TERMOTEK P320-20240 User manual

Version 1.1 P300 WW

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

INSTRUCTION BOOK

P320-20240

Keep for later use!

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

2

Termotek AG reserves the right to make technical changes or improvements to this document

without giving prior notice. Furthermore, it is possible that the customer wishes to make

modifications such as colour, side panels, level display, conductivity measurement, voltage,

frequency, which lead to inaccuracies in the displayed photos.

No part of this document may be copied in any way or transmitted without written permission of

Termotek AG.

© Termotek AG, Baden-Baden, 2013

All rights reserved.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

3

CONTENTS

1. NOTES TO USING THIS MANUAL................................................................................................. 4

2. SUMMARY OF THE WARNING AND PRECAUTIONARY NOTES................................................ 6

3. INTRODUCTION.............................................................................................................................. 7

3.1 PRODUCT DESCRIPTION .........................................................................................................................7

3.2 NOTES TO APPLICATION.........................................................................................................................7

3.2.1 Electrical safety..................................................................................................................8

3.2.2 Operational safety.............................................................................................................. 8

3.2.3 Safety labels....................................................................................................................... 8

4. GETTING STARTED........................................................................................................................ 9

4.1 UNPACKING THE UNIT............................................................................................................................9

4.2 OPERATING THE CHILLER.....................................................................................................................10

4.2.1 Positioning........................................................................................................................ 10

4.2.2 Connecting the water hoses............................................................................................. 10

4.2.3 Setting Up the Electrical Connections..............................................................................11

4.2.4 Getting ready to operate .................................................................................................. 13

4.3 PREPARING THE COOLANT WATER-FEEDBACK CHILLER FOR TRANSPORT TO THE CUSTOMER...............13

4.3.1 Storage............................................................................................................................. 13

4.3.2 Place of Operation ...........................................................................................................14

4.3.3 Transport to the customer................................................................................................14

5. SYSTEM DESCRIPTION............................................................................................................... 15

5.1 SET UP AND FUNCTION.........................................................................................................................15

5.1.1 Refrigerant circuit............................................................................................................. 15

5.1.2 Coolant water circuit......................................................................................................... 16

5.1.3 Industrial water circuit ......................................................................................................17

5.1.4 Electrical circuit................................................................................................................19

6. MAINTENANCE WORK................................................................................................................. 23

6.1 SAFETY NOTES.....................................................................................................................................23

6.2 REPLACING THE WATER FILTER............................................................................................................23

6.3 REFILLING WATER................................................................................................................................25

6.4 REPLACING THE WATER.......................................................................................................................26

6.5 REFRIGERANT CIRCUIT ........................................................................................................................27

7. INSTRUCTIONS FOR REPAIR. .................................................................................................... 28

7.1 SAFETY NOTES.....................................................................................................................................28

7.2 REPAIRS TO THE ELECTRICAL CIRCUIT .................................................................................................29

7.2.1 Replacing the fuses.......................................................................................................... 29

8. OTHER........................................................................................................................................... 30

8.1 SERIAL NUMBER ..................................................................................................................................30

8.2 WASTE DISPOSAL INSTRUCTION...........................................................................................................30

8.3 NOT SATISFIED?...................................................................................................................................31

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

4

1.Notes to using this manual

This manual has been designed to support the user with the transport, installation,

commissioning, operation, inspection, servicing and repair of the unit.

The user should read the manual before beginning to install the unit. Termotek AG takes no

responsibility for damage caused through incorrect installation, commissioning, repair or

operation of this unit.

This chiller complies with the current European standards. Changes made to the construction or

deviations from the intended application by the customer can void this compliance.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

5

The notational convention to this user manual

The following notation and symbols apply throughout the whole document.

CAUTION.DANGER!

CAUTION.CORROSIVE MATERIAL

CAUTION.HOT OR COLD SURFACES

CAUTION.ELECTRICAL VOLTAGE

CAUTION.NOXIOUS MATERIAL

RE-MOVE PLUG BEFORE OPENING

USEFUL INFORMATION

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

6

2. Summary of the warning and precautionary notes

Service and repair work should only be carried out by appropriately qualified personnel.

Undertake no work on the refrigerant circuit as there is a danger that poisonous and

corrosive gas (R134a) may leak out. Any work carried out on the refrigerant circuit must be

carried out by refrigeration experts. (Refrigerant R134a).

When working on the chiller, ensure that the unit is disconnected from the power supply.

Switch the power supply off. Ensure that unauthorised reconnection of the power supply is

not possible.

Do not disable any security measures.

The electrical connection is designed according to the VDE and the EN- and IEC-

Standards. Ensure that the live and neutral wires are correctly connected. Furthermore,

ensure that the unit is correctly earthed.

Do not operate the unit without water to avoid damaging internal components e.g. pump.

Use only filtered (less than 50 µm) industrial water in accordance to the specification

chapter 5.1.3.

Do not operate the chiller unit without a water filter.

Refill the unit only with the permitted filtered (< 25 µm)coolant water.

Do not use or maintain the chiller outdoors. These units were not designed to withstand

outdoor weather conditions.

Ensure that sufficient air circulation is maintained to guarantee the required heat transfer.

Do not alter the controller setting. An altered setting can render the unit non-functional.

Note the water flow direction when connecting the water hoses.

Before transporting the unit, it must be thoroughly drained. Otherwise it is possible that the

unit be damaged by residual water freezing inside the unit.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

7

3.Introduction

3.1 Product description

The chiller unit was constructed and developed to maintain the temperature of a user medium

(de-ionised water) between two predefined limits with the help of a cooling process. It has been

designed to operate under continual operation for the purpose of cooling systems such as for

laser equipment. The noise emission is lower than 70dB, in an integrated system.

The chiller operates within is a closed circuit system and is fitted inside a robust and compact

steel enclosure.

Advantages of the chiller unit:

compact enclosure

low service

simple operation and handling

intended for use at ambient temperatures of +15°C to +40°C

reliable, quiet operation

high temperature stability of the coolant water

3.2 Notes to application

The chiller unit is intended, exclusively, to cool filtered (< 25 µm) water in compliance with all the

corresponding installation and safety regulations.

Termotek AG takes no responsibility for damage caused through improper use or improper

operation of the unit.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

8

3.2.1 Electrical safety

The chiller unit has been built according to the generally recognised technical regulations.

Caution, danger of electrical shock!

Ensure that the unit is disconnected from the power supply before carrying out any assembly

work. All work undertaken on the chiller unit, particularly on electrical equipment, is only to be

carried out by suitably trained personnel.

3.2.2 Operational safety

The chiller unit is a compressor chiller design with a closed cooling circuit.

Attention!

Do not operate the chiller without coolant water. Check the coolant water level at regular

intervals. The chiller is quoted as secondary component of the complete system (Slave). At

error messages of the chiller (low/high temp.), it must be rapidly switched off. If you don’t follow

these instructions, consequential damage to the complete system can’t be ruled out. For these

damages TERMOTEK excludes liability.

3.2.3 Safety labels

Information!

Damaged or unreadable safety labels must be replaced immediately. When reordering please

give the article number.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

9

4.Getting started

4.1 Unpacking the unit

The chiller contains many electrical and mechanical components. In order to protect the

individual components during transport, a special packaging material has been used. This

material absorbs most of the shock and vibration likely to occur.

The internal packaging material consists of PE - foamed material. The external packing material

used is cardboard. This protects the unit from dust and other pollution.

When unpacking the unit proceed as follows:

1. Check the packaging for signs of damage.

2. Open the packaging and remove the packing foam

3. Take the chiller out.

4. Check the chiller for signs of transport damage.

Information!

Should the chiller have been damaged during transport, inform both the haulage firm and the

supplier in writing without delay. Retain the packaging material and note the external and

internal damage. Take one or more photos.

5. Place the chiller at the planned operating location.

6. Protect the chiller from dirt and dampness prior to installation.

7. Dispose of the packaging material.

Information!

Please ensure that the surrounding cardboard, the transport pallet and the packing foam are

disposed of separately for recycling purposes.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

10

4.2 Operating the chiller

4.2.1 Positioning

The chiller unit is designed as a 19” euro rack slide-in unit. The chiller must be installed

horizontally. Fasten the chiller with the front panel. Ensure that the chiller lies with the botton

plate on the side rails from the rack.

Ensure that the air flow through the side panels is not restricted. Avoid short circuiting the air

inlet and outlet.

Do not use or maintain the chiller outdoors. These units were not designed to withstand outdoor

weather conditions.

4.2.2 Connecting the water hoses

Before the chiller can be operated together with the user equipment, the water hoses must be

connected correctly. Ensure that the hoses to be used are designed to operate at the maximum

pressure required by the unit. The water connections are located on the rear panel of the chiller.

Connect the water supply to the chiller. Please ensure that the connection points are not under

any strain. If necessary, take steps to ensure that no strain on the connections can occur during

operation of the chiller.

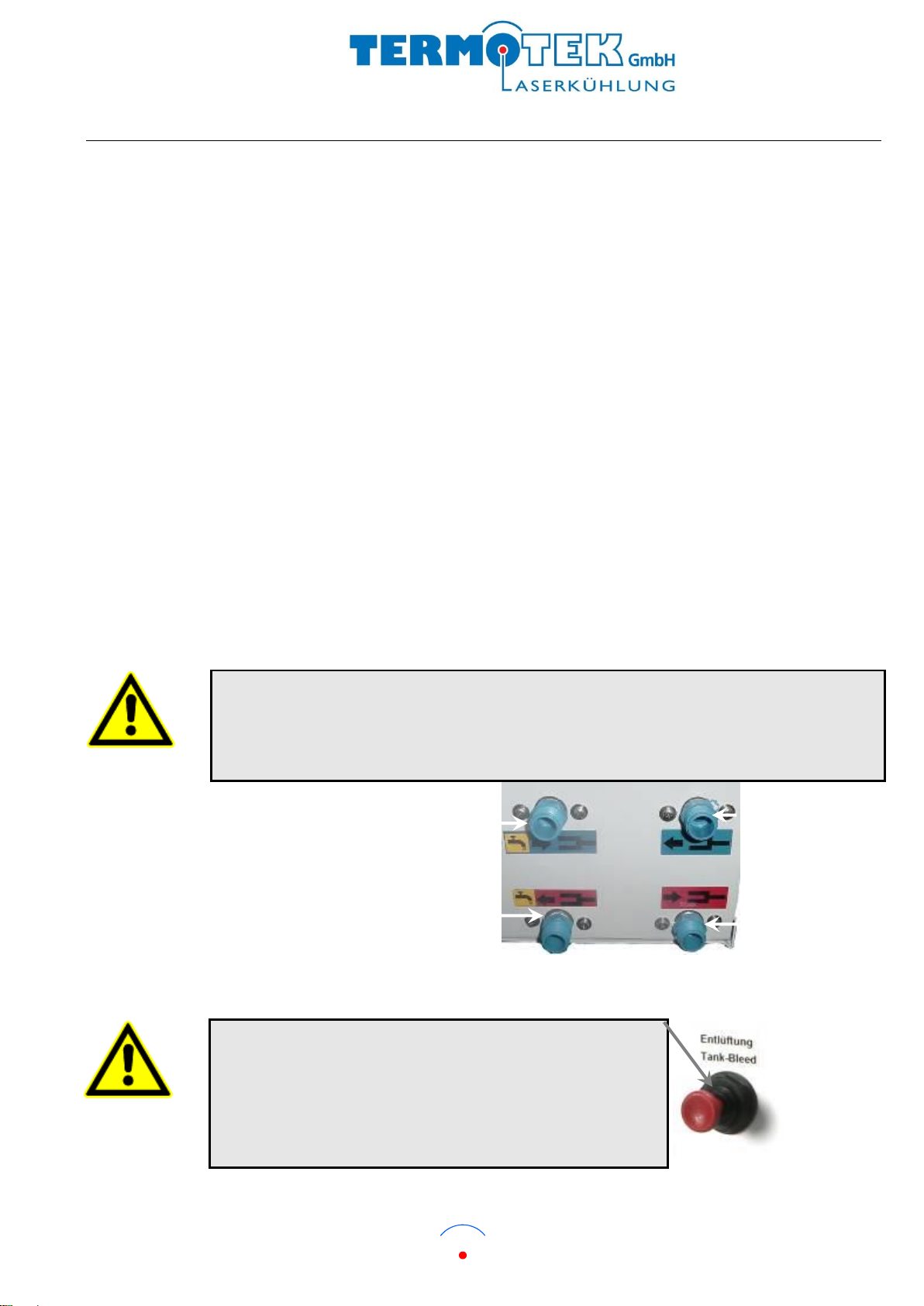

Attention!

Note the direction of flow when connecting the hoses:

Blue label = cold water

Red label = heated water

Industrial water supply inlet (BLUE)

Industrial water supply outlet (RED)

Water outlet (to

user) BLUE

Water inlet (from

user) RED

On the first start you must fill up the pump. Open the bleeding

cap on the front panel of the chiller and the filler. Fill the water in

the chiller via the filler neck on the front panel up to the maximum

water level. Close the bleeding cap.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

11

4.2.3 Setting Up the Electrical Connections

Connecting the Power Supply

A cable has been fitted on to the rear panel for the purpose of connecting the electrical power

supply. Connect the chiller power supply using an external separator with sufficient contact

separation and ensure that it is located near the chiller unit and is clearly labelled as belonging

to the unit. Use a 16A. fuse in the power phase. When using an automatic cut out fuse

(Charakteristic C) it is possible to use this as the power supply separator as long as this fulfills

the requirements. The fuses must be designed for inductive loads!

power supply

230 V AC, 50/60 Hz

Signal connector (9pin SUB D, M)

Signal interface RS232 (9pin SUBD, FM)

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

12

Connections for the data transfer

The 9 pin Sub-D connectors for data transfer and interface are located on the rear panel of the

chiller unit. Open circuit in error case. Maximum load of contacts 150mA/24V.

Signal connector

Pin Connections

Signal Outputs

Pin 1

High pressure

Pin 2

High/low temperature

Pin 3

Flow monitor

Pin 4

Collective fault contact

Pin 5

Alarm water level

Pin 6

Alarm conductivity

Pin 7

Common

Pin 8

GND for remote start from customer

Pin 9

+24 V DC remote start from customer

Signal interface RS 232

Pin Connections

Signal Outputs

Pin 1

NC

Pin 2

TxD

Pin 3

RxD

Pin 4

NC

Pin 5

GND

Pin 6

NC

Pin 7

NC

Pin 8

NC

Pin 9

NC

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

13

4.2.4 Getting ready to operate

1. After connecting the power supply, “water level alarm” appears in the chiller controller display

and the red LED lights.

2. Fill the chiller with water using the filler pipe located on the front panel of the chiller until the error

message “water level warning” appears (chap 4.2.2 and 6.3).

3. Continue filling the chiller until no more water level error message appears. Confirm the

message with the quit –key (). The red LED switches off.

4. If the maximum water level is reached, you can switch on the chiller by pressing the UP-button.

If the chiller has the option remote start, it is has to be switched on via remote start.

5. Sometimes the hose system of the laser must be filled. Therefor activate the filling mode in the

2nd programming level and fill the hose system via the filler pipe of the chiller (Chap 5.1.4). The

filling mode disables the water level control and activates the pump for a short period to fill the

hose system in one process.

Fill water in any event if you use the filling mode. Otherwise there is danger of dry

running and damaging of the pump and is danger of damaging the chiller and laser!

4.3 Preparing the coolant water-feedback chiller for transport to

the customer

Since the chiller comprises of a large number of sensitive, electronic and mechanical

components, keep to the following requirements and instructions before storing, installing or

transporting the unit. The chiller weight is ca. 70 kg.

4.3.1 Storage

Should the expected storage time of the chiller exceed four weeks then the coolant water should

be completely drained out of the unit (see chapter 6.4). The chiller must be stored in a horizontal

position. Ensure that the unit is protected from pollution and dampness.

The following ambient conditions are necessary during storage:

Temperature: +5°C to +65°C

Relative humidity: 10 –75%, no condensation

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

14

4.3.2 Place of Operation

Do not install the chiller in an environment where other equipment is likely to cause a high

ambient temperature. The chiller operates efficiently foe ambient temperatures of up to 40°C. An

over-pressure switch protects the refrigerant circuit from pressure increases.

The chiller unit must be installed such that sufficient air circulation can be maintained. Ensure

that the air inlet and outlets of the rack enclosure system are completely unrestricted during

operation at a later date. A restriction of the air flow will have an adverse effect on the cooling

capacity of the unit.

To reduce the vibration the parts from the chiller are mounted on vibration dampers. If the

vibration for the complete unit is too high, mount the whole chiller with the botton plate on

vibration dampers.

4.3.3 Transport to the customer

The chiller should be transported as carefully as possible, with a minimum of shock and

vibration. Please take note of the following precautions:

The chiller must be completely drained before being transported.

The chiller must be kept upright during transport and may not be thrown.

Use only suitable packing materials - which absorb shock and vibration –in order to ensure

that sensitive components inside the chiller are not damaged during transport. Ensure that

the unit is protected from dust and other pollution. Also ensure that the chiller is packed to

prevent damage from shock or being dropped.

Should the chiller be despatched individually, then use the original packing materials.

Ship the chiller only fixed on a pallet.

Before transportation, the packed unit should also be labelled: “protect against moisture“,

“Transport and store this way up“, “Fragile“.

Attention frost damage!

Before transportation, the unit should be completely drained otherwise there is a danger of

residual coolant water freezing and causing damage inside the chiller.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

15

5.System description

5.1 Set up and function

The chiller is a compressor chiller with a closed coolant circuit. The chiller is a closed unit and

has the following circuits:

Refrigerant circuit

Coolant water circuit

Industrial water circuit

Electrical circuit

5.1.1 Refrigerant circuit

The refrigerant circuit is a closed system, inside which the refrigerant medium circulates.

Within the refrigerant circuit, the compressor sucks gaseous refrigerant medium R 134a out of

the evaporator and compresses it. The heat generated by the compressed refrigerant is

transferred to the industrial water. During this compressing process the refrigerant changes from

gas to fluid.

The refrigerant fluid then passes through the dryer, which removes any residual moisture, and is

finally injected into the tank (heat exchanger) via an expansion valve (nozzle). The refrigerant

evaporates at the reduced pressure, and takes the energy required for this process from the

coolant water circuit. This results in the coolant water being cooled.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

16

5.1.2 Coolant water circuit

The warm water flows into the chiller via the water inlet hose. A flow monitor, located directly

after the water inlet point, monitors the flow in the water circuit. The water flows through the heat

exchanger into the tank. The heat is transferred in the heat exchanger.from the refrigerant to the

coolant water. The cooled water is then pumped out of the tank into the pump.

The coolant water flows from the pump to the filter. The filter removes minute dirt particles out of

the water. After passing through the filter, the coolant water flows out of the chiller via the chiller

outlet hose.

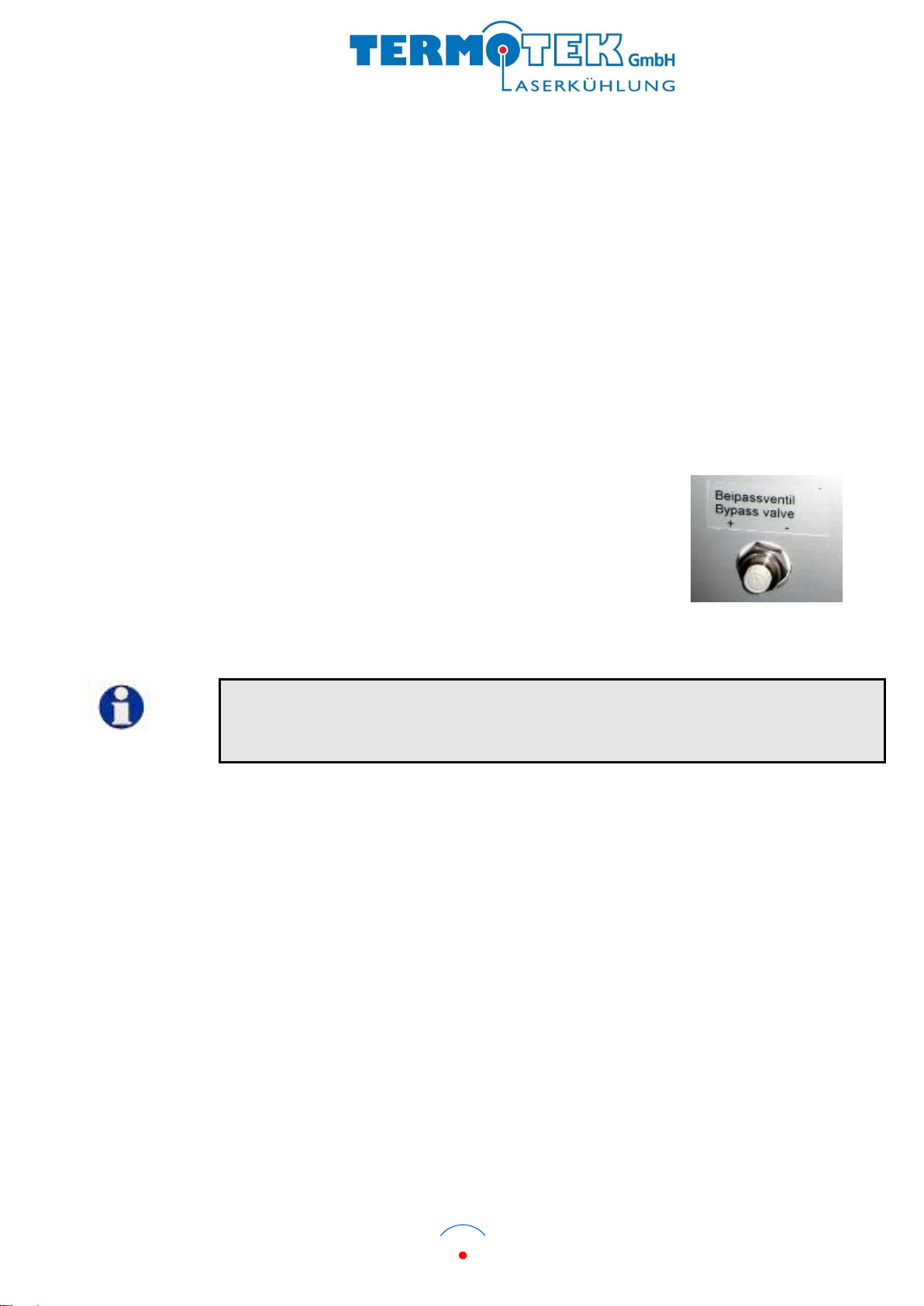

Bypass on front panel

A bypass valve is mounted. You can adjust the flow to the

heat source +/- 30 % there. The chiller has to work while

adjusting! To adjust proceed as follows:

Adjust the required flow. Therefore adjust the valve and

check the flow on the display.

Information!

The filter should be changed at regular intervals. More detailed information can be found in the

chapters for Service work and Replacing the filter.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

17

5.1.3 Industrial water circuit

The industrial water supply flows in the chiller then it flows through a filter. The industrial water

cools, via the heat exchanger, the refrigerant to the required temperature.

After passing through the heat exchanger, the warmed supply water flows back out of the chiller.

Specification for industrial water

To minimize chiller troubles you should maintain the following values for water contents and their

parameters.

Contamination

Please regard to maintain the DIN regulations for drinking- and heating water, Vd-TÜV

(Technical Inspections Authority) guidelines and the AGFW regulations for water contents.

(See chart 1)

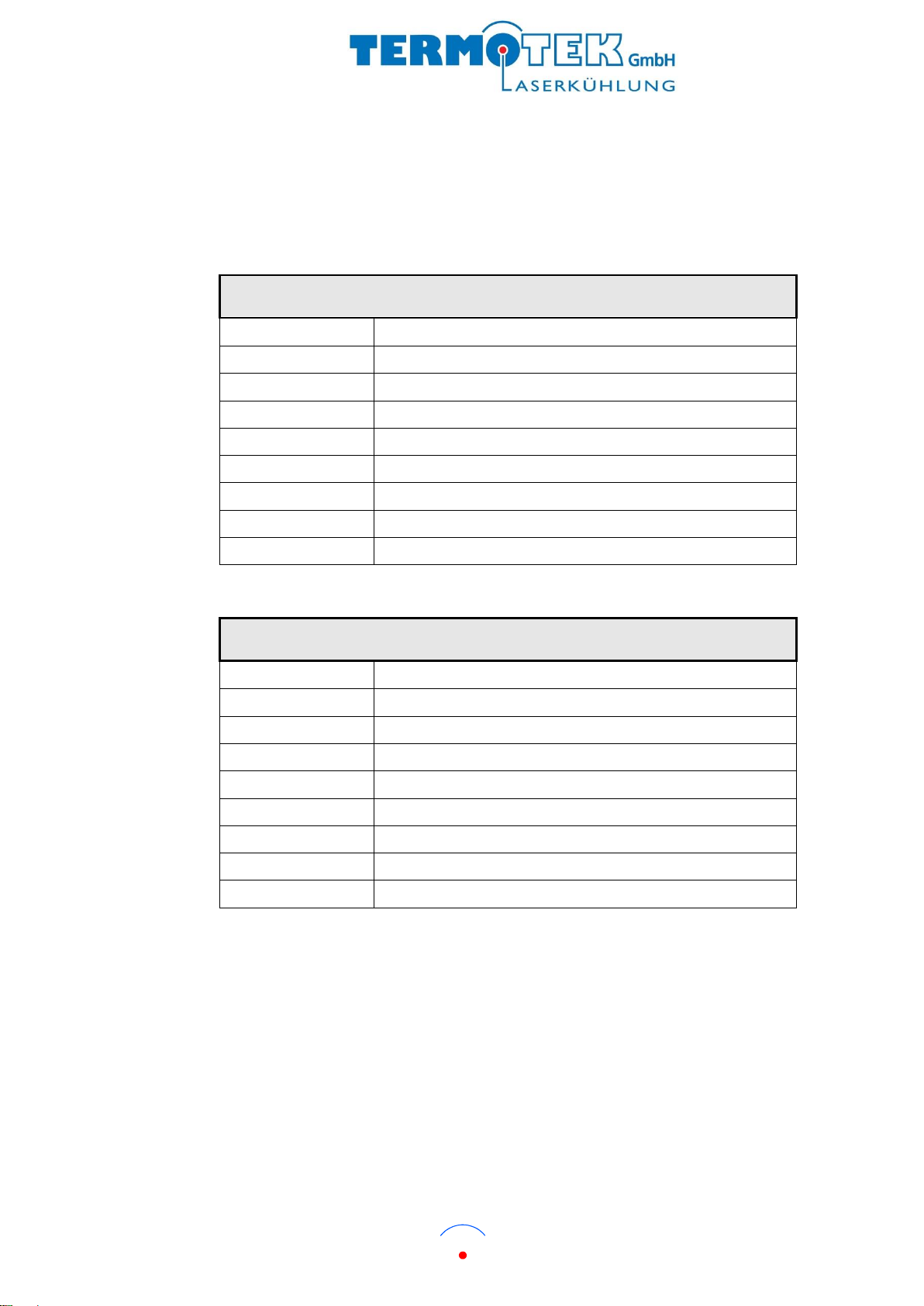

Chart 1:

Water content + parameter

unity

Value

PH Value

°dH

7-9

Total hardness of water

mg/l

6-15

Filtered substances

mg/l

< 30

Chlorides (up to water temperature of 50°C)

mg/l

< 200

Free chlorine

mg/l

< 0,5

Sulfate

mg/l

< 100

Sulfide

mg/l

< 1

Conductivity

µS/cm

10-500

Hydrosulfide

mg/l

< 0,05

Ammoniac

mg/l

< 2

Hydrogencarbonate

mg/l

< 300

Hydrogencarbonate / Sulfide

mg/l

< 1

Nitrate

mg/l

< 100

Nitrite

mg/l

< 0,1

Dissolved ferric

mg/l

< 0,2

Manganese

mg/l

< 0,1

Free aggressive carbonic acid

mg/l

< 20

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

18

Cleaning

Should you expect a coating to be generated due to the water quality ( such as a high

water hardness or pollution), clean the chiller (heat exchanger) regularly.

It is possible to clean the heat exchanger by rinsing it against the flow direction.

The tolerable chloride concentration changes depending on the water temperature (see chart 2).

Chart 2:

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

19

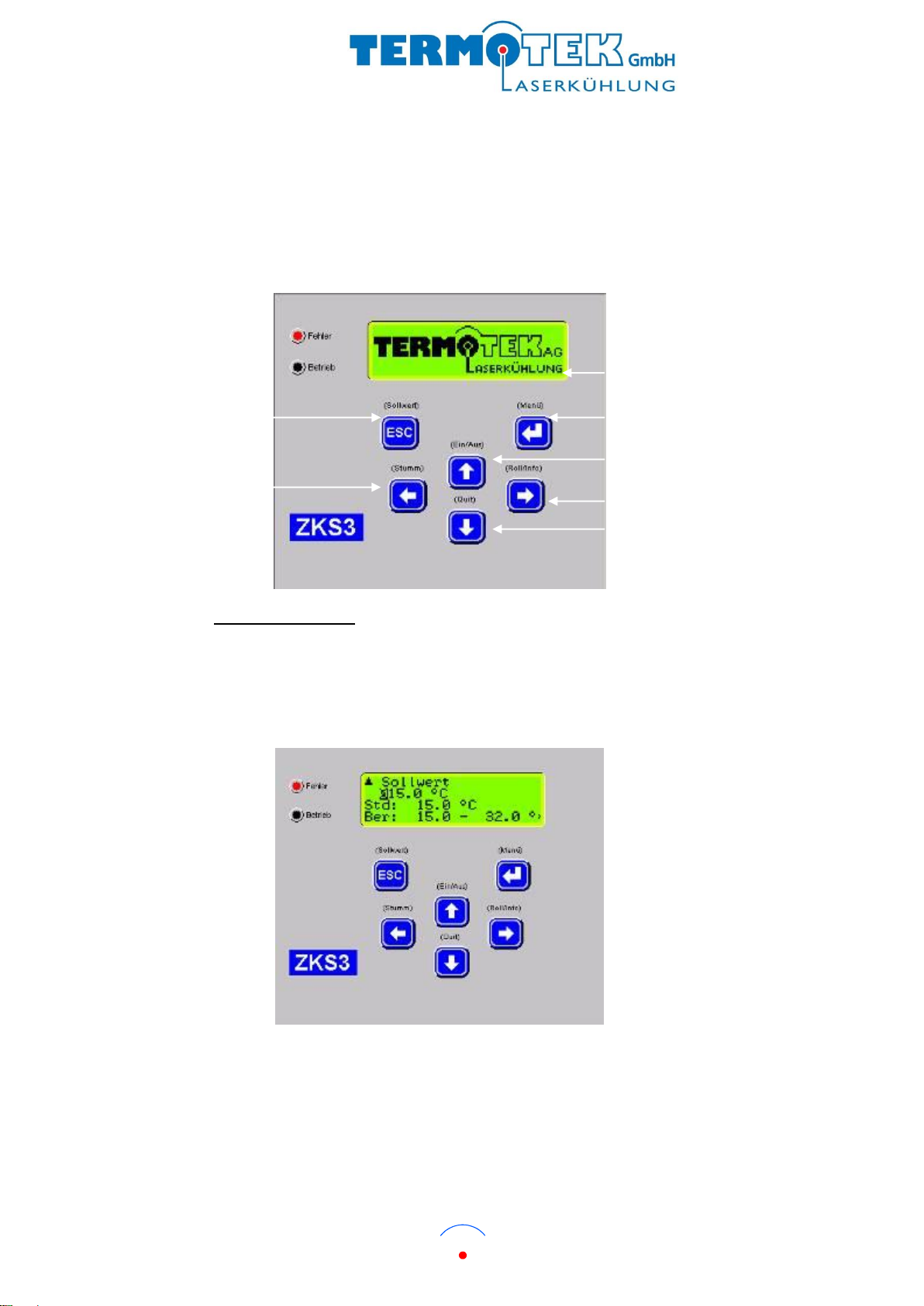

5.1.4 Electrical circuit

The operational mode is indicated by lighting of the green LED. If a fault occurs, the red LED will

light. It depends to the fault and the adjusted parameters whether the chiller discontinues

operating. In this case, the green LED goes out. The beeper can be disabled by pressing the

mute-button. The error messages are self-explanatory.

error LED

operational mode LED

ESCAPE/set value

LEFT/mute

display

ENTER/menu

UP/on/off

RIGHT/roll/info

DOWN/quit

Adjusting set value

By pressing the escape-button, you can reach the set value display (1st programming level). By

pressing the UP- and DOWN-button you can adjust the value of the digit, with the RIGHT- and

LEFT-button you can choose the digit. The set value is affirmed by pressing the ENTER-button,

you can cancel the input by pressing the ESCAPE-button.

Version 1.1 P300

Im Rollfeld 6

Phone: +49(0)7221/97 11-0 –Fax: +49(0)7221/97 11-111

76532 Baden-Baden, Germany

E-Mail: info@termotek.de - www.termotek.de

20

Adjusting parameters

By pressing the ENTER-button, you can reach the 2nd programming level. Therefor, please enter

your user-password (0020). By pressing the UP- and DOWN-button you can adjust the value of

the digit, with the RIGHT- and LEFT-button you can choose the digit. The set value is affirmed by

pressing the ENTER-button, you can cancel the input by pressing the ESCAPE-button.

You can use and change following functions and parameters.

Language

Sensor function

Temperature water function

Filling

Pressure function

Passwords

System function

Flow 1 function

Calibration

Control function

Flow 2 function

Diagnostics

Choose the required parameter and confirm the ENTER-button. To save, press the ESCAPE-

button afterwards until the following display appears.

You can confirm the storage by pressing the ENTER-button, you can cancel the input by pressing

the ESCAPE-button and return to the start screen.

Caution. Danger of damage!

Do not alter the controller setting. An altered setting can render the unit non-functional.

Table of contents

Popular Chiller manuals by other brands

Elkay

Elkay ERC8-1B/2B installation instructions

KoolMore

KoolMore OF-700 Instructions for use

CIAT

CIAT AquaCIAT LD Series User brochure

dIXEL

dIXEL XB570L Operating and instruction manual

Retigo

Retigo Comfort 1011 operating manual

Mitsubishi Electric

Mitsubishi Electric CLIMAVENETA NECS-ME Series Technical bulletin