Teryair SG-6K Operating manual

Operation & Maintenance Guide

FF - MM - 75 REV - 0

Sheet 1 of 5

STRAIGHT GRINDER

SG6K

ISO 9001 : 2008

Pneumatic Straight Grinder

SG-6K

AIR SUPPLY :

To enable the tool to function satisfactorily, it is essential that a constant 90 psi pressure of clean, dry air is supplied to the

hose connection (18). A short leader hose of 16mm I.D should be attached to the tool and the length of the pipe should

be less than 12 meters. The installation of air line separator, a filter to purify and dry the air supply (FRL unit)

recommended, and should be connected as close to the tool as operation will allow.

DAILY BEFORE OPERATION :

Disconnect and pour in 1 to 2 ounces of recommended oil into the air inlet and reconnect hose after blowing out any

accumulated dirt in the hose line before connection. Tighten both spindle nuts properly

SAFETY INSTRUCTIONS :

Always wear suitable protection, eye goggles, ear muffs, safety shoes etc to safe guard against possibility of flying

particles. Ensure that a wheel guard is fitted onto the tool and the wheel is secured properly.

Never operate the tool over the rated 90 psi pressure, Check that all bolts and other fasteners are tightened correctly. Do

not exert excessive pressure against the work surface. Never use larger wheels than recommended and check new

wheels for cracks before using them on the tool. Keep hoses in good condition. Check hoses for wear and ensure that

fittings are secure. Accidental disconnection while tool is in use can make the hose whip and can be safety hazard.

Remove wheel from the tool before attempting to dis- assemble this grinder . Check that the cause of the problem is not

external.Check that the inlet air pressure is O.K. i.e. 90 Psi. At the tool. Check for wet and dirty air moisture is not carried

into the tool, and corrode the internal parts. Dirt in the air tends to get into the motor parts and causes loss of

performance.

MAINTENANCE :-

A regular maintenance schedule will greatly add to the durability of the tool. Disconnect air supply to the tool. Unscrew

both spindle nuts (1) so that wheel collar (2) and one washer for wheel (3) will come out. Remove grinding wheel from

the tool. Take out another wheel collar (2) and washer (3)

Take out wheel guard (9) by loosening both nuts (5) remove clamp (8) and then take out hex head bolt (7) with plain

washers (6) With the help of a suitable wrench unscrew bearing clamp nut (10)

and remove it so that both ball bearings (14) will come out . Tap out gently to the spindle (12) so that

spindle (12) will come out from bearing (11) Remove coupling (15) Now from another end unscrew hose nipple (39)

along with ' O ' ring (38). Unscrew Air inlet bushing (37). Unscrew control body (33). Control body (33) will come out

along with rotary valve (34) and control sleeve (36). Remove

control sleeve (36) and tap out cylindrical pin (35) and slide out rotary valve (34) Also remove 'O' ring (32) Now with help

of spanner, unscrew rear housing (31) and remove it . Unscrew governor housing (26) and take it out. Tap out roll pin

(27) and remove seat (30), governor spring (29) then

housing cover (28) and all the three steel balls (25). Preserve all these items neatly.Pull out complete air motor. Tap out

ball bearing (24) so that lower end plate (18) will come out . Also remove rotor blades (19) and pull out rotor (20) from

another end of cylinder liner (21). Now tap out other end of rotor (20) and take out ball bearing (14) so that upper end

plate (16) and bearing spacer (17) will come out.

Sheet 2 of 5

FF - MM - 75 REV - 0

Pneumatic Straight Grinder, SG-6K

Operation and Maintenance Guide

Problem

Improper tightening of

mechanical parts or, improper

assembly of the tool.

Insufficient air flow (cfm)

Loss of

power

Use a line oiler, see chart on lubrication for oil selection.

Lowered compressor output

Excessive moisture in air

Repair compressor for proper output

Check hoses etc. for leaks

Disassemble tool, thoroughly clean and inspect all parts.

Check ball bearings for rough, bumpy action or exessive end

play. Check rotor blades for wear, damaged or swelling.

Replace defective parts, re-lubricate and re-assemble.

TROUBLE SHOOTING

SolutionProbable Causes

Low air pres sure at the tool For rated performance 90 psi air pressure is required at the

tool while tool operating

Foreign material in tool inlet. Remove foreign material

Tools run

erratically

If suggested remedies fail to correct the problem, dis-assemble and inspection must be performed to

determine the cause.

Sheet 3 of 5 FF - MM - 75 REV - 0

Pneumatic Straight Grinder, SG-6K

Operation and Maintenance Guide

Clean all parts in suitable solvents. Examine them for wear and tear. Replace any damaged components. Coat

parts with light oil and re-assemble carefully in reverse sequence.

LUBRICATION REQUIREMENTS :

Always install a line lubricator on the air line as close to the tool as possible. A filter-regulator lubricator unit (FRL) is

strongly recommended. Keep the lubricator bowl topped up with recommended grade of oil and check that the oil is

reaching the tool. Running the tool without lubrication is likely to cause damage to the components causing

premature replacement.

RECOMMENDED LUBRICANTS :

TECHNICAL DATA:

Maximum wheel size :- 150mm dia

Air inlet pressure :- 90 psig

Hose inside dia :- 16mm

Air Inlet :- 3/8" BSP

Free speed :- 6000 rpm

RPM on load :- 3000 - 3500

Air consumption :- 26 cfm

Power :- 1.10 watts.

Weight :- 3.5 Kgs.

INTENDED USE :

This grinder is rugged & dependable tool to give you years of satisfactory service. It is generally used for finishing

welding seam, cleaning of burrs in castings, and for rough hand grinding. It is also used for repair of metal structure.

PROHIBITIVE USE

Straight Grinder is prohibited to be used from purpose other than mentioned in intended use.

Following safety precautions should be taken

. Wear appropriate personal protective equipments.

. Do keep hand & clothing away from moving parts.

. Straight grinder should be stored in dry environment.

. Do not allow the equipment to run unattended.

. Do not modify this equipment.

. Do not use petrol (gasoline) thinners or any other high flash point solvent to clean the equipment.

. Please check the hose connection prior to starting the Straight grinder.

ABOVE 270

C - 800F 50C-270

C 400

F-800

F BELOW 50C 400F

SHELL Toona R. 72 Toona R. 41 Toona R.27

MOBIL Almo 529 Almo 527 Almo 525

ESSO ----- Arox.EP.65 Arox EP.45

CALTEX Rando Oil 100 Rando Oil 100 Rando Oil 46

CP ----- ----- Airolene Tool Oil

TEXACO Regal oil F (R&O) Regal Oil PE (P&E) Regal Oil PE (R&O)

DALTRON Silkolene 881 Silkolene 548/T Silkolene 733

BURMAH

CASTROL

Castrol RD Oil 3 Castrol Rd Oil Light Megna SPX

DUCKHAM Garnet 7 Garnet 6 Zero Fio 5

STERNOL Merlin 87 Merlin 71 Merlin 54

PETROFINA Purifoc 53 Purifoc 46 Purifoc 32

CHEVRON Vistac Oil 18X Vistac Oil 19X Vistac Oil 9X

IND OIL Servo Spyn – 22 ----- -----

Sheet 4 of 5

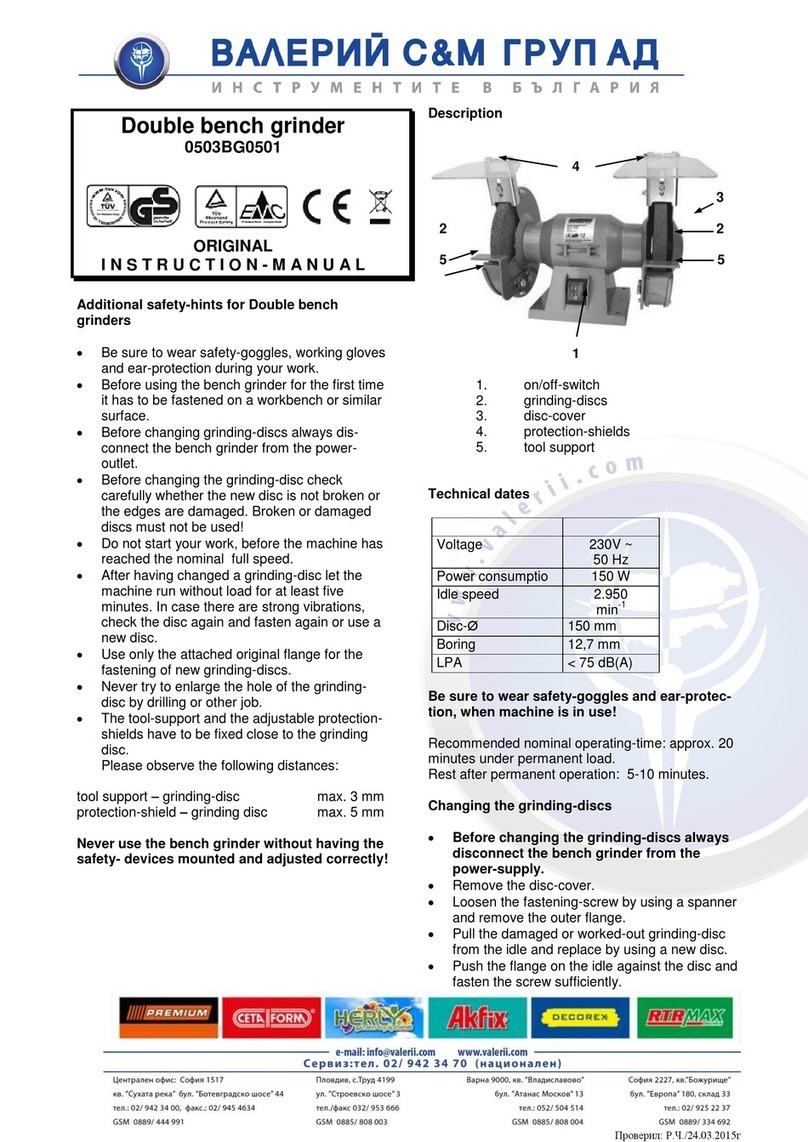

Exploded View

FF - MM - 75 REV - 0

Pneumatic Straight Grinder, SG-6K

Assembly And Part List

Sheet 5 of 5 FF - MM - 75 REV - 0

Pneumatic Straight Grinder, SG-6K

Item No. Part Number Description Qty

1 455 21 04 Spindle Nut 2

2 455 21 05 Wheel coller 2

3 455 40 26 Washer for wheel 2

4 Grinding wheel 1

5 150 40 25 Nut M6 2

6 320 01 36 Plain washer M6 2

7 298 00 73 Hex. Head bolt 2

8 455 30 24 Clamp 1

9 455 30 23 Wheel Guard 1

10 455 21 15 Bearing clamp nut 1

11 455 50 28 Ball bearing # 6004 2

12 455 21 06 Spindle Nut 1

13 455 10 02 Spindle housing 1

14 455 50 29 Ball bearing # 6002 2

15 455 21 14 Coupling 1

16 455 21 13 Upper end plate 1

17 455 21 20 Bearing spacer 1

18 455 90 33 Roll pin for cylinder liner 2

19 455 39 24 Rotor blade 5

20 455 21 07 Rotor blade 1

21 455 05 01 Cylinder liner 1

22 455 21 08 Lower end plate 1

23 455 21 22 Lock nut 1

24 500 50 32 Ball bearing # 6202 1

25 500 50 32 Steel ball 3

26 455 21 16 Governor housing 1

27 500 90 47 Roll pin 1

28 455 21 17 Housing cover 1

29 455 51 31 Governer Spring 1

30 455 21 18 Seat for spring 1

31 455 10 03 Rear housing 1

32 455 40 32 O' Ring for control Body 1

33 455 21 09 Control Body 1

34 455 21 19 Rotory valve 1

35 455 50 30 Cylindrical pin for rotary valve 1

36 455 21 10 Control Sleeve 1

37 455 21 11 Air inlet Bushing 1

38 190 40 51 O' ring for hose nipple 1

39 455 21 12 Hose nipple 1

Table of contents

Other Teryair Grinder manuals

Popular Grinder manuals by other brands

Bluerock Tools

Bluerock Tools 120D Operational manual

Deltafox

Deltafox DP - CAG 2015 Translation of the original instructions for use

Pro-Cut

Pro-Cut KMG-32 owner's manual

VALERII S & M GROUP

VALERII S & M GROUP 0503BG0501 Original instruction manual

MEISTER CRAFT

MEISTER CRAFT MWS 2400 Translation of the original instructions

VALERII S & M GROUP

VALERII S & M GROUP RTH122 Original instruction manual