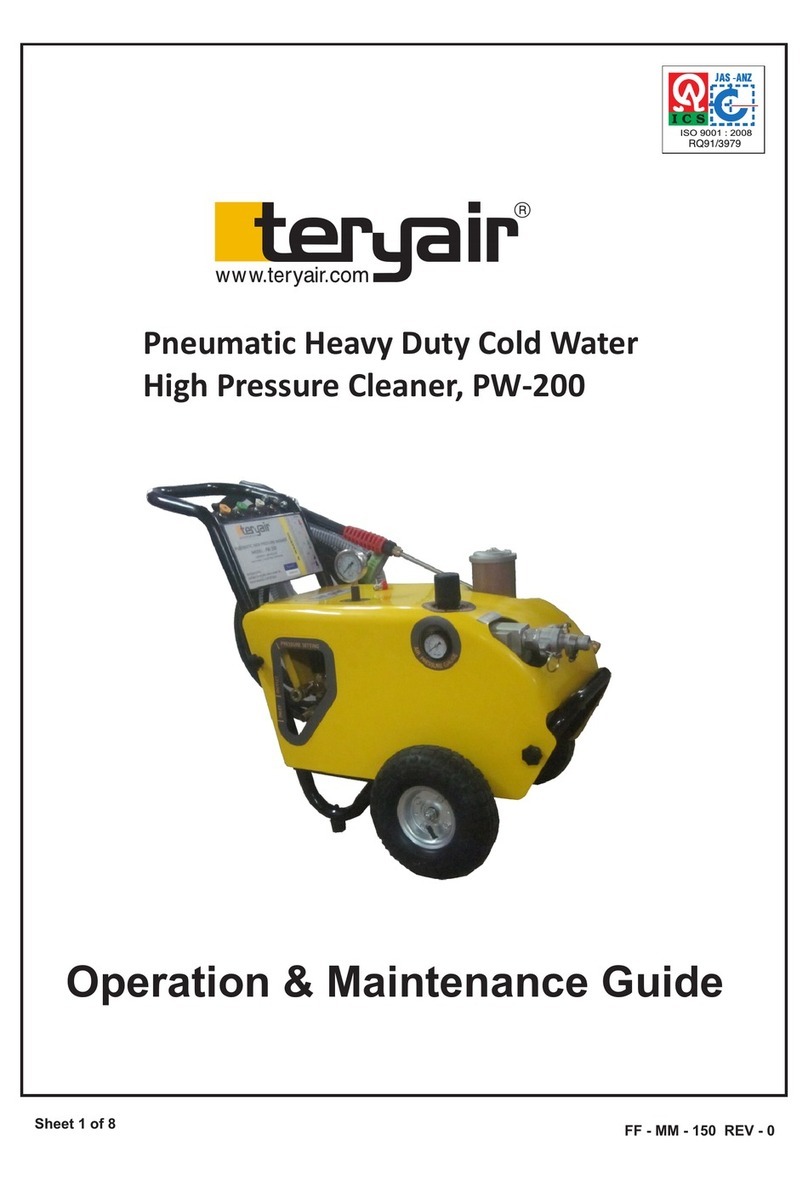

Teryair PW-200 Instruction Manual

Models Descriptions IMPA Number

PW-200 Pneumatic Pressure Washer - 200 Bar 59 08 51

PW - 200

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-311-REV - 01

Page 2

Operation and Maintenance Guide Pneumatic Pressure Washer

Table of Contents

3 Introducon

3 Technical Data

3 OperangInstrucons

5 UnPacking

6 Assembly&Diassembly

7 SafetychecksbeforeandaeroperangtheHighPressureWasher

9 Troubleshoong

10 Maintenance

11 DiassemblyandRe-assemblyforPW-200

12 BillofMaterialsforPW-200

13 ExplodedViewforPW-200

16 ExplodedViewpfHighPr.PumpPW200Bar

17 TestCercateOfMaterials,Performance

18 EuDeclaraonOfConformity

19 WarrantyCercate

FF-MM-311-REV - 01

Page 3

Operation and Maintenance Guide Pneumatic Pressure Washer

Introduction

Teryair Pneumatically Operated High Pressure Cleaners are designed for heavy duty cleaning

operations in hazardous environments. ese Pneumatic High Pressure Cleaners ensure safe

cleaning of hazardous areas where inammable gases & liquid exists. ese heavy duty high

pressure cleaners are used for removing Dirt, salt, rust deposits from Ship Decks / oors, Paint &

grati o walls, Oil & Grease o engines.

Technical Data

Model Pneumatic Motor Water Pressure

generated

Water Flow

rate

Air supply

recommended

Dimensions

L X W X H Weight

HP kW Speed PSI Bar Gpm LPM Bar PSI mm Kgs

PW-200 9 6.6 1500 2900 200 3.3 15 7 100 1000x520x750 75

Intended Use

• Biological growth from concrete or steel

constructions

• Hard caked mud from construction

machinery like dozer tracks.

• Paint, dirt, mud from walls and oors

• Oil and grease from High Pressure Washer.

• Dirt, paint from sea going vessels.

Prohibitive use

• Any use in an explosive atmosphere is

prohibited

• Use on materials containing asbestos is

prohibited

• Use by an underage, untrained or

operator who is under the inuence of

drugs or alcohol.

• Use with non genuine spare parts or

accessories is prohibited

• Use with safety devices un functional or in

need of service is prohibited

• Do not use with hot water, this High

Pressure Washer is for use with cold water.

Operating Instructions

Warning

is manual must be read and the operating

instructions carefully followed, because of the

high pressure developed, severe injuries can be

caused by negligent operation

Warning

Do not run the high pressure washer without

a proper and adequate supply of potable water

connected. Insucient water supply will cause

damage to the seals in a few minutes of use.

Caution

Operators under 18 not allowed to operate

this Pneumatic Needle Scaler. Operators must

be made familiar with the instructions in

this

Warning

Operators under 18 not allowed to operate this

High Pressure Washer. Operators must be made

familiar with the instructions in this manual

before attempting to operate the High Pressure

Washer. Ensure that job site is clear of bystand-

ers. e high pressure jets are capable of causing

serious injury do not direct spray on people or

animals. Do not spray electried equipment.

Caution

Use only genuine Teryair or Teryair approved

accessories.

Following symbols are used through out this

manual.

FF-MM-311-REV - 01

Page 4

Operation and Maintenance Guide Pneumatic Pressure Washer

Warning

Use only for high pressure cleaning, do not use

for any other application.

Warning

Safety and protective clothing, eyewear, head-

gear, ear protection, gloves and footwear to be

worn during operation of this High Pressure

Washer. Please see Table C at end of this section.

Warning

While starting operation and also during opera-

tion there is a considerable kickback force from

the lance due to the high energy generated, be

aware of this at all times and keep a rm con-

trol on the direction of the spray jet. Always use

both hands to operate the gun.

Warning

is High Pressure Washer is not designed for

use in an explosive environment.

Warning

Medical attention

Personnel who sustain injuries caused by high

pressure jets MUST be given immediate hospital

attention. It’s important to apprise the medical

attendants of the manner in which the injury

has been caused, namely a high pressure jet.

Caution

Keep the gun trigger locked when not operating.

Warning

Completely turn o the machine and disconnect

air supply line before attempting any service.

Read Assembly and Dis assembly instructions.

Warning

Take care not to exceed the maximum 7 bar

(100 psi) supply air pressure. Use a lter and

regulator and lubricator as close to the equip-

ment inlet as operation will allow to ensure a

clean and regulated and lubricated air ow.

Safety wear mandatory while operating high

pressure washer

Warning

Eye and face and ear protection must be worn at

all times during operation of the High Pressure

Washer. ere is a chance of ying debris from

the jobsite and the quality of wear should be

such to protect against such ying debris such as

akes of the removed layer.

Warning

Eye and face and ear protection must be worn at

all times during operation of the High Pressure

Washer. ere is a chance of ying debris from

the jobsite and the quality of wear should be

such to protect against such ying debris such as

akes of the removed layer.

Warning

Suitable heavy duty gloves must be worn at all

times during operation.

Warning

Suitable heavy duty gloves must be worn at all

times during operation.

FF-MM-311-REV - 01

Page 5

Operation and Maintenance Guide Pneumatic Pressure Washer

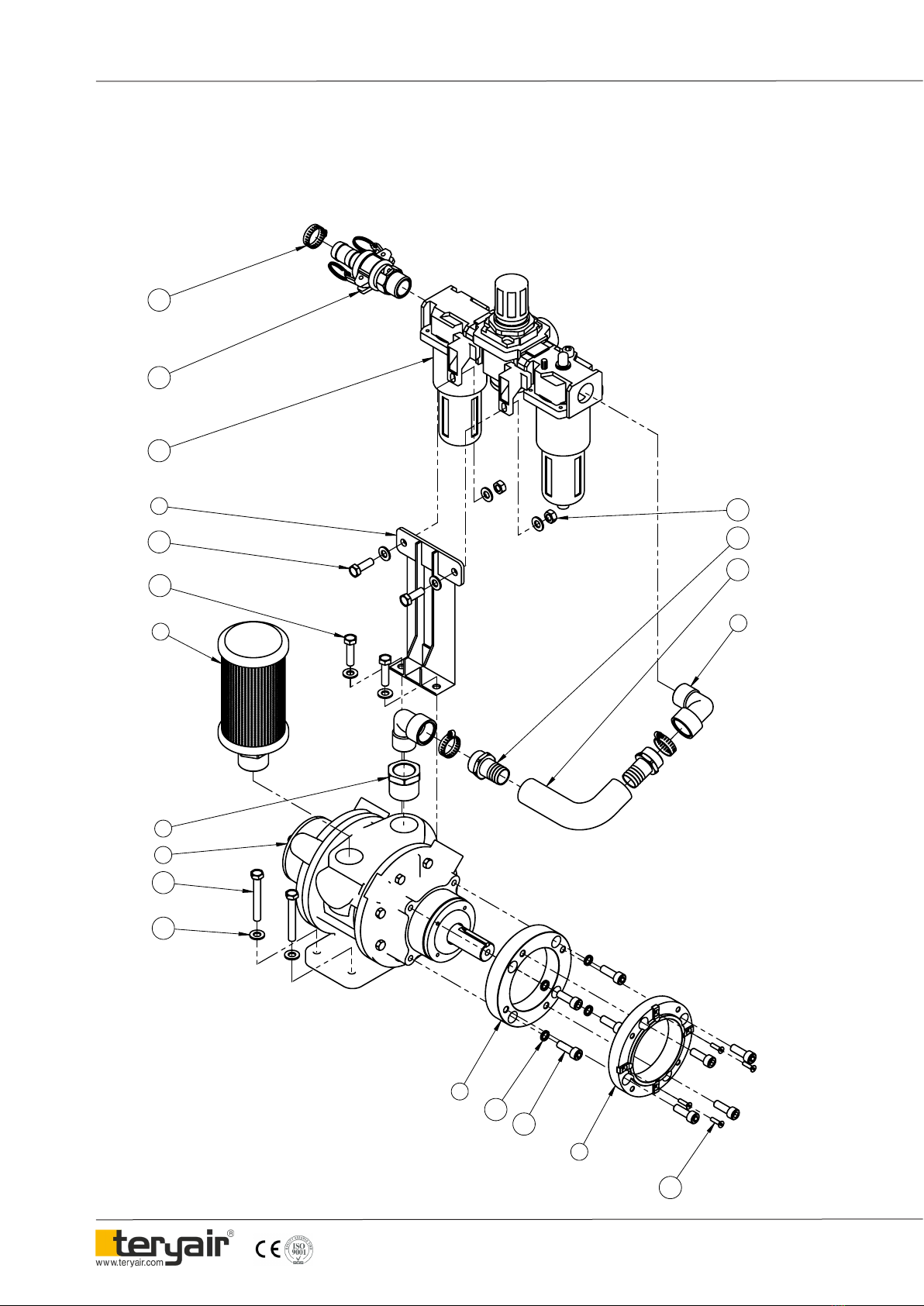

Un Packing

Identify all the components as shown earlier, contact your supplier if any parts are missing or dam-

aged.

Be aware that minor visual dierences may be noticed between actual motor/frame/pump and High

pressure hoses because this components vary depending on the model ordered. is illustration is for

identication only.

Unless specially requested the motor, pump and frame are factory tted to each other.

Spray Tip detail

Gun Hook

Lance

Gun

Pressure Gauge

Handle with Nozzels

High Pr. Pump + Stand with

Wheel + FRl + Pneumatic motor

High Pressure Hose

Cleaning Fluid Hose

FF-MM-311-REV - 01

Page 6

Operation and Maintenance Guide Pneumatic Pressure Washer

Fill lubricating oil

Make Sure that the tted oil plug is removed. Fill lubricating oil 10W15 up to half way mark of Oil

Indicating Glass window.

And Fit Breathing cap provided with pump. Do not t Oil Plug.

Caution – a) If oil plug tted aer lling oil instead of breathing cap- Pump will over heat during use

and will damage all internal parts of pump and machine will stop working / developing pressure.

b) If oil is lled fully in pump up to top / maximum level of Oil indicating window, there will be no

space for breathing of oil during use and pump will be over heated which will damage pump internal

parts.

Ok Level

Make Sure to ll Oil in the pump as shown below befor start.

Plug (Red Colour) For Transportation

Purpose Only To Replace With

Breathing Cap (Shown As Above)

Breathing Cap

Excess Oil Level Low Oil Level

FF-MM-311-REV - 01

Page 7

Operation and Maintenance Guide Pneumatic Pressure Washer

Safety checks before and after operating the High Pressure Washer

Air Supply.

• Ensure that an adequate pressured air supply is

available at 6 bar and at least 250 cfm.

• PW200 is supplied with a FRL unit. Always make

sure to top up lubricator with specied oil grade __.

Failed to do so will cause pre-mature failure of air

motor.

Lubrication.

• e oil sump in the Pump unit should contain

SAE15W40 grade oil.

• Ensure that the oil is at the half level by looking at

the transparent window.

• If the number of hours has crossed y, drain out

the oil by opening the Oil drain plug (4) at the side

of the pump housing. Re x the plug and open the

Vented oil cap (4) to top up oil to the correct level

(Refer g on page 11). ereaer repeat aer every

500 hours of use or whenever the level of oil has

dropped or looks contaminated.

Check list before starting the High Pressure

Washer.

• Check safety wear mentioned earlier in warnings.

• Check the hoses, especially the high pressure hoses

for damage or leaks.

• Make sure that the air supply is maintain by a pres-

sure regulator.

• Make sure that pneumatic hoses are not damaged

and all the connectors between gun, lance, hoses

and pump are secure.

• Make sure that the lter cone on the water supply

in in place.

• Turn on the water supply.

Starting the High Pressure Washer

• Hold the gun securely with both hands, ( the gun

will kick back when rst started )

• start the air supply, and depress trigger of the gun

to start the jetting.

• Adjust the output pressure as required by the pres-

sure regulator.

Warning

keep distance from gun tip to job at

least 8 inches.

Warning

is high pressure washer is a high powered

High Pressure Washer and it is imperative that

it must be operated by a competent and trained

operator. See warnings.

Warning

e high pressure washer needs a constant sup-

ply of water during operation, any starvation of

water to the High Pressure Washer will result in

overheating and quick damage to High Pressure

Washer.

Warning

With the motor running and the jetting o, the

high pressure water circulates in the circuit. DO

NOT pause jetting for more than TWO minutes.

Instead shut down the high pressure washer see

“Shutting down” later in this section

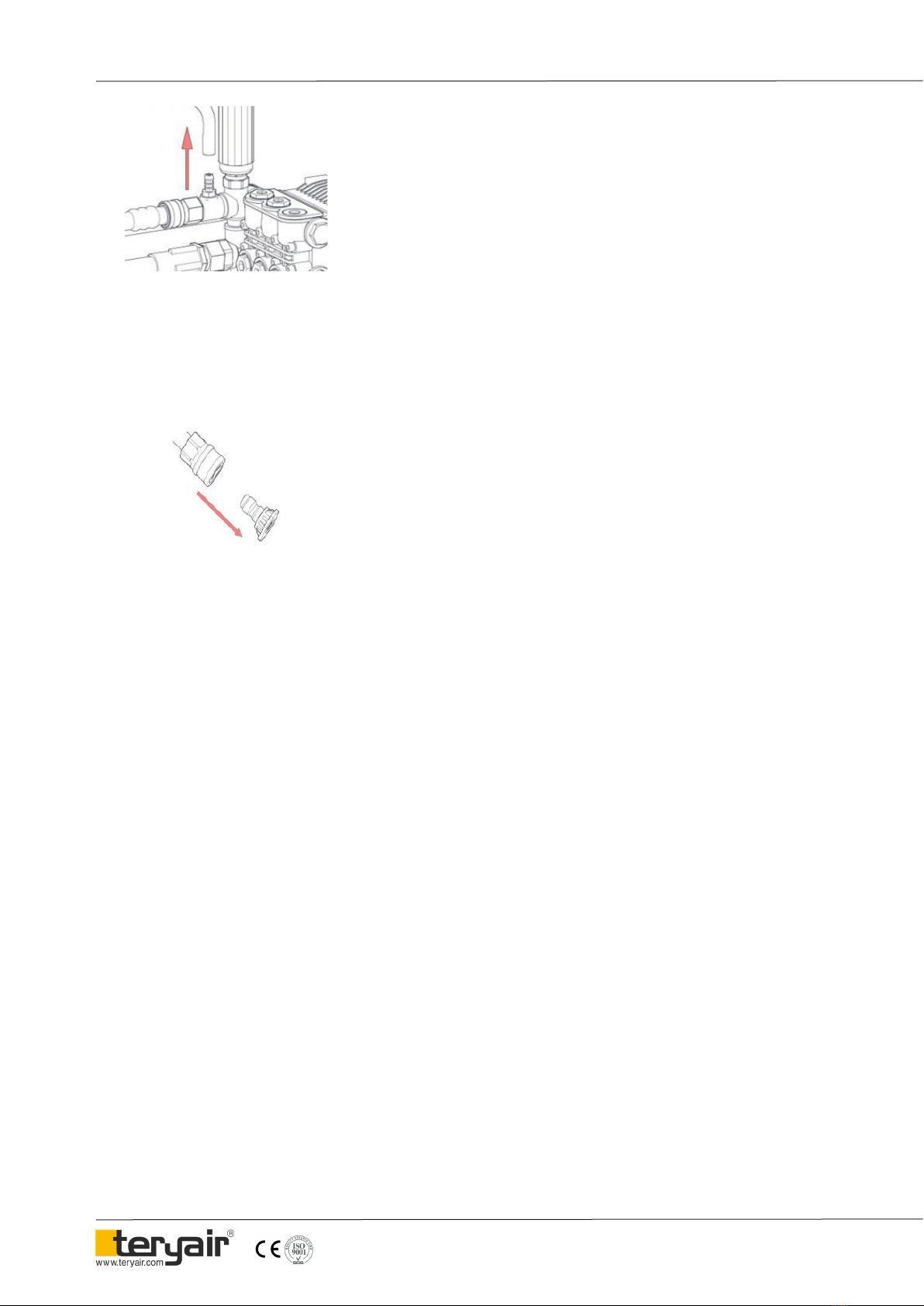

Changing spray nozzle tips

• Choose appropriate nozzle.

• Engage the trigger lock

• Pull back the collar

• Remove spray tip

• Install desired tip,

• Release collar

• Tug on tip to ensure proper seat

Cleaning solution injection

All Teryair high pressure washers have a fa-

cility of injection of Cleaning Fluids to aid in

the cleaning process.ere are several brands

& types of cleaning solutions available in the

market today. Whichever you choose make sure

it designed for use in high pressure washer. It

should say so on the level, if it does not say it,

don’t use it.

Warning: Never use bleach or bleach based

products as they can damage the pump.

• Once you have your cleaning solution is

ready to go, check to make sure that injec-

tor tube is securely attached to the pump as

shown.

FF-MM-311-REV - 01

Page 8

Operation and Maintenance Guide Pneumatic Pressure Washer

• en insert the other end into the cleaning

solution.

• A pressure washer will only siphon clean-

ing solution when in low pressure mode.

So a lowpressure soap nozzle must be use

on the gun + lance ( Refer Spray tip detail).

• Caution

Aer cleaning Fluid application it is recom-

mended to disconnect the injection system to

allow clean water to rinse through the system

for few minutes.

Shutting down

• DO NOT turn o water source before

switching o the motor.

• Switch o the air supply and disconnect

the air hose.

• Turn o the water source.

• Pull the lance trigger to relieve any residu-

al water pressure.

Storage

• Disconnect the gun from the high pressure hose

and the hose from the pump.

• Hold gun vertically and depress trigger to re-

move all residual water from the gun and lance.

• Drain the hose too in a similar way.

• Remove the water supply hose and drain.

• Run the pump for ten seconds to eject any resid-

ual water that may have remained in.

• Store in a clean and dry place.

• Store under a tarpaulin is recommended.

FF-MM-311-REV - 01

Page 9

Operation and Maintenance Guide Pneumatic Pressure Washer

Troubleshooting

Serial No Causes Remedial Action

1e motor does not turn aer energizing A loose connection

Check connections and retry

2e motor hums but does not turn

Low voltage

Check voltage and verify correct and re try

Pump is stuck

Service Pump see Maintenance section

3Pump is noisy

Pump is sucking air along with water

Check hose ttings

Valves are tight

Service pump

Bearings worn

Service Pump

4 Low pressure when new

Water supply not adequate

20 litres per min at 20 PSI recommended

Leak in high pressure hose tting

Check use sealant tape if needed.

Nozzle obstructed

Clean Nozzles, see maintenance section

Water lter is clogged

Clean and ensure clean supply

Defective un loader valve

Service Pump

Air in hose

Switch o motor, disconnect water hose from pump inlet

and allow water to ow removing air bubbles, reconnect.

5Cleaning solution not getting sucked

Cleaning solution lter clogged

Clean or replace

Wrong Cleaning uids

See section

Cleaning solution residue clogging the pump

Service pump

6Low pressure aer normal use Pump needs service

Service Pump

7Water leaking at Gun Check hose ttings

Use sealant tape or replace ttings

8Water leaking at Pump

Check ttings

Use sealant tape or replace ttings

If not solved

Service Pump

9Oil Leaking at Pump Seals or O rings worn

Service Pump

10 Pump pulsates Clogged nozzle

Clear nozzle

FF-MM-311-REV - 01

Page 10

Operation and Maintenance Guide Pneumatic Pressure Washer

Maintenance

Servicing the Pump

Follow instructions in “Shutting Down” section earlier in the manual.

Dis assemble the hoses and the air hose from the High Pressure Washer and Air motor respectively.

FF-MM-311-REV - 01

Page 11

Operation and Maintenance Guide Pneumatic Pressure Washer

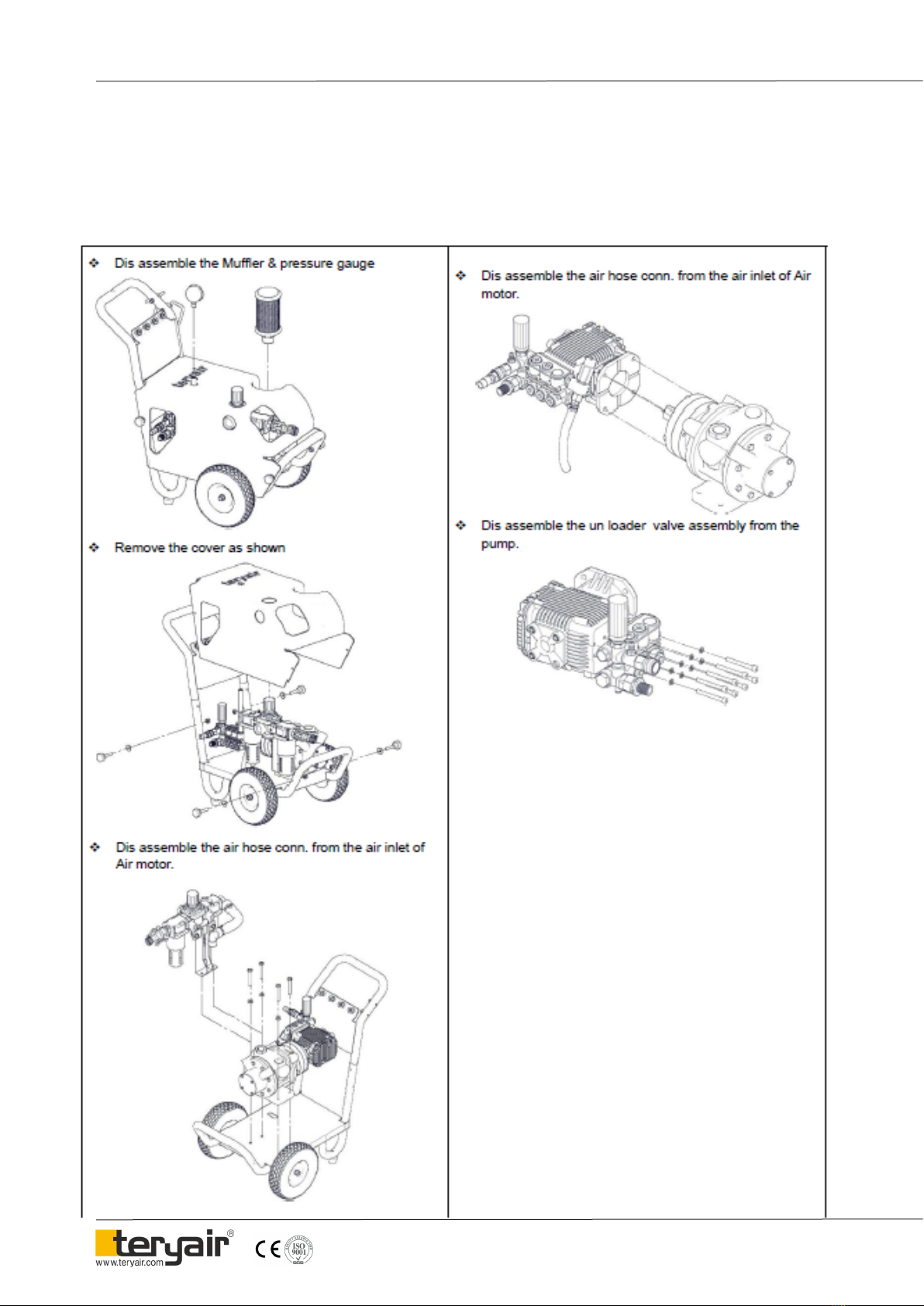

Diassembly and Re-assembly for PW-200

a. Shut o air supply and allow residual Pres-

sure to bleed o.

b. Unscrew Camlock Coupling (33) from FRL

Unit (10) & unscrew Inlet Filter with Pipe

(23) & Discharge Hose (24) from High pres-

sure pump (3).

c. Take out Nozzle (5) from Gun (25) to re-

place it with new one. (If found damaged/

worn-out)

d. Unscrew High Pressure Gauge (22) from

Extension Pipe (21) & unscrew Muer (9)

from Air Motor (2).

e. Unscrew Knobs (27) with Washers (29) on

Cover (26) & remove the cover (26) from

Trolley (1).

f. Loosen Jubilee clips (32) to remove Hose

(11) from Hose Nipples (31) & Unscrew

Elbow (7) from FRL Unit (10) then unscrew

Hose Nipple (31) from Elbow (7)

g. Unscrew Hex bolt (17) with Washer (18)

from Bracket for FRL (8) to remove FRL

Unit (10).

h. Unscrew Hex bolt (19) and Hex bolt (20)

with Washer (18) from Air Motor (2) & re-

move Air motor and High pressure pump

assembly from Trolley (1)

i. Unscrew Extension pipe (21) & Unloader

Valve Kit (34) from High Pressure pump

(3) & Loosen Jubilee Clip (36) to remove

Hose (37) from Unloader Valve Kit (34).

j. Unscrew Allen bolt (13) with Spring

Washer (12) from High Pressure pump (3)

to replace it with new one. (If found dam-

aged/worn-out)

k. Unscrew CSK Screw (13) & Allen Bolt (15)

from coupling (4) & unscrew Allen Bolt

(15) with Spring Washer (35) from Cou-

pling for motor (5) to replace it with new

one. (If found damaged/worn-out)

High Pressure Pump:

a. Replacement of Seal Kit:

• Unscrew Allen Bolts (13) with Washers (12)

from Pump Housing (10) & remove Pump

Housing assembly from Pump Body (1).

• Remove Seal Kits (17) from Pump Housing

(10) and replace it with new one.

b. Replacement of Valve Kit:

• Unscrew Plug (14) (3nos on front side &

3 on top side) from Pump Housing (10) &

remove Valve kit (15) from Pump Housing

(10) and replace it with new one.

c. Examine for any wear or damage to compo-

nents and replace it if required. Now follow

the above steps in reverse manner to reas-

semble the PW200.

FF-MM-311-REV - 01

Page 12

Operation and Maintenance Guide Pneumatic Pressure Washer

Bill of Materials for PW-200

Illustration

Number Part Number Description PW-200

1 637 98 11 TROLLEY COMPLETE 1

2 637 98 24 AIR MOTOR 1

3 637 98 25 HIGH PRESSURE UNIT 1

4 637 21 04-R COUPLING 1

5 637 21 03 COUPLING ON MOTOR 1

6 637 25 33 ADAPTOR 1

7 637 25 08 BRASS ELBOW 2

8 637 31 12 BRACKET FOR FRL UNIT 1

9 637 40 30 MUFFLER 1

10 FRL-25 FRL UNIT ASSLY. 1

11 637 40 14 HOSE 1

12 637 27 67S SPRING WASHER 4

13 637 27 68S ALLEN BOLT 4

14 637 27 19S ALLEN BOLT 8

15 637 90 18 CSK SCREW 4

16 637 27 69S HEX NUT 6

17 637 27 70S HEX HEAD BOLT 2

18 637 27 71S PLAIN WASHER 12

19 637 27 72S HEX HEAD BOLT 2

20 637 27 73S HEX HEAD BOLT 2

21 637 23 06 EXTENSION PIPE 1

22 637 90 17 HIGH PRESSURE GAUGE 1

23 637 97 26 INLET FILTER WITH PIPE 1

24 637 97 38 DISCHARGE HOSE 1

25 637 97 61 GUN 1

26 637 40 35 COVER 1

27 637 08 02 KNOB 4

28 637 27 74S HEX NUT FOR KNOB 4

29 637 27 37S WASHER FOR KNOB 4

30 637 97 60 QUICK CONNECT NOZZLE (5 PIECE SET) 1

31 637 25 34 HOSE NIPPLE 2

32 637 27 63S JUBILEE CLIP 3

33 637 97 64 CAMLOCK COUPLING 1

34 637 97 62 UNLOADER VALVE KIT 1

35 637 27 75S M10 SPRING WASHER 4

36 637 27 65S JUBILEE CLIP 1

37 637 40 66 HOSE FOR UNLOADER VALVE KIT 1

FF-MM-311-REV - 01

Page 13

Operation and Maintenance Guide Pneumatic Pressure Washer

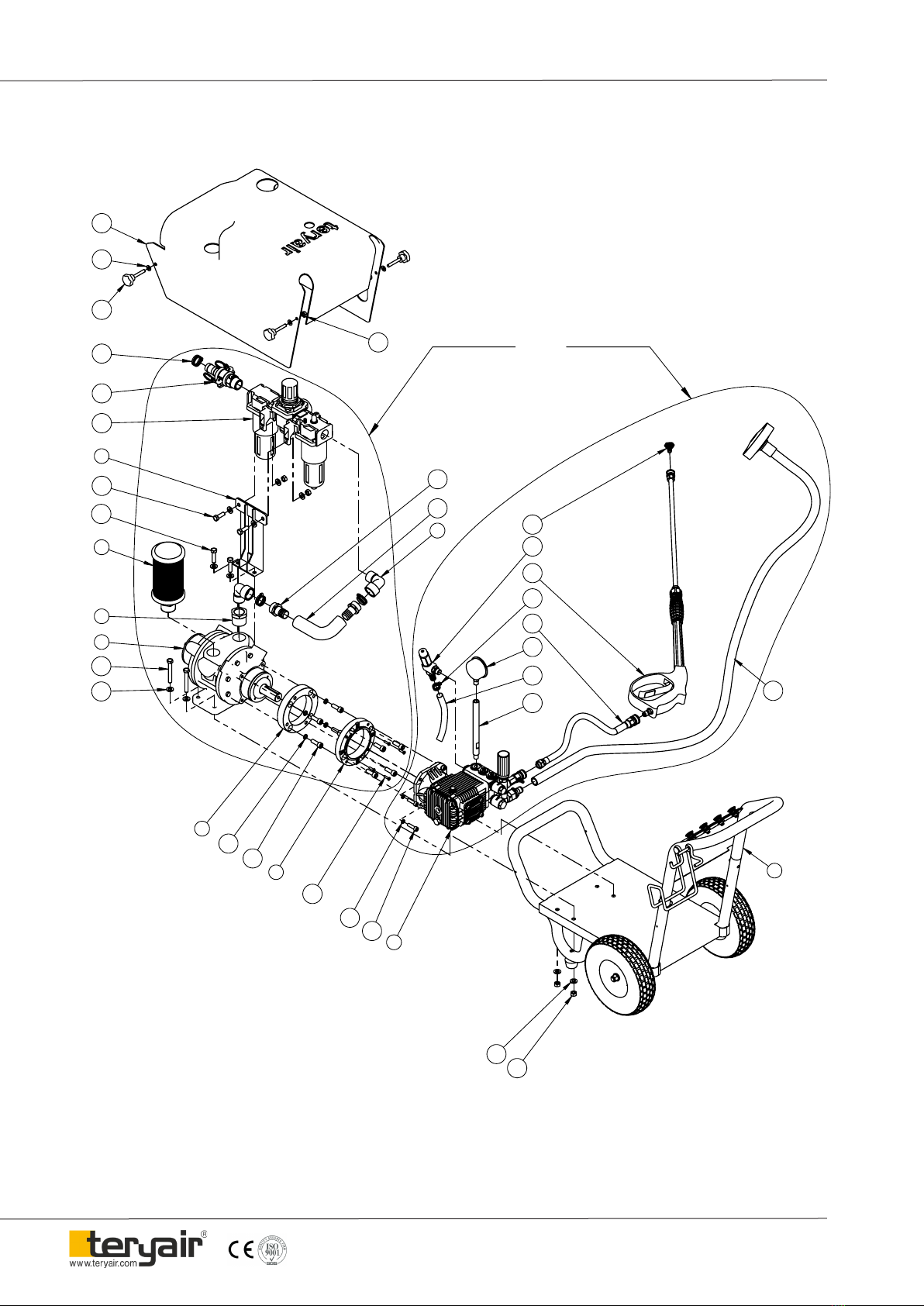

Exploded View for PW-200

1

2

20

18

10

19

17

8

9

33

32

27

29

26

28

7

6

5

35

14

4

15

12

13

16

18

3

23

24

25

30

21

22

37

34

11

31

36

DETAIL A DETAIL B

FF-MM-311-REV - 01

Page 14

Operation and Maintenance Guide Pneumatic Pressure Washer

Exploded View Detail-A for PW-200

31

11

7

10

19

17

8

9

32

33

6

18

20

2

5

35

14

4

15

16

DETAIL A

FF-MM-311-REV - 01

Page 15

Operation and Maintenance Guide Pneumatic Pressure Washer

Exploded View Detail-B for PW-200

23

3

12 13

24

25

30

21

22

37

34

36

DETAIL B

FF-MM-311-REV - 01

Page 16

Operation and Maintenance Guide Pneumatic Pressure Washer

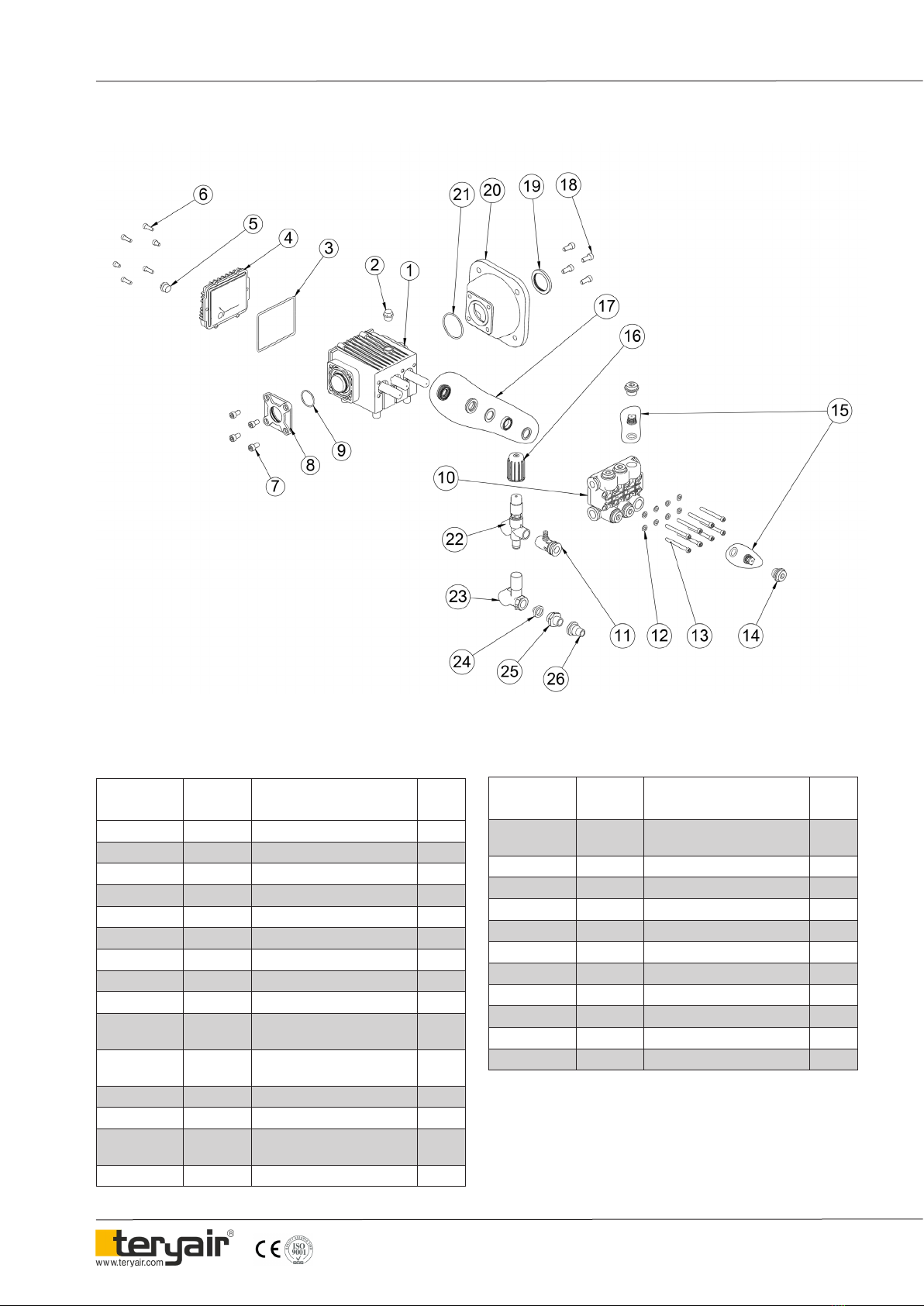

Exploded View pf High Pr. Pump PW200 Bar

Bill Of Material High Pressure Pump - PW200 Bar

Illustration

Number

Part

Number Description Qty

1 6429501 PUMP BODY 1

2 6429502 PLUG (RED) WITH O-RING 1

3 6429503 O- RING FOR END COVER 1

4 6429504 END COVER 1

5 6429505 DRAIN PLUG 1

6 6429506 BOLT FOR END COVER 4

7 6429507 BOLT FOR SAID COVER 4

8 6429508 SAID COVER 1

9 6429509 O-RING SAID COVER 1

10 6429510 PUMP HOUSING (BRASS)

110BAR 1

11 6429511 QC WITH CHEMICAL

INJECTOR 1

12 6429512 WASHER FOR PUMP HSG. 8

13 6429513 BOLT FOR PUMP HSG. 8

14 6429514 PLUG WITH O-RING

FOR PUMP HSG 6

15 6429743 VALVE REPLACEMENT KIT 6

Illustration

Number

Part

Number Description Qty

16 6429515 CAP FOR PRESSURE

REGULATOR 1

17 6429742 SEAL REPLACEMENT KIT 3

18 6429516 BOLT FOR FLANGE 4

19 6429517 OIL SEAL FOR FLANGE 1

20 6429518 FLANGE 1

21 6429519 O-RING FOR FLANGE 1

22 6429520 UNLOADER VALVE ASSY 1

23 6429521 INLET ASSY 1

24 6429522 INLET STRAINER 1

25 6429523 INLET ADOPTER 1

26 6429524 INLET NIPPLE 1

FF-MM-311-REV - 01

Page 17

Operation and Maintenance Guide Pneumatic Pressure Washer

TEST CERTIFICATE OF MATERIALS, PERFORMANCE

DATE :

MODEL NUMBER :

PART DESCRIPTION & S.NO. :

We Hereby Certify at e Above Referenced Product Has Tested And Inspected In Accordance With Our Standard Test Pro-

cedures And Meets e Specications For Material And Performance Values As Published In Our Literature. We Further Certify

at e Product Has Been Given Our Standard Factory Test. is Product Is Certied To Be Produced In Our Factory, And Is

Of Current Production. It Has Been Produced In A Workmanlike Manner And Meets All Quality And Performance Standards

Established By e Company

Authorised Signatory

Q.A Manager

Place - Vasai, Maharastra

FF-MM-311-REV - 01

Page 18

Operation and Maintenance Guide Pneumatic Pressure Washer

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description :

Model Number :

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and

Harmonized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16832

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2021

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-311-REV - 01

Page 19

Operation and Maintenance Guide Pneumatic Pressure Washer

Warranty Certificate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied

by the company be free from defects in material and workmanship for a period of six

months from date of Teryair authorized dealer invoice to customer, or one year from

date of Teryair invoice to dealer, whichever is earlier. Failure due to normal wear,

misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot

guarantee the suitability of any product or part for a particular application and Teryair

shall not be liable for any consequential damage or expense arising from the use or

misuse of its products on any application. Teryair does not warranty bought out

products or components such as electric motors and hardware but will assist in

directing warranty queries to the dealer/manufacturer responsible. Teryair

responsibility is limited solely to replacement or repair of defective Teryair products

or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if:

(i) a Product is altered, changed, modified or tampered with in any way, (ii) a Product is damaged after deposit with the

transporter for shipment; (iii) a Product is not properly preserved, packaged, stored, processed or handled after receipt; (iv) a

Product is not used and maintained in accordance with Teryair's recommended operating and maintenance manuals,

instructions and procedures, if any; (v) a Product is not properly incorporated or installed in, or not properly combined with, an

Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises

out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by

Teryair; (vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of,

compliance with any design, specification or other specific requirement of Dealer/End User; (viii) a Product is used in a manner,

with a substance or for a purpose other than the normal manner, substance and purpose for which it is intended or is otherwise

subjected to abnormal use or service; (ix) a Product is subjected to a power surge, brown out or other similar occurrence; (x)

the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, normal wear

and tear of such Product (including, without limitation, things such as worn seals, diaphragms, balls, O rings, gaskets, chisels,

cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Dated :

Product Model Number :

Product Serial Numbar : Ajay Bhagat, Q.A. Manager

(Company Seal)

Other manuals for PW-200

1

This manual suits for next models

1

Table of contents

Other Teryair Pressure Washer manuals