If you do not understand any portion of this manual, contact

Generac or your nearest Generac Authorized Service Dealer

for starting, operating and servicing procedures.

Throughout this publication and on tags and decals affixed to

the engine, DANGER, WARNING and CAUTION blocks

are used to alert you to special instruction about a particular

operation that may be hazardous if performed incorrectly or

carelessly. Observe them carefully.

These safety warnings cannot eliminate the hazards that they

indicate. Strict compliance with the special instructions while

performing the service plus “common sense” are major

measures to prevent accidents.

The following definitions apply to DANGER, WARNING,

CAUTION and NOTE blocks found throughout the manual.

These safety symbols indicate the following:

DANGER: After this heading you can read handling,

installing, operating or servicing instructions that, if not

strictly complied with, will result in personal injury.

WARNING: After this heading you can read

handling, installing, operating or servicing instructions

that, if not strictly complied with, may result in personal

injury.

CAUTION: After this heading you can read

instructions for handling, installing, operating or

servicing the engine that, if not strictly complied with,

may result in damage to equipment and/or property.

NOTE: After this heading you can read explanatory

statements that require special emphasis.

These symbols indicate the following:

Points out important safety information that, if not

followed, could endanger personal safety and/or

property of yourself and others.

Potential explosion hazard.

Potential fire hazard.

ᏘPotential electrical shock hazard.

RULES FOR SAFE OPERATION

Study these RULES FOR SAFE OPERATION carefully

before operating or servicing this equipment. Become familiar

with the OWNER’S MANUAL and with the engine. The

engine can operate safely, efficiently and reliably only if it is

properly operated and maintained. Many accidents are caused

by failing to follow simple and fundamental rules or precautions.

Generac cannot possibly anticipate every possible circumstance

that might involve a hazard. The warnings in this manual and on

tags and decals affixed to the equipment, are therefore, not all-

inclusive. If you use a procedure, work method or operating

technique Generac does not specifically recommend, you must

satisfy yourself that it is safe for you and others. You must also

make sure the procedure, work method or operating technique

that you choose does not render the engine to be unsafe.

DANGER: Do not tamper with the engine governed

speed. High operating speeds are dangerous and

increase the risk of personal injury or damage to the

equipment. Operating at low speeds with heavy load may

shorten the engine’s life.

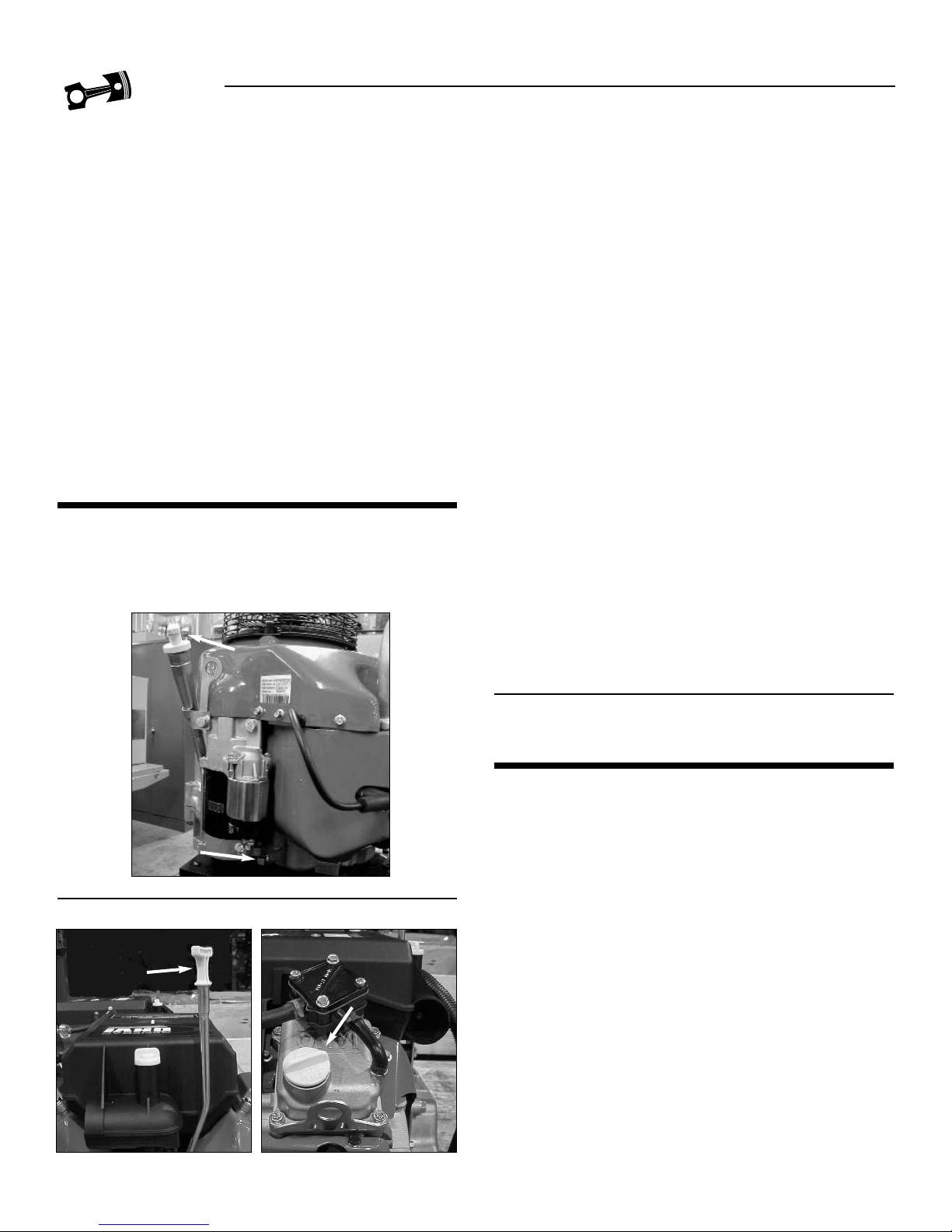

BEFORE OPERATING

• Gasoline is highly FLAMMABLE and its vapors are

EXPLOSIVE. Do not permit smoking, open flames,

sparks or heat in the area while handling gasoline. Avoid

spilling gasoline on a hot engine. Comply with all of the

laws regulating storage and handling of gasoline.

• Store gasoline and other fuels only in containers

designed and approved for the storage of such

materials.

• Add gasoline in a clean, well-ventilated area. Wipe up

any spilled gasoline immediately.

If gasoline has been spilled, let it dry completely before

starting the engine.

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING:

4

GTV/GTH - 990/760 OHVI SERIES ENGINES