6 seconds

or more.

The unit will move into the zero-clear mode. When

this happens “CAL” will be displayed.

3. Release the POWER button.

When zero clear is finished, the unit will operate.

4.2 Power ON Press the POWER button.

The power will turn ON.

When pressed and held for 6 seconds or more the

unit will move into zero-clear mode.

4.3 Power OFF Press and hold thePOWER button for 3 seconds

or more.

The power will turn OFF.

The power will also turn OFF If there is no button

operation for 5 minutes or more (auto power OFF

function).

4.4 Units Display Switching

1. Press and hold the POWER and LIGHT

buttons for 3 seconds or more.

The units on the LCD display will flash.

2. Press the LIGHT button

The units will change (refer to the units table).

3. Press the POWER button

The units are set and the units display

setting is complete.

(For products with units switching function).

4 Settings (continued)

Units available

MPa > bar > psi > kgf

kPa > bar > psi >

inHg > mmHg

kPa > bar > psi > kgf

4.5 Peak / Bottom display

Press the POWER button.

•For Peak display

To display the maximum pressure value, with “P”

displayed on the LCD. The display will change if the

pressure exceeds the pressure being held.

Press the POWER button.

•For Bottom display

To display the minimum pressure value, with “b”

displayed on the LCD. The display will change if the

pressure falls below the pressure being held.

Press the POWER to complete the setting.

Since this function is combined with the power OFF operation, the button

should be released when the “P” or “b” is displayed.

4.6 Auto Power OFF function

The power is turned OFF when there has been no

button operation for 5 minutes.

(To cancel this function refer to the lock mode

function below).

4.7 Lock mode function

Press and hold the POWER and LIGHT buttons

for 6 seconds or more.

The lock mode is activated and the auto power OFF

function is cancelled.

“L” is displayed on the LCD display.

When the power is turned OFF the lock mode is

released.

4.8 Turning ON the Backlight

Press the LIGHT button.

The display lights up when the button is pressed.

In lock mode it lights up when pressed and turns

OFF when pressed again.

However the maximum lighting time is

approximately one minute.

4.9 Zero clear function

Press the POWER button for 6 seconds or

more.

The zero displayed at atmospheric pressure can be

automatically adjusted.

This means it is possible to eliminate a display

discrepancy at atmospheric pressure.

1. Turn the power OFF.

2. Release the supply pressure to atmosphere.

3. When the POWER button is pressed and held

for 6 seconds or more the zero clear function is

performed and “CAL” is displayed on the LCD.