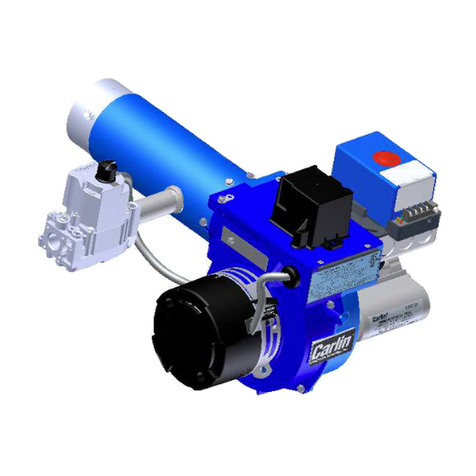

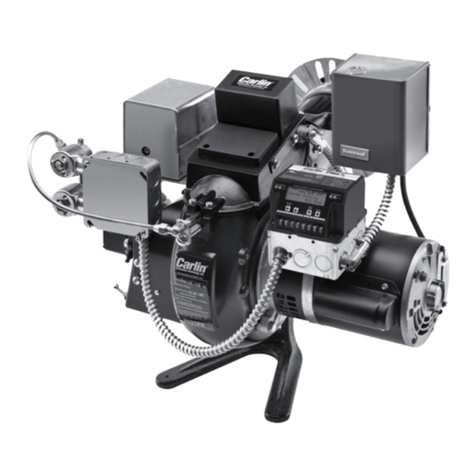

Model 201GAS burner — Instruction manual

Carlin part number MN201GAS Rev. 03/14/11

– 6 –

Where appliance instructions differ from this manual, follow the appliance instructions.

Verify clearances

• Verifythattheburner/appliancewillmaintainallclearancestocombus-

tiblewallsoroorandallclearancesrequiredforservice/maintenanceas

required in the appliance manual and applicable codes.

Prepare the appliance

Burner input: Install a gas burner sized for the normal input

ratingoftheappliance.Donotinstallaburnerwithahigher

ringratethantheappliancerating.Donotinstallaburner

with a firing rate more than 10% lower than the appliance

rating. The appliance and vent system could be damaged

due to condensation.

Clean the appliance: Clean the appliance thoroughly and

seal all joints. Test all electrical components and verify the

relief valve works (boilers only).

Verify combustion chamber dimensions comply with the

minimum dimensions shown in Figure 3, page 7. Install or re-

place chamber liner if required by the appliance manufacturer.

The burner must not extend into the combustion chamber.The

end of the burner air tube must be within ¼” of the inside

face of the chamber. If the space around the burner air tube

is more than ¼”, wrap the burner air tube with minimum

2300 °F – rated ceramic fiber blanket to seal off the gap.

Repair or replace damaged appliance components.

Inspect the appliance thoroughly. Follow appliance manufac-

turer’sguidelinesforrepairorreplacementofanycomponent

found defective.

When cleaning the appliance or working with ceramic fiber refrac-

tories or fiberglass insulation, see WARNING on this page.

Failure to comply with the above could result in severe per-

sonal injury, death or substantial property damage.

Prepare appliance for burner mounting

The universal flange supplied with 201GAS burners is

intended only for firing chambers with negative overfire pres-

sure. For pressurized firing, you must obtain a burner with a

welded flange, designed for use with the appliance. You can

also use the optional forced draft flange. Failure to comply

could result in severe personal injury, death or substantial

property damage.

Seepage19forrequireddimensionsandboltlocations.

1. Prepare site • prepare burner • mount burner (continued)

Prepare installation site

Verify combustion/ventilation air openings (continued)

When sizing air openings for combustion and ventilation,

include air required for exhaust fans and other appliances,

such as clothes driers, that require air for operation.

Check appliance manual and applicable codes for required sizing of com-

bustion and ventilation air openings.

• Verifythatopeningsareunobstructed.

• Verifythatappliancespaceandairsourcespacesarefreeof:

– Gasoline or other flammable liquids or vapors.

– Combustible materials.

– Air contaminants, such as laundry products, paint, thinner, varnish,

etc.

• Conrmwithuserthattheareawillbekeptfreeofthesematerialsatall

times.

Ceramic ber or

Fiberglass insulation

Ceramic fiber materials, such as chamber liners, may

contain carcinogenic particles (chrystobalites) after

exposure to heat. Airborne particles from fiberglass or

ceramic fiber components have been listed as poten-

tially carcinogenic by the State of California. Take the

following precautions when removing, replacing and

handling these items.

Avoid breathing dust and avoid contact with skin or

eyes. Wear long-sleeved, loose-fitting clothing, gloves

andeyeprotection.UseaNIOSHN95certiedrespira-

tor. This respirator meets requirements for protection

from chrystobalites. Actual job requirements or NIOSH

regulations may require other or additional protection.

Forinformation,refertotheNIOSHwebsite,http://www.

cdc.gov/niosh/homepage.html.

Ceramic fiber removal:To prevent airborne dust, thor-

oughly wet ceramic fiber with water before handling.

Place ceramic fiber materials in a plastic bag and seal

to dispose.

Avoid blowing, tearing,sawing or spraying fiberglass

or ceramic fiber materials. If such operations are neces-

sary, wear extra protection to prevent breathing dust.

Wash work clothes separately from other laundry.

Rinse clothes washer thoroughly afterwards to prevent

contamination of other clothing.

NIOSH First aid procedures:

Eye exposure — irrigate immediately

Breathing—freshair.