Teres 200 Series User manual

Teres 200 Series

Turntable Manual

14-Feb-2007

I. Bearing Assembly

The Teres bearing was designed to

have a lot of viscous damping. This

damping helps swamp the effects of

stylus drag, resulting in better speed

stability. For this reason heavy oil (30

weight) is provided. With heavy oil

the bearing will turn smoothly but

there will be a lot of resistance. This

is by design.

lease read this information carefully

before assembling your bearing. The

Teres bearing has been machined with

very close tolerances. The radial

clearance in the bearing is only 4 to 5

ten-thousandths. This tight tolerance

results in superb stability reducing

rocking to microscopic levels.

However, with these tolerances it is

imperative that the bearing is clean

and that proper procedure is used for

assembly. The objective is to have the

bearing completely full of clean oil,

including the recess in the top of the

bearing housing. If air becomes

trapped in the bearing it will not seat

properly. The bearing must be

assembled dry to avoid trapping air.

Note: Your bearing assembly may

come partially assembled. If any

components are already installed they

do not need to be removed and the

step may be skipped. The procedure:

1. Using the included 6-32 screw

attach the bearing ground wire

(bare wire extending from the

sensor cable) to the bottom of the

brass bearing housing. ointing the

crimp connector toward the center

of the bearing will make it easier to

install the bearing into the base.

2. Attach the brass bearing housing to

the base using the supplied 1-1/8"

nut. Hold the bearing housing

tightly in one hand and tighten the

bearing nut with a large wrench or

pliers. The bearing nut should be

snug but not excessively tight.

3. Clean the bearing housing and

spindle thoroughly. Wiping down

the bearing surfaces with rubbing

alcohol on lint free cloth works well.

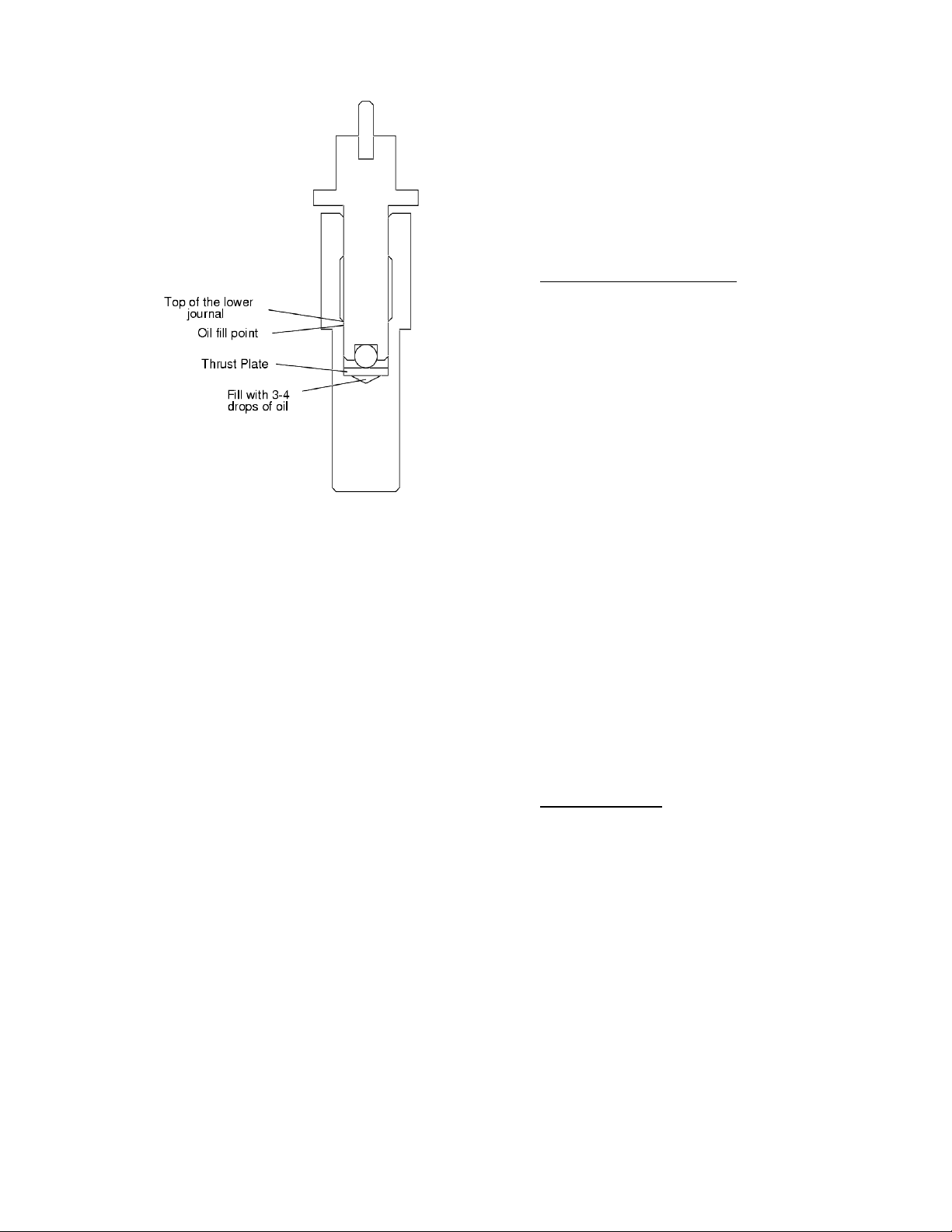

4. Fill the recess in the bottom of the

spindle with oil and press in the ball

bearing. This displaces air in the

recess and will hold the ball bearing

in place. Be sure to completely wipe

away any excess oil.

5. If not already installed place the

brass thrust plate in the bottom of

the bearing housing with the white

Delrin button facing upward. The

thrust plate needs to be held flat as

it is lowered into the bearing. A

simple method is to attach a small

loop of tape to the end of a pencil.

Then stick the thrust plate to the

pencil and lower it in place. Be

sure that the Delrin button is facing

up!

6. Carefully pour 3.8ml of oil into the

bearing housing without getting any

oil on the sides of the bearing. The

oil level should be just slightly

below the top edge of the lower

journal as shown in the illustration.

7. Insert the spindle into the bearing.

The spindle will stop about 3/4"

before it is fully seated. And if no

air is trapped it will not feel spongy

or pop up when released. If air is

trapped you must start over.

8. lace the platter on the spindle.

The platter will generally slide onto

the spindle with only a small

amount of downward force.

However, in some cases the

clearances are a little tighter and it

will take more force to seat the

platter. Once the platter is in place

wait for the spindle displace the

extra oil and fully seat. This will

take 1 to 2 hours so be patient.

When fully seated the gap between

the platter and the base will be

about 0.140” (slightly more than

1/8th inch). WARNING, do not spin

the platter until the bearing has

fully seated!

9. With the correct amount of oil the

recess at the top of the bearing will

be at least partially full of oil. If

there is excess oil remove the

platter and wipe up the excess. See

section III for instructions for

platter removal.

10. Once the bearing has fully seated

visually check for clearance (about

1mm) between the strobe disk and

the sensor.

11. Thread the chrome record

centering pin into the top of the

spindle. Tighten the centering pin

with pliers will keep it from backing

out while using the clamp.

II. Turntable Setup

1. Insert the armboard mounting bolt

into the bottom of the base and

thread into the armboard. Using

the included allen wrench tighten

the armboard bolt just enough to

hold armboard steady but loose

enough that it can be adjusted by

hand.

2. Install the tonearm and cartridge

and adjust the overhang by

rotating the armboard.

3. After the overhang adjustment is

complete tighten the armboard

bolt. Tighten only enough to hold

the armboard firmly in place. Do

not over tighten!

4. Install motor and battery option as

described in the Motor manual.

5. lace the black Delrin washer

packaged with the record clamp

over the record centering pin. The

Delrin washer must be placed

directly on the platter and under

the record.

III. Operation

The Teres controller utilizes an

embedded microcontroller that makes

operation simple and elegant. To start

the motor press the controller button

or give the platter a push. The red

LED comes on when the motor is

coming up to speed. After 10-15

seconds the green LED should also

come on indicating that the speed is

within 1%. The green LED will flash

several times before coming on steady.

After the green light has been on for

about 4 seconds then the red LED will

turn off indicating that the speed is

locked in.

To turn off the motor press the

controller button again or slow down

the platter by hand.

Holding the pushbutton down for more

than one second will switch between

33.3 and 45 rpm.

I . Platter Removal

To avoid damage to the bearing

surfaces the platter must be removed

without pulling the bearing shaft out

of the bearing assembly. The removal

process requires two small blocks of

wood (or some other suitable material)

roughly ¾” thick. Both blocks must be

the same thickness. A piece of wood 8

to 14” long is also required. Use the

following procedure:

1. Carefully raise the platter up just

high enough to slide blocks of

wood under the platter. lace the

blocks on opposite sides of the

platter to provide even support.

2. Lay a piece of wood on top of the

centering pin and press down

firmly until the spindle has been

pushed down and out of the

platter

3. Lift the platter off of the bearing.

Be sure that the bearing spindle is

fully disengaged from the platter

before lifting.

. Drive Belts

Teres turntables come with a drive

belt fabricated from ½” mylar tape.

We prefer the sound of mylar tape but

there is not a clear consensus about

the best drive belt material. Other

materials such as silk thread, fly

fishing line and rubber belts have

been used with good results.

I. Additional Information

Detailed product information and

updates are available from the Teres

web page.

Http://www.teresaudio.com

Other Teres Turntable manuals