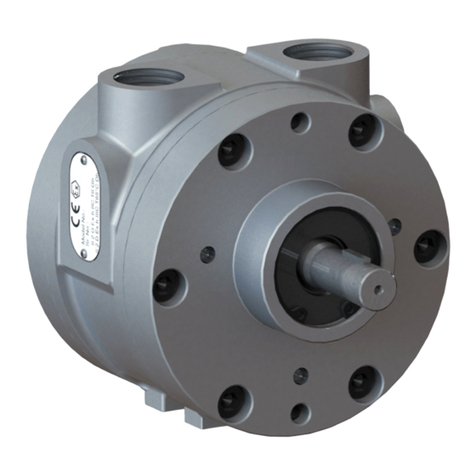

Teryair 20PMTAAP Instruction Manual

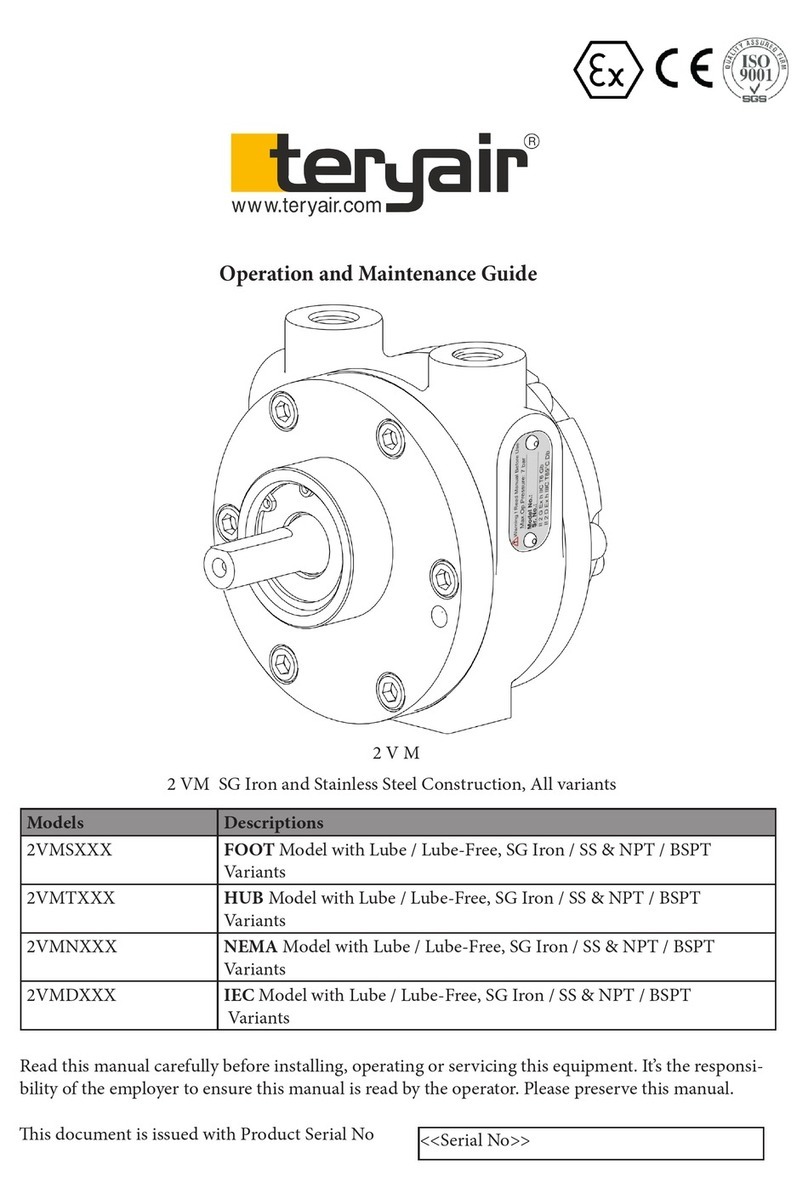

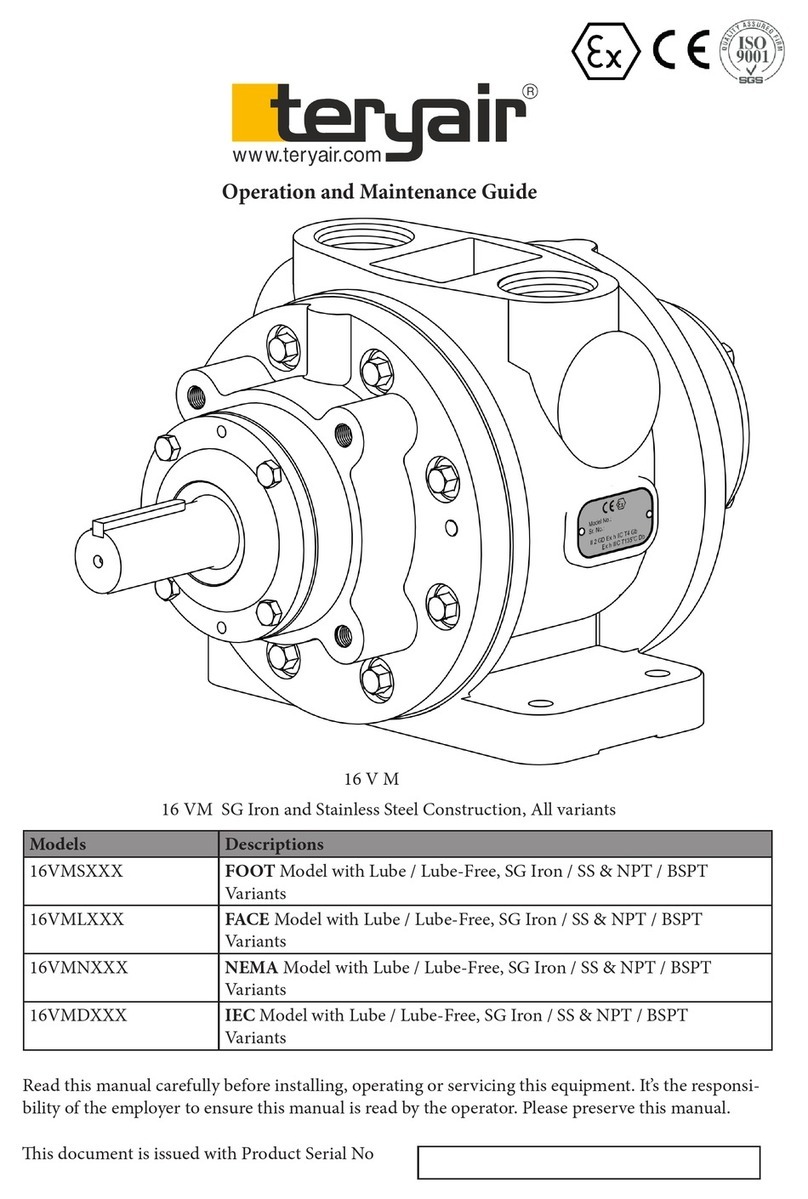

Models Descriptions

20PMTAAP HUB Model with Lube / Lube-Free, Aluminum BSPP Variants

20 P M

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-406-REV - 00

Page 2

Operation and Maintenance Guide Piston Air Motor Series

Table of Contents

3 Nomenclature

3 Technical Data

4 Safety Instructions

5 Installation Instructions

5 Operating instructions

6 Suggested Lubricants

6 Troubleshooting

7 Exploded View for 20 PM Air Motor

8 Bill of Materials for 20 PM

9 Dimensional Data

9 Repair Kits for 20 PM

10 Paint Stirrer Accesories

11 Test Certicate Of Materials, Performance

12 Warranty Certicate

FF-MM-406-REV - 00

Page 3

Operation and Maintenance Guide Piston Air Motor Series

Nomenclature

X XX X X X X

Size Motor Type Mounting Lubricated or

Lube-Free

Material of

Construction

Threading on Inlet

and Outlet

10

20

30

PM - Piston Type

S- Foot Type

T - Hub

D- IEC

N - NEMA

A- Lubricated

O - Lube Free

A - Aluminum

S - SS

P-BSPP

For example, 20PMTAAP is a size 20, Piston type, Hub Mounted, Lubricated, Aluminum MOC with BSPP threading

Technical Data

Power upto 0.07 kW (0.10HP)

Air Consumption 10.2 to 30.5 m3/hr (6 to 18 cfm)

Max speed 4000 rpm

Operating Pressure 6 Kg/cm2 (90 PSI)

Motor Weight 1 kgs (2 lbs)

FF-MM-406-REV - 00

Page 4

Operation and Maintenance Guide Piston Air Motor Series

Safety Instructions

Warning: If not followed could

cause personal injuries

Caution: If not followed could result in dam-

age to equipment.

Warning

is manual must be read and the operating

instructions carefully followed.

Warning

Safety and protective clothing, eyewear,

headgear, ear protection, gloves and foot-

wear to be worn during operation of this

piston motor

Caution

Install proper guard around the output sha

as needed.

Warning.

Operators under 18 not allowed to operate

this Piston motor operators must be made

familiar with the instructions in this man-

ual before attempting to operate the piston

motor Ensure that job site is clear of by-

standers. Do Not dis-assemble in explosive

atmosphere.

Caution

Use only genuine Teryair or Teryair ap-

proved accessories.

Intended And Prohibitive Use

Intended Use

Prohibitive use

Use with non-genuine spare parts or

accessories is prohibited

Caution

Completely turn o the piston motor and

disconnect air supply line before attempting

any service. Read Assembly and Dis-assembly

instructions.

Warning

Do not use a hammer on the sha or

connections. Do Not dis-assemble in explosive

atmosphere.

Warning

Take care not to exceed the supply air pressure

maximum 7kg/cm²(100 psi) for Lubricated and

maximum 5.6 kg/cm²(80 psi) for Lube-free .

Caution

Do not exert excessive pressure against the

work surface. Keep hoses in good condition.

Check hoses for signs of wear, cracks & bulges

and ensure that they are secure. Accidental

disconnection while hose is pressurized makes

the hose whip and can be a safety hazard.

Caution

• Please check the hose connection prior to

starting motor

• Keep hands & clothing away from

moving parts.

• Store these piston motors in secure & dry

environment.

• Do not modify this piston motor in any

way as this will invalidate the warranty and

could lead to serious injury.

• Do not drag this piston motor by air hose.

Following symbols are used through out this

manual.

FF-MM-406-REV - 00

Page 5

Operation and Maintenance Guide Piston Air Motor Series

Warning

Check the site to make sure that the piston

motor will be adequately ventilated and that

there is no external heat input.

Installation Instructions

An automatic air line lubricator should be in-

stalled in the air line as close as possible and no

more than 18inches (1/2 meter) from the air

motor. Install the lubricator level with or above

the air motor so that the oil mist will blow direct-

ly into or fall down into the motor. Install a ilter

in the air line before the connection to the motor.

Next install an air pressure regulator to control

motor speed and torque.

Clean the compressed air connection with low

pressure air to remove any dirt from the line

before connecting to the ports. Use the proper

sized fasteners. For the most ecient output and

control of speed, use air lines that are the same

size as the motor inlet port if the connection is

less than 7 feet (2 meters). For longer connec-

tions, use the next pipe size larger than the motor

intake port. Connect lines to motor in the proper

direction

Safety wear mandatory while operating Piston

motor

Air stream from product may contain solid o

liquid particle that can result eye or skin dam

age.Eye and face and ear protection must be

worn at all times during operation

Suitable gloves must be worn at all times during

operation.

Daily Before Operating

1. Disconnect air line and muer.

2. Add ushing solvent directly into motor. If

using liquid solvent pour in 1 to 2 ounces of

recommended oil into the motor.

3. Rotate the sha by hand in both directions for

a few minutes.

4. You must wear eye protection for this step.

Cover exhaust with a cloth and reconnect the

air line.

5. DO NOT use kerosene or ANY other

combustible solvents to ush this product.

6. Restart the motor at a low pressure of

approximately 10 PSI/0.7 bar until there is no

trace of solvent in the exhaust air.

7. Listen for changes in the sound of the motor.

If motor sounds smooth, you are nished.

If motor does not sound like it running

smoothly, installing a service kit will be

required.

Air Supply

e air should be clean and dry. Supply

air pressure maximum 7kg/cm²(100 psi) for

Lubricated and maximum 5.6 kg/cm²(80 psi) for

Lube-free.

Hoses

• Daily before operation check the hoses,

especially the high pressure hoses for damage

or leaks

• Use genuine Teryair spares and if possible

mention the serial number of the piston

motor when ordering spares.

Operating instructions

Piston motors are rugged dependable product

designed to give you years of satisfactory

service. Follow the instructions mentioned here

to enhance life and performance. Check the

direction of the motor airow. A single rotation

motor will operate properly only in one

direction.Single rotation motors require a

muer to be connected to the air port. Remove

the plastic shipping plugs from the ports. Save

plugs for future use during shutdown.

FF-MM-406-REV - 00

Page 6

Operation and Maintenance Guide Piston Air Motor Series

Mounting

is product can be installed in any orientation.

Mount the motor to a solid metal base plate that is

mounted to a stable, rigid operating surface. Use

shock mounts to reduce noise and vibration. Install

a pressure regulator or simple shut-o valve to

control motor.

Storage

• It is your responsibility to follow proper

shutdown procedures before storage.

• Turn o air intake supply.

• Disconnect air supply and vent all air lines.

• Remove Piston motor from connecting

machinery.

• Remove the muer.

• Wear eye protection. Keep away from air stream.

Use clean, dry air to remove condensation from

the inlet port of the motor.

Troubleshooting

L ow Torque Low Speed Won’t run Runs well but

slows down Reason & Remedy for problem

√ √ √ Dirt or foreign material present. Inspect

and ush.

√ √ √ Internal rust. Inspect and ush.

√ √ Low air pressure. Increase pressure.

√ Air line too small. Install larger line(s).

√ √ Restricted exhaust. Inspect and repair.

√ √ √ √ Motor is jammed. Have motor serviced.

√ √ Air source inadequate. Inspect and repair.

√ √ Air source too far from motor. Recongure

setup.

Suggested Lubricants

Brand Above 27 Deg C ( From 5 Deg C to 27 Deg C Below 5 Deg C

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- Arox EP.65 Arox EP.45

Caltex Rando Oil 100 Rando Oil 100 Rando Oil 46

Texaco -- -- Airolene Tool OiI

Daltron Regal Oil F (R&O) Regal Oil PE(P&E) Regal Oil PE(R&O)

Burmah Castrol Silkolene 881 Silkolene 548/T Silkolene 733

BP Castrol RD Oil 3 Castrol RD Oil Light Megna SPX

Duckham Garnet 7 Garnet 6 Zero Fio 5

Sternol Merlin 87 Merlin 71 Merlin 54

• Lubricate motor with a small amount of

oil into the intake port. Rotate sha by

hand several times to distribute oil.

• Plug or cap each port.

• Coat output sha with oil or grease.

• Store motor in a dry environment.

Lubrication Requirements

Lubricated Piston motor: Always install a line

lubricator on the air line as close to the Piston

motor as possible. A Filter Regulator Lubri-

cator unit (FRL) is strongly recommended.

Keep the lubricator bowl topped up with

recommended grade of oil and check that the

oil is reaching the Piston motor Running the

Lubricated Piston motor without lubrication

is likely to cause damage to the components

causing premature replacement.

FF-MM-406-REV - 00

Page 7

Operation and Maintenance Guide Piston Air Motor Series

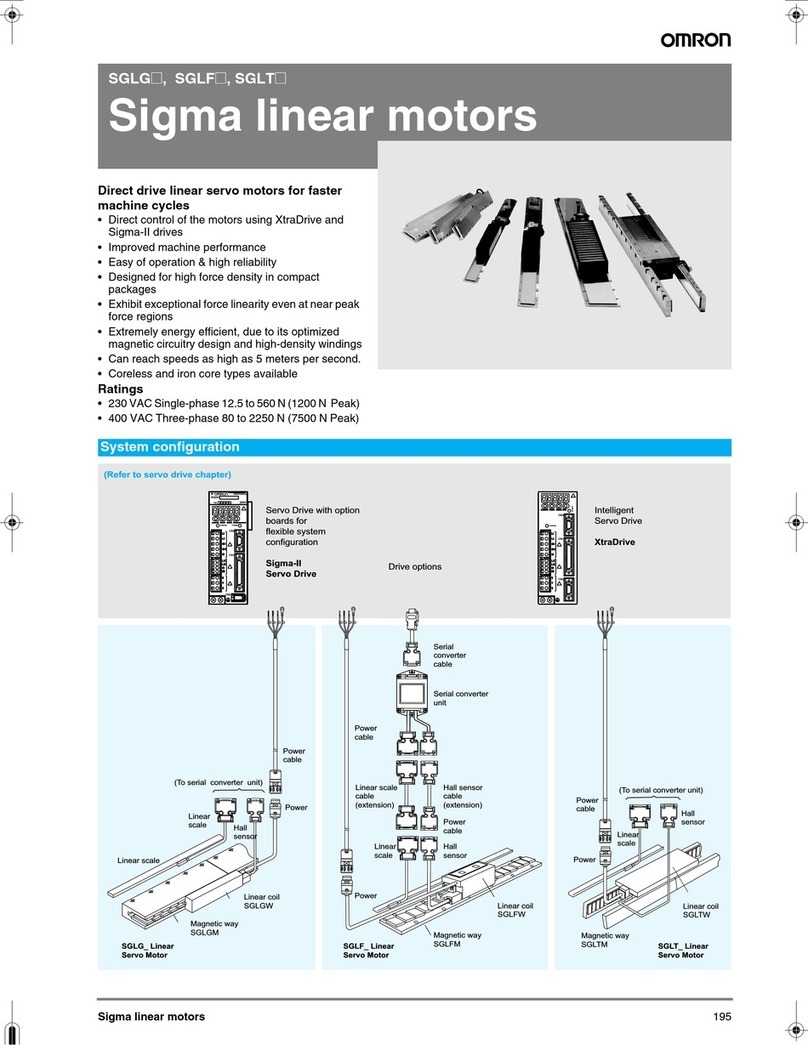

Exploded View for 20 PM Air Motor

15

17

14 820 5

16

4

3

19

9

11

18

12

10

7

13

1

2

6

21

22

23

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1 812 10 01 1

2812 21 02 1

3812 10 03 1

4812 10 02 3

5812 21 04 3

6

SKF - 6003 -

12,SI,NC,12_68

1

7

812 21 01-2

1

8812 21 05 3

9812 21 03 1

10 812 31 01 2

11 812 36 01 1

12 812 24 01 2

13 812 02 01 3

14 812 21 06 3

15

SKF - 6002 -

12,SI,NC,12_68

1

16 550 90 28 12

17

IS 3075 NE- 15

1

18

SKF - HK 1010 -

18,DE,NC,18

1

19 812 40 01 1

20 812 40 02 3

21 812 40 03 3

22 812 04 01 1

23 812 21 07

ADAPTER 1/2"NPT - 1/2" BSP

1

24

812 21 01-1 (25 09

2021)

1

FF-MM-406-REV - 00

Page 8

Operation and Maintenance Guide Piston Air Motor Series

Bill of Materials for 20 PM

Illustration

Number Description Part Number 10 PM

1 MAIN HOUSING 812 10 01 1

2 SLEEVE 812 21 02 1

3 END COVER 812 10 03 1

4 SIDE CAP 812 10 02 3

5 PISTON CHAMBER 812 21 04 3

6 BEARING 812 50 02 1

7 SHAFT 812 21 01 1

8PISTON 812 21 05 3

9 SCREW 812 21 03 1

10 WASHER 812 31 01 2

11 BUSH 812 36 01 1

12 SPACER 812 24 01 2

13 CONNECTING ARM 812 02 01 3

14 DOWEL PIN 812 21 06 3

15 BEARING 812 50 01 1

16 ALLEN BOLT 812 90 01 12

17 EXTERNAL CIRCLIP 812 90 02 1

18 BEARING 812 50 03 1

19 O-RING 812 40 01 1

20 O-RING 812 40 02 3

21 O-RING 812 40 03 3

22 MUFFLER 812 04 01 1

23 ADAPTOR 812 21 07 1

18 SPRING WASHER 805 90 01 -

19 MUFFLER 811 50 03 1

FF-MM-406-REV - 00

Page 9

Operation and Maintenance Guide Piston Air Motor Series

Piston Air Motor 20 PM

Dimensional Data

Repair KIT Ordering No Suitable for

2129701 Suitable for 20PM all variants

Repair Kits for 20 PM

Note - Note - Repair Kit includes Bearings, Dowels, Piston, Piston chamber, Connecting Arm and O rings

156.50

9.90

16.00

6.00

8.50

27.00

41.75

93.00

33.20

45.20

AIR INLET 1/2"

AIR EXHAUST

116.00

67.00

62.50

FF-MM-406-REV - 00

Page 10

Operation and Maintenance Guide Piston Air Motor Series

Paint Stirrer Accesories

1

2

3

4

4a

Bill of Materials

Paint Stirrer Accessories

Illustration

Number Description Part Number

1RADIAL PISTON AIR MOTOR 20PMTAAP

2 SHAFT HOUSING 270582PS1

3 STIRRING ROD ASSEMBLY 270582PS2

4 3 3 BLADE IMPELLER 270582PS5

4a HOLLOW IMPELLER 270582PS6

FF-MM-406-REV - 00

Page 11

Operation and Maintenance Guide Piston Air Motor Series

TEST CERTIFICATE OF MATERIALS, PERFORMANCE

DATE :

MODEL NUMBER :

PART DESCRIPTION & S.NO. :

We hereby certify that the above referenced product has tested and inspected in accordance with our standard test proce-

dures and meets the specications for material and performance values as published in our literature. We further certify that

the product has been given our standard factory test and meets all quality and performance standards established by the

company. is product is certied to be produced in our factory, and is of current production.

Authorised Signatory

Q.A Manager

Place - Vasai, Maharastra

FF-MM-406-REV - 00

Page 12

Operation and Maintenance Guide Piston Air Motor Series

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-406-REV - 00

Page 13

Operation and Maintenance Guide Piston Air Motor Series

is page is intentionally

Le blank.

Table of contents

Other Teryair Engine manuals

Popular Engine manuals by other brands

DANA

DANA 4360-47 parts list

Bosch

Bosch Performance Line CX System manual

Alcatel-Lucent

Alcatel-Lucent dunkermotoren BG 45 MI Series instruction manual

Rotek

Rotek Y80 series Operation & maintenance manual

Louvolite

Louvolite R1710 Programming instructions

LOMBARDINI MARINE

LOMBARDINI MARINE LDW 1603 M Use and maintenance manual