Teryair AG 4 Instruction Manual

Models Descriptions IMPA Code

AG 4 Pneumatic Angle Grinder 59 03 01

AG 7 Pneumatic Angle Grinder 59 03 02

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

AG 4 AG 7

FF-MM-407-REV - 00

Page 2

Operation and Maintenance Guide Pneumatic Angle Grinder

Table of Contents

3 Introducon

3 Technical Data

3 Intended Use

3 SafetyInstrucons

4 Maintenance

5 Suggested Lubricants

6 TestCercateOfMaterials,Performance

7 EuDeclaraonOfConformity

8 WarrantyCercate

FF-MM-407-REV - 00

Page 3

Operation and Maintenance Guide Pneumatic Angle Grinder

Introduction

Teryair Pneumatic Angle Grinders are well suited for rugged production use. ey are economical-

ly designed and kept as light as possible to reduce fatigue. Speed governors are standard equipment

which ensure optimum performance.

Intended Use

• Teryair angle grinder AG-4 is rugged and

dependable tool to give you years of sat-

isfactory service.It is generally used for

sanding, rust removal, rough grinding and

cutting application.

Prohibitive Use

Pneumatic angle grinder is prohibited to be

used for purposes other than mentioned in

intended use.

Following safety precautions should be taken

• Wear appropriate Personal Protective

equipments .

• Do keep hands & clothing away from mov-

ing parts.

• Pneumatic angle grinder should be stored

in dry environment.

• Do not allow the pneumatic angle grinder

to run unattended.

• Do not modify pneumatic angle grinder.

• Please check the hose connection prior to

starting the pneumatic angle grinder.

Teryair

Model No

IMPA

Code

Wheel Size

mm

Free Speed

R.P.M Air Inlet Air Hose

mm

Spindle Thread

Wheel

Weight

Kgs

AG 4 59 03 01 100 13,600 1/4” 9.5 M10 x 1.5 P 1.7

AG 7 59 03 02 180 7,600 3/8” 12.7 M12 x 1.25 P 3.0

Technical Data

Safety Instructions

• Stay alert and use common sense - Do not

Always wear suitable protection, eye gog-

gles, ear mus, safety shoes etc to safe guard

against possibility of ying particles. Ensure

that a wheel guard is tted onto the tool and

the wheel is secured properly. Never oper-

ate the tool over the rated 90 psi pressure,

Check that all bolts and other fasteners are

tightened correctly. Do not exert excessive

pressure against the work surface. Never use

larger wheels than recommended and check

new wheels for cracks before using them

on the tool. Keep hoses in good condition.

Check hoses for wear and ensure that ttings

are secure. Accidental disconnection while

tool is in use can make the hose whip and

can be safety hazard.

• Only well- instructed personal should op-

erate the tool. Any integral part of this tool

should not be removed for independent use

or for any other application. Always observe

safe working pratice and local safely regu-

lation at all times. Do not use this tool in

wet location.Do not expose to rain. Do not

modify the tool and also do not use it for

any heavy work more than for which it is

intended for. Disconnect the tool from air

supply when not in use. Do not use in ap-

proprite attachment in an attempt to exceed

max. capacity of the tool.

FF-MM-407-REV - 00

Page 4

Operation and Maintenance Guide Pneumatic Angle Grinder

Daily Before Operation

Disconnect and pour in 1 to 2 ounces of

recommended oil into the air inlet and recon-

nect hose aer blowing out any accumulated

dirt in the hose line before connection. Tighten

both spindle nuts properly

Air Supply

To enable the tool to function satisfactorily ,it is

essential that a constant 80 PSI pressure of clean

dry air issupplied to the Inlet Nipple. A short

leader hose of 9.5 mm I.D. should be attached

to the tool and length of the hose should be

less than 12 meters. e installation of air line

separator, a lter to purify and dry the air supply

(FRL unit ) recommended and should be con-

nected as close to the tool as operation allows.

Maintenance

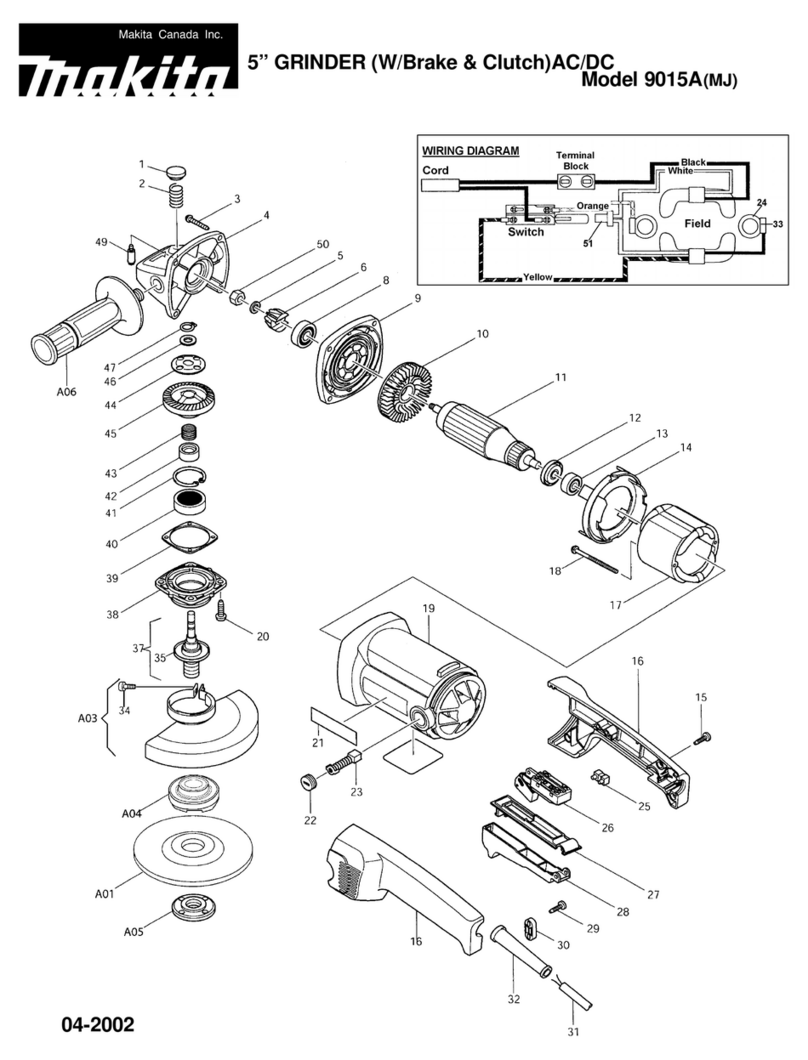

1. Disconnect air supply and remove inlet con-

nection from Air inlet nipple (26) Unscrew

and remove air inlet nipple (26) with help

of allen key, unscrew and remove four nos

socket head screws (15) along with spring

washers (4) Hold side handle (35) in one

hand and pull out rotor housing (25) along

with complete drive assembly. Keep aside

assy. In spindle housing (13) Now pull out

drive assy. By holding pinion gear (17) Tap

out ball bearing (11) at rear end of rotor so

that rear end plate (24) will also come out .

Slide out cylinder (22) but take care not to

fall down rotor blade (21) keep aside rotor

blades (21) Now hold some at in ithe slot

of rotor (20) and with help of wheel spanner

(33) unlock pinion gear and remove it. Tap

gently on to front end plate (18) so that it

will come out along with two ball bearings

(11) Remove bearing spacer (19) If neces-

sary tap out roll pin (32) so that lever (31)

will come out. Unscrew valve cap (27) and

press from other side valve steam (30) and

valve spring (28)

2. Now to dismantle driven side assy.- Unscrew

spindle nut (1) with help of wrench (34) out

take out grinding wheel (2) Unscrew and

remove socket head screws four nos for

wheel guard (5) along with four spring

washers (4) and remove wheel guard (5)

3. Now rest faced ball bearing (8) by

keeping same space between two jaws of

vice so that spindle (6) will

4. remain free within keep aside spacer

(12). Take a solid pin and rest it on face

of spindle and tap it so that

5. bearing (11) on spindle end will come

out .

6. Now with help of circlip piler take out

circlip (10) and again tap an end of

spindle (6) so that bevel gear (9)

7. and bearing (8) will come out . Pull out

Woodru key (7)

8. Clean all metal parts in light solvent and

inspect carefully for signs of wear.

Replace components that

9. appear worn out or damaged . Coat parts

with recommended light oil and

reassemble carefully in the reverse

sequence.

FF-MM-407-REV - 00

Page 5

Operation and Maintenance Guide Pneumatic Angle Grinder

Suggested Lubricants

Brand Above 27ºC / 80ºF 5ºC to 27ºC / 41ºF to 80ºF Below 5ºC / 80ºF

Shell Toona R 72 Toona R 41 Toona R 27

Mobil Almo 529 Almo 527 Almo 525

Esso -- Arox EP.65 Arox EP.45

Caltex Rando Oil 100 Rando Oil 100 Rando Oil 46

Cp -- -- Airolene Tool OiI

Texaco Regal Oil F (R&O) Regal Oil PE(P&E) Regal Oil PE(R&O)

Daltron Silkolene 881 Silkolene 548/T Silkolene 733

Burmah Castrol Castrol RD Oil 3 Castrol RD Oil Light Megna SPX

Duckham Garnet 7 Garnet 6 Zero Fio 5

Sternol Merlin 87 Merlin 71 Merlin 54

Petrona Purifoc 53 Purifoc 46 Purifoc 32

Chevron Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

Lubrication Requirements

Always install a line lubricator on the air line as

close to the tool as possible. A lter-regulator

lubricator unit (FRL) is strongly recommend-

ed. Keep the lubricator bowl topped up with

recommended grade of oil and check that the oil

is reaching the tool. Running the tool without

lubrication is likely to cause damage to the

components causing premature replacement.

FF-MM-407-REV - 00

Page 6

Operation and Maintenance Guide Pneumatic Angle Grinder

TEST CERTIFICATE OF MATERIALS, PERFORMANCE

Date :

Model number :

Part description & s.No. :

We hereby certify that the above referenced product has tested and inspected in accordance with our standard test proce-

dures

and meets the specications for material and performance values as published in our literature. We further certify that the

product has been given our standard factory test and meets all quality and performance standards established by the compa-

ny. is product is certied to be produced in our factory, and is of current production.

Authorised Signatory

Q.A Manager

Place - Vasai, Maharastra

FF-MM-407-REV - 00

Page 7

Operation and Maintenance Guide Pneumatic Angle Grinder

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description :

Model Number :

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and Har-

monized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16832

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2021

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-407-REV - 00

Page 8

Operation and Maintenance Guide Pneumatic Angle Grinder

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-407-REV - 00

Page 9

Operation and Maintenance Guide Pneumatic Angle Grinder

is page is intentionally

Le blank.

This manual suits for next models

3

Table of contents

Other Teryair Grinder manuals