Teres Certus 460 User manual

Certus Model 460

Turntable Manual

25-Jun-2007

I. Bearing Assembly

The Teres bearing was designed to have a

lot of viscous damping. This damping

helps swamp the effects of stylus drag,

resulting in better speed stability. For this

reason relatively heavy oil (10 weight) is

provided. With this oil the bearing will

turn smoothly but there will be a lot of

resistance. This is by design.

lease read this information carefully

before assembling your bearing. The

Teres bearing has been machined with

very close tolerances. The radial

clearance in the bearing is only 4 to 5 ten-

thousandths. This tight tolerance results

in superb stability reducing rocking to

microscopic levels. However, with these

tolerances it is imperative that the

bearing is clean and that proper

procedure is used for assembly. The

objective is to have the bearing

completely full of clean oil, including the

recess in the top of the bearing housing.

If air becomes trapped in the bearing it

will not seat properly. The bearing must

be assembled dry to avoid trapping air.

The procedure:

1. Clean the bearing housing and spindle

thoroughly. Wiping down the bearing

surfaces with rubbing alcohol on paper

towel works well.

2. Fill the recess in the bottom of the

spindle with oil and press in the ball

bearing. This displaces air in the recess

and will hold the ball bearing in place.

Be sure to completely wipe away any

excess oil.

3. lace 3 to 4 drops of oil into the

bottom of the bearing housing.

4. If not already installed place the brass

thrust plate in the bottom of the

bearing housing with the white Delrin

button facing upward. The thrust plate

needs to be held flat as it is lowered

into the bearing. A simple method is to

attach a small loop of tape to the end of

a pencil. Then stick the thrust plate to

the pencil and lower it in place. Be

sure that the Delrin button is facing up!

5. Carefully dispense 5.0ml of oil into the

bearing housing without getting any oil

on the sides of the bearing.

6. Insert the spindle into the bearing. The

spindle will stop about 1/2" before it is

fully seated.

7. Install the platter on the spindle. The

platter is very heavy and will require

two people to install. Inflate the

provided air jacks so that they are

about 1” thick. lace the air jacks on

both sides of the base under where the

platter will go. Orient so that the tubing

will not be under the plater. With two

people carefully lower the platter so

that it rests on the air jacks. Slowly let

air out of both jacks to lower the platter

onto the bearing spindle. As the platter

is being lowered rotate the platter as

required to align the platter mounting

holes with the holes in the spindle. A

small screwdriver may inserted into the

mounting holes to rotate the spindle for

final alignment.

8. Install but do not tighten the 8, 10-32

screws used to fix the platter to the

bearing spindle.

9. Once the platter is in place wait for the

spindle displace the oil and fully seat.

This will take roughly 30 minutes so be

patient. When fully seated the gap

between the platter and the base will

be about 0.10” (slightly less than 1/8th

inch). WARNING, do not spin the

platter until the bearing has fully

seated!

10.Once the platter has seated use the

provided dial indicator to accurately

center the platter onto the spindle as

follows:

loosen all 8 of the platter mounting

screws and then lightly tighten two

screws on opposite sides.

Wrap the end of the dial indicator

rod with scotch tape to avoid

scratching the edge of the platter.

Setup the dial indicator and stand

so that the rod of the dial indicator

presses against the edge of the

metal platter plate. The dial

indicator shaft should point

straight out from the edge of the

platter.

lace the dial indicator so that the

dial is deflected at least one half of

a rotation.

Slowly rotate the platter and locate

the point where there is maximum

deflection of the needle. Also note

the amount of deflection.

Use the provided rubber mallet to

tap on the edge of platter (at the

point of maximum deflection) to

move the platter ½ of the amount

of deflection noted before. You may

need to hold the dial indicator base

in place to keep it from being

jarred during this operation. A

series of small taps works best.

Repeat this process until there is

less than 0.002 (two tick marks) of

deflection as the platter is rotated.

This is a tricky process and may

take some time to master. lease be

patient.

Once the platter is centered tighten

two of the bolts and then recheck.

Sometimes tightening the bolts will

change the centering slightly. If

this happens loosen the bolts just

enough that the platter can be

adjusted and repeat the centering

process.

Tighten the remaining 6 bolts.

11. Thread the chrome record centering

pin into the top of the platter. Tighten

the centering pin with pliers will keep it

from backing out while using the

clamp.

12.Connect the cable from the base to the

motor controller.

II. Armboard etup

The model 460 armboard is secured by a

3/8” bolt extending from the armboard to

the bottom of the 460 base. A 3/16” allen

wrench and a ratchet with a 11/16” socket

are required to adjust and tighten the

armboard.

1. Start by using the 3/16” allen wrench

to set the armboard tension so that the

armboard is steady but loose enough

that it can be adjusted by hand. The

allen wrench is inserted into the center

of the armboard bolt from underneath

the turntable base.

2. Install the tonearm and cartridge and

adjust the overhang by rotating the

armboard.

After the overhang adjustment is

complete tighten the armboard bolt. Start

by using the 3/16” allen wrench to tighten

the armboard bolt. The proper amount of

torque is roughly what can reasonably be

exerted using a small allen wrench. Next

tighten the armboard bolt locking nut

using a ratchet and a 11/16” socket. Only

use light pressure when tightening the

armboard nut.

III. Operation

The Certus controller has a single control

switch with 5 positions, off and 0, 33, 45

and 78 R M.

ower on the controller by rotation the

switch from off to the 0 R M position.

When the controller is first powered up it

goes through a 5 second sequence that

aligns the motor magnets. The red and

yellow LEDs light during this process and

the platter movement will be erratic.

To start the turntable simply rotate the

switch to the desired speed. The red LED

will light during the spin up process. The

green LED lights when the desired speed

has been reached but the speed is not

fully stabilized until the red LED shuts off.

To stop rotate the switch to the 0 R M

position. It's best to not power down the

controller until the listening session is

over. Do not spin the platter by hand.

The Certus controller has a sleep timer

feature that will shut off the controller

after 42 minutes of uninterrupted play.

The yellow LED flashes to provide a two

minute shutoff warning. When the sleep

timer expires the motor will shut off and

the yellow LED will flash slowly. Reset

the sleep timer by turning the controller

switch to the off position. The sleep timer

may be disabled if desired.

IV. Reflex Clamp

A reflex clamp is provided with the model

460 and it's use is optional. Unlike other

Teres models clamping may or may not

produce the best results. To use the reflex

clamp place the black Delrin washer

packaged with the record clamp over the

record centering pin. The Delrin washer

must be placed directly on the platter and

under the record. lace the record over

the spindle and then thread on the clamp.

Be sure to remove the Delrin washer if

the clamp is not used.

Only a small amount of clamping pressure

is needed. A simple method for finding the

ideal pressure is to tap on the edge of the

record while clamping. Taping the edge of

the record will make a slight clicking

sound as the record edge contacts the

platter. Tighten the clamp to the point

where the edge of the record has the best

contact as indicated be the least amount

of “clicking”. The pressure is not critical

and after a little use the process will

become automatic.

V. Controller Options

The Certus motor controller has a small

number of options that may be adjusted

via internal switches mounted on the front

CB. The top cover must be removed for

access to the switches.

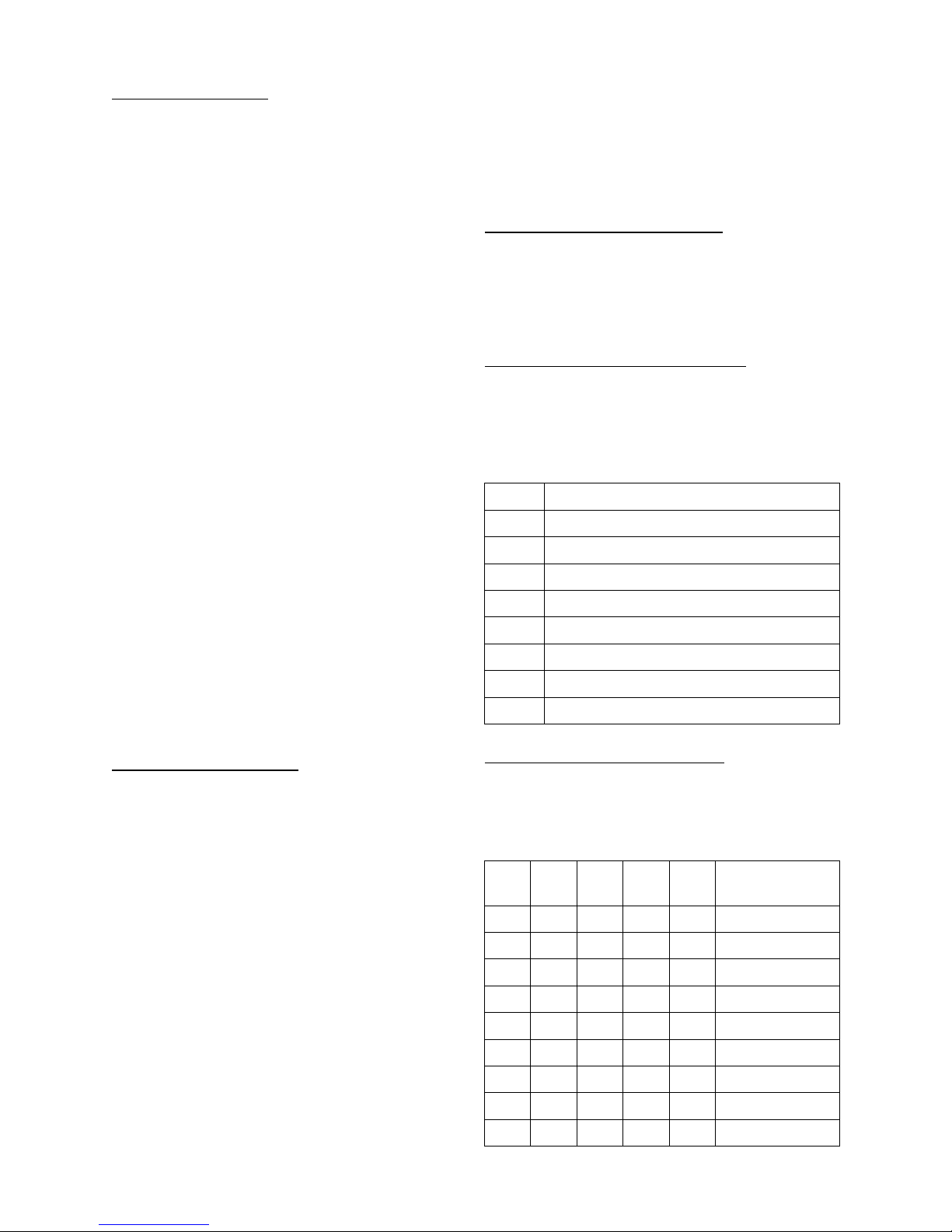

2 (8 position rotary switch)

S2 may be used to fine tune motor torque

for desired sound quality. The default

setting has been carefully optimized and

will likely be the preference for most

listeners.

2 Torque Percent @ 33-1/3 RPM

0 58.6%

1 63.5%

2 68.4%

3 73.2%

4 78.1% (default)

5 83.0%

6 87.9%

7 92.8%

1 (8 position DIP switch)

Sw1-5: itch adjust

Sw6-7: Must be off

Sw8: Sleep timer, on = enabled

itch Adjust Settings

w1 w2 w3 w4 w5 Pitch @

33-1/3

Off Off Off Off Off -4.880%

On Off Off Off Off -4.570%

Off On Off Off Off -4.258%

On On Off Off Off -3.945%

Off Off On Off Off -3.629%

On Off On Off Off -3.311%

Off On On Off Off -2.990%

On On On Off Off -2.668%

Off Off Off On Off -2.344%

w1 w2 w3 w4 w5 Pitch @

33-1/3

On Off Off On Off -2.017%

Off On Off On Off -1.688%

On On Off On Off -1.357%

Off Off On On Off -1.024%

On Off On On Off -0.688%

Off On On On Off -0.351%

On On On On Off -0.011%

(default)

Off Off Off Off On +0.332%

On Off Off Off On +0.677%

Off On Off Off On +1.024%

On On Off Off On +1.373%

Off Off On Off On +1.725%

On Off On Off On +2.080%

Off On On Off On +2.437%

On On On Off On +2.796%

Off Off Off On On +3.158%

On Off Off On On +3.523%

Off On Off On On +3.890%

On On Off On On +4.259%

Off Off On On On +4.632%

On Off On On On +5.007%

Off On On On On +5.385%

On On On On On +5.765%

VI. Technical pecifications

Dimensions:

•Model 460: 22 x 17" x 15.25"

•Motor Controller: 13" x 13.5" 5.5"

Weight:

•Model 460: 220 Lbs. (excluding

controller)

•latter: 60+ Lbs.

•Motor Controller: 18 Lbs.

Drive ystem:

•Low cogging multi-phase permanent

magnet synchronous (patent pending)

•Magnetic damping via eddy current

brake (patent pending)

•High torque capability (563 oz/inch)

•High resolution digital drive signal

synthesis

•Speeds Supported: 33-1/3, 45 and 78

•Speed Accuracy

•33-1/3 R M: -0.011% +- 0.003%

•45 R M: -0.006% +- 0.003%

•78 R M: -0.160% +- 0.003%

•itch adjustment available via

internal DI switch, 32 steps at

0.34% per step (33-1/3 R M) and

0.461% per step (45 R M).

•Optional sleep timer (shuts off after

42 minutes of uninterrupted

operation)

Bearing Assembly:

•Upward facing, platter embedded

•Massive 1" diameter stainless steel

spindle

•High center of gravity (thrust surface

is above lower platter surface)

•Thrust surface: 1/2" precision ball

bearing and a replaceable

Delrin/brass thrust plate.

•High precision ground and polished

bearing surfaces with precise 4-5 ten

thousandths radial clearance.

•Oil bath design with viscous damping

and superior lubrication

Power Requirements:

•115-125vac, 0.7 Amps, 85 watts

•230-250vac, 0.35 Amps, 85 watts

•Fuse:

120vac - 1.5 amp slow blow

240vac - 1 amp slow blow

Table of contents

Other Teres Turntable manuals