Terak 8510/a User manual

).

"

-:"

'System Installation

~§[][QJ/§]

GRAPHieS

COMPUTER

SYSTEM

8510/a

GRAPHies

COMPUTER

SYSTEM

INSTALLATION

&

USERS

GUIDE

This document describes the installation of aTERAK 8510/a Graphies Computer

System. Single and multiple disk drive configurations are presented, along with

system acceptance test procedures. Operating environment requirements, abasic

troubleshooting guide, maintenance

procedures

and descriptions of the system

components

are also included. Contained

in

appendices are descriptions of the

system modules and apart number listing of the major assemblies.

teral<

SCOrr5DALE,

ARIZONA

Part

No. 50-0010-001

"TERAK

CORPORATION

believes

that

the

infornlation contained herein

is

accurate.

In

no

event

will

TERAK

be

Hable

for

any losses

or

damages whether direct or indirect resulting from the

use

of

such

information, including, without limitation,

lasses

arising frorn claims

of

patent,

copyright,

and

trademark

infringement. No license

is

granted

hereby

for·the

use

of any

patent

or

patent

rights of

TERAK.

TERAK

reserves

the right

to

update

the

information contail1ed herein at

any

time without

further notice.

The

inforrnation

contained

herein is proprietary

to

TERAK,

CORPORATION

and

must

be

treated

as

confidential.

It

may

not

be

disclosed

to

others

or

used

for

any

purpose

except

as

expressly

consented

ta

by

"·ERAK."

8510/a

GRAPHieS

COMPUTER

SYSTEM

INSTALLATIO,N &

USERS

GUIDE

Part

No. 50-0010-001

FIRST

EDITION

Copyright

1980

by

TERAK CORPORATION

"Ail Rights Reserved"

TERAK

is

atrademark

of

TERAKCORPORATION.

DEC,

PDP-l1,RT-ll

and'LSI-l1

are

trademarks

of

DIGITAL

EQUIPMENT

CORPORATION.

{

CONTENTS

PAGE

)

INTRODUCTION.

... . 1

SECPflON

1.

PRE-INSTALLA~rION

CONSiDERATIONS

t,

••••••••••••••••••••••••••

2

1.1

PHYSICAL

INSPEC1-ION

OF

SYSTEM

COMPONENTS

,)

2

1.2

SYSTEM

POWER &OPERi\TING ENVIRONMENT REQUIREMENTS 2

1.2.1 Input Voltage &Frequency Options 2

1.2.2

Power

Requirements

t

•••••••••••••••••••••••••••••••••••

2

1.2.3

Temperature

Limits 2

1.2.4 Relative Humidity R,ange 3

1.3

UNIT

DIMENSIONS

' 3

1.4

UNIT'WEIGHT

'3

2.

SYSTEM

INSTALLATION

PROCEDURES

3

2.1

SINGLE DISK

DRIVE

CONFIGURATI()N 3

2.2

MULTIPLE

DISK

DRIVE

CONFIGURAT·ION 4

58

UNIT

COVER

REMOVAL-REPLACEMENT

8

5.1 8510, 8512 &8515 UNITS 8

5.2 8532-1

MONITOR

9

6.

UNIT

AC

INPUT

VOLTAGE

SELECTION

9

6.1

8510/12/15 UNITS 9

6.2

8532-1

MONITOR

UNIT

11

7.

UNIT

CHANGES

FOR

50

Hz

&

60

Hz

AC

POWER

FREQUENCIES

12

8.

IJ~~I<:

1rIl(){jIJI-IE5;II()()lrl~(i

13

9.

SYSTEM

DESCRIPTION

a

•••••••

a

••••••••••••••••

a

•••••••••••••••••

17

9.1 8510

DATA

PROCESSOR

SYSTEM a

••••••••••••••••••••••••••••••••••••••••••

17

9.2·

8532-1

MONITOR

a'

•••••••••••••••••••••••••••••••••••••••••

a

•••••••••

a

••••

a

•••••

0

••••••

17

9.3 8532-2.KEYBOARD a

••••••

a

•••••••••••••••••••••••••••••••••••••••

a

••••••••••••••••••••••

17

9.4 8512 DISK SUBSYSTEM

17

9.5 8515 EXPANSION

SySTEM

a

•••••••••••••••••••••••••••••••

a

•••••••••••••••••••••••••••

19

(

f,

)

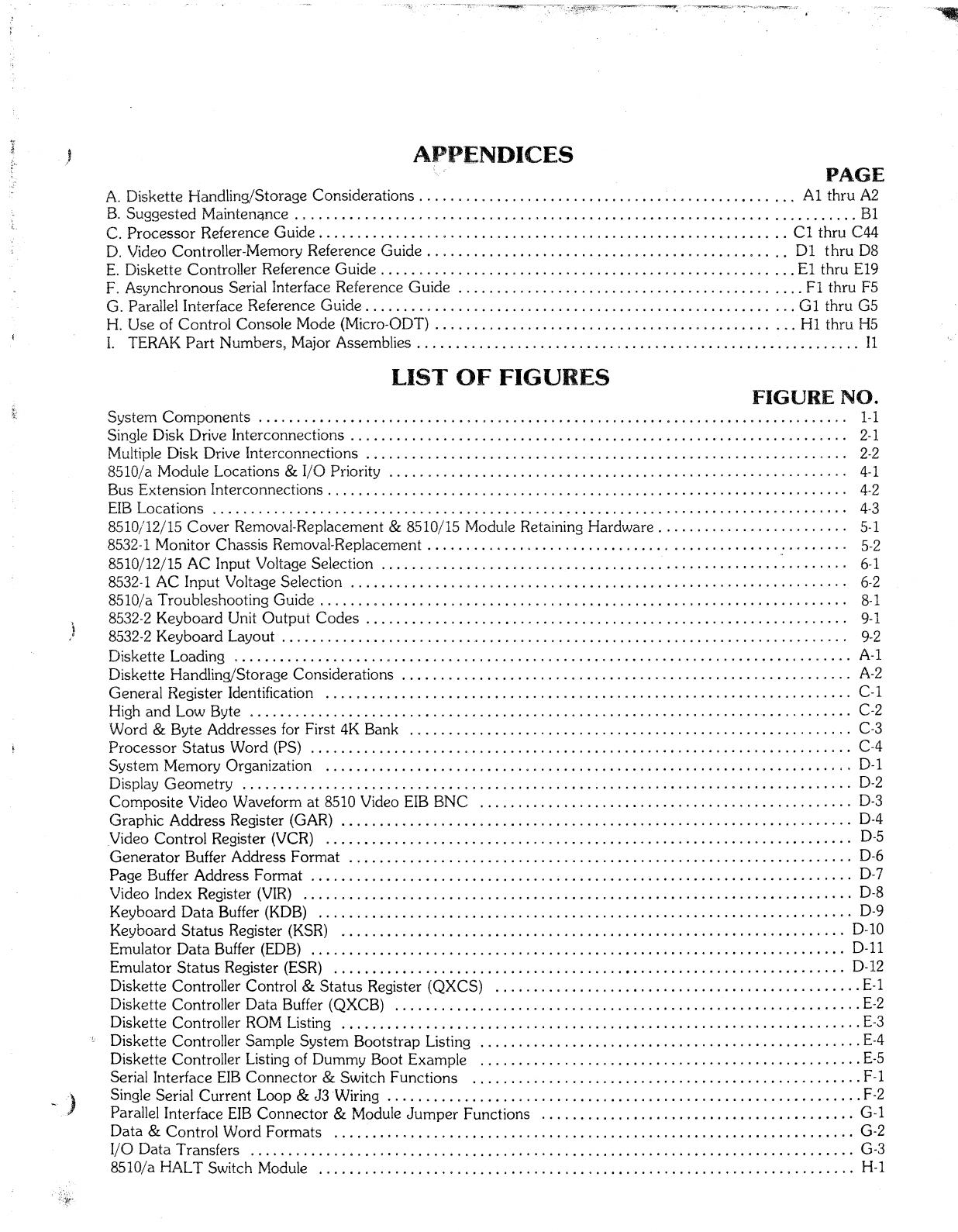

APPENDICES

PAGE

A.

Diskette Handling/Storage

Considerations.

. . .

.. ..

~

..

1 1

••••••••••••••

1

•••••

~

••••••••••

, • •

••

Al

thru

A2

B.

Suggested Maintenance 0 • 0

••••••••••••••

0

••••••

>

•••

0'

••••••••••

0 • 0

••

0 • 0

••••••

0 0 • 1

010

•••••

BI

C. Processor Reference Guide 0

•••

0.0

•••••••

1'

•••

1

••••••••••

1

•••

1

•••

1

••••••

0

•••••••••

0

......

Cl

thru

C44

D. Video Controller-Memory Reference Guide

...

0'

•••••••••••••

0

••••••

0

•••••••

0

••••

0 1 0

•••

0

'0

Dl

thru

08

E.

Diskette Controller Reference Guide

..

0

•••••••••••••

0 • o

••••••••••••

o

••

o0

El

thru

E19

F.

Asynchronous

SeriaI Interface Reference

Guide

1'

•••••••••••••••••••

0

••••••••

0 0

••••••

fl

thru

F5

G. Parallel Interface Reference Guide

~

Gl

thru G5

H.

Use

of

Control

Console Mode (Micro-OOT) 1

•••••

1

••••••••••••••••

1

•••••

~

•••••••

••

•

••

Hl

thru

1-I5

1.

TERAK

Part

Numbers, Major Assemblies 1

•••••••••••••••••••••••••••••••

0

,"'

••••

1,.1.

Il

LIST

OF

FIGURES

FIGURE

NO.

System Components '0 • 1

••

0

•••••

0 • 0

••••

0 0

••

1··1

Single Disk Drive Interconnections 0

••

0

•••

0 • 0

••••••

0 • 0 • 0

••

0

••••

0

•••

0 0 0

••

0

•••

0 0 0 • 0 • 0

••••

0

•••

0 • 0

2-1

Multiple Disk Drive Interconnections o

••

0

••••••

0 • 0

•••••••

0

•••••••••••••

000

••

0 • 0 • 0

••

0 0

•••••

0 • " 0

••••

0 0

2-2

8510/a Module Locations &

I/C)

Priority

0.0

•••••••••

0

••••••

0.

0 • 0

••

0

•••

0 0

••••

0 • 0

••••••••

0

••

0

••

'0'

0 •

••

4-1

Bus Extension Interconnections 0

•••••

0

••

0

•••

0 • 0 • 0

••••

0

•••

0

•••••••

0 0 • 0 • 0 • 0

••

0 • 0

•••••••

0 • 0 0

••

0 • • • • •

••

4-2

EIB

Locations

..

0

••••

0

•••••

0 0 • 0

•••••

0

•••••••••

0

•••••

0

••••

0 • 0 • 0 • 0 • 0

••

0

•••

0 0

••

0 0 0 0

••••

0 • 0

•••••••••

0

4-3

8510/12/15

Caver

Removal-Replacement &8510/15 Module Retaining Hardware 0

00

••••

0

•••

0

••

0 •

0.01.

• •

••

5-1

8532-1

Monitor Chassis Ren1oval-Repla.cement 0 0 • 0 0

•••••••

0 0

••••

0

••

0

••

0

••

0 0 • 0

•••••••••••

0 • • •

••

• 0 • •

••

5-2

8510/12/15 AC Input Voltage Selection .000

•••••••

0

•••••

0

•••••

'0

••

0 • 0 • 0

••

0.

0

.0'

••••

0 0

••

0

•••

'~

•

••••

•

••

6-1

8532-1

AC Input Voltage Selection

..

0

•••

0

•••••

0

••••••••••••••••

0 • 0

•••

0

••••••••

0 0 • 0

••••

0

••••••••

0

••

0

6-2

8510/a Troubleshooting Guide

000

•••

0

•••

0

••

0.0

•••••

000.0

•••••••••••

0

••••••

0 •

••

8-1

8532-2

Keyboard Unit Output Codes

00

••

0.00.0

••

0

•••••

0 0

•••

0

•••

0

••••••••

0

•••••••

0 0 •

00'

•••••

0

•••

0 •

••

9-1

8532-2

Keyboard

Layout .0 • 0 • 0

•••••

0 0 • 0 0 0

•••

0

••

0 • ,

•••

0

••••••••••••••••••

0

••••••

0 • 0

••

0 • 0 0 •

000

..

0 • • •

••

9-2

Diskette Loading

..

0000

•••

0 0 • 0 0 • 0

.0'

•••

0 • 0 0

•••••••••••••••••

0 • 0

•••

0

••

0

••••

0'

•••••••

00.

00

••••••••••

A-l

Diskette HandlingJStorage Considerations

...

0

••••

0 • 0

••

0

••••••••••

0

••

0

•••••••••••

0

••

0

••

0

••••

0 0 • • • • •

••

A-2

General I<egister Identification 0 0

•••

0 0 0 • 0 • 0

••

0 • 0 0 • 0

••

0 • 0 • 0 0

••••

0 0 • 0 0 0

•••

0000000• 000

••

0 0

•••

0

•••

0 • 0 •

o'

C-l

High and Law Byte .0 0 0 0

••

0

••

0

••

0 • 0 0 0 0 0

••

0 • 0 •

0"

••

0

••

0 • 0 0

••••

0 • 0 • 0 • 0 0 0 0 • 0 0

•••••••••••

0 •

'.

0

••••••••

0 0

C-2

Ward

&Byte Addresses

for

First

4K

Bank

o,.

0 • 0 • 0

•••

0

••

0 • 0

•••

0 0 • 0

••••

0 0 • 0

••••

0 • 0 • 0

•••

0 0 0 • 0 • 0

•••

0 •

••

C-3

Processor Status Ward (PS) o

••

0

••••••••

0 0 • 0 • 0 0

••••••

0

•••••••

0

••••

0 • 0 0 • 0 0

••

0 • 0 0

•••

0

••

0

••

0 • 0 0 • 0

•••

0 0 C-4

System Memory Organization .0 • 0

••••••

0 0

•••••••

0 • 0

•••••••••

0 0

•••••••••••••

0 0

•••••

0 • 0

••••

0 0

••

0 • •

••

D-1

Display Geometry

..

0

••

0 • 0

••••••••

0

•••••••••

0 0

••

0

••••••••••••

0

••••••••••••

0 0

••

0

•••••

0 • 0 0 • 0

••••••••

'D-2

Composite Video Waveform at 8510 Video

EIB

BNe

0

•••••••

0 •

o'

•0

••••••

0 • 0 • 0 0

•••••••••

00

D-3

Graphie Address Register (GAR) 0 0

•••

0

•••

0 • 0

••

0

•••••••

0

••••••

0

••

0

•••••

0 • 0

•••••

0

•••

0

••

0

••

0 0 0

•••

0

••

0 0

D-4

,Video Control Register (VeR)

..

0

•••

0 • 0 •

00'

••

0

••

0 0

•••••••••••

000

•••

0 0 • 0 • 0

••

0 • 0 • 0 0

00

••

0

•••

00'

00'

0 0

.0

D-5

Generator Buffer Address Format

o.,

0 0 0 0 0 0 0

••

0 0

••

0 • 0 • 0

•••

00'

0

•••

00

••

0

00'

••••••

0

.00.

0 • 0 • 0

0000

•••

0 •

o'

0-6

Page Buffer Address

Format.

0 0 • 0 • o

••

0 • 0 • 0 0 • 0 • 0 • 0 0 0 • 0 0 0

••

0

••

0

0000000

••

00'

0 0

0000

••

0 0 0

0000000

••••••

o'

D-7

Video Index Register

(VIR)

0 0

••••

0 • 0 0 0

••

0 0 0 0 • 0 0

••

0

••

0 0

•••

0

•••

0 0 0 0

••

0 • 0 0 0 0 0 • 0

••

0 0 • 0 • 0 0 0 0 0 0 0

••••

0

••

0 0

D-8

Keybaard Data Bufter

(KDB)

0 0 0

••

0 • 0 0 0 0 • 0 0

•••••••

0 0

••

0 0

••••••

0

••

0 0

••

0 0 • 0 • 0 0 0

••••

0 0 • 0

••

0 0

••

0

D-9

Keyboard Status Register

(KSR)

.0 0

••

0 0 • 0 0 0 • 0

••••••

0 0 0

••••

0

•••••••••••

0

•••

0000• 00000

••

0 0 0 0 0 0

••••

o'

0-10

Emulator Data Buffer

(EDB)

o'

0

••

0 0 • 0 0

••

0 0 0

••••••

0

•••••••

0

••

0 0 • 0 • 0 0

••••

0 0 • 0 0 0 • 0 • 0 0 0 0 • 0 0 0 0 0 • 0

D-11

Emulator Status Register

(ESR)

...

0 0 0

••

0 • 0 • 0 0

••

0 0

•••

0 0 0 0 • 0 0 • 0 0 • 0

••

0

••••

0 0 • 0 0 0

•••

0

••

0 0 • 0 • 0 0 0 0 0

••

0 • 0

0-12

Diskette Controller Control &Status Register (QXCS)

00'

o'

0 0

•••

0 • o

••••

0

••

0'

00'

••

00000

•••

000

•••••

o.

00'

E-l

Diskette Controller Data Buffer (QXCB)

..

0.0

•••

0 0

•••

0 • 0

•••••••••••••••••

0 • 0

••

0

••••

0

•••

0'

0 •

00

• 0

.0

••••

E-2

Diskette Controller

ROM

Listing 0 0 • 0 0 • 0 0 0

••

0 0 • 0 0

•••••••••••••

0 0

•••••••••

0 • 0 0 0

••

0 0

••••••

0 0 0

••••••••

0 •

E-3

Diskette Controller Sample System Bootstrap Listing o

••

0

•••

0 0

••••••

0 0

•••

0 0 0 0 • 0 • 0

••••

0

•••

0 0 0 0

...

0 0

••••••

E-4

Diskette Controller Listing of Dummy Boat Example

....

0

••

0

•••••••••••

0 0 0

•••••••

0 0 0 0

••

0 0 0

•••

0

••••

0 • 0 •

E-5

SeriaI Interface

EIB

Connector &Switch Functions o

•••••••

000

••

00'

••

00'

0.00000.

0

o'

••

0

••

0.0

••

0

••

o'

•••

F-1

Single Seriai Current Loop &J3 'Wiring

..

0 0

••

0 0

•••

0 0

000

••••

0 • 0 •

o'

00'

0000

••••

0

••

0

•••

0 0 • 0 0 • 0

.00000.00

••

F-2

Parallel Interface

EIB

Connector &Module

Jumper

Functions

.0.0

••

0 • 0

•••

0 • 0

•••

0 •

0000000.

0

••

o'

•0000000 G-1

Data &Control Word Formats 0 0 • 0 0 • 0

••••

0

•••

0 0

••••••••••••

0 • 0 0

•••••

0

••

0

•••

0 • 0 • 0

•••••

0

••

000

••

0 • 0 • 0

G-2

1/0 Data Transfers

.0

•••••••

0

•••••

0

••

0

••

0

000

••••

0 0 0 • 0

•••••

0

••

0 • o

••••

00

••

0

••••

0 0

••

0 • 0

•••

0

••

0 •

00

••

o'

G-3

8510/a HALT Switch Module

...

0 0

•••••

0 0

••••••••

0

••••

o'

•••••

0

•••••

0

0.0

••••

0

••••••••

0 0

••

00'

••

0 0

••••

H-1

:(

.

<,

INTIIODUCTION

)

The

TERAK

8510/a

is a

general-purpose,

disk-based

cornputer

intended

for

data

processing

and

medium-

resolution

.graphies applications. A320 x240

dot

pattern

and/or

1920

eharacters

(24 lines of 80)

can

be

displayed

(under

program

control)

on

a

12

in.

monochrome

CRT.

Four

drives,

accommodating

IBM 3740

formatted

(8 in.)

Happy

di?kettes,

can

be

included

in a

systern

configur-

ation.

The

hardware

is

madularized

into a

keyboard

unit,

a

CRT

display, a

data

proeessor

unit,

bus

expansion

unit

and

optional

drive units. T'he

system

companents

are

shawn

in Figure

1-1.

AlI

components

are

light-weight

and

are

suitable

for office

and

laboratory

environments.

This

document

describes

the

installation

of

aTERAK

8510/a

Graphie

Computer

System.

The

installation

consists

of

the

interconnection

and

aeceptance

testingof

the

system

hardware. Aiso included is abrief trouble-

shooting

guide

and

system description.

Appendices

contain

diskette

handling/storage

considerations,

sug-

gested

maintenance

procedures,

a

parts

list

and

reference

guides

for

the system hardware.

Figure

1·1

System

Components

0001-000

1

1PRE-INSP"f

ALLATION

CONSIDERA,TI'ONS

1.1

PHYSICAL INSPECTION

OF

SYSTEM

COMPONENTS

Carefully unpack

aU

the shippingcontainers; save

aH

the

containermaterials for equipment

storage

or

future re-

shiprnent.

Each

container

is

marked

with

the

'unitpart

number(s)

and individual seriaI number(s). (AppendixI lists

the

part

numbers

of the major assemblies.)

Use

the

fol1owing

1iSt5

ta

verify

the

contents

of

each

container.

8510

Container:

8510

Data

Processor

1ea.

8510/a

Systern

Acceptance

,Disk 1ea.

8510/a Docurnentation Kit 1ea.

AC

Power

Cord

. . . . . . . . . . . . . . . . . . . .

..

1ea.

8515 Container:

8515

Expansion

System

0

1ea.

Cable, Aux. Drive,

Short

1ea.

8510

Bus

Exte,nsion

EIB

(packed

inside

the

8515 unit) 1ea.

AC

Power

Cord

. . . . . . . . . . . . . . . . . . . .

..

1'ea.

8512

Container:

8512

Disk

Subsystem

1ea.

Cable,

Aux. Drive,

Short

~.

1ea.

A,C

Power

Cord

. . . . . . . . . . . . . . . . . . . .

..

1ea.

8532-1,

8532-2

Container:

8532-1 Monitor 1ea.

8532

Monitor

Cable (6 ft.)

..........•...

lea.

8532-2

Keyboard

(with integral 8532

KeyboardCableAssembly)

';

1ea.

AC

Power

Cord

'

..

'. . . . . . . . . . . . . . . . . .

..

lea.

Inspect

aIl

iteIns

for

obvious signs of damage.

DO

NOT

interconnect

a

damaged

item

ta

asystetn;

contact

T'ERAK,

or its representative, for further information.

NOTE:

The

8510, 8512

and

8515 diskdrive-heads

are

protected

during

shipmentby

foam

blacks

that

are

inserted

in

the

disk drive openings. These

blocks

ensure

that

the

cloors

will

stayopen,

so that the -drive ,heads

remain

unloaded

(not clown)

and

therefore

protected.

Remove

and

save

these

blocks for future re-shipment.

Shipping

the

units without

the

foam blacks in

placemay

result

in

damage

to

the drive heads: -

1.2

SYS1"'EM

POWER

&OPERATING

ENVIRONMENT

REQUIREMEN~rS

The

'TERAK

8510/a system

requires

single-phase

ac

power

sources and

earth-grounded

chassis

protection.

Each

system

unit

that

requires

ac

power

input

is

delivered with

an

ac

power

cord

that

cantains

three

insulated 18-gauge stranded wires.

The

chassis

ground

wire is

connected

to

the

round

pin of

the

ac

power

cord.

2

A

grounding

conductor

that

is

equal,

or

greater

in

size,

to

tnepower

cord,

must

be

a

part

of

the

branch

circuit

that

supplies

each

unit of the 8510/3 system.,

The

grounding

conductor

mentioned

ab

ove

must

be

grounded

to

earth

at

the

service

equipment

or

otber

acceptable

building

earth

ground such as the building

frame in

the

case

'of ahigh-rise steel frarne

structure.

The

attachment-plug

receptacles

in

the

vicinityof

each

unit of

the

8510/a

system

are

aIl

ta

be

ofa

groundingtype,

and

thegrounding

conductors

serving

these·receptacles

are

to

be

connected

to

earth

ground

at

the

serviceequip-

ment

or

other

acceptacle

building earth

ground

such as

the

building frame

in

the case

of

ahigh-rise steel frarne

structure.

1.2.1 AC Input Voltage &

Frequency

Options

100

V

RMS

50

Hz/60 riz

120 vRMS 50

Hz/60

f'iz

220

V

RMS

50

Hz/6ü

I-Iz

240

V

RMS

50

Hz/6ü

Hz

~

Each

unit has

been

factory wired

for

aparticular

ac

input

voltage and frequency. Labels, indicating the values,

were affixed to

the

unit

whenit

was initiallyshippedfrom

the

factory.

Ta

use

an

acvoltage

other

than

that

indicatedby

the

label,

internaljurrlpeismust

be

changed.

See

Section

6

for

adescription of voltage selection.

Each'unit

has

been

configured for either,SÜ

l-Iz

or

60

Hz.

operation.

For 50

Hz

operation, alabel'signifying

that

frequency

wa~,

affixedto<the

unitwhenit.

wasinitially

,

shipped

'from

tb~

factory.·See'Section.7

for

adescription

of

thechangesnecessary

to

aperate

atSOI-iz

vs 60

l-iz.

~NI:N!iJ

THE 8512,8532·1 AND

8532·2

UNITS AREDESIGNED

AND

INTENDED FOR US·EONLY'WITH

THE.

8510

UNrr.

ANY

ATTEMPTTO

CONNECT

THE

8512,

8532-1

OR

8532-2

UNITS

TOADEVICEOTHER THAN

THE

8510

UNIT

MA

y

RESIJL

T

IN

DAMAGE TO THE

EQUIPMENT.

1.2~2.Power

Requirements

8510 Unit:

250

Watts

(Maxirnum)

8512 Unit:

100

Wa~ts'

(Nominal)

8515 Unit:

250

Watts.(Maximum)

8532-1

Unit:

24

'Watts'(Nominal)

8532-2 Unit:· 2.S·Watts. (Nominal)

1.2.3 Temperature Limits

System

OperatingRange:

SOF (10

C)

to

100 F

(37.7

C)

Hardware

Storage

Range:

~40F

(·40

C)

to

167F

(75

C)

·~.Media

'Storage

Range:

SOF

(IOC)

to120

F

(49

C)

.

(

(,

(

t-'

11.2.4 Relative

I--Il.1miejity

Ra.11ge

Operating:

201.?f)

ta

BOOk>

w'ithout condensation

Storage:

5~b

ta

98%

without

condensation

of

the

units. In

the

following

descriptions,

the

inter-

connec

tian

diagrams

indicate

which

EIBs

are

involved

in

aparticular configuration.

Labels

on

each

cable

identify

their use.

1.3 UNIT DIMENSIONS

8510: 7.5 in (19

cm)

Hx12.2 in (31

cm)

Wx

18 in. (46

cm)

D

8515:

Same as

8510

8512: 5.5 in. (14 cm)

1-1

x12.2 in. (31

cm)

W x

18

in. (46 cm) 0

8532-1: 15.5 in. (39 crn)

I-I

x12.2 in.

(31

cm)

W x

12 in. (30.5 cm)

1)

8532-2: 2.5 in. (6.4 cm)

I-I

x17.8 in. (45

cm)

Wx

7.1 in. (18 cm) 0

1.4

UNI1·

WEIGHT

8510: 45.5 lbs. (Shipping

container

wt.: 53.5 lbs.)

851S: 41.5 lbs (Shipping

container

wt.:

50

lbs.)

8512:

31

lbs. (Shipping

container

wt.:

40

lbs.)

8532-1: 30.8 lbs.

(Sl'"

lb

8532-2: 6.3 lbs.

11pPlng

contaIner

wt.:

48,.2

s.)

2

INSTALLATION

PROCEDURES

Installation

of

an

8510/a

system

is

straight-forward

and,

typicaHy,

can

be

accamplished

within 15

minutes.

[

The

system

can

be

configured via plug-in

modules,

connectors

and

switches

~ounted

on

External

Interface

Boards

(EIBs)

that

are

Il1stalled

on

the

rear

surfaces

~~'c

....

...

__

..

=_

____,-_-----

2.1

SINGI_E

DISK

DRIVE

CONFIGURATION

Figure 2-1

depicts

the

sta.ndard configuration of 8510

EIBs

as

installed

at

the

factory. Asixft. cable,

packed

in

a

plastic

bag

in

the

8532 shipping

container,

is

used

ta

connect

the

8532-1 Monitor

ta

the

Video

EIB

of

the

8510

Data

Processor

unit.

Another

six ft. cable, integral

ta

the

8532-2

Keyboard,

a1so plugs into

the

Video EIB..

1"he

connectors

on

the

Video EIB

are

labeled

"Monitor"

and

"Keyboard",

and

are

of

different

size,

for

easy

recognition.

The

"Keyboard/Emulator"

s\vitch,

on

the

Video

EIB,

must

be

in

the

Sl'"[)

(off) position

ta

use

the

8532-1

Monitor

and

8532-2

Keyboard

as

the

system

console.

The

switch

is

OFF

when

a

red

bar

appears

at

the

ON

sicle

of

the

housing;

canversely,

the

switch

is

ON

when

a

red

bar

appears

at

the

OFF

sicle.

The

switches

on

the

8510

Asynchronaus

SeriaI Interface

EIB

must

be

set

as

shawn

in

Figufe

2-1.

The

8532-1

Monitor

and

··8510

Data

Processor

have

individual

ac

power

cards.

Asingle

switch

on

the

8510

contraIs

tht2

ac

power

ta

bath

units.

This

completes

the

single disk drive

interconnections.

Proceed

further

in

Sections

2&4for

other

system

configurations.

Back of 8532-1 Monitor

Back Of 8510

Data

Processor

8510 Floppy Disk

EIB

o~

~

o

Blank Cover

o

c:=:==::::J

Seriai Interface EIB 0

c==J

CJ

W0

(PN 31-0003-250) Video

EIB

0

q.....

l0l

'-=====:;:::=============~

'?c::....:-~F--

9--'---'"

----;::

.....

.#

\ \

Monitor Cable (lncluded With 8532-1 Monitor )(PN 90-0012-006)

"\

\

,\"

\Composite Video

\\

Output

BNe

\

Connector

(Similar

T0

\ElA

RS-170)

\\\

"-

\\\\

/ 1 2

Keybo~d/Emulator

SW.

Must

o

Iml

Be

Off

For

8532-1,-2

Selection.

nDepress

Off

Skie

Of Switch;

Red

Off Marking Appears At

Opposite

Sîde

On:AJt

Off:Std.

Back

of

8532-2

K::~:r:

/ / J

.,.

...

Ke.

board

Cable (Included With 8532-2 Keyboard)(PN 91-0032-001

.....

"

<"

._----.,.

~:.R

Serial ElB Switches

(*Indicates the switch state)

(Depress On/Off Side Of Switch;

Red Marking Appears At OppOsite Sicle.)

Figure

2-1

Single Disk Drive

Interconnections

0002-000

3

(

An

Alternative Unit

Stacking

Arrangerrlent.

(Long Ribbon

Cable

Option

Required)

or

AC'"

p... Short Ribbon Cable Induded With An

8512

Unit

;?

__

-...

ower

(PN90~OOO8~OOl)

,I~~

"

__

~

/

'Tf

-~--.".

~

..........

---------.

:=:dL

---

.....

"\'

~.~._-:

/S:~:;8512

~\-;

~

l====~~

/ic=>

1

.....

ü

10

~

/

<75..8

,

--

..o~====

/

ë2~...,--_",",""=,,

Empty Dip Sockets

__

...

0

\

Back

of

8512

\

\:Ë

\

~CJ

\.8c

\

tf)2

~9'6:

-\

--

:-Q

\==::::-====~

'7~\

0:: _

~\

°D~~

,~.\

p..-/~

\

0"2

\ .

./

\

"',7\/----:::::-/~

c::>

---~

....

Back of

8512

Video

EIB

Blank Cover

Seriai

Interface

EIB

0c::::::::::J

r--\

L.-~

0_'

-----il

.

...-J

~c:=:JI,I~_=

~

~

1

Back

of

8510

r--'---=--.--s------.t-----

(PN

31-0003-250J-iL

..

1

8532-1-2

~;

Connections

ToAC

Power

Driver T

erminator

Dip 0

8510

Floppy

Disk

EIB

........

0

~o

--n

;..J"'I..-.......:...----:-l

8512

Floppy Disk BBs-

:0

Back

of

8512

Disk Drive

Empty Dip

03ULI'\.~L~i-

-.

-'-i

Recommended

Back

of 8512

Maximur11

Unit

Stacking

Disk

Drive

Figure

2-2

Multiple Disk Drive Interconnections

0003-000

2.2

MUI..~TIPLE

DISK

DRIVE

CONFIGURATION

Refer

to

r--"'igure

2-2. A

maximum

of four

disk

drives

can

be

utilized in

an

8510/a

system.

As shawn,

the

8512

Disk

Subsystems

can

be

stacked

on

top of

the

8510,

or

alternatively,

can

be

stacked

separately. Each8512

has

a

disk

drive "daisy

chain"

connector

EIB;

these

EIBs

are

interconnected

to

the

8510

Floppy

Disk EIB

by

rneans

of

8

inch

fiat

ribbon

cables

(Part

Nurnber 90-0008-001).

One

ribbon

cable is

packed

inside

each

8512 (or 8515) ship-

ping

container.

An

optional.27

inch fIat ribbon

cable

(Part

Number

90-0008-002)

can

be

usedto

position

the

85125

at

adifferent location

on

the

user's

workspace.

The

cable

and

unit

connectors

are

keyed

to

prevent

in-

correct

coupling;

check

the

cable

connector

orient-

ation

.

before

attempting

to

insertit in

the

EIB

connector.

T'erminating

resistors

for

the

disk

drive daisy

chain

are

contained in a14-pin Dual-In-Line

Package

(DIP),

on

the

8510

Disk

Drive

EIB.

For

convenience,

the

terminator

resistor

DIP

should

remain

in the 8510

socket.

If

the

optional

27

in.

cable

is used, the

terminator

resistor

DI?

should

be

moved

to

the

daisy chainEIB

socket

on

the

drive unit

that

is

last

in

the

daisychain

connection.

NOTE:

The

DIPmust

be

oriented

50

that

pin 1is

at

the

lower

right-hand

corner

ofthesocket,

when viewed

fram

the

rear

of

the

unit. Pin 1is identified

by

a

dot

or

depression,

or

the

nun1ber 1,

on

the

package.

Each

8512

has

an

ac

input

power

requirement;

however,

the

control

ofac

power

i5

by

means

of

the

main

ac

power

ON/OFF

switch

on

the

8510

unit

3

SYSTEM

ACCEPTANCE

TESTS

After

an

851ü/a

system

has

been

interconnected

in

accordance

with Section 2of this

document,

the

system

should be initially

tested

by

means

of

the

TERAf<

System

Il

Acceptance

Disk{PartNumber

61-0006-001).

The

diskette

cantains

GO/NO-GO

tests

that

exercise

the

hardware

subsystems.

Each test is

precededby

an

explanatory

message

on

the

display;

user

instructions

will

also appear

on

the

display.

NOTE:

If

the

following

procedures

cannot

be

accomplished,

refer

to

Section

8for

troubleshooting

steps.

3e1

POWER ON;

DISKETTE

LOADING

T

urn

the

system

on

by rneans·

of.

the

ac

power

switches

located

inthe

upper right corners

of

the

8510

and

8515

(if

used)

front

panels. If closed,

open

the·diskette

loading

door

on

the

8510

(Drive

QXO)

by

depressing

the

button

just

below

the

door.

NOTE:

If

you

are

unfamiliar

with

diskette

hand1ing

procedures,

referto

Appendix

Afirst.

Remove

the

System

Acceptance

Disl~ette

from

its

pro-

tective envelope;

keep'your

fingers. 9ft

of

the

exposed

magnetic

surfaces

of tI1é'âiskette.

Holding

the

diskette

with

the

label

sideup,3s'snown

in

Figure

A-l,

insertit

into

the

QXOdri~e

~ntilit

carl go

no

further.

The

diskette

will

"latch~'~'·}nto

position.

Close

the

drive

door;

the

drive··head-down' light

(Red

Light Emitting Diode

embedded

in

the

door

button)

will

turn

on.

(

(

4

3.2

SYSTEM ACCEPTANCE TEST

PROCEDURES

ejected.

RetTIove

the

diskette

and

return

it

ta

its

protective

envelope.

)After

the

Systenî

Acceptance

Test

diskette

has

been

inserted

in drive

QXO,

and

the

drive

door

has

been

closed,

the

operating

system

should

loaditself

(boat)

into

main

mernory.

Within

20

seconds,

an

acceptance

test-

related

message

should

appear

on

the

display.

The

test

-n~lated

rnessage

will

prompt

the

user

to

execute

a

carriage

return

to

display

the

"menu"

of

tests.

Select

a

test

by

typing

the

displayed

test

name,

followed

by

a

carriage

return.

The

test

procedures

will

then

appear

on

the display.

N01~E:

Once

a

test

has

begun,

the

user

should

not

type

anything,

unless

prompted

by

a

message.

Typing

during

the

test

execution

can

produce

unpredictable

results

and

an

apparent

test

failure.

NOTE:

Ta

exit

from

any

test,

at

any time,

re-boat

the

operating

system

by

depressing

the

upper

half of

the

8510

ac

power

switch;

the

acceptance

test-related

message

will

re-appear

on

the

display.

3.3

DISKETTE REMüVAL.

After

the

System

Acceptance

Tests

are

completed,

remove

the

diskette

by

depressing

the

drive

door

button.

The

door

will

open

and

the

diskette

will

be

partially

4-

SYSTEM

EXPANSION

A8510

system

can

be

expanded,

by

means

of

modular

options,

to

allow

the

user

to

interconnect

avariety

of

peripheral

equipment.

TERAK,

or

other

LSI-ll

bus-

compatible

modules

can

be

installed in

the

8510

and

8515

units.

The

8510

and

8515 units

each

contain

an

LSl·ll

bus-

cornpatible

backplane.

Each

backplane

cantains

sixteen

36 pin

connectors,

as

shown

in

Figure

4-1.

The

L5I-l1

bus

is

based

on

the

use

ofdual-height (8.9

in

Wx5.2 in

H)

modules;

that

is,

modules

that

plug

into

pairs

of

connectors

(A&B

or

C&D).

A

module

has

an

1/0

priority

that

is

based

on

itselectrical

distance

from

the

processor

module,

as

shawn

in

Figure

4-1.

For

instance,

if

aquad-height (8.9 in W x 10.5 in H)

processor

module

were

instal1ed in

s1ot5

1

and

5of

the

backplane,

the

highest priority slot would

be

#2.

The

arrows

on

Figure

4-1

signify

the

descending

order

of

priority. Aquad-height

module

uses

slot

connectors

A&B for 1/0priority signaling; adual-height l'nodule

uses

either

A&B

or

C&D.

An

LSI-l1

bus-compatible

quad-

height

module

maintains continuity of

the

prioritysignaIs

through

slots C&D

by

means

of

etched

circuit

jumpers

on

the

module

Note:

AH

modules

that

plug into the backplanes have their

components

facing

downward

5lot

7CD:

bus

extender

card,

seriaI, parallel

or

other

interface modules

510t 3AB: samE as

7CO,

except

for

the

bus

extender

card

Selection of siot 7CO for either backplane was arbitrary -actual slots

used

depend

upon actual configuration

8515 Backplane

Connectors

(User-Specified Modules)

-.f

Toward The Rear

-

lOf

The

Un:t

:

43

~,~

",1.

.Highest

\.

},

Priority

2Module Slot If

The

CPU

Module

Is

Installed In

Siots lAB (And

5eO).

B

~

A

::

BA

BA2

BA

==r-'

,Bus

Extender

Inteconnector

"Cables, If Required.

!8

1

~~~~~-=-----"---=---~_~:"'--_.:-...t.

i ---

ri

71'

.:J

Bus

Extender

1

-~--=:---==---__=_--:---

--,

i6Lowest Priority Slot

For

This Configuration

1

15

0 C

1!

11

1

1

1

1

1

1

1

1

1

1

1

1

1

Figure

4·1

8510/a Module

Locations

&

1/0

Priority 0004-000

5

4.1

PROCESSOR

B'US

EXTENSION

Refer

to

Figures

4-2

&4-3.

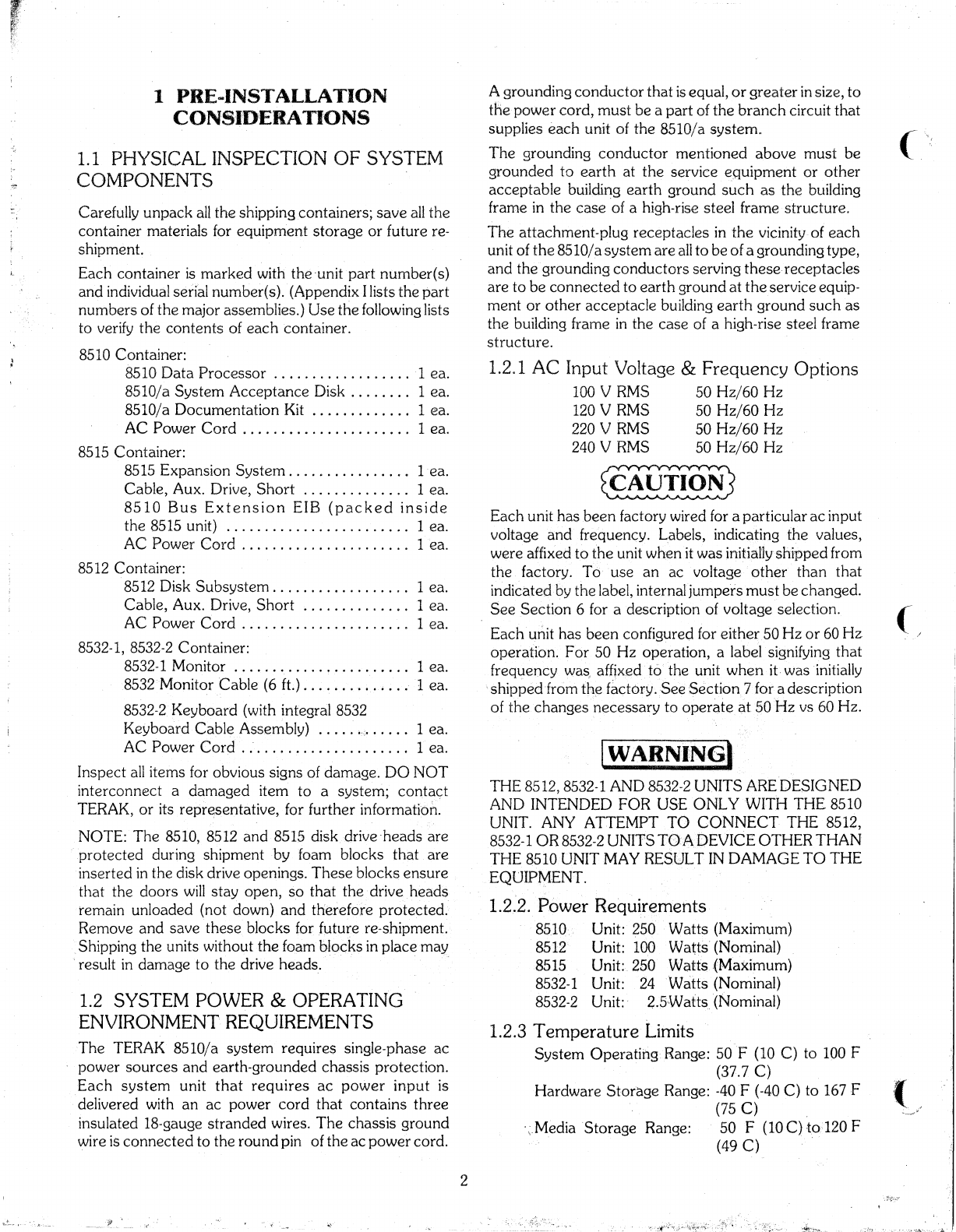

The

Bus

Extension EIBs

and

the

8515 Backplane provide

the'

"(J$\.

wrthameans

of

extending

the

8510's

data

bus.

An 8515 unit

is

shipped

,with

afactory-installed Floppy

Disk

EIS,

two

Cable

Clamp

Cavers

and aBlank

Caver,

as

shawn in Figure

4-3.

The

8510

Bus

Extension EIB

has

been

packed

inside the

8515

for

shipment;

this

EIB

must

be

removed

from

the

8515

and

installedin

the

8510. In

the

process,

the

8510 Floppy Disk EIB

must

be

relocated.

RelTIOVe

the

8510

and

8515

covers

in

accordance

with

Part

5.1,

Section

5. Remove

the

8510

Sus

Extension

EIB

from

the

8S15.

Check

to

see

that

the

8515 Bus Extension

EIB

cable

card

is

plugged

into

the

8515 Backplane.

(See

Figure

4-1

for Backplane locations.) Additional rnodules

may

be

installed in

the

8515

at

this'time.

Note

the

device

1/0

priority indicated

by

Figure

4-1.

The

8515

caver

can

he

reinstaHed

at

this

tinle

..

AIl

EIBs

are

attached

to

the

units

by

means of 4Phillips

head

screws,

one

in

each

corner

of

the

EIB.

RelTIOVe

the

Blank .

Caver

frorn

the

8510;

save

it

for future Use.

Unfasten

the

Floppy Disk

EIB

from

the

top

..

most

location

and

let

it

hang

loose.

Remove

the

module

retainer

bracket

in

the

8510 (see

Figure

5-1).

The Bus Extension

EIB

cqrd

mustnow

be

installed

in

the

8510

backplane

slot

that

is

shawn

in

Figure 4-1.

The

component

(connector)

sicle of

the

card

must

be

facing

downward

wh

en

it

is

inserted.

[jft

the

ribbon cable

through

the

notch

in

thecard;

slide

the

card

through

the

module

guide

and

insert

it

into

the

backplane.

Pass

the

card's

ribbon

cable

and

attached

EIB

through

the

rear

of

the

8510.

Secure

the

Bus

Extension

EIB

to

the

top-mûst

EIB location with four

screws,

then

install

the

Disk Drive

EIB,

just below it.

The

8510

caver

can

now

be

re-installed.

As

shawn

in Figure 4-2,

the

bus

extension

cables

that

emerge

frOlTI

the

8515

Cable

ClampCover

are

connected

to

the

Bus

Extension

EIB

on

the

8510.

The

shortest

(innennost) cable of this pair plugs into

the

DATA

connector

on the

8510

Bus

Extension

EIB;

the

other

cable plugs into

the

CONTROL

connector.

An

8

inch ribbon cable, (Part

Number

90-000S-001,

packed

in

the

8515 shipping container),

connects

the

8510 Floppy

Disk EIB

ta

the

8515

Floppy

Disk

EIS.

The

8515 requires

ac

input

power

and

is controlled from

aswitch

on

its front panel.

Both

the

8510

and

8515

ac

power

switches

must

be

on

for

the

8510/a

system

ta

operate.

The

system

can

he

reset

trom

{2ither

the

8510

or

8515

power

on/reset

switches.

(

r-r

---------------------

I

Back

Of

8512 1

l '

. !

Further

Disk Drive

Expansion

i

11

l,

, 1

(

Sicle of 8515

Sicle of 8510

Cable

Clamp

Cover

Short

Ribbon

Cable

Factory Installed (Inclucled With An 8515

Or

8512 Unit)

,-EIBs

~----'"

8532-1,-2

Connections

Back

Of

8515

Blank

Cover

~---.I

Cable

Clamp

Caver

8515,Floppy Disk EIB

(Empty Dip

Socket)

(For Disk Drive

I;xpansion)

Bus

Extension

Cables

Seria.I

Interface

EIB

Video

EIB

.....

10

rr::*=============:::::XC:::>

~o

~""""-+

@]--J'0

M

ToAC

Power

Recommencled

Maximum

Unit Stacking

Figure

4

...

2

System

Processor

Bus

Extension

Interconnections

0005-000

(

6

Single

EIB

Location

o

8512

Floppy Disk

EIB*

o

)

Back Of 8512

EIB

Locations

--

Back

Of

8515

EIB

Locations

Back

Of

8510

o0

'---------_

..

_-----_

..

-

00

Blank

Caver

*

00

00

Cable Clamp Cover*

00

00

8515

Floppy Disk

EIB*

00

0

()

Cable Clamp Cover*

00

00

Bus Extension

E18*

00

00

8510

Floppy Disk

EIB*

00

00

SeriaI Interface

EIB

*

00

00

Video EIB*

00

)

!.'.'

/-

*Standard Factory-Installed

EIB

Configuration; Can

Be

Aitered With Any Combination Of

EIBs.

NOTE:

AIl

Locations Must

Be

Filled With

An

EIB

Or

ACover Plate

Ta

Maintain Proper

Air

Flow Through Aunit.

Figure

4·3

EIB

Locations

7

0006-000

4.2

MODULE

INS~rALLATION

5

UNI1~,

COVER

REMOvAL-

REPLACEMENT

Figure

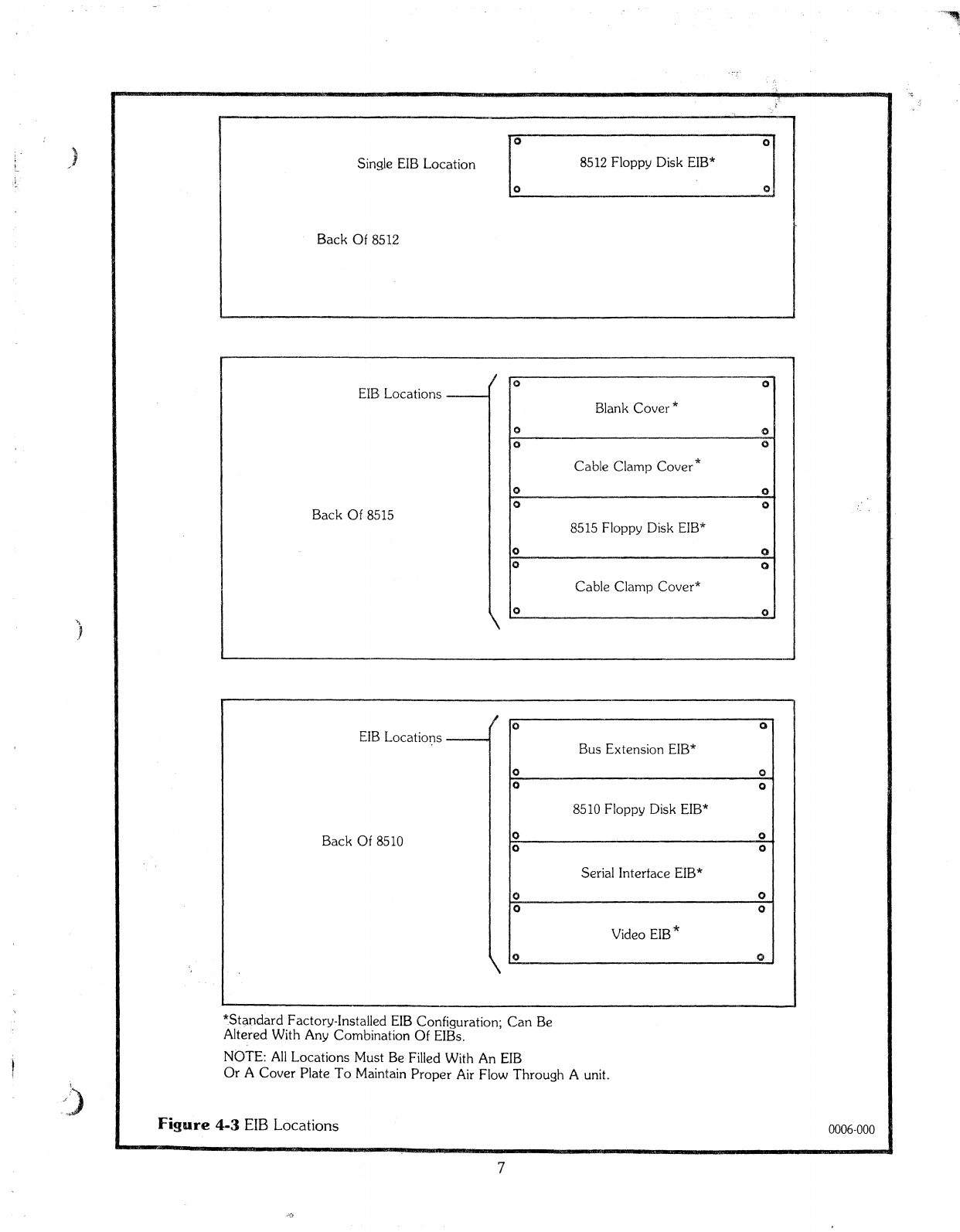

5·1

8510/12/15

Caver

Removal-Replacement &

8510/15 Module Retaining

Hardware

(

.ô\\.

(

(

0007·000

Cover:Rétaining

Screws,·BoÙom

(Screws With Metal Washers)

(WARNI~~)

*"

Due

ta

the

complex

nature

o(the

system

r.:omponents,

unit

caver

removal-teplac'Èi'ment,

and-

-subsequent

maintenance

and

repairs, should·only

be

perforrned

by

technically-qualified

personnel.

~

DISCONNECT

THE

UNIT

AC

POWER CORDS

BEFORE

REMOVING

THECOVERS

5.1 8510, 8515 &

8512

UNITS

The

unit

covers

are

held

in

place

by

four

Phillips-head

screws,

as

indicated

by

Figure 5-1.

RelTIOVe

the

two

retaining

screws

and

nylon finishing

washers

at

the

rear-

-sicles

of

the

unit.

Loosen

the

two

retaining

screws

with

the

metal

washers

at

the

bottom-front

of

the

unit. It

is

not

necessary

to

remove

these

screws

completely.

Don't

stand

aunit

on

its

rear

feet

to

loosen

the

bottonl-front

Caver

Retaining

Sicle,

Screws

8510/15 Module Retainer

'The installation

of

a-rnoduleis

quite stra'ight-forward.

As

described.

in

Part.4,

the

·1/0

p(jority

o~

..

-_

]1flM);t:1:ule

15

a

function

of -its

electricaldistance

from

the

system

processor

module~

Only

I_SI-11

bus-compatible

modules

are

ta

be

installed. After

the

unit

caver

and

module

retainer

bracket

have

been

removed

(see

Part

5.1

and

Figure 5-1), a

dual

or

quad-height

module

can

be

plugged

into a

backplane

location. (The

power

supplies in

the

8510

and

8515 units

can

provide a

maximum

of 12 A@5

VDC

and

6 A @12

VDC

to-the

backplanes;

the

available

power

i5

afunction

of

the

nurnber

and

type

of

modules

installed.)

Peripheral

connections.

to

a

module

are

by

means

of

External

Interface

Boards

(EIBs).

These'EIBs,

located

at

the

rear

of

the

units,

as

shawn

in

Figure

4-3,

are

held in

place

by

four Phillips-head

screws.

With

the

exception

of

the

bus

extension

EIBs

(described

in

Part

4.1).

the

module EIBs

can

be

installed in

any

location

at

the

rear

of

the

8510

and

8515 units.

Neatly

fold

the

EIB-module

ribbon

cable(s)

along

the

chassis

when

re,·installing aunit

caver,

50

that

the

cables

are

not

pinched

when

the

caver

is

fastened down. EIB

connector

pin listings

and

switch

settings (if applicable)

are

described

in

the

Appendices.

8

)

screws

if

cables

are

connected

ta

EIBs.

Instead,

slide

the

unit

forward

until it

protrudes

far

enough

beyond

the

desk

or

bench

edge

to

allow

access

to

the

botton1 front

screws.

Slide

the

integral

front

panel~cover

forward

until

it

separates

from

the

chassis.

Re-install a

caver

by

sliding it

back

onto

its

chassis,

taking

care

not

to

pinch

any

ribbon

cables

that

may

be

protruding

slightly. W'hen

the

cover

is in

place,

tighten

thebottom

front

screws

and

then

replace

the rear-side

screws.

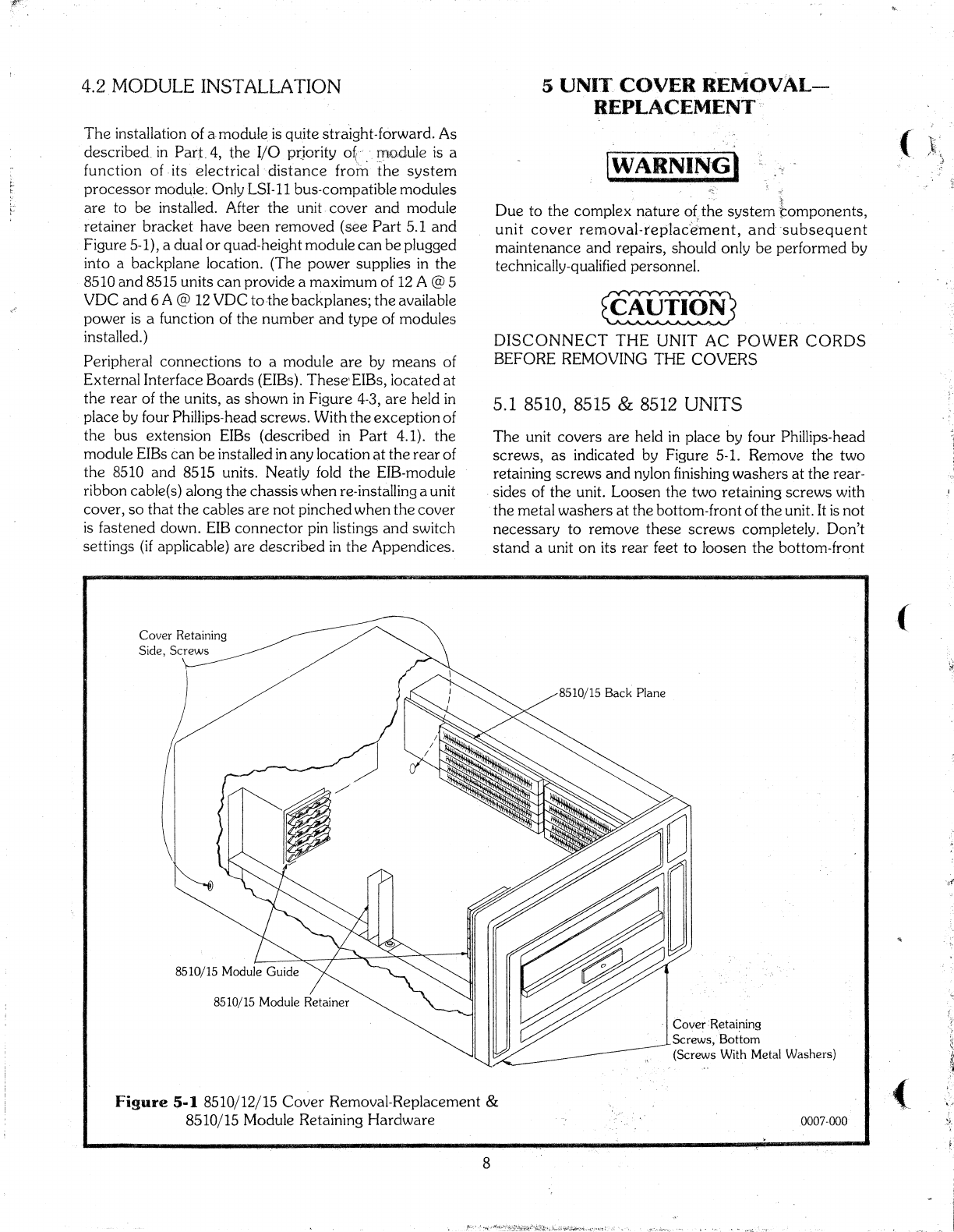

5.2 8532-1 MONITOR

~

AVOlD

STRIKING

THE PICTURE TUBE

The

Monitor

chassis

i5

held

in

place

by 8Phillips pan-

head

screws;

six (#8'5)

on

the

bottom

and

two

(#6's)

on

the

rear

of

the

cabinet,

as

shawn

in Figure

5-2.

Renîove

these

screws

and

slide

the

chassis

straight

back

out

of its

cabinet.

NOTE:

Do

not

remove

the

fiat-head

screws

securing

the

stand

to

the

Monitor

cabinet.

6UNIT'

AC

INPUT VOLTAGE

SELECTION

[WARNING)

THE

VOL

TAGES REQUIRED BY THE SYSTEM ARE

pO~rENTIALL

y

HAZARDOUS:

ONL

y

TECf-f-

NIC,ALLyQUALIFIED PERSONNEL

SHOULD

PERFORM 1'HE AC INPUT VOLTAGE SELECTION

CHANGES.

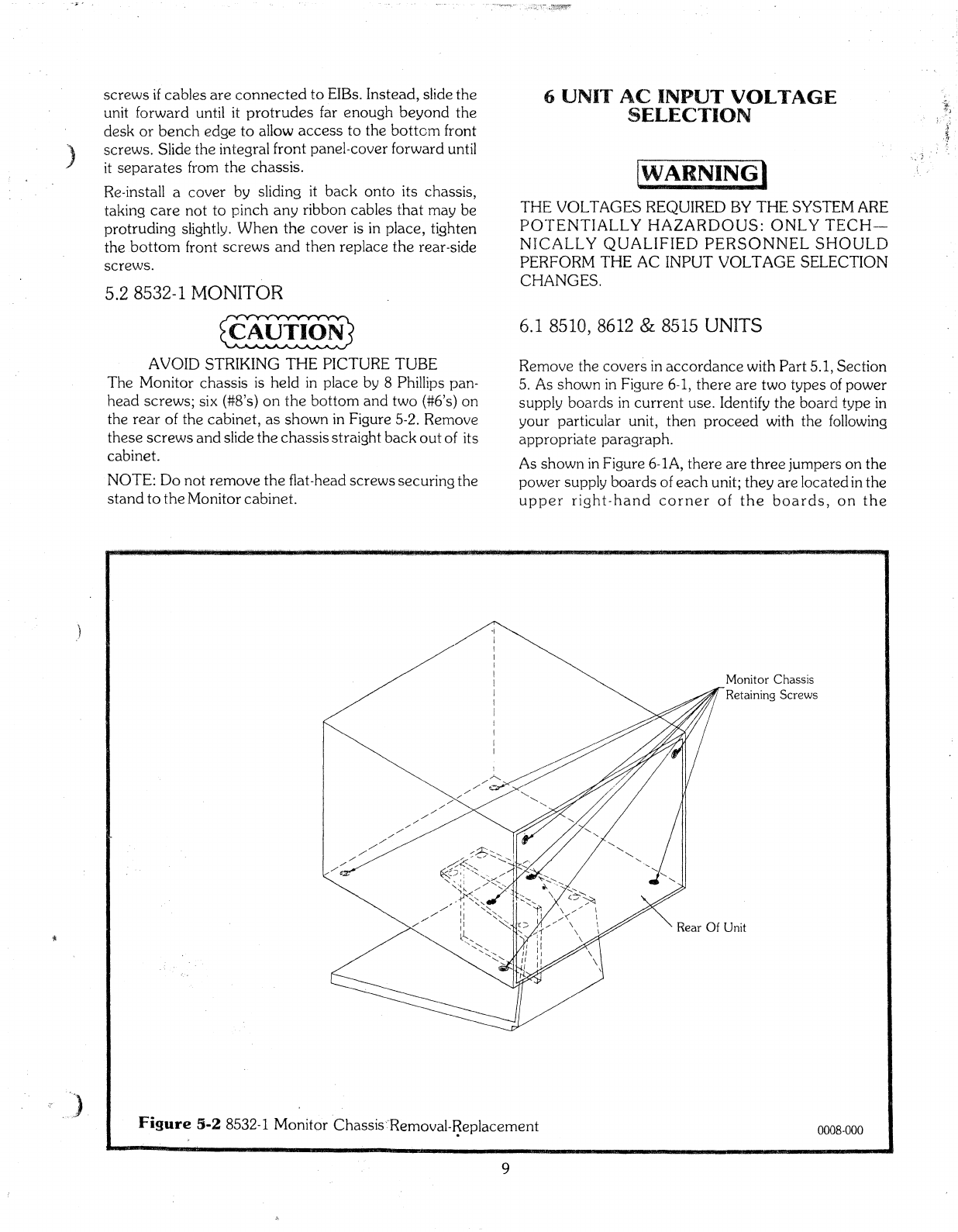

6.1 8510, 8612 &8515 UNITS

Remove

the

cavers

in

accordance

with

Part

5.1,

Section

5.

As

shawn

in Figure

6-1,

there

are

two

types

of

power

supply

boards

in

current

use. Identify

the

board

type

in

your

particular unit,

then

proceed

with

the

following

appropriate

paragraph.

As

shawn

in

Figure

6~

lA,

there

are

three

jumpers

on

the

power

supply

boards

of

each

unit;

the

y

are

locatedin

the

upper

right-hand

corner

of

the

boards,

on

the

Monitor Chassis

7Retaining Screws

""

Rear

Of

Unit

Figure

3·2

8532-1

Monitor

·Chassis·

..

·Removal-~eplacement

9

0008-000

A

~

Hale

And

510t

(For

Access

To' Disk Drive

Chassis

Fastening

Screws)

85JO/15

l;lnit

Powe.r

Supply

Board

----}'

r_----, .240 V!

~

1

=.1

t::j

Sa/60Hz

22~1~

6bo660o~

J23

AC

Line

120

v1

.1:=1

:::'j

c::::

1

(RMS)

lOOV H!

:::t

r=

J

8512 Unit

Power

Supply

Board

~--c:::;---=-.--:::-

1

~;~~.

=

==

~

JI

9<>

09 9099 J8

120

Vib

r=

:::

1

100

v::::l

=:1:::

1

Sû/60Hz AC

____

Line

(RMS)

Typical

Jumper

(

(

0009-000

l

Connector

1 1

J

16

Connector

J

Voltage

Select

Board

Voltage

Select

Board

8510/15 Unit Power Supply

Board

(This Board

TabSurface

Indicates

The

Voltage

~

.

(~,_ele_ct_ed_)

-

----,

~

'8512

Power

Supply Board

~

~\

o~6.

\

sv.{!{!\'l

'<ÇP

/

/'

e'(

~/

\",o\Y

1

/

Hale

And

510t

(For

Access

T0Disk Drive

Chassis

Fastening Screws)

AC, Input Voltage

Select

Board

Location

"

240

AC

Input

Voltage Select

Board

,Figure

6-1

8510/12/15 AC Input Voltage Selection

10

J

component

sicle.

~rhe

8510 &8515

jumper

jacks

are

labeled

J16

through

J'23;

the

8512 jacks

are

labeled

JI

through

J8.

Insert

the

jurnpers

into

the

jack

pairs

that

are

color-banded

together

for a

particular

voltage.

For

instance,

to

operate

an

8512 unit

at

120 V,

the

jumpered

pairs would be: J2

ta

J3;

J4

to J5;

J6

to J7.

As

shawn

in Figure 6-1B, a

printed

wiring

board

is

used

for voltage selection. 'This

board

must

be

inserted

into a

connectar

located

in

the

upper

right-hand

corner

of

the

power

supply

board.

The

connector

is labeled J16.

Ta

select adifferent

ac

input

voltage,

rem

ove

the

board

and

re-insert

it

sa

that

the

desired

voltage

is

indicated

on

the

board

tab

surface

that

is

nearest

ta

the

front

and

top

of

the unit) as

shoVJl1

in

Figure 6-1B.

6.2 8532-1 UNIT

Rernove

the

Monitor

chassis

in

accordance

with

Part

5.2,

Section

5. In Figure 6-2,

the

plugs labeled

Pl

and

P2

contain

the

jumpers.

P2 is actually apair of plugs:

one

is

for 100V &

120\/

operation;

the

other

is

for 220V&24üV

operation.

When

the

pin in

Pl

must

be rnoved, use a

MOLEX

HT

2285

Extractor

Tool, (or equivalent),

ta

rernove

the

pin.

Insert

the

pin in its

alternate

location

until

it

locks

in place.

lOOV

Operation

1.

Insert

the

"120" labeled P2 plug inta

J2.

2.

Move

the

brown-wiredpin in

Pl

ta

location3

of

Pl.

3.

Insert

Pl

into

JI.

120V

Operation

1.

Insert

the

"120" labeled

P2

plug into

J2.

2.

Move

the

brown-wiredpin in

Pl

ta

location 1of

Pl.

3.

Insert

Pl

into

JI.

220V

Operation

1.

Insert

the

"220" labeled P2 plug into J2.

2.

Move

the

brown-wired pin in

Pl

to location 3

of

Pl.

3.

Insert

Pl

inta

JI.

240V

Operation

1.

Insert

the

"220" labeled P2 plug into J2.

2.

Move

the

brown-wired pin in

Pl

ta

location 1of

Pl.

3. Insert

Pl

into

JI.

8532-1

Monitor

Top

View

({j

/~

"'\

\\

C:::::<~

•

-----'

Extractor T

001

(Molex

HT

2285)

Pl

Brn.

Pl

Brn.:

!Grn.

~

For

120

Vand

240

VOperation

Grn.

===;=g;

~

For

100

Vand

220

VOperation

Red·

Red

Figure

6·2

8532-1

AC

Input Voltage

Selection

Il

~p~

1------iJ·,'

,

P2

0010-000

7

UNIT

CHANGES

FOR

59

Hz

&

69Hz

POWERFltEQUENCf'ES

The

pulleys

on

the

disk drive

\-ilc)tors

and

the

drive beIts

of

the

8510,8512

and

8515 units rnust

be

replaced

when

changing from 50 rIz

ta

60

Hz

operation,

or

vice versa.

The

Video

Board

in

the

8510

unit

must

also

be

exchanged.

The

fol1owing TERAK

part

numbers

are

applicable:

Item

50Hz

60

Hz

Video

Board

92-0014-011 92-0014-010

Pulley,

matar

39-0012-001 39-0012-002

Belt, disk drive 39-0013-001 39-0013-002

1.

Remove

the

unit

covers

(see Part 5.1,

Section

5).

2.

Remove

the

8510, 8515 module

retainer

brackets

(see Figure 5-1).

3. Remove the modules from

the

8510 &8515

backpl.anes.

4.

Remove

the

four Phillips-head

screws

that

fasten

adisk drive chassis

to

aunit chassis.

Two

of

these

screws

are

accessed

through

ahale

and

a

510t

in a

power

supply

board

'(see Figure 6-1). The other

two

screws

are

on

the

unit

chassis

sicle

that

i5

opposite

the

power

supply board.

s.

Slide

the

disk drive

chassis

forward until

the

disk

drive

PWB

connectors

can

be

easily

dis-

connected.

Remove

the

disk drive chassis.

6.

Stand

the

disk drive chassis

on

its side

50

that

its

PWB

is

visible. Remave

the

four

slotted

hex.-

agonal

screws

that

fasten

the

PWB

to

the

chassis

housing. Swing

the

PWB

clear of

the

mator

pulley

and

belt drive.

There

are

three

connectors

still

fastened

to

the

PWB;

they

do

not

have

tobe

dis-

connected.

7.

Remove

the

disk drive belt.

8.

Using a1/16

in.

Allen

wrench,

remove

the

small

pulley

on

the

motor

shaft.

9.

In5ta11

the

new pulley

and

new

drive belt.

10.

Re-instal1

the

PWB

and

disk drive unit; re-install

aIl

modules

except

for

the

MemoryVid'eo module.

Il.

Remove

the

ribbon

cable

cannectors

from

Pl,

then

P2,

of

the

Men10ry

board.

12.

Separate

the

Memory

and

Video

boards

by

removing

the

four

corner,

and

two middle, Phil-

lips-heàd

screws

that

hald

the

boards

together.

13.

Fasten

the

Memory

board

to

the.

NEW

Video

board.

14.

Re-connect

the

ribbon

cab

les

ta

P2,

then

Pl,

of

the

Memory

board.

12

15. Re-install

the

Memory-Video rnodule

in

the

8510

backplane,

then

replace

the

module

retainer

bracket.

16. Re-install

the

unit covers. (

(

)

8

BASIC

TROUBLESHOOTING

DlJE

Tü

THE COMPLEXITY

OF

THE

SYS'TEM

AND

TI-IE REQUIREMENT FOR TEST

E(~UI.PMENT,

REPAIRS

AND/OR ADJUSTMENTS

Ta

THE

VAR-

IOUS SUBSYSTEMS

OF

THE8510/a

SHOULD

ONL

y

BE

PERFORMED

SY

QUALIFIED

TECHNîCAL

PERSONNEL

..

The

following

procedures

in Figure

8~

1

are

intended

as

a

fundarrlental guide for problerns

that

could

prevent

the

execution

of

the

Systenl

Acceptance

Tests.

These

procedures

can

help

ta

isoiate aproblen1,

and

in

50

doing, effect a

faster

solution

\tvhen

contacting

TERAK's

Product

Service

Department.

Be

sure

to

include

the

unit

seriaI

numbers

in

any

telephone

or

letters

correspondence

with TERAI<

Product

Service.

WARNING

The voltaqes

required

by

the

system

are

patentially

hazardous.

Only

technically-qualified

personnel

should

perform

the

troubleshooting

stepsenclosed

within this

type

of

box.

Voltage

and

frequency

of

power

source

matches

voltage and

frequency

labels of

aIl

units.

,

Yes

t

r--

No

~_=

_______.1._

...

_

Set

8510, 8512, 8515 &8532-1 units

to

proper

voltage &frequency.

....

--~--~~--

Yes

Yes

N0

't

Check

line fuses,

cords

and

power

source.

Remove

air filters

ta

verify

that

the

fan impellers

rota

te

~

l:eel

y.Air

exhausts

from

851~

only.

,

No

L+

Verify

that

voltage &

frequency

of

power

source

matches

voltage &frequency

setting

of

aIl

units, by

removing

covers

&inspecting

power

supply.

Jo

-

Yes

Air filters

are

clean. Yes

No

[

Clean

air filters.

\--No

Air

exhaust

flow is weak.

Turn

on

system

at

8510

and

(if

present)

8515 units.

Air

is

exhausting

trom

front

panels

of

aIl

(8510,8512

..

and

8515) units.

Power

switch

on

8510 &8515 units

rotates

freely

to

upper

position,

returns

to

center

position

when

released.

No

significant

drag

is

present.

Check

that

aH

floppy disk daisy chain

cab

les

are

propet-ly installed. Relay click

can

be

heard

inside

8532-1

or

8512 units.

'No'

No

Remove

8510

caver.

Check

power

supply

module

by

observing

LED lights. AC

power

indicated

O.K.

,)

Loosen

caver

&realign with

power

switch

rocker.

Yes

!

A

Figure

8-1

Troubleshooting

Guide

No

+

BD

0011-000

13

AB

1

No

Investigate voltage &

frequency

of

local 'power.

Correct

power

supply

voltage

selection,

if

required.

c

y~s

~_--L--

OC

power

is

indicated

O.K~

o

Yes

No

Replace

power

supply Inodule.

~------No-------'

Yes

----,-

.......

-----,----

....

----------------------""""--'-----v..

Verify

that

aIl

PWBs

are

fully

inserted

and

that

the

retaining

clamp

is

mounted

firmly.

Verity

that

aIl

fIat

cables

are

securely

mounted

ta

their

corresponding

edge

connector

on

the

PWBs. Ifrequired,

remove

the

PWBs

and

clean

the

edge

fingerswith

a

clean

cloth

and

a.lcohol,

search

for

components

on

the

PWBs

which may

have

been

damaged

during

shipment,

service,

or

systen1 configuring,

then

remount

in original

arder

and

sec

ure

with

retaining

clamp.

Verify

that

aIl

connectors

in

the

chassis

harness

are

fully

seated.

Relay click

can

be

heard

inside 8532-1 unit,

but

not

inside 8512 unit.

Replace

Happy

disk

controller,

EIB,

or

daisy

chain

cables.

No

Yes 1

____

-1.,_-----.

(

No

Verify

that

keyboard

is

connected

to

video EIB.

Remove

cable

and

rneasure 4.7

ta

5.3

volts

OC

between

pins 1

and

3of

the

video EIB

keyboard

connector.

Remove

the

keyboard

caver.

Verify

that

the

connector

on

the

edge

of

the

keyboard

PWB

is

securely in

place.

Inspect

keyboard

for

damage

during

shipment.

Relay click

can

be

heard

inside 8512 unit,

but

not

inside 8532-1 unit.

Verify distributionof

power

through

system

PWBs,

harness,

EIBs

andcables.

Replace

video

controller~

video EIB,

or

video

cable.

Ye~et

switches. 1

'EML/KBD'

switch

on

the

video EIB

is

set

off

and

left four

switches

on

the