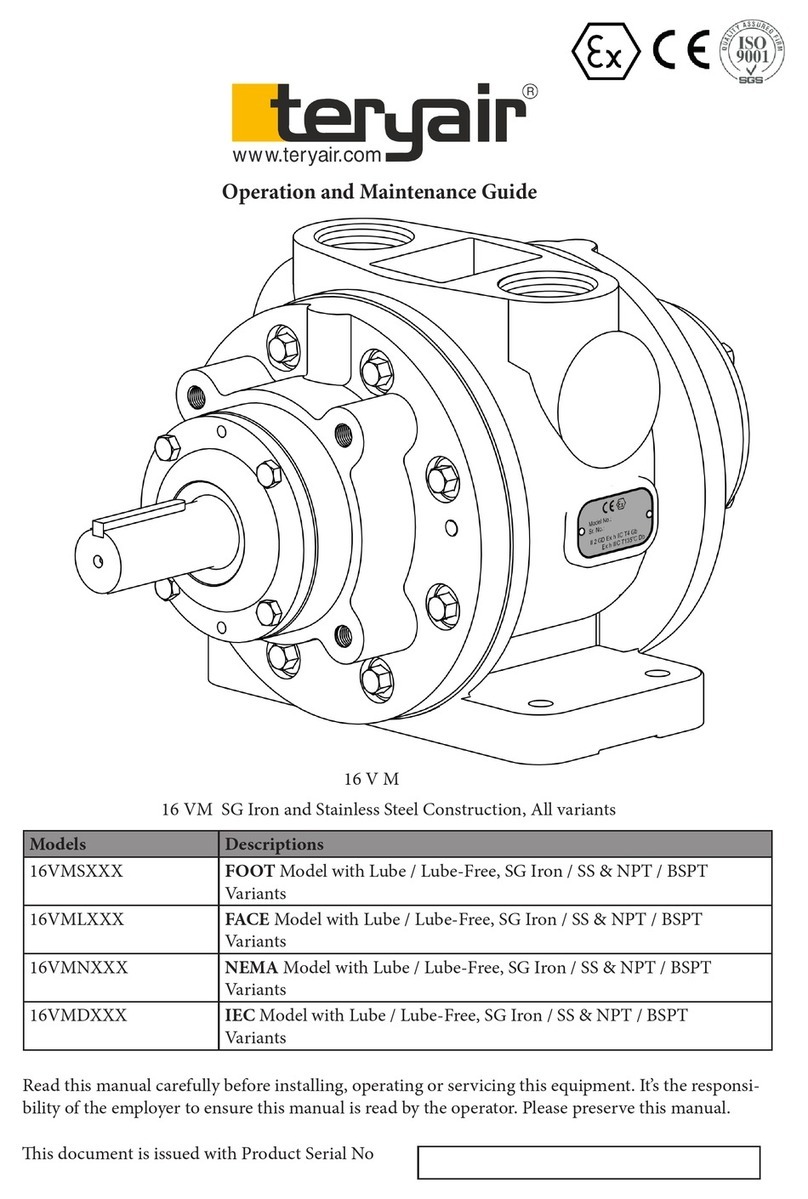

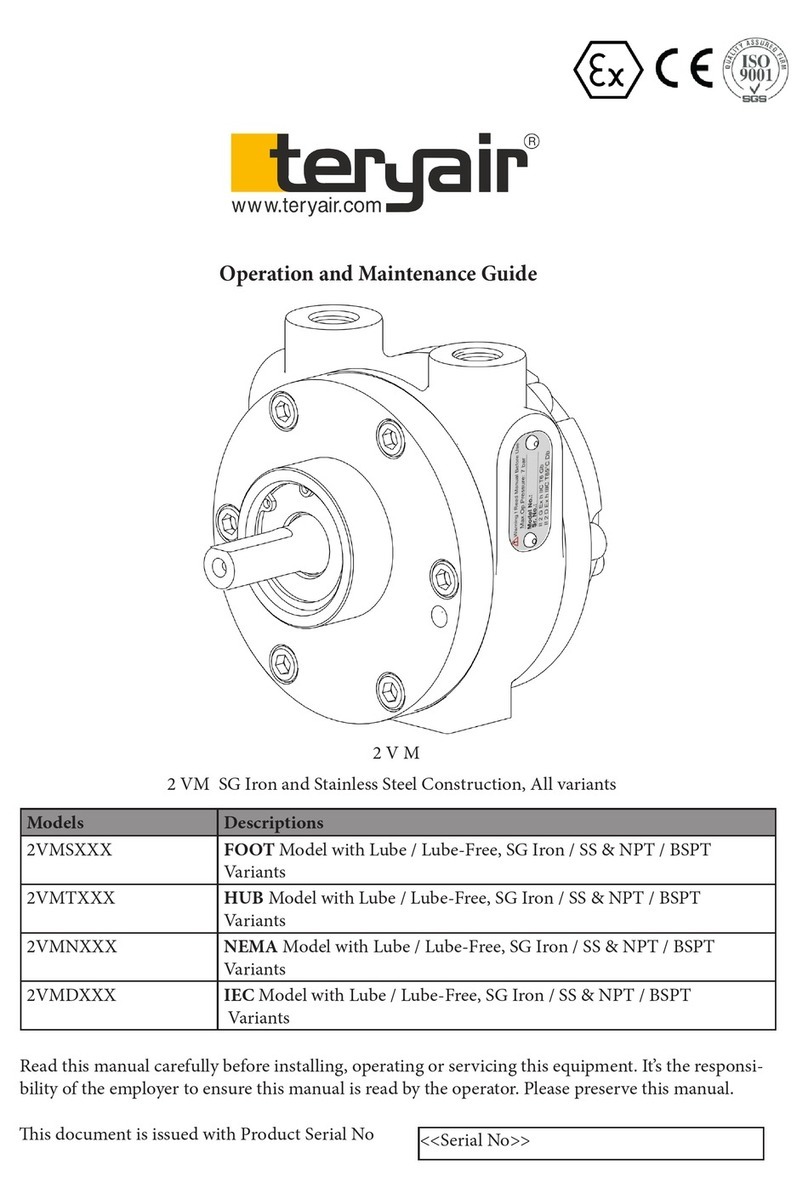

Teryair 4 VM Series Instruction Manual

4 VM SG Iron and Stainless Steel Construction, All variants

Models Descriptions

4VMSXXX FOOT Model with Lube / Lube-Free, SG Iron / SS & NPT / BSPT

Variants

4VMLXXX FACE Model with Lube / Lube-Free, SG Iron / SS & NPT / BSPT

Variants

4VMNXXX NEMA Model with Lube / Lube-Free, SG Iron / SS & NPT / BSPT

Variants

4VMDXXX IEC Model with Lube / Lube-Free, SG Iron / SS & NPT / BSPT

Variants

4 V M

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-369-REV - 02

Page 2

Operation and Maintenance Guide 4 VM Air Motor Series

Table of Contents

3

3

4

5

6

7

7

8

9

10

11

12

14

15

16

Nomenclature

Technical Data

SafetyInstructions

InstallationInstructions

Operatinginstructions

SuggestedLubricants

Troubleshooting

DisassemblyandRe-assembly

ExplodedViewfor4VMAirMotor

BillofMaterialsfor4VMSeries(SGIron)

BillofMaterialsfor4VMSeries(SS)

Dimensional Data

RepairKitsfor4VM

Performance EuDeclarationOfConformity

WarrantyCertificate

FF-MM-369-REV - 02

Page 3

Operation and Maintenance Guide 4 VM Air Motor Series

Nomenclature

X XX X X X X

Size Motor Type Mounting Lubricated or

Lube-Free

Material of

Construc-

tion

Threading on Inlet

and Outlet

1

2

4

6

8

16

VM - Vane Type

PM - Piston Type

VG - Vane Geared

PG - Piston Geared

L - Face Type

S- Foot Type

T - Hub

D - IEC Flange Type

N - NEMA Flange Type

A- Lubricated

O - Lube Free

L - SG Iron

S - SS

R- NPT

G - BSPT

For example, 1VMTALR is a size 1, Vane type, Hub Mounted, Lubricated, SG Iron MOC with NPT threading

Technical Data

Power upto 1.25 kW (1.7 HP)

Torque upto 4 Nm (35 lbs-in)

Air Consumption 0 to 120 m3/hr (0 to 72 cfm)

Motor Weight 3.8 kgs (8.3 lbs)

Operating Pressure 1.4 to 7kg/cm2 (20 to 100PSI)

Max Allowable speed 3500 rpm (ATEX limit)

500 2500

20001000 1500 35003000

SPEED in rpm

0.36

0

1.80

1.44

1.08

0.72

in HP

POWER

1.4

1.05

0.70

0.35

0

in kW

Power

Torque

@100 psi

@80 psi

4 VM

62

49.6

37.2

24.8

in lbs-in

12.4

0

TORQUE

7

5.25

3.5

1.75

0

in Nm

@40 psi

@60 psi

@20 psi

@100 psi

@80 psi

@60 psi

@40 psi

@20 psi

Air supply Pressure

@100 psi = 7bar = 7Kg/cm2

16

0

500 2500

20001000 1500 35003000

SPEED in rpm

AIR CONSUMPTION

80

64

48

32

140

105

70

35

0

in cubic feet/min

in mt3/hr

Air

Consumption

@100 psi

@80 psi

4 VM

@40 psi

@60 psi

@20 psi

Air supply Pressure

@100 psi = 7bar = 7Kg/cm2

Power and Torque Graphs 4VM Air Consumption Graph 4VM

FF-MM-369-REV - 02

Page 4

Operation and Maintenance Guide 4 VM Air Motor Series

Safety Instructions

Warning: If not followed could

cause personal injuries

Caution: If not followed could result in damage

to equipment.

Warning

is manual must be read and the operating

instructions carefully followed.

Warning

Safety and protective clothing, eyewear, head-

gear, ear protection, gloves and footwear to be

worn during operation of this Vane motor.

Caution

Install proper guard around the output sha as

needed.

Warning.

Operators under 18 not allowed to operate this

Vane motor operators must be made familiar

with the instructions in this manual before

attempting to operate the Vane motor Ensure

that job site is clear of bystanders. Do Not

dis-assemble in explosive atmosphere.

Caution

Use only genuine Teryair or Teryair approved

accessories.

Warning

is Vane motor is designed for use in an ex

p losive environment for Zone 1 & 2 for Gas

and Dust.

Warning

Operate the motor for approximately 2 hours at

the maximum desired load. Measure the sur-

face temperature of the motor on the casting

opposite the pipe ports. e maximum surface

temperature listed on the motor is for nor-

mal environmental and installation conditions.

Fort air motors Temp. Class T6 (Gas) and T85°

C (Dust). e maximum surface temperature

Ex code

ll 2 G Ex h IIC T6 Gb

ll 2 D Ex h IIIC T85° C Db

Amb. Temp ( +1° C to +40° C)

Checklist for installation in

hazardous areas

Read air motor label to check that motor has

been designed for use in a hazardous

application:

• Hazardous zone

• Hazardous category

• Equipment group

• Temperature class

• Maximum surface temperatures

Intended And Prohibitive Use

Intended Use

Marine and Oshore industries. Can be in

various application subjected to availability of

air pressure.

e design of this pneumatic vane motor is

conrming to EN/ ISO 80079-36 and 80079-37

explosive atmosphere suitable to use in zone 1

& 2 area, gas group IIC and Dust group IIIC,

temp. Class T6 (85°C).

i. EN / ISO 80079-36 : 2016 : Explosive

atmospheres—Part 36 :Non-electrical

equipment for explosive atmospheres—

Basic metod and requirements

ii. EN / ISO 80079-37 : 2016 : Explosive

atmospheres—Part 37 : Non-electrical

equipment for explosive atmospheres—

Non-electrical type of protection construction-

al safety ‘c’, control of ignition sources ‘b’, liquid

immersion ‘k’.

Prohibitive use

Use with non-genuine spare parts or

accessories is prohibited

Following symbols are used through out this

manual.

FF-MM-369-REV - 02

Page 5

Operation and Maintenance Guide 4 VM Air Motor Series

Warning

Check the site to make sure that the Vane

motor will be adequately ventilated and that

there is no external heat input.

Caution

Completely turn o the Vane motor and

disconnect air supply line before attempting

any service. Read Assembly and Dis-assembly

instructions.

Warning

Do not use a hammer on the sha or

connections.

Do Not dis-assemble in explosive atmosphere.

Warning

Take care not to exceed the supply air pressure

maximum 7kg/cm²(100 psi) for Lubricated

and maximum 5.6 kg/cm²(80 psi) for Lube-

free .

Caution

Do not exert excessive pressure against the

work surface. Keep hoses in good condition.

Check hoses for signs of wear, cracks & bulges

and ensure that they are secure. Accidental

disconnection while hose is pressurized makes

the hose whip and can be a safety hazard.

Caution

• Please check the hose connection prior to

starting motor

• Keep hands & clothing away from

moving parts.

• Store these Vane motors in secure & dry

environment.

• Do not modify this Vane motor in any way

as this will invalidate the warranty and

could lead to serious injury.

• Do not drag this Vane motor by air hose.

should not exceed 80º C. Do not continue

to operate the motor if the measured surface

temperature exceeds temperature listed on the

motor. If your measured temperature does ex-

ceed listed value, consult with your Distributor

/ Representative for a recommendation.

Installation Instructions

An automatic air line lubricator should be in-

stalled in the air line as close as possible and no

more than 18inches (1/2 meter) from the air

motor. Install the lubricator level with or above

the air motor so that the oil mist will blow direct-

ly into or fall down into the motor. Install a ilter

in the air line before the connection to the motor.

Next install an air pressure regulator to control

motor speed and torque.

Clean the compressed air connection with low

pressure air to remove any dirt from the line

before connecting to the ports. Use the proper

sized fasteners. For the most ecient output and

control of speed, use air lines that are the same

size as the motor inlet port if the connection is

less than 7 feet (2 meters). For longer connec-

tions, use the next pipe size larger than the motor

intake port. Connect lines to motor in the proper

direction

Safety wear mandatory while operating Vane

motor

Air stream from product may contain solid o

liquid particle that can result eye or skin dam

age.Eye and face and ear protection must be

worn at all times during operation

Suitable gloves must be worn at all times during

operation.

Operators must wear helmets of suitable

strength at all times. Helmet must be able to

withstand 10G in 8ms without fracturing.

Waterproof heavy duty outerwear and Shoes

with toe cap protection are a must during

operation

FF-MM-369-REV - 02

Page 6

Operation and Maintenance Guide 4 VM Air Motor Series

Daily Before Operating

1. Disconnect air line and muer.

2. Add ushing solvent directly into motor. If

using liquid solvent pour in 1 to 2 ounces of

recommended oil into the motor.

3. Rotate the sha by hand in both directions for

a few minutes.

4. You must wear eye protection for this step.

Cover exhaust with a cloth and reconnect the

air line.

5. DO NOT use kerosene or ANY other

combustible solvents to ush this product.

6. Restart the motor at a low pressure of

approximately 10 PSI/0.7 bar until there is no

trace of solvent in the exhaust air.

7. Listen for changes in the sound of the motor.

If motor sounds smooth, you are nished.

If motor does not sound like it running

smoothly, installing a service kit will be

required.

Air Supply

e air should be clean and dry. Supply

air pressure maximum 7kg/cm²(100 psi) for

Lubricated and maximum 5.6 kg/cm²(80 psi) for

Lube-free.

Hoses

• Daily before operation check the hoses,

especially the high pressure hoses for damage

or leaks

• Use genuine Teryair spares and if possible

mention the serial number of the Vane motor

when ordering spares.

Operating instructions

Vane motors are rugged dependable product

designed to give you years of satisfactory

service. Follow the instructions mentioned here

to enhance life and performance. Check the

direction of the motor airow. A single rotation

motor will operate properly only in one

direction.Single rotation motors require a

muer to be connected to the air port. Remove

the plastic shipping plugs from the ports. Save

plugs for future use during shutdown.

Mounting

is product can be installed in any orientation.

Mount the motor to a solid metal base plate that is

mounted to a stable, rigid operating surface. Use

shock mounts to reduce noise and vibration. Install

a pressure regulator or simple shut-o valve to

control motor.

Storage

• It is your responsibility to follow proper

shutdown procedures before storage.

• Turn o air intake supply.

• Disconnect air supply and vent all air lines.

• Remove Vane motor from connecting

machinery.

• Remove the muer.

• Wear eye protection. Keep away from air stream.

Use clean, dry air to remove condensation from

the inlet port of the motor.

• Lubricate motor with a small amount of oil into

the intake port. Rotate sha by hand several times

to distribute oil.

• Plug or cap each port.

• Coat output sha with oil or grease.

• Store motor in a dry environment.

Lubrication Requirements

Lubricated Vane motor: Always install a line

lubricator on the air line as close to the Vane motor

as possible. A Filter Regulator Lubricator unit (FRL)

is strongly recommended. Keep the lubricator bowl

topped up with recommended grade of oil and check

that the oil is reaching the Vane motor Running the

Lubricated Vane motor without lubrication is likely to

cause damage to the components causing premature

replacement.

FF-MM-369-REV - 02

Page 7

Operation and Maintenance Guide 4 VM Air Motor Series

Troubleshooting

L ow Tor qu e Low Speed Won’t run Runs well but

slows down Reason & Remedy for problem

√ √ √ Dirt or foreign material present. Inspect

and ush.

√ √ √ Internal rust. Inspect and ush.

√ √ Low air pressure. Increase pressure.

√ Air line too small. Install larger line(s).

√ √ Restricted exhaust. Inspect and repair.

√ √ √ √ Motor is jammed. Have motor serviced.

√ √ Air source inadequate. Inspect and repair.

√ √ Air source too far from motor. Recongure

setup.

Suggested Lubricants

Brand Above 27 Deg C ( From 5 Deg C to 27 Deg C Below 5 Deg C

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- Arox EP.65 Arox EP.45

Caltex Rando Oil 100 Rando Oil 100 Rando Oil 46

Texaco -- -- Airolene Tool OiI

Daltron Regal Oil F (R&O) Regal Oil PE(P&E) Regal Oil PE(R&O)

Burmah Castrol Silkolene 881 Silkolene 548/T Silkolene 733

BP Castrol RD Oil 3 Castrol RD Oil Light Megna SPX

Duckham Garnet 7 Garnet 6 Zero Fio 5

Sternol Merlin 87 Merlin 71 Merlin 54

FF-MM-369-REV - 02

Page 8

Operation and Maintenance Guide 4 VM Air Motor Series

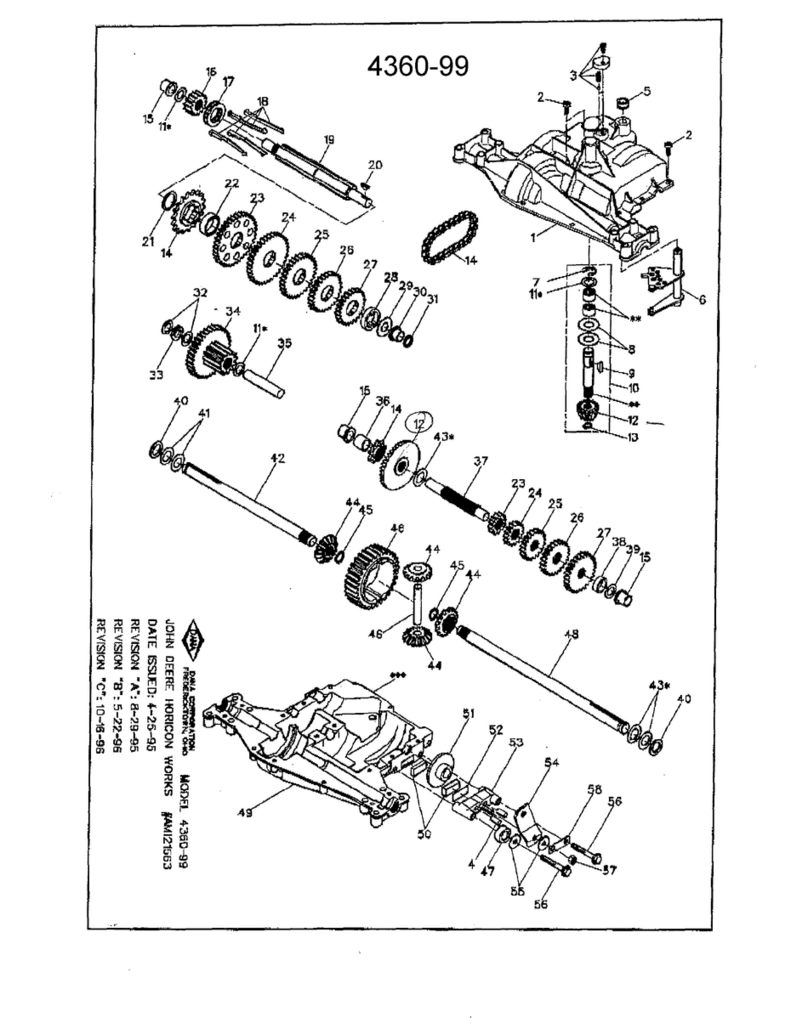

Dis assembly and Re-assembly

Disconnect air supply and vent all air lines.

Air stream from product may contain solid or

liquid material that can result in eye or skin

damage.

Flush this product in a well ventilated area.

Do Not use kerosene or other combustiblesol-

vents to ush this product.

Failure to follow these instructions can result

in eye injury or other serious injury.

Always open from the back side rst.

Use proper tools to open the fasteners.

a. Unscrew Allen Bolts (12) with Spring

Washer (11) from Bearing Cap (5) from

Rear Flange (3). Remove O-ring (8) on

Bearing Cap (5) and replace with new one

(if found damaged).

b. Unscrew Allen Bolts (15) with Spring

Washer (19) from Rear Flange (3) from

Housing (1) & replace Shim (10) with new

one (if found damaged).

c. Now remove Ball bearing (6) from Rear

Flange (3) using mallet and replace it with

new one (if worn-out).

d. Now remove the Rotor Sha (4) with Rotor

Blades (16) from the Housing (1), Now

remove the Rotor Blades (16), Spring Cap

(18) & Compression Spring (17) from

Rotor Sha (4) and replace them with new

ones. (if found damaged)

e. From front side of motor remove Internal

Circlip (20) using circlip plier from Front

ange (2) then remove Oil Seal (9), Now

remove Ball bearing (6/7) by using puller

and replace it with new ones (bearing & oil

seal).

f. Aer installation bearing seals then install

the Internal Circlip (20) using circlip plier

in the internal groove of Front Flange (2).

g. Now assemble Compression Springs (17)

with Spring Caps (18) on both end of

springs. Aer that, insert the same into the

Rotor Sha’s (4) through holes (use small

amount of grease to prevent Spring caps to

fall during assembly). Now place the 4

nos. Rotor Blades (16) into the rotor sha

grooves.

h. Now install the above Rotor Sha assem-

bly into the Housing (1) and Front Flange

bearing using press/mallet precisely and

ensure that rotor face is not above the

housing face.

i. Now follow the above steps ‘c’ & ‘b’ in

reverse manner to assemble the motor.

j. Now aer assembly, ensure that Rotor

Sha (4) is rotating smoothly inside, else

tap lightly on the rotor sha front end or

rear end until you obtain smooth rotation

of Rotor Sha (4).

k. Once smooth rotation is achieved follow

the step ‘a’ in reverse manner and com-

plete the assembly.

FF-MM-369-REV - 02

Page 9

Operation and Maintenance Guide 4 VM Air Motor Series

Exploded View for 4VM Air Motor

1

3

4

5

6

8

10

11

12

14

15

19

2

9

15

19 6

20

21

22

13

18

17

16

FACE

FOOT

20

15

9

7

19

2

IEC/

NEMA

23

FF-MM-369-REV - 02

Page 10

Operation and Maintenance Guide 4 VM Air Motor Series

Bill of Materials for 4VM Series (SG Iron)

Illu.

No. Description Part

Number FACE FOOT IEC NEMA

4VMLAL 4VMLOL 4VMSAL 4VMSOL 4VMDAL 4VMDOL 4VMNAL 4VMNOL

1* HOUSING-NPT 804 05 01 1 - 1 - 1 - 1 -

1* HOUSING -NPT (LUBE-FREE) 804 05 01LF - 1 - 1 - 1 - 1

1** HOUSING-BSPT 804 05 11 1 - 1 - 1 - 1 -

1** HOUSING -BSPT (LUBE-FREE) 804 05 11LF - 1 - 1 - 1 - 1

2 FRONT FLANGE 804 05 04 1 - 1 - - - - -

2 FRONT FLANGE (LUBE FREE) 804 05 04LF - 1 - 1 - - - -

2 IEC FLANGE 804 05 09 - - - - 1 - - -

2 IEC FLANGE (LUBE FREE) 804 05 09LF - - - - - 1 - -

2 NEMA FLANGE 804 05 10 - - - - - - 1 -

2 NEMA FLANGE (LUBE FREE) 804 05 10LF - - - - - - - 1

3 REAR FLANGE 804 05 03 1 - 1 - 1 - 1 -

3 REAR FLANGE (LUBE FREE) 804 05 03LF - 1 - 1 - 1 - 1

4 ROTOR SHAFT 804 21 08 1 1 1 1 - - - -

4 ROTOR SHAFT- IEC 804 21 09 - - - - 1 1 - -

4 ROTOR SHAFT- NEMA 804 21 10 - - - - - - 1 1

5 BEARING CAP 804 21 02 1 1 1 1 1 1 1 1

6 BEARING 2Z/ ZZ 804 50 01 2 2 2 2 1 1 1 1

7 BALL BRG. 2Z,/ZZ 803 50 01 - - - - 1 1 1 1

8 O' RING 804 40 01 1 1 1 1 1 1 1 1

9 OIL SEAL 804 60 01 1 1 1 1 - - - -

9 OIL SEAL 804 60 02 - - - - 1 1 1 1

10 SHIM 804 37 01 2 2 2 2 2 2 2 2

11 SPRING WASHER 805 90 01 3 3 3 3 3 3 3 3

12 ALLEN BOLT 550 90 28 3 3 3 3 3 3 3 3

13 KEY 804 22 02 1 1 1 1 - - - -

13 KEY (IEC) 803 22 01 - - - - 1 1 - -

13 KEY (NEMA) 804 22 04 - - - - - - 1 1

14 ROLL PIN 804 90 04 4 4 4 4 4 4 4 4

15 ALLEN BOLT 804 90 03 12 12 12 12 12 12 12 12

16 ROTOR BLADE 804 39 01 4 4 4 4 4 4 4 4

17 COMPRESSION SPRING 804 98 01 2 2 2 2 2 2 2 2

18 SPRING CAP 804 21 03 4 4 4 4 4 4 4 4

19 SPRING WASHER 536 90 04 12 12 16 16 12 12 12 12

20 INTERNAL CIRCLIP 804 90 02 1 1 1 1 - - - -

20 INTERNAL CIRCLIP 210 90 24 - - - - 1 1 1 1

21 FOOT 804 31 01 - - 1 1 - - - -

22 ALLEN BOLT 804 90 05 - - 4 4 - - - -

23* MUFFLER-NPT 200 97 15 1 1 1 1 1 1 1 1

23** MUFFLER-BSPT 804 50 04 1 1 1 1 1 1 1 1

Note -1) „ * „ Marks part are applicable for NPT Models Only

2) “ ** “ Marks part are applicable for BSPT Models Only

FF-MM-369-REV - 02

Page 11

Operation and Maintenance Guide 4 VM Air Motor Series

Bill of Materials for 4VM Series (SS)

Illu.

No. Description Part

Number FACE FOOT IEC NEMA

4VMLAS 4VMLOS 4VMSAS 4VMSOS 4VMDAS 4VMDOS 4VMNAS 4VMNOS

1* HOUSING-NPT 804 07 01 1 - 1 - 1 - 1 -

1* HOUSING -NPT (LUBE-FREE) 804 07 01LF - 1 - 1 - 1 - 1

1** HOUSING-BSPT 804 07 06 1 - 1 - 1 - 1 -

1** HOUSING -BSPT (LUBE-FREE) 804 07 06LF - 1 - 1 - 1 - 1

2 FRONT FLANGE 804 07 02 1 - 1 - - - - -

2 FRONT FLANGE (LUBE FREE) 804 07 02F - 1 - 1 - - - -

2 IEC FLANGE 804 07 04 - - - - 1 - - -

2 IEC FLANGE (LUBE FREE) 804 07 04LF - - - - - 1 - -

2 NEMA FLANGE 804 07 05 - - - - - - 1 -

2 NEMA FLANGE (LUBE FREE) 804 07 05LF - - - - - - - 1

3 REAR FLANGE 804 07 03 1 - 1 - 1 - 1 -

3 REAR FLANGE (LUBE FREE) 804 07 03LF - 1 - 1 - 1 - 1

4 ROTOR SHAFT 804 27 01 1 1 1 1 - - - -

4 ROTOR SHAFT- IEC 804 27 02 - - - - 1 1 - -

4 ROTOR SHAFT- NEMA 804 27 03 - - - - - - 1 1

5 BEARING CAP 804 27 04 1 1 1 1 1 1 1 1

6 BEARING 2Z/ ZZ 804 50 01 2 2 2 2 1 1 1 1

7 BALL BRG. 2Z,/ZZ 803 50 01 - - - - 1 1 1 1

8 O' RING 804 40 01 1 1 1 1 1 1 1 1

9 OIL SEAL 804 60 03 1 1 1 1 - - - -

9 OIL SEAL 803 60 02 - - - - 1 1 1 1

10 SHIM 804 37 01 2 2 2 2 2 2 2 2

11 SPRING WASHER 811 90 04 3 3 3 3 3 3 3 3

12 ALLEN BOLT 803 90 01 3 3 3 3 3 3 3 3

13 KEY 804 27 05 1 1 1 1 - - - -

13 KEY (IEC) 803 27 05 - - - - 1 1 - -

13 KEY (NEMA) 803 27 06 - - - - - - 1 1

14 ROLL PIN 804 90 06 4 4 4 4 4 4 4 4

15 ALLEN BOLT 171 27 47S 12 12 12 12 12 12 12 12

16 ROTOR BLADE 804 39 01 4 4 4 4 4 4 4 4

17 COMPRESSION SPRING 804 98 01 2 2 2 2 2 2 2 2

18 SPRING CAP 803 27 07 4 4 4 4 4 4 4 4

19 SPRING WASHER 171 27 23S 12 12 16 16 12 12 12 12

20 INTERNAL CIRCLIP 804 90 07 1 1 1 1 - - - -

20 INTERNAL CIRCLIP 210 90 24S - - - - 1 1 1 1

21 FOOT 804 82 02 - - 1 1 - - - -

22 ALLEN BOLT 803 90 03 - - 4 4 - - - -

23* MUFFLER-NPT 804 50 03 1 1 1 1 1 1 1 1

23** MUFFLER-BSPT 804 50 05 1 1 1 1 1 1 1 1

Note -1) „ * „ Marks part are applicable for NPT Models Only

2) “ ** “ Marks part are applicable for BSPT Models Only

FF-MM-369-REV - 02

Page 12

Operation and Maintenance Guide 4 VM Air Motor Series

Foot Mounting 4VM

FACE Mounting 4VM

Dimensional Data

FF-MM-369-REV - 02

Page 13

Operation and Maintenance Guide 4 VM Air Motor Series

NEMA Flange Mounting 4VM

IEC Flange Mounting 4VM

FF-MM-369-REV - 02

Page 14

Operation and Maintenance Guide 4 VM Air Motor Series

Repair KIT Ordering No Suitable for

8049701 Suitable for 4 FACE / FOOT VM variant

8049702Suitable for 4 VM IEC / NEMA variant

Repair Kits for 4VM

Note - Repair Kit includes Blades, Bearings, Shims, Blade springs, Oil Seals and O rings

FF-MM-369-REV - 02

Page 15

Operation and Maintenance Guide 4 VM Air Motor Series

EU DECLARATION OF CONFORMITY

Object of declaration

PRODUCT : PNEUMATIC VANE MOTOR

MODEL : 4VM XXXXX,

MANUFACTURER’S NAME : TERYAIR EQUIPMENT PVT. LTD.

ADDRESS : SITE - 1: BUILDING A - 1/2, 102 TO 105 & BUILDING C 12 & 13,

TIRUPATI UDYOG NAGAR, SATIVALI ROAD, VASAI (E),

PALGHAR : 401208.

SITE - 2: AUGUSTINE - II, COLACO INDUSTRIAL COMPLEX, GALA NO

101 TO 107, SATIVALI ROAD, VILLAGE WALIV, VASAI (E), PALGHAR:

401208

To provide presumption of conformity in order to directive 2014/34/EU; the following harmonized standards and/or other

normative documents as referenced within the following ocial journals are applied:

APPLICABLE DIRECTIVE: ATEX DIRECTIVE (2014/34/EU)

APPLICABE STANDARDS:

EN ISO 80079-36: 2016 : Explosive atmospheres —Part 36: Non-electrical equipment for explosive atmospheres

Basic method and requirements.

EN ISO 80079-37:2016 : Explosive atmospheres —Part 37: Non-electrical equipment for explosive atmospheres

Non- electrical type of protection constructional safety ‘c’, control of ignition sources ‘b’,

liquid immersion ‘k’.

Notied body to whom Technical le has logged with: - Technicka Inspekcia (Ref: 1354).

DECLARATION: - TERYAIR EQUIPMENT PVT. LTD., declare that under our sole responsibility for the supply of the

product dened above, the said product complies with all the applicable Directives, Regulations and all essential Health and

Safety requirements applying to it.

I, the undersigned, hereby declare that the product specied above conforms to the above standard(s).

ATEX MARKING APPLIED: ll 2 GD Ex h IIC T6 Gb

Ex h IIIC T85C Db

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-369-REV - 02

Page 16

Operation and Maintenance Guide 4 VM Air Motor Series

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-369-REV - 02

Page 17

Operation and Maintenance Guide 4 VM Air Motor Series

is page is intentionally

Le blank.

This manual suits for next models

4

Table of contents

Other Teryair Engine manuals