KRB-5426c-2-

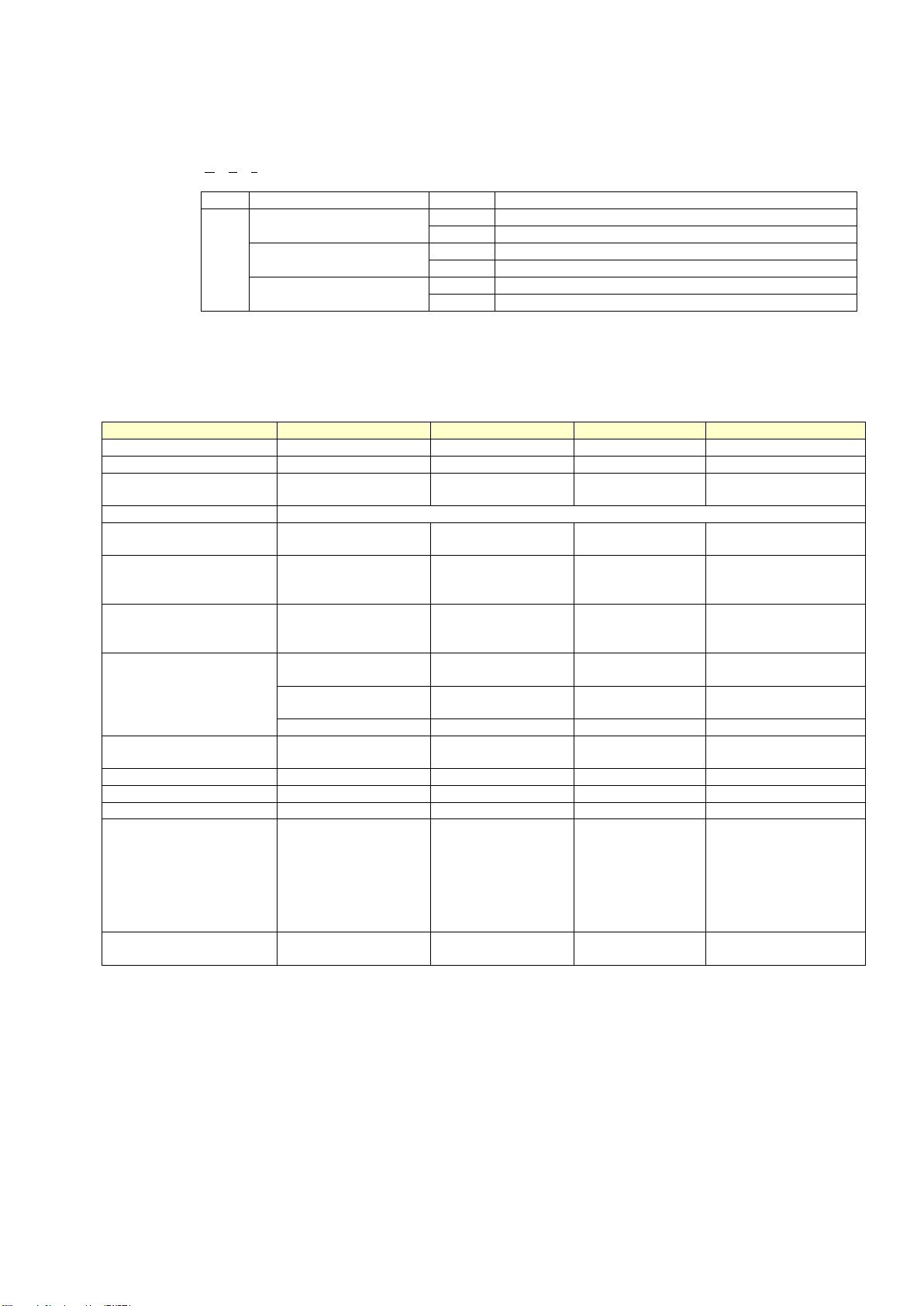

1. Safety Notices................................................................................................................................................................. 3

2. Specifications.................................................................................................................................................................. 4

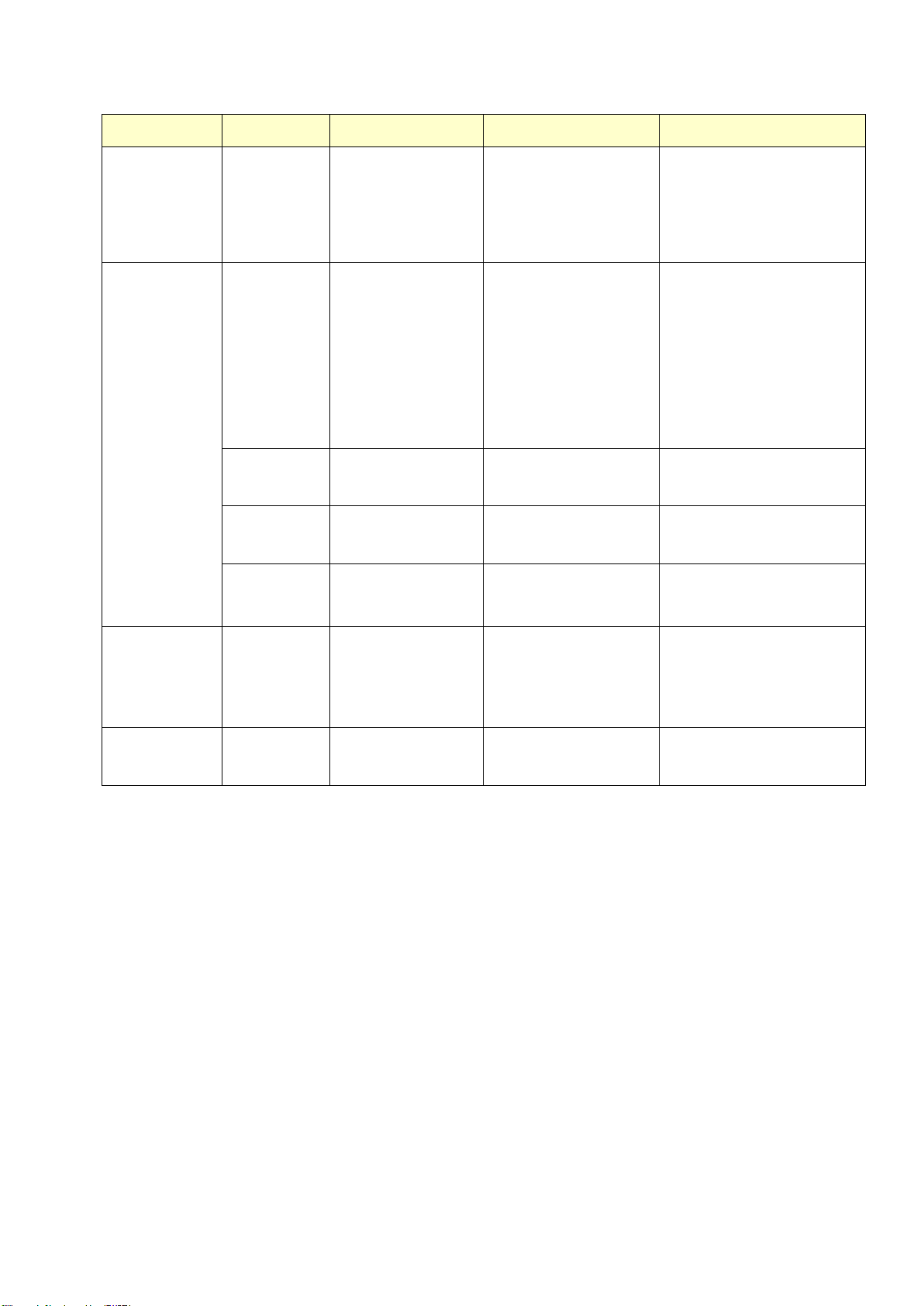

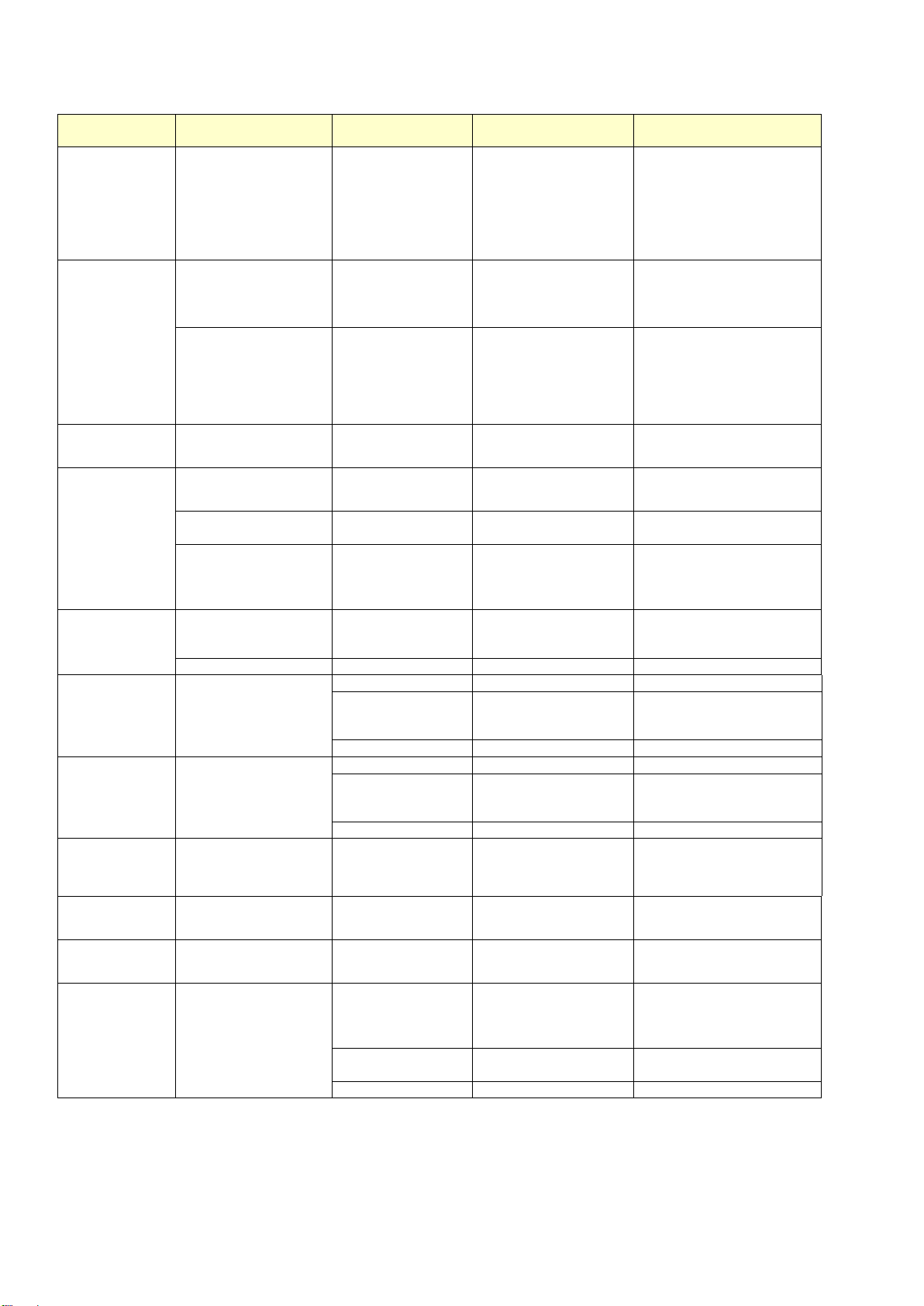

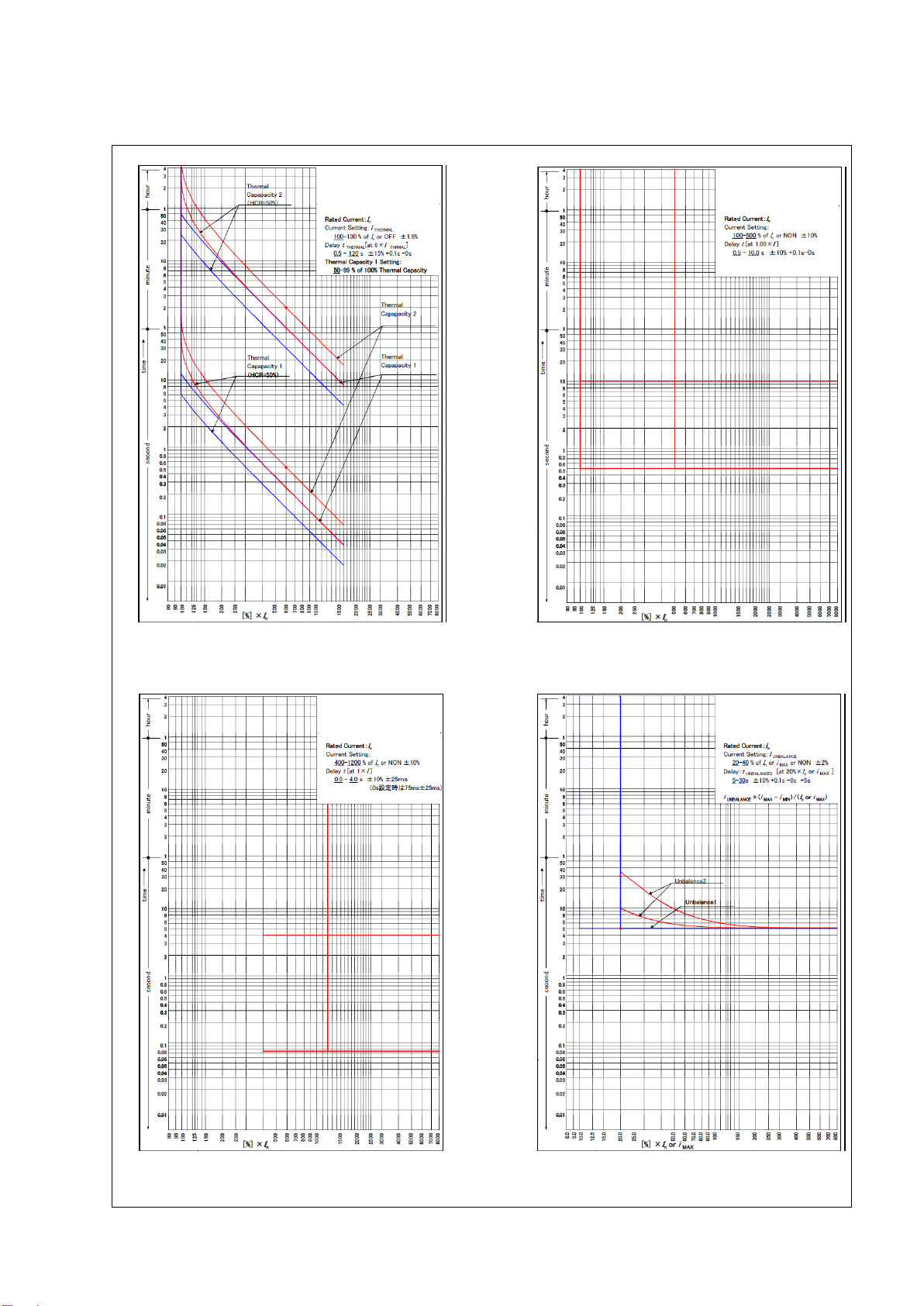

3. Characteristics................................................................................................................................................................ 5

4. Component Identifications ............................................................................................................................................ 10

5. Installation......................................................................................................................................................................11

6. Connection.................................................................................................................................................................... 12

6-1. Circuits and Ratings.......................................................................................................................................... 12

6-2. Terminal Connection Procedure........................................................................................................................ 13

7. How to Display Measurements and Make Settings....................................................................................................... 14

7-1. General ............................................................................................................................................................. 14

7-2. Navigation to Each Setting Item Screen After Power ON (from INI-A-1 through to MA-A-1)............................. 15

7-3. Navigating between Measured Value Display Item Screens (from MO-A-1 through to MO-G-2)...................... 16

7-4. Navigating between Characteristic Value Setting Item Screens (from S-A-1 through to S-D-1)........................ 18

7-4-1. Navigating between setup item screens (from S-A-1 through to SU-L-1)............................................... 20

7-4-2. Navigating between password setting/authentication screens (from SU-L-1 through to P-A-4).............. 23

7-4-3. Navigating between setting item screens (from S-A-1 through to ST-A2-3①)........................................ 25

7-4-3-1. Navigating between setting item screens (from S-B-2①through to ST-B2-1)............................. 27

7-4-3-2. Navigating between setting item screens (from S-B-2②through to ST-C2-1).............................. 29

7-4-3-3. Navigating between setting item screens (from S-C-1 through to ST-L-1).................................... 31

7-4-3-4. Navigating between setting item screens (from S-D-1 through to ST-W-1)................................... 39

7-5. Navigating between Maintenance Item Screens (from MA-A-1 through to MA-I-2)........................................... 47

7-6. Screen Transition in the Event of Trip or Alarm (TR-A-1, AL-A-1) ..................................................................... 52

7-7. Function Test and Relay Test (from MA-B-1 to AL-A-1)..................................................................................... 53

7-8. History and Trip/Alarm Activation Display Screens............................................................................................ 55

7-9. Responses to Abnormal Events ........................................................................................................................ 56