TERMOTECHNIKA Ecomat 15 User manual

TERMOTECHNIKA

OPERATION AND MAINTENANCE MANUAL

FOR PELLET BURNERS ECOMAT

TERMOTECHNIKA MICHAŁ KOTELBA Address: Postępu 190 A, Zgorzała, 05-500 Piaseczno

Office address: Marynarska 14 lok.310, 02-674 Warszawa; NIP (tax ID): 716-230-90-85 REGON (statistical no.): 060301812 E b

i u r o @ s u p e r g r z a n i e . p l M + 4 8 –601-086-243 M + 4 8 6 0 6 1 6 7 4 6 7

www.ecomat.waw.pl

1

Table of contents

1. Safety of use ............................................................................................................................... 3

1.1. Commentary ........................................................................................................................... 3

1.2. Hints and tips for fitters and users .......................................................................................... 3

1.3. Conditions for safe operation .................................................................................................. 3

2. General information .................................................................................................................... 4

2.1. Adjusting boiler and burner heating power to central heating and usable warm water heating

purposes ................................................................................................................................ 4

2.2. Burner structure and its elements ........................................................................................... 5

2.3. Recommended fuel and fuel storage ...................................................................................... 6

2.4. Short technical description and sequence of the burner’s functions ........................................ 6

2.5. Auxiliary equipment for burner and boiler ............................................................................... 7

3. Technical specification .............................................................................................................. 9

3.1. Technical parameters of the burners ...................................................................................... 9

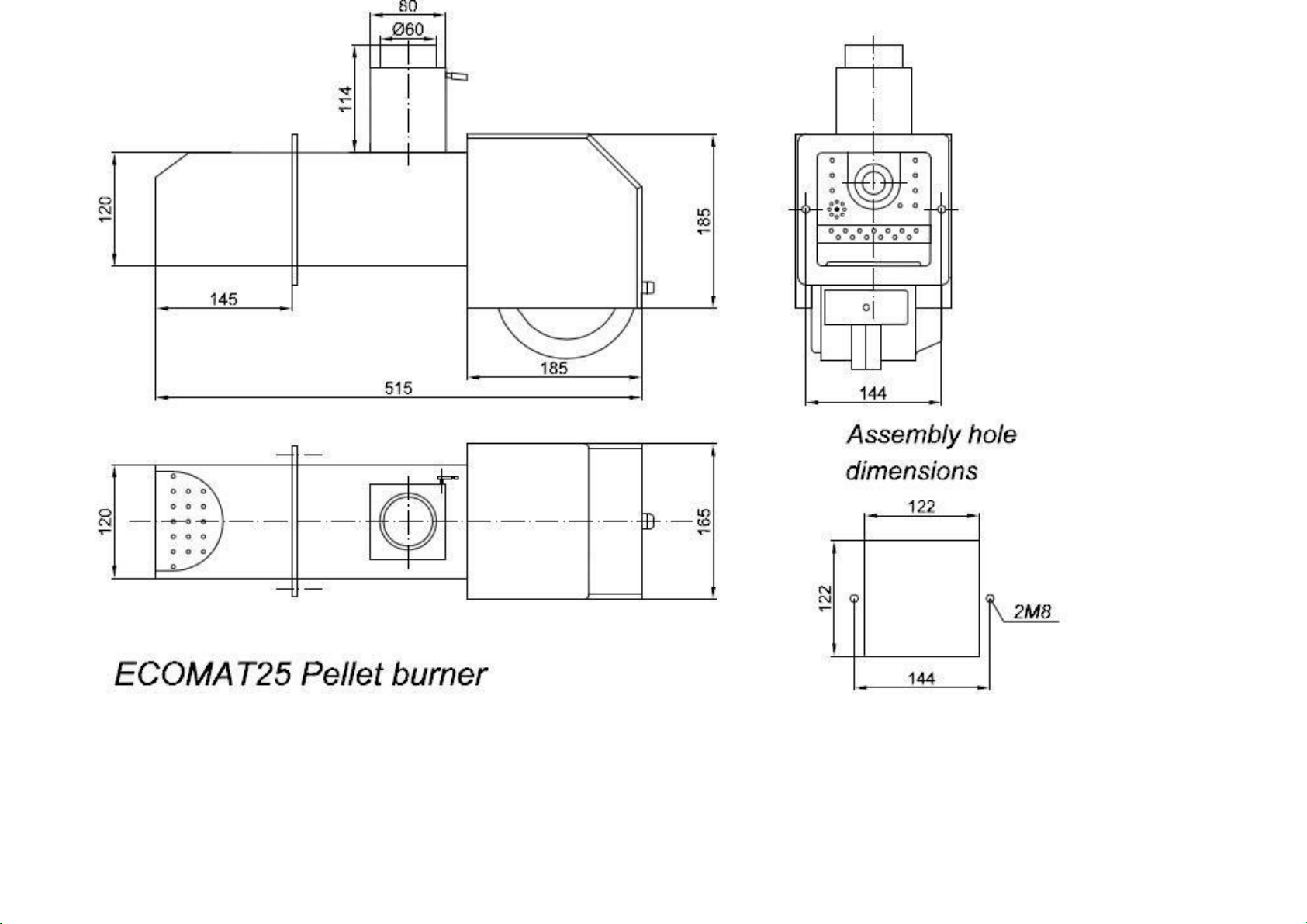

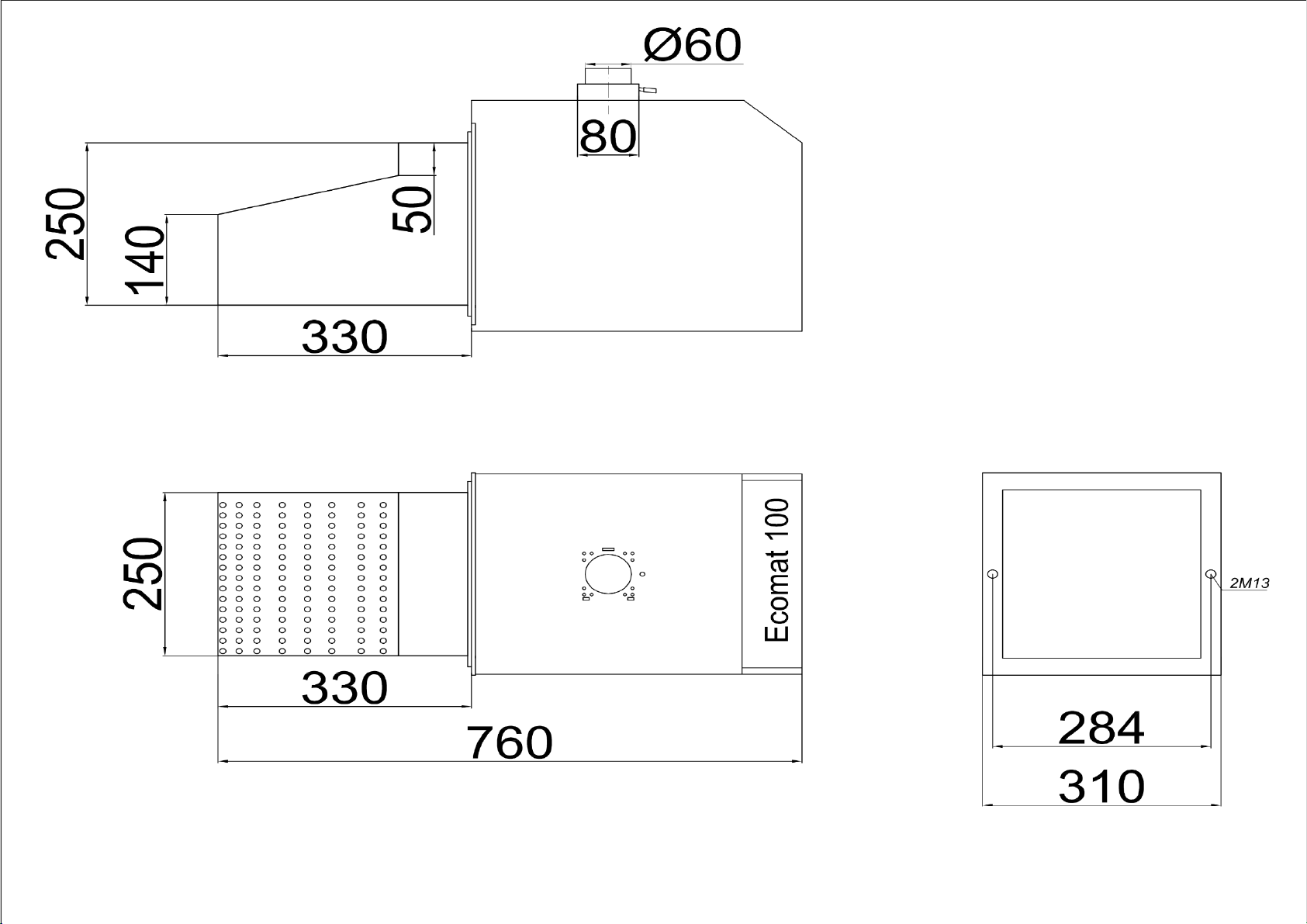

3.2. Burner and feeder dimensions and conditions for installation within the boiler ...................... 10

3.3. Burner presets ....................................................................................................................... 16

3.4. Electric connection ................................................................................................................. 16

3.5. Assembling, launching and adjusting the burner ................................................................... 17

4. Maintenance .............................................................................................................................. 19

4.1. Cleaning - setting burner cleaning mechanism - examples ................................................... 19

4.2. Replacing the ignition device ................................................................................................ 20

4.3. Causes of faulty operation and fault removal ........................................................................ 22

4.4. Burner disposal .................................................................................................................... 23

5. Declaration of conformity for the ECOMAT burners .............................................................. 25

6. Assembly report ....................................................................................................................... 26

7. Warranty card ........................................................................................................................... 27

Schedule 1 –Approximate heat demand of buildings ............................................................... 29

Schedule 2 - Boiler temperature adjuster operation manual ..................................................... 30

2

.

1. Safety of use.

1.1. Commentary

This operation and maintenance manual includes important information about correct

assembly and operation of the Ecomat burner which is designed to be used with a

boiler. This manual is primary intended for fitters who possess necessary knowledge

and experience in operation and maintenance of heating systems. The first launch of

the burner shall be done by a duly trained professional. Improper launch or assembly

of the burner results in warranty loss.

1.2. Hints and tips for fitters and users

Assembly and operation should be done according to local norms and standards

concerning:

- appropriate positioning of the boiler, manner of combustion air supply and

flue gas discharge;

- technical and safety equipment for water heating systems.

1.3. Conditions for safe operation

Burner and boiler shall be operated in properly fitted rooms only. Since boiler with the

pellet burner uses combustion air from the room (the boiler-house) which it is

positioned in, thus insufficient air intake may cause flue gas emission and a threat of

carbon monoxide presence. Hence, it is forbidden to downsize or close the inlet and

outlet holes.

The size of an inlet hole which supplies combustion air should be at least the

same as the cross-section of the boiler’s chimney. In order to illustrate

importance of the above, it is worth mentioning that e.g. the Ecomat 25 burner

that operates at full capacity of 25 kW burning about 5.5kg of pellet per hour

requires approx. 100m3 of combustion air.

If such an irregularity occurs, it should be immediately corrected. Otherwise, further

operation of the boiler must be discontinued and the fitter has to inform the user in

writing about such a situation.

As far asthe chimney isconcerned, it is crucial to secure an appropriate flue draught.

Chimney height shall be as follows:

3

- from at least 2m at a diameter of 100mm or more to maximum chimney height of about

8-9 meters which corresponds to the flue draught of less than 25Pa.

Chimneys of flue draught exceeding 25Pa should be equipped with a flue draught

6

limiter. The Ecomat burner can be assembled within a boiler which water heating

system is secured by an expansion vessel or within a boiler which includes a cooling

coil with a water valve.

Boiler with the burner assembled should be operated only by adults who are familiar

with operation manuals of both the boiler and the burner. Children are not allowed to

stay in the vicinity of the operating boiler without supervision of adults. Ash produced

during combustion should be removed into a non-combustible container with a lid.

2. General information.

2.1. Adjusting boiler and burner heating power to central heating and usable

warm water heating purposes.

In order to select the right burner for a boiler, it is necessary to determine the boiler

heating capacity. Generally, the burner should not have a greater heating capacitythan

the boiler. Otherwise, when the boiler has a greater heating capacity than the burner,

the condensation of flue gases may occur and boiler corrosion can be intensified.

Therefore, it is a matter of principle that the Ecomat burner is connected to the boiler

of the same heating capacity or a capacity within a tolerance of 10%.

Approximate boiler heating capacity can be selected on the basis of a parameter which

refers to the cubic space of the rooms being heated. The parameter depends on the

building thermal insulation degree. In case of very good insulation degree, the heating

capacity of 40 W/m3 should be assumed. In case of building with poorer thermal

insulation degree, the coefficient should amount to about 60 W/m3. Another way

consists in calculating heat demand of a building as a total capacity of individual

heaters. In this case the heat demand should be increased by 20% in order to avoid

operating burner and boiler at maximum heating capacities.

Boiler heating capacities calculated for various cubic spaces of buildings, wall

insulation levels and types of applied fitting are listed in the schedule 1 to this manual.

2.2. Burner structure and its elements

7

The Ecomat 15, Ecomat 25, Ecomat 40, Ecomat 70 burners, which burn tiny wood

briquettes (pellets), are optimal devices designed to work with heating boilers of

heating capacity 4-15 kW, 6-25 kW, 12-45 kW and 20-65 kW respectively. Burners can

be installed into most solid fuel boilers and some oil-fired boilers, provided that the

combustion chamber of the boiler allows ash aggregation and its periodical removal.

The Ecomat pellet burners cannot be installed into boilers with water-cooled grate. In

order to install the burner in a solid fuel boiler with a cast iron grate, it is necessary to

remove the grate allowing ash to fall from the burner into the ash pit. The burner

mounted above a water-cooled grate will not operate correctly because such a grate

constitutes an obstacle that disables free movement of ash into the ash pit. TheEcomat

burners have been designed in such a way to provide automatic operation. Thanks to

a movable grate and a special skimmer, the burner head cleans automatically. The

Ecomat burners are environmental-friendly and economic devices - they are

characterized by low flue gas emission and low electric energy consumption (less than

40W in average).

Efficiency level of burners mounted within a boiler amounts to about 98%. When the

burner is mounted within the boiler, the whole burner head is positioned in the boiler

and the external surface of the burner does not excessively warm up during operation.

Operation of the burner proceeds automatically, beginning from ignition, through

burning and ending with cooling and cleaning the burner head off residues of ash and

sinter, and then switching into the stand-by mode.

The Ecomat burners are composed of the following units:

1. the burner with a burner head and a movable grate mounted within its body as well

as other elements and wiring covered with a metal housing;

2. an external conveyor system of 1.5m in length (standard);

3. electric control box with electronic burner adjuster;

4. flexible plastic feeding pipe which supplies fuel and connects the feeder with the

burner.

8

2.3. Recommended fuel (pellet) parameters:

- diameter ø 6 (for all burners) or 8 mm ( above Ecomat 25);

- maximum length: 4-5 times the pellet diameter;

- content of fine fractions i.e. fractions of 3mm and less (sawdust and ashes): not

more than 1%;

- calorific value above 16 MJ/kg or 4.7 kW/kg;

- dust content: not more than 2%;

- moisture content: less than 10%;

- pellet must not contain any loose inclusions, such as: bark, wood chips etc.

There are no special requirements for pellet storage. However, the storage place

should be roofed over and kept free of excessive moisture as pellets easily absorb

moisture and crumble. It is not recommended to store larger volumes of pellet for

longer periods of time. It should be used up within a single heating season.

2.4. Short technical description of operation of a boiler equipped with a pellet

burner.

Heating boilers with the Ecomat pellet burners operate automatically. The most

important controlling unit is the controller which controls the heat source i.e. the pellet

burner, fuel feeder and the central heating and usable warm water pumps.

The adjuster’s display shows information about current status of the automatic

operation. When the boiler and the burner do not operate, the status is displayed as

“stand-by” provided that the burner has been completely switched off (“STOP” status).

The “stand-by” status means that the adjuster awaits for a signal to launch central

heating or usable warm water heating. Heating begins when the room thermostat is

launched and it ends when temperature inside the house reaches required level.

Thus, it should be obligatory to install the room thermostat. On the other hand, usable

water is being heated within hours set on a separate timer (recommended auxiliary

equipment).

When central heating and usable warm water heating is conducted at the same

time, the user can select heating priority for the usable water on the adjuster or

9

continue heating both the house and the water. In the latter case, time needed to heat

water to desired temperature will be appropriately longer.

In order to heat usable water only (e.g. during summer season), it is enough to

switch the adjuster into the “summer” mode (central heating system is switched off,

then).

When the burner and the boiler finish heating the house to desired temperature

and finish heating usable water to desired temperature, the burner duty cycle

concludes and the device switches into “stand-by” mode.

This solution allows saving considerable amounts of fuel because thermal energy

is produced only when the central heating system demands it.

In each duty cycle, the Ecomat burners automatically ignite and then they operate

at maximum power, modulated power or minimum power accordingly with varying

demand for heat. Once the tasks for both central heating system and usable water

heating system are accomplished, fuel feeding is stopped, the burner burns residues

of fuel that remain on the grate and it automatically cleans off the ash - according to

preset duty cycle. Hence, the device operates automatically.

The user is only required to replenish fuel in the fuel hopper, remove ash from the

boiler’s ash pit and periodically clean the boiler.

2.5. Auxiliary equipment for burners and boilers.

- room thermostat;

Room thermostat is an auxiliary equipment for the burners. Typically, the thermostat

is installed during the last stages of assembling the burner within the boiler. By

default, the burner is sold with a jumper (bridge) for GH connectors in the lowvoltage

terminal block of the burner adjuster. During assembly, the bridge needs to be

removed and the COM-NO clean contact of a room thermostat should be plugged.

- usable warm water module;

Usable warm water module is another optional equipment for the burners. It works

with all types of room thermostats that allow weekly settings and it enables the user

to set times which the usable warm water is to be prepared in. Except for the set

times, heating of usable water is electronically disabled which allows saving fuel. The

10

goal of the two auxiliary parts of equipment (i.e. room thermostat and usable warm

water heating module) is to allow the central and usable warm water heating systems

operate at the same time. It helps to save fuel and ensures optimal operation of the

burner-boiler unit.

- emergency stop;

The last item of auxiliary equipment for the Ecomat 15, Ecomat 25 and Ecomat 40

burners is the so-called emergency stop, i.e. a limit switch which is mounted onto

the door of a boiler which the burner was installed in. The limit switch has to be

installed in such a way to ensure that the emergency stop function is launched when

the door is opened (i.e. the burner stops operation).

Therefore, the burner can only operate when boiler’s door remain closed. It is a kind

of fire protection system which prevents from starting the burner when the door is

open. It is also helpful at removing ash from the boiler because it protects against

launching the burner accidentally during that operation. Suggested solution is

illustrated in the image below:

11

By default, the burner is equipped with a bridge installed over the X-connector (E-F).

Limit switch for the emergency stop should be plugged after removing the bridge

installed over the connector.

3 . Technical specification.

3.1. Technical parameters of the

burners.

- nominal heat output for Ecomat 15 : 4-15 kW;

- nominal heat output for Ecomat 25 : 7-25 kW;

- nominal heat output for Ecomat 40 : 12-40 kW

- nominal heat output for Ecomat 70 : 20-65 kW;

- heating efficiency: 94%;

- Ecomat 15 weight: 11 kg

- Ecomat 25 weight: 11.5 kg

- Ecomat 40 weight: 15.5 kg

- Ecomat 70 weight: 25 kg

- standard feeder: length 1.5m;

- fuel: pellets ø 6 mm or ø 8 mm;

- supply voltage: 230 VAC 50 Hz;

- average power consumption: about 40 W;

- degree of protection: IP 40.

12

3.2. Burner and feeder dimensions and conditions for installation in the boiler

13

14

15

16

17

Assembly hole

dimensions

ECOMAT100 Pellet burner

18

Fuel feeder diagram for ECOMAT 15 and ECOMAT 25

Fuel feeder diagram for ECOMAT 40

Fuel feeder diagram for ECOMAT 70

19

Conditions for installation within the boiler.

The Ecomat burners have been designed in such a way that the flame burning

direction in unobstructed space is at an angle of about 45 degrees. It allowed

custom installation of the burner within boilers which have a narrow and at the same

time a tall combustion chamber (as in the case of upper combustion boilers) as well

as in the boilers with a lengthier and at the same time a low combustion chamber

(as in the case of lower combustion boilers or oil-fired boilers).

Irrespectively of the above, the boiler combustion chamber for Ecomat 15 and

Ecomat 25 should be characterized of the following minimum dimensions: -

minimum depth: 300 mm;

- minimum space over burner combustion pipe: 100 mm (taking into account the above

minimum depth);

- minimum width of the combustion chamber: 250mm;

The boiler combustion chamber for Ecomat 40 should be characterized of the following

minimum dimensions: - minimum depth: 500 mm;

- minimum space over burner combustion pipe: 200 mm (taking into account the above

minimum depth);

- minimum width of the combustion chamber: 400mm;

The boiler combustion chamber for Ecomat 70 should be characterized of the following

minimum dimensions: - minimum depth: 600 mm;

- minimum space over burner combustion pipe: 300 mm (taking into account the above

minimum depth);

- minimum width of the combustion chamber: 500mm;

When the burner is assembled (e.g. within the lower boiler door), the inside

of its combustion chamber should allow ash to fall freely from the burner, favourably

into an ash drawer made of metal. Minimum distance between the bottom of the

20

burner and the bottom of the ash pit should not be lesser than 100mm - the larger

is this distance, the less often it is necessary to remove ash.

3.3. Burner pre-sets.

The burner pre-sets adjusted by the manufacturer are as follows:

- power is set to the nominal value, i.e. 15 kW, 25 kW, 40 kW and 70 kW respectively.

Modification of power parameters needs to be done by a fitter (authorized serviceman).

The user can adjust (change) power to his/her boiler by way of selecting 60% to 100%

power level through settings available in the user’s menu. - all parameters have been

adjusted to the following types of fuel: type 1 –pellet ø 6 mm of average quality with

up to 1% of ash content. In case of other type of pellet (e.g. ø 8 mm or a pellet of lower

quality), it is possible to select and set parameters for fuels labelled as type 2, 3 and 4.

This should be done by an authorized serviceman.

- burner cleaning parameters are appropriate for a pellet of average ash content, i.e.

1% - “automatic” mode and the burner is cleaned after each work cycle. It is possible

to change cleaning mode when a pellet of increased ash content is used. In such cases

it is recommended to set the “combo” cleaning mode, i.e. the mode including cyclic

cleaning during regular operation of the burner as well as the final cleaning conducted

after the work cycle ends. This should be done by an authorized serviceman.

- by default, the burner is set to central heating as well as usable warm water heating

mode of work. However, if the burner should only heat the central heating system, then

the usablewarm water circuit needs to be switched off (set the usable warm water circuit

parameter into “off” mode).

3.4 Electric connection.

Make the electrical connection in accordance with the burner manufacturer's operating

instructions.

3.5 Assembling, launching and adjusting the burner

This manual suits for next models

3

Table of contents

Popular Burner manuals by other brands

Ecoflam

Ecoflam MINOR 20.1 manual

Riello

Riello 20045452 Installation, use and maintenance instructions

Outdoor Gourmet

Outdoor Gourmet TF2002501-OG-00 Assembly instruction

Carlin

Carlin 201GAS instruction manual

Riello Burners

Riello Burners BF3 installation manual

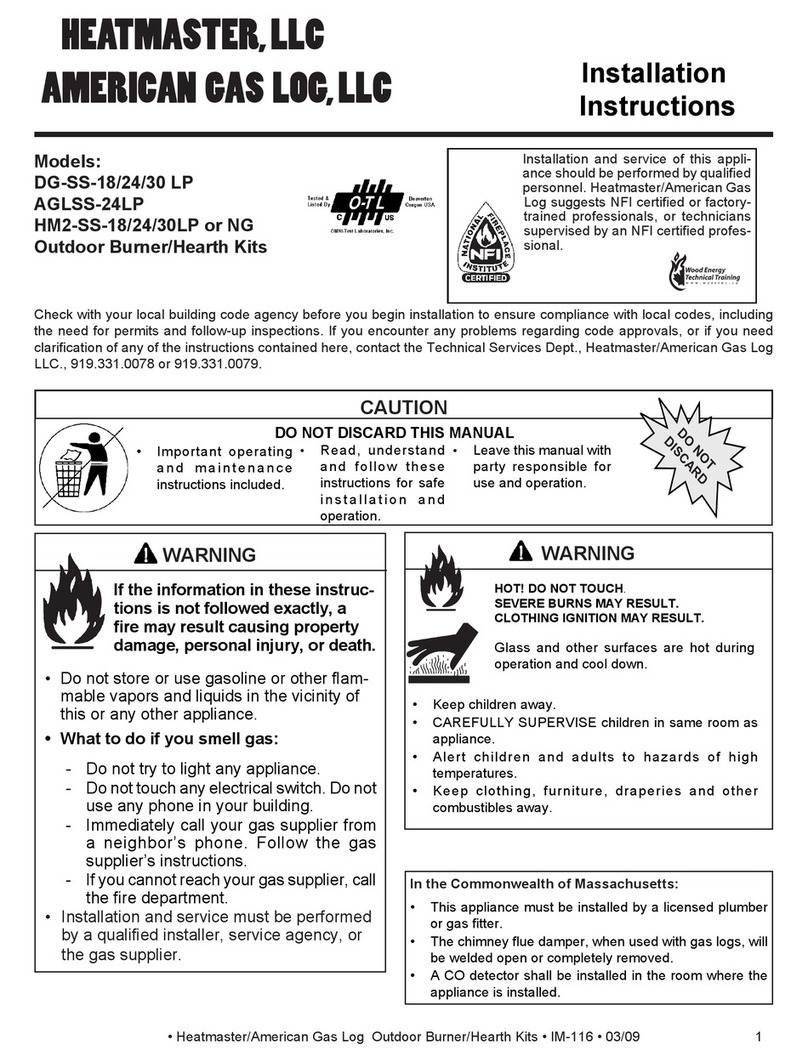

Heatmaster

Heatmaster DG-SS-18 installation instructions

Town & Country Fireplaces

Town & Country Fireplaces TC36.NG04C instructions

EarthCore

EarthCore ISF-SBVT24VE(N,P) Installation & owner's manual

Riello

Riello G20KI instruction manual

Riello

Riello DB9 LSE C13 TC FS1 A0 Installation, use and maintenance instructions

baltur

baltur TBL 85P Instruction

Midco

Midco Incinomite J83-DS Installation and service instructions