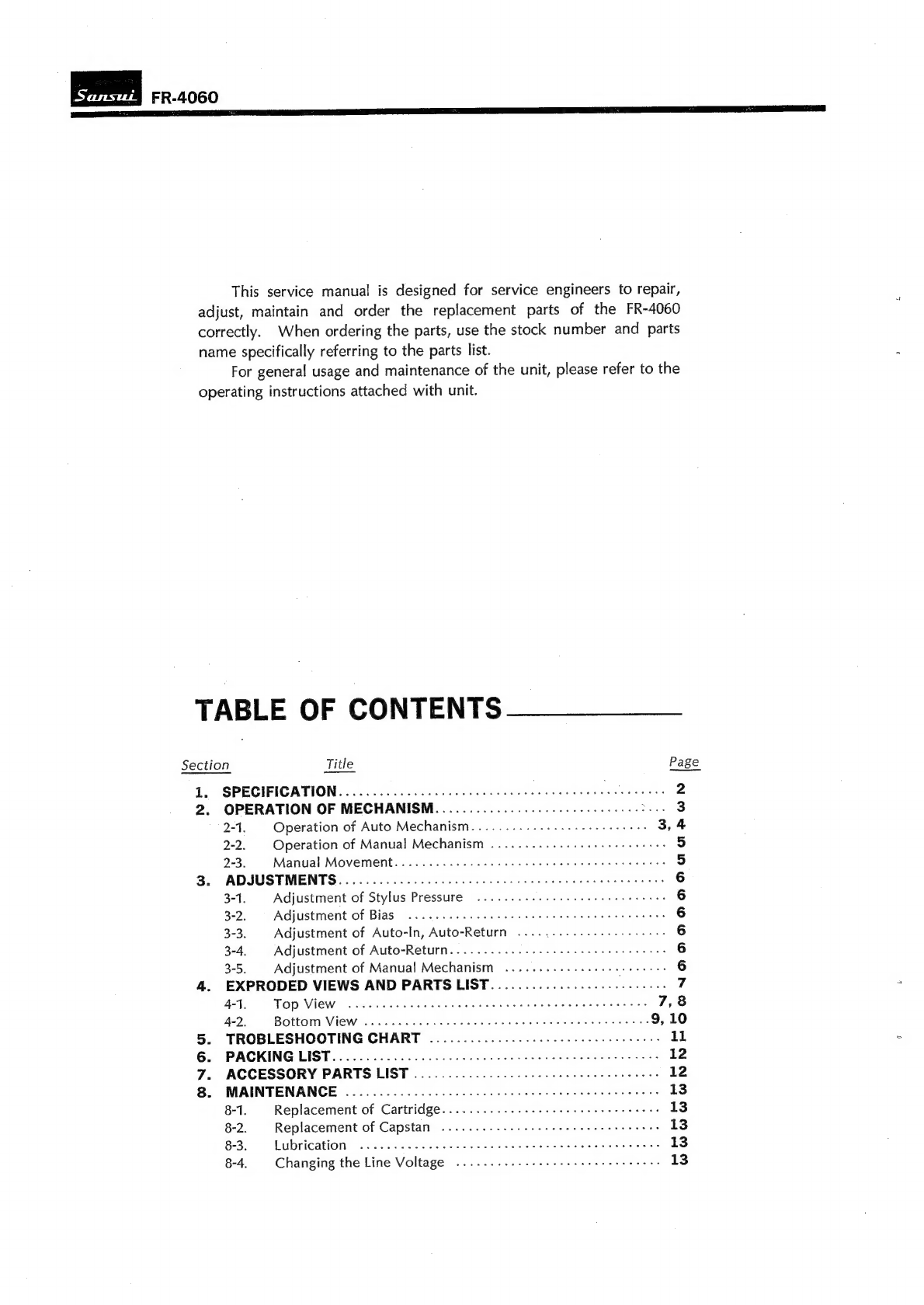

FR-4060

This

service

manual

is

designed

for

service

engineers

to

repair,

adjust,

maintain

and

order

the

replacement

parts

of

the

FR-4060

correctly.

When

ordering

the

parts,

use

the

stock

number

and

parts

name

specifically

referring

to

the

parts

list.

For

general

usage

and

maintenance

of

the

unit,

please

refer

to

the

operating

instructions

attached

with

unit.

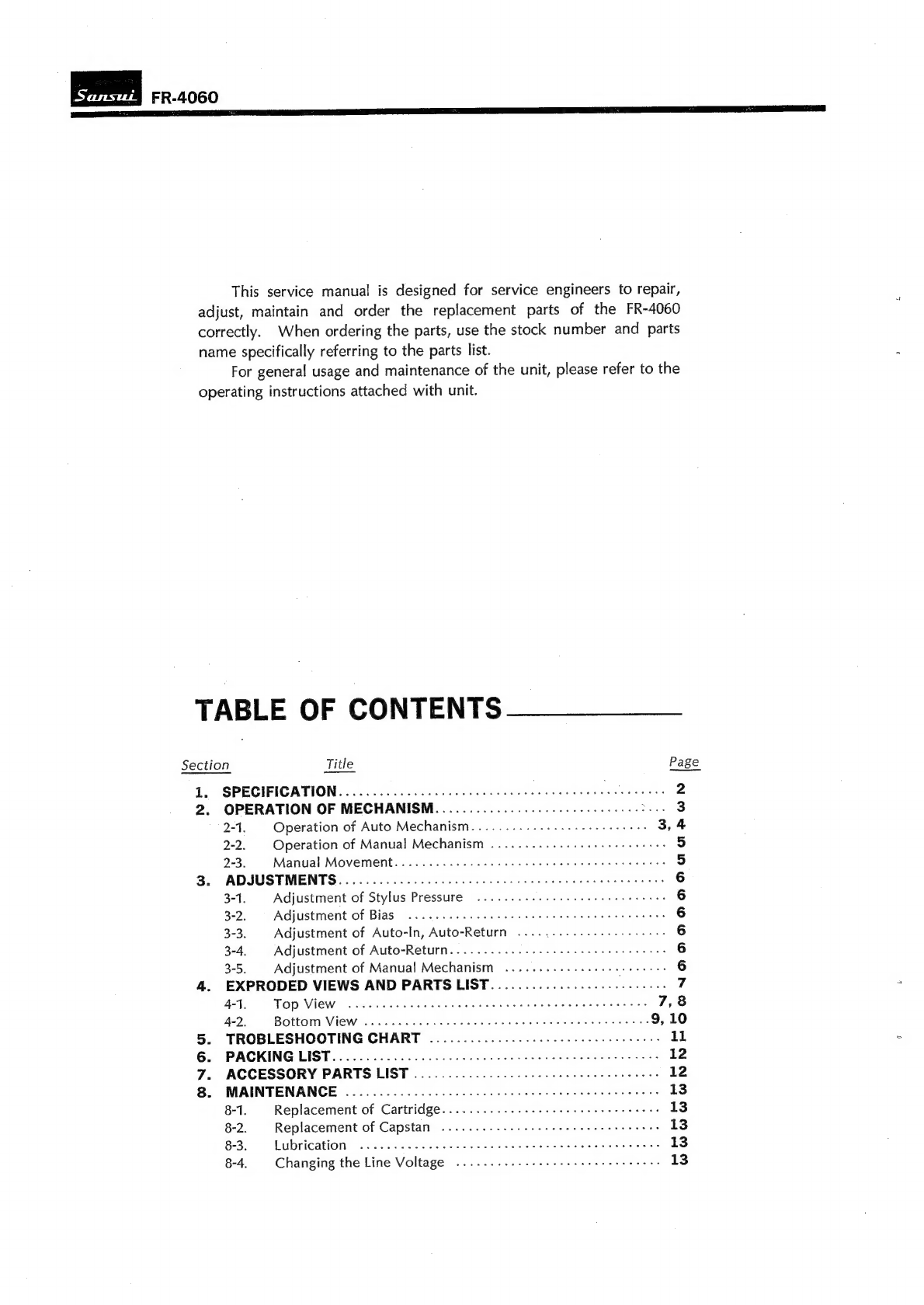

TABLE

OF

CONTENTS

Section

Title

Page

1.

SPECIFICATION...................

wiht

edie

aint

Sa

at

ES

See

taiase

Se

fp

2

2.

OPERATION

OF

MECHANISM....................-..0e

eee

3

2-1.

Operation

of

Auto

Mechanism........-.-.-6-

+02

eee

ees

3,4

2-2.

Operation

of

Manual

Mechanism

....-.-.+---

sees

sees

eens

5

2-3.

Manual

Movement...........

cc

ese

e

cere

renee

eee

e

ee

eeee

5

3.

ADJUSTMENTS................

00.00

ccc

eee

een

ees

6

3-1.

Adjustment

of

Stylus

pressure

Ladhye

aun

ones

aes

san

6

3-2.

Adjustment

of

Bias

2...

6...

cece

cece

ee

nent

eee

6

3-3.

Adjustment

of

Auto-In,

Auto-Return

........

2

sees

eee

e

ee

6

3-4.

Adjustment

of

Auto-Return....

0.6.6.0

eee

eee

eee

eee

ees

6

3-5.

Adjustment

of

Manual

Mechanism

.....-.--.-.

sees

eee

sees

6

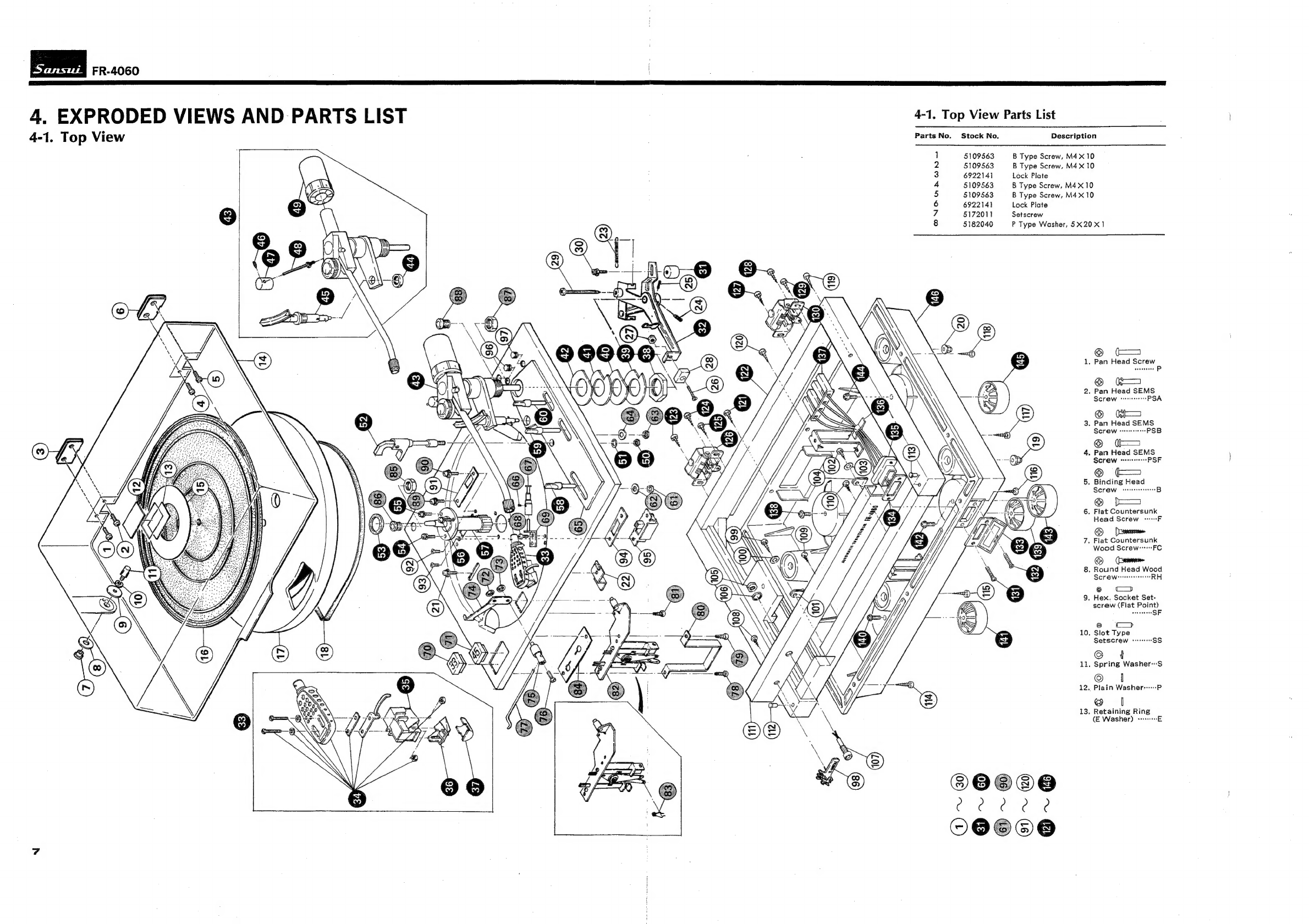

4.

EXPRODED

VIEWS

AND

PARTS

LIST.................-.

Peer

7

AT.

TOp

VIEW

ooo

cece

cece

cece

teen

ene

e

nen

ee

7,8

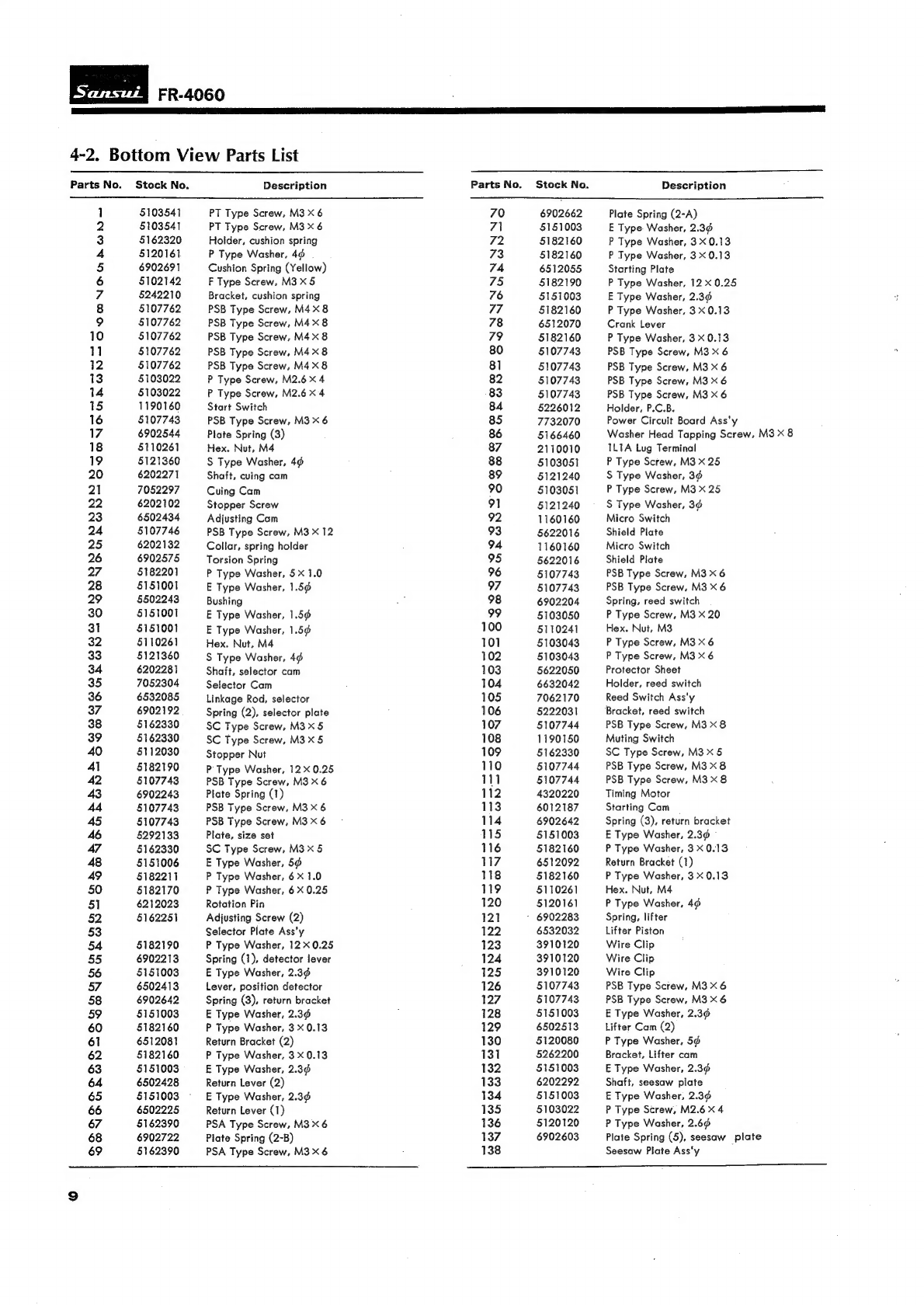

4-2.

POttOT

VIEW

setedsccs

Hei

ede

ea

tant

ees

aaa

9,10

5.

TROBLESHOOTING

CHART

..................50.

5.

eee

eee

eee

11

6.

PACKING

LIST.................

Rags

caked

dine

Dee

Sertionecs

st

12

7.

ACCESSORY

PARTS

LIST

..............

00.

e

cece

eee

eee

eens

12

8.

MAINTENANCE

...................0

00

cee

cece

eee

eee

eee

ees

13

8-1.

Replacement

of

Cartridge

iatwosleotaaeade

tamil

trees

eae

13

8-2.

Replacement

of

Capstan

........

520s

eee

eee

eee

eee

eens

13

8-3.

CUDPICALION:

-aSacccecaceedine

en

Rigen

elated

tees

13

8-4.

Changing

the

Line

Voltage

......-.

56.

eee

ence

eee

ees

13