TI2000-009 Transformer

NOTE: All users must read this entire manual prior

to operating the TI2000-009 Transformer.

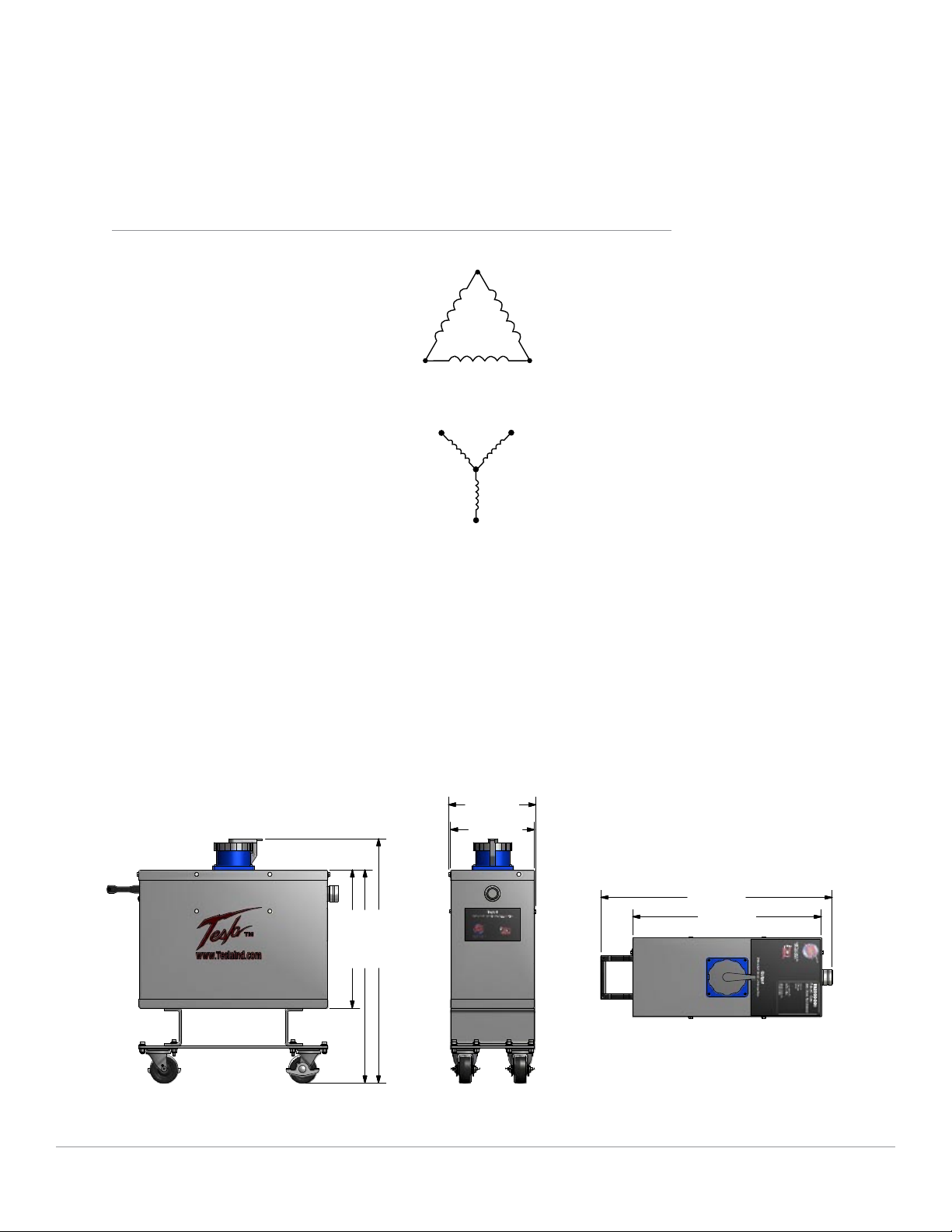

The TI2000-009 Step Down Transformer is a limited maintenance-free and sealed unit. No repairs are

authorized. Warranty will be voided if unit is tampered with in any way, or if unauthorized repairs are made.

For technical support please contact:

TESLA™ INDUSTRIES INCORPORATED

101 CENTERPOINT BLVD.

CENTERPOINT INDUSTRIAL PARK

NEW CASTLE, DELAWARE 19720

PHONE: (302) 324-8910

FAX: (302) 324-8912

WEBSITE: www.teslaind.com

EMAIL: tesla1@teslaind.com

Improper use or failure to follow instructions in this user manual can result in unit damage and/or injury or

death by electrical shock.

Any attempts to open or examine the inside of the TI2000-009 Step Down Transformer via a tool or device

(borescope, probe, etc.) can result in unit failure and/or injury by electrical shock.

Always protect the unit from short circuit.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying, recording, or any information storage and retrieval system, without prior

written permission from Tesla Industries, Inc.

Copyright © 2014 by Tesla™ Industries, Incorporated. All rights reserved.

Shock Hazard Potential

CAUTION

02-11-14