Tessera Technology AD-MS/PJ4 User manual

Motor Sensor Board

(AD-MS/PJ4)

Hardware Manual

Date published: July 2011 (First Edition)

Tessera Technology Inc.

- 1 -

CAUTION:

・ The information in this document is subject to change without notice.

・ No part of this document may be copied or reproduced in any form or by any means without

prior written consent of Tessera Technology Inc.

・ Tessera Technology Inc. assumes no responsibility for inaccuracies or misprints of this

document.

・ Tessera Technology Inc. does not license assurance or enforcement of intellectual property

rights and other rights of Tessera Technology Inc. and third parties by the use of the

products and/or the information in this document. Tessera Technology Inc. does not

assume any liability for infringement of rights of third parties by the use of the products

and/or the information in this document.

・ Descriptions of circuits, software and other related information in this document are

provided for illustrative purposes in semiconductor product operation and application

examples. The incorporation of these circuits, software and information in the design of a

customer's equipment shall be done under the full responsibility of the customer. Tessera

Technology Inc. assumes no responsibility for any losses incurred by customers or third

parties arising from the use of these circuits, software and information.

- 2 -

TABLE OF CONTENTS

1······································································································ 4Introduction

2··········································································································· 5Features

2.1

Resolver 1 I/O Connector (CN12)··········································································6

2.2

Motor Control 1 Connector (CN14) ········································································8

2.3

Analog Input Connector (CN7) ··············································································9

2.4

Digital I/O Connector (CN10) ············································································· 11

····································································································· 122.4.1 CAN

··································································································· 132.4.2 UART

·························································································· 152.4.3 Digital Output

····························································································· 162.4.4 Digital Input

2.5

Power Supply································································································· 17

- 3 -

1Introduction

This manual describes the features and hardware specifications of the Motor Sensor Board

(AD-MS/PJ4). The Motor Sensor Board is used with connecting to EB-850/PJ4E, which the 32-bit

single-chip microcomputer V850E2/PJ4-E from Renesas Electronics Corporation is mounted on.

- 4 -

2Features

CPU Board

Analog Input

Connector

Resolver 1

I/O Connector

Motor Control 1

Connector

Power

Digital I/O AC Adopter Input

CPU 用ボード接続

CPU Board

Connectors

- 5 -

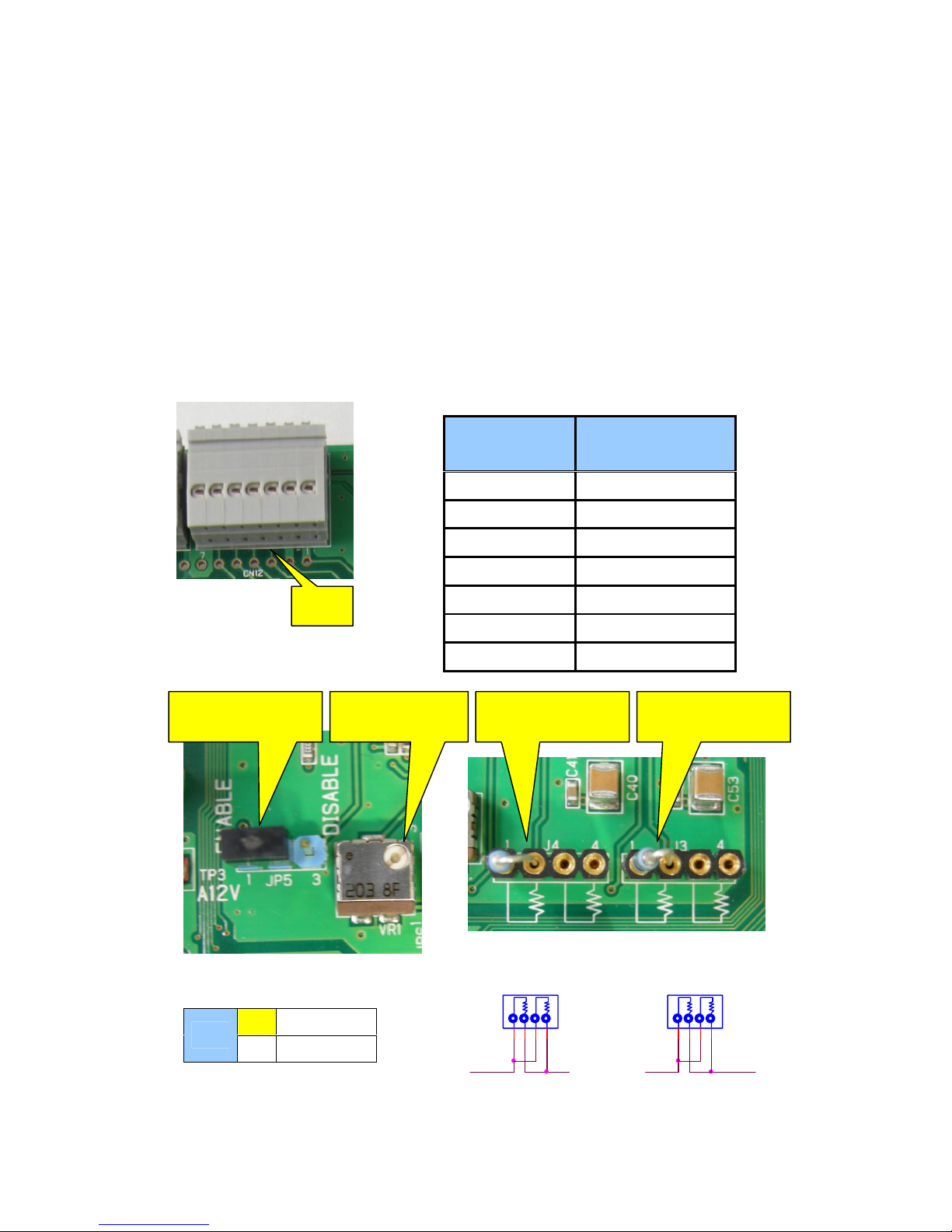

2.1 Resolver 1 I/O Connector (CN12)

This is the connector for excitation signals for resolver and SIN / COS signals for detection

coil.

Excitation signal outputs PWM signals through LPF (this can be set to disable. JP3) and

current AMP. It has variable resistance for level adjusting. Also, at the current AMP, it can

change the feedback adjusting resistance (J3,J4). As the default setting, the resistance is set

to 10kΩ. The feedback adjusting resistance can implement two parallel connections in one

socket.

The adjusting variable resistance (VR1) is a variable resistance of 20KΩ.

Connector Pin Signal Function

Number

1 Excitation Output +

2 Excitation Output -

3 SIN Input +

4 SIN Input -

5 COS Input +

CN12

6 COS Input -

7 AGND

The SIN, COS, and excitation signal of the detection coil are adjusted to the input level of the

microcomputer. It is connected to the microcomputer after noise canceling by LPF that is set

to Fc=234kHz for the level conversion and noise canceling purpose.

1-2 LPF Enable

JP5 2-3 LPF Disable

LPF Enable/Disable

Switch

Adjusting Variable

Resistance

Feedback Adjusting

Resistance

Feedback Adjusting

Resistance

J4

XR2C-3211-N(4pin)

3

4

1

2

J3

XR2C-3211-N(4pin)

3

4

1

2

- 6 -

For V850E2/PJ4-E, connections to CPU terminals are shown below.

Signals CPU Terminals

PWM Output P1_8/TPB0O/CSIG0SO/UARTH0TXD

Excitation Input + ADCA1I1/DFR10IM0

Excitation Input - DFR10IP0

SIN Input + ADCA1I2/DFR10IM1

SIN Input - DFR10IP1

COS Input - ADCA1I3/DFR10IM2

COS Input - DFR10IP2

- 7 -

2.2 Motor Control 1 Connector (CN14)

Motor Control 1 Connector is a connector to output digital signals for six-phase motor. It

connects six digital signals for UVW and one digital signal for gate block. The output is an open

drain output. It pulls up with 1KΩ for internal 5V.

Connector Signal Function

Pin Number

1 6-Phase PWM (Motor Control 1) U

2 6-Phase PWM (Motor Control 1) _U

3 6-Phase PWM (Motor Control 1) V

4 6-Phase PWM (Motor Control 1) _V

5 6-Phase PWM (Motor Control 1) W

6 6-Phase PWM (Motor Control 1) _W

CN14 7 Gate Block Output 1

8 DGND

Signals CPU Terminals

6-Phase PWM (Motor Control 1) U P1_1/TSG20O1

6-Phase PWM (Motor Control 1) _U P1_2/TSG20O2

6-Phase PWM (Motor Control 1) V P1_3/TSG20O3

6-Phase PWM (Motor Control 1) _V P1_4/TAUJ0O0/TSG20O4

6-Phase PWM (Motor Control 1) W P1_5/TAUJ0O1/TSG20O5

6-Phase PWM (Motor Control 1) _W P1_6/TAUJ0O2/TSG20O6

Gate Block Output 1 P4_2/UARTH2RTS/TSG20PTSI1/ENCA0E1/CSIG2SO

- 8 -

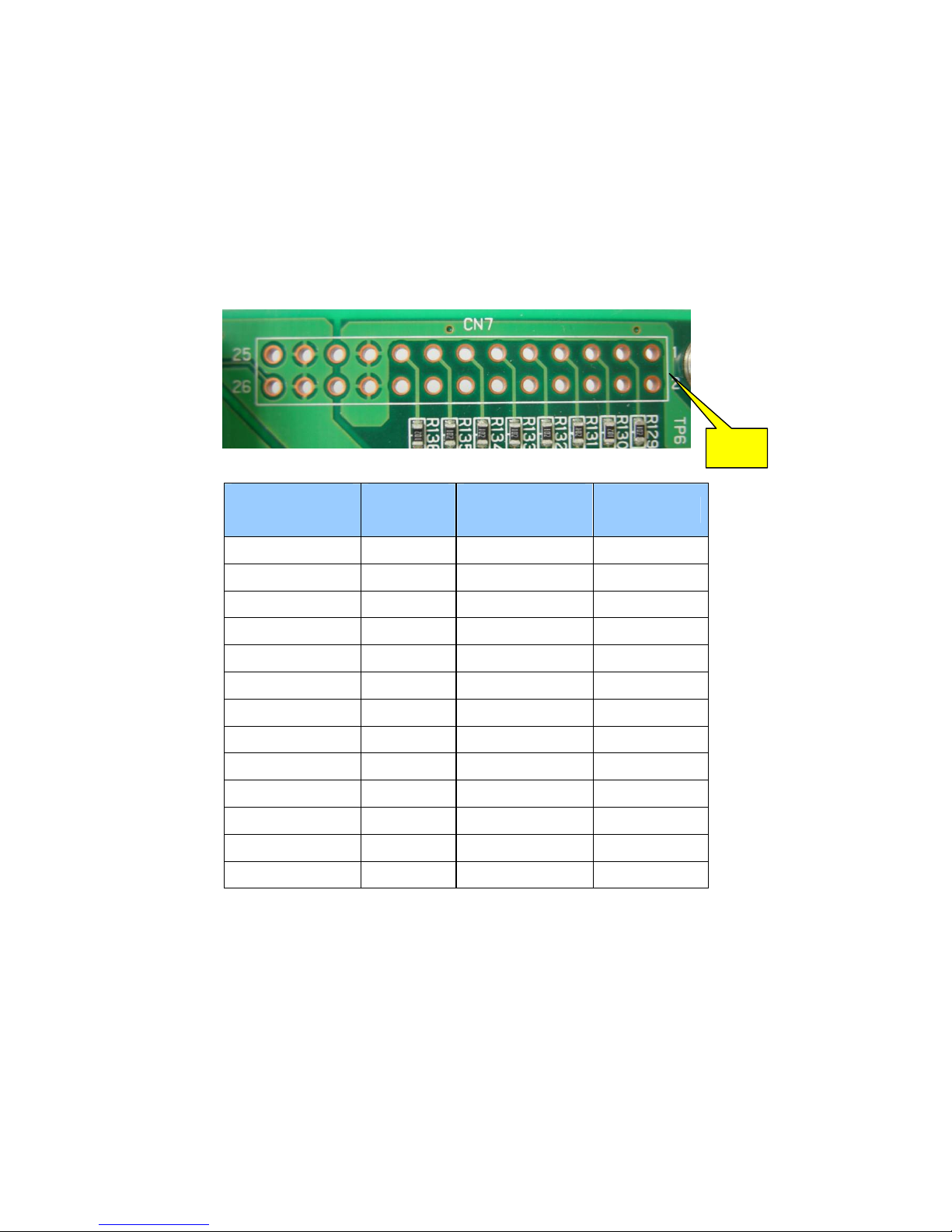

2.3 Analog Input Connector (CN7)

The Analog Input Connector is connected to CPU analog input terminal with adding protection

diode and resistance. The connector itself is not mounted, and it is 2.54pitch through-hole.

To use it for controlling, it has 1 digital input function. For some analog and digital signals, the

connection destination can be changed by JP settings.

CN7

Connector Pin Signal Connector Pin Signal Function

Number Function Number

1 A5V 2 A5V

3 ADCA0I1 4 ADCA0I2

5 ADCA0I3 6 ADCA0I4

7 AIN0 8 AIN1

9 ADCA0I14 10 ADCA0I15

11 ADCA0I16 12 ADCA0I17

13 ADCA0I18 14 ADCA0I19

15 ADCA0I20 16 ADCA0I21

17 ADCA0I22 18 ADCA0I8

19 AGND 20 AGND

21 NC 22 NC

23 DGND 24 DGND

25 DGND 26 Digital Input

- 9 -

Signals CPU Terminals

ADCA0I1 ADCA0I1

ADCA0I2 ADCA0I2

ADCA0I3 ADCA0I3

ADCA0I4 ADCA0I4

ADCA0I14 ADCA0I14

ADCA0I15 ADCA0I15

ADCA0I16 ADCA0I16

ADCA0I17 ADCA0I17

ADCA0I18 ADCA0I18

ADCA0I19 ADCA0I19

ADCA0I20 ADCA0I20

ADCA0I21 ADCA0I21

ADCA0I22 ADCA0I22

ADCA0I8 ADCA0I8

JP8:1-2 JP9:OPEN ADCA0I5

AIN0

JP8:2-3 JP9:SHORT ADCA0I10

JP12:1-2 JP13:OPEN ADCA0I6

AIN1 JP12:2-3 JP13:SHORT ADCA0I11

JP15:1-2 P0_5/TAUJ0I2/TAUJ0O2/UARTH2RXD/INTP2/CSIG0SI

Digital Input JP15:2-3 OPEN

JP13

JP9

JP15

JP12

JP8

- 10 -

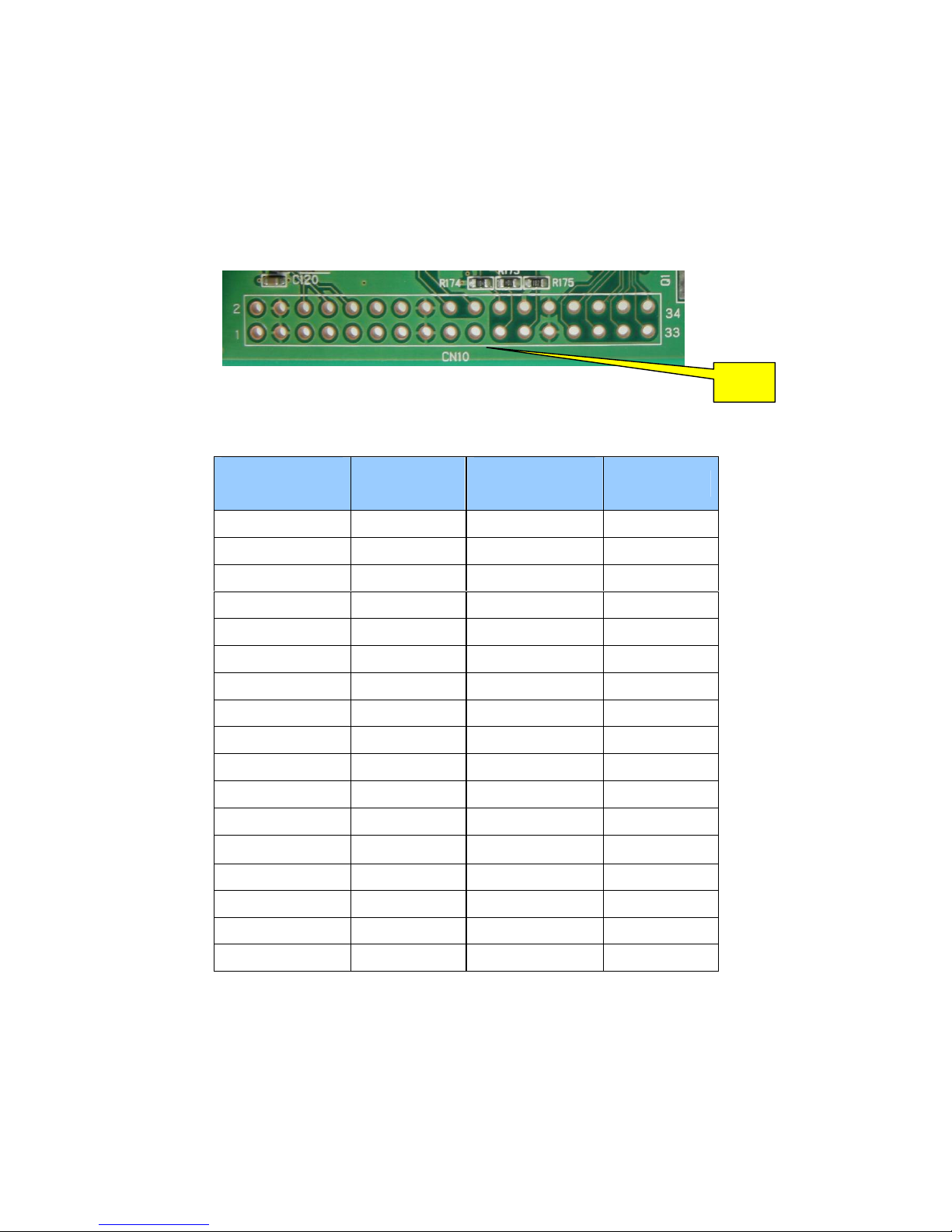

2.4 Digital I/O Connector (CN10)

The Digital I/O Connector is a connector with the functions for I/O of digital signals, UART

signals ( 5V level), and CAN communication. The connector itself is not mounted, and it is

2.54pitch through-hole.

CN10

Connector Pin Connector Pin

Signal Function Signal Function

Number Number

1 D5V 2 CN_RESO1

3 DGND 4 DGND

5 CN_LED1 6 CN_LED2

7 CN_LED3 8 CN_LED4

9 CN_LED5 10 CN_LED6

11 D5V 12 D5V

13 CN_CANH 14 CN_CANL

15 DGND 16 DGND

17 CN_UART0_TX 18 CN_UART0_RX

19 CN_UART1_TX 20 CN_UART1_RX

21 CN_BUSY0 22 CN_BUSY1

23 CN_RESETOUT 24 D5V

25 DGND 26 DGND

27 CN_SW1 28 CN_SW2

29 CN_SW3 30 CN_SW4

31 CN_SW5 32 CN_SW6

33 CN_ER1 34 CN_ER2

- 11 -

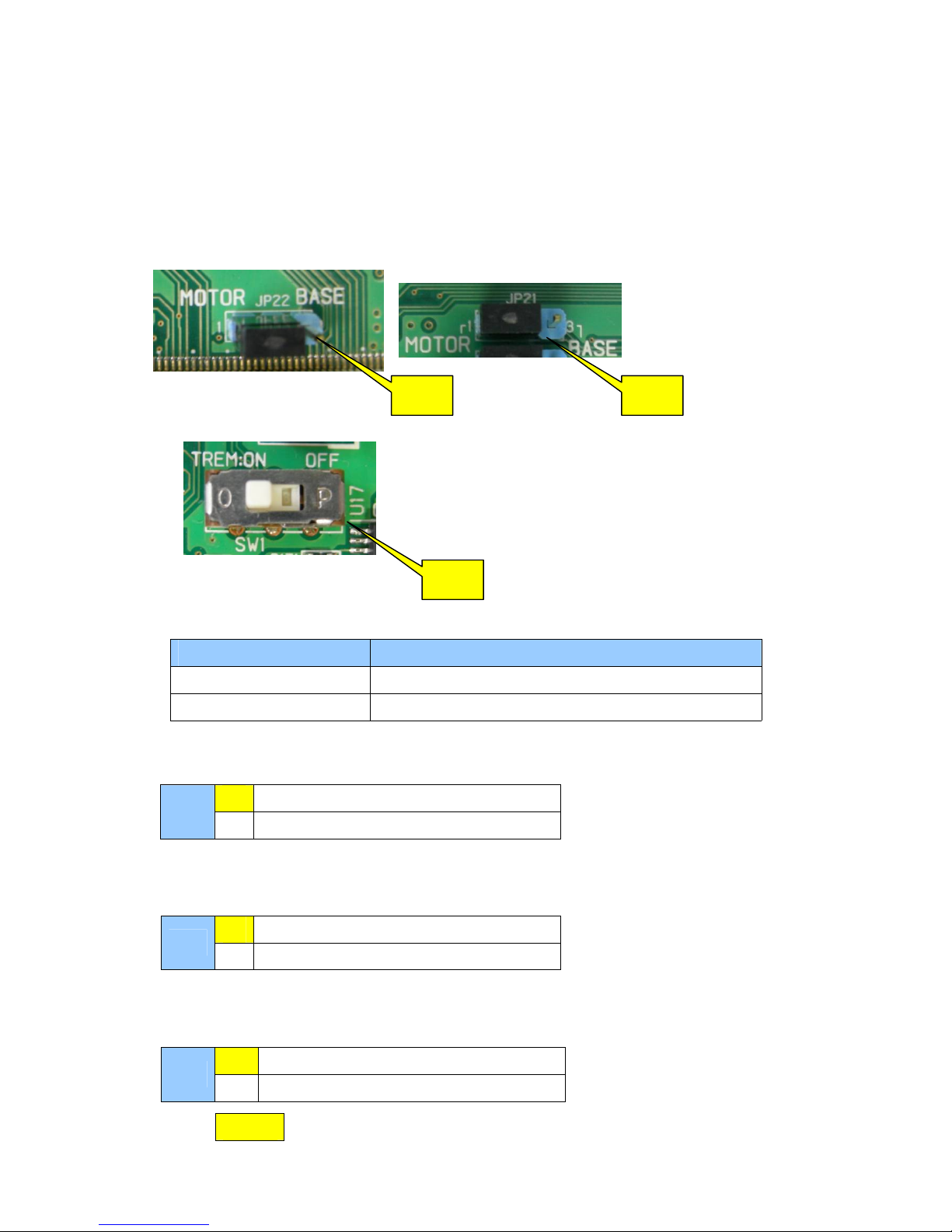

2.4.1 CAN

The communication signals from CPU board are connected to the connectors through CAN

transceiver.

It can be disconnected from the CAN transceiver on the motor board with JP setting. Also, the

termination resistance can be ON/OFF with SW

JP22 JP21

SW1

Signals CPU Terminals

transceiver TX P0_3/FCN0TX/UARTH0CTS/MODE1

transceiver RX P0_4/FCN0RX/UARTH0RTS

P0_3/FCN0TX/UARTH0CTS/MODE1 Connection Destination Settings

1-2 Connect to MOTOR Board Transceiver

JP21 2-3 Connect to BASE Board

P0_4/FCN0RX/UARTH0RTS Connection Destination Settings

1-2 Connect to MOTOR Board Transceiver

JP22

2-3 Connect to BASE Board

CAN Communication Line Termination Resistance Settings

ON Connect to Termination Resistance (120Ω)

SW1 OFF No Connection to Termination Resistance

Default

- 12 -

2.4.2 UART

The communication signals from CPU are connected to the connectors through buffer. The

output is an open drain output. It pulls up for internal power. It can be disconnected with jumper

setting.

Signals CPU Terminals

CN_UART0_TX P0_1/INTP4/ADCA0TRG1/CSIG0SO/UARTH0TXD/FCN1RX

CN_UART0_RX P0_0/INTP5/ADCA0TRG2/CSIG0SI/UARTH0RXD/INTP0/FCN1TX

CN_UART1_TX P3_1/TAUA1I3/TAUA1O3/TAUA1I2/TAUA1O2/UARTH1TXD/TAUA1O12

CN_UART1_RX P3_0/TAUA1I1/TAUA1O1/TAUA1I0/TAUA1O0/UARTH1RXD/INTP1/TAUA1O10

P0_1/INTP4 TXD/FCN1RX Connection Destination Settings

P0_0/INTP5/ADCA0TRG2/CSIG0SI/UARTH0RXD/INTP0/FCN1TX Connection Destination

Setti

P3_1/TAUA1I3/TAUA1O3/TAUA1I2/TAUA1O2/UARTH1TXD/TAUA1O12 Connection Destination

Settings

/ADCA0TRG1/CSIG0SO/UARTH0

ngs

1-2 Connect to MOTOR Board

JP23 2-3 Connect to BASE Board

1-2 Connect to MOTOR Board

JP24 2-3 Connect to BASE Board

1-2 Connect to MOTOR Board

JP25 2-3 Connect to BASE Board

JP23

JP24

JP25

JP26

- 13 -

P3_0/TAUA1I1/TAUA1O1/TAUA1I0/TAUA1O0/UARTH1RXD/INTP1/TAUA1O10 Connection

Destination S

ettings

1-2 Connect to MOTOR Board

JP26 2-3 Connect to BASE Board

- 14 -

2.4.3 Digital Output

The communication signals from CPU are connected to the connectors through buffer. The

output is an open drain output. It pulls up for internal power.

Signals CPU Terminals

CN_RESETOUT P6_0/CSIG2SI/TAUA0O12/TSG20O0/SIF0OE0

CN_LED1 P0_7/TAUJ0I0/TAUJ0O0/CSIG0SC

CN_LED2 P3_7/TAUA1I15/TAUA1O15/TAUA1I14/TAUA1O14/CSIG2RYI

CN_LED3 P4_1/UARTH2CTS/TSG20PTSI0/ENCA0E0/CSIG2SI

CN_LED4 P6_1/CSIG2SO/TAUA0O10/SIF0OE1

CN_LED5 P6_2/CSIG2SC/TAUA0O11//SIF0OE

CN_LED6 P7_7/TAUA0I14/TAUA0O14/TSG21O7/NMI/CSIH0CS7

- 15 -

2.4.4 Digital Input

The communication signals to CPU are connected through buffer. Some specific signals can be

disconnected with jumper setting. Also, the connections of CN_RESO1 can be selected.

JP20

JP24

Jumper

Signals CPU Terminals Settings

CN_SW1 1-2

P0_2/INTP3/ADCA0TRG0/CSIG0SC/UARTH0SC

CN_SW 2 3-4

P4_4/TAUJ0I0/UARTH1RTS/ESO0/INTP6/CSIG0RYO/CSIH0RYI/ADCA1TRG0

CN_SW 3 5-6

P6_3/UARTH1RXD/INTP1/TAUA1O10

CN_SW 4 7-8

P6_6/UARTH0RXD/INTP0/TAUA1O13

CN_SW 5 P6_7/UARTH0SC/TAUA1O14 9-10

JP20

CN_SW 6 11-12

P6_8/UARTH0TXD/TAUA1O15

CN_ER1 13-14

P4_6/TAUJ0I2/ADCA0CNV1/ESO2/INTP8/CSIH0SO/ADCA1TRG2/ADCA1CNV1

CN_ER2 15-16

P4_7/NMI/TAUJ0I3/ADCA0CNV0/ESO3/INTP9/ADCA1CNV0/CSIH0SC

CN_RESO1 JP18

P0_6/TAUJ0I1/TAUJ0O1/UARTH2TXD/CSIG0SO

CN_BUSY0 -

P6_4/UARTH1SC/TAUA1O11

CN_BUSY1 -

P6_5/UARTH1TXD/TAUA1O12

P0_6/TAUJ0I1/TAUJ0O1/UARTH2TXD/CSIG0SO Connection Destination Settings

1-2 Connect to MOTOR Board

JP18

2-3 Connect to BASE Board

- 16 -

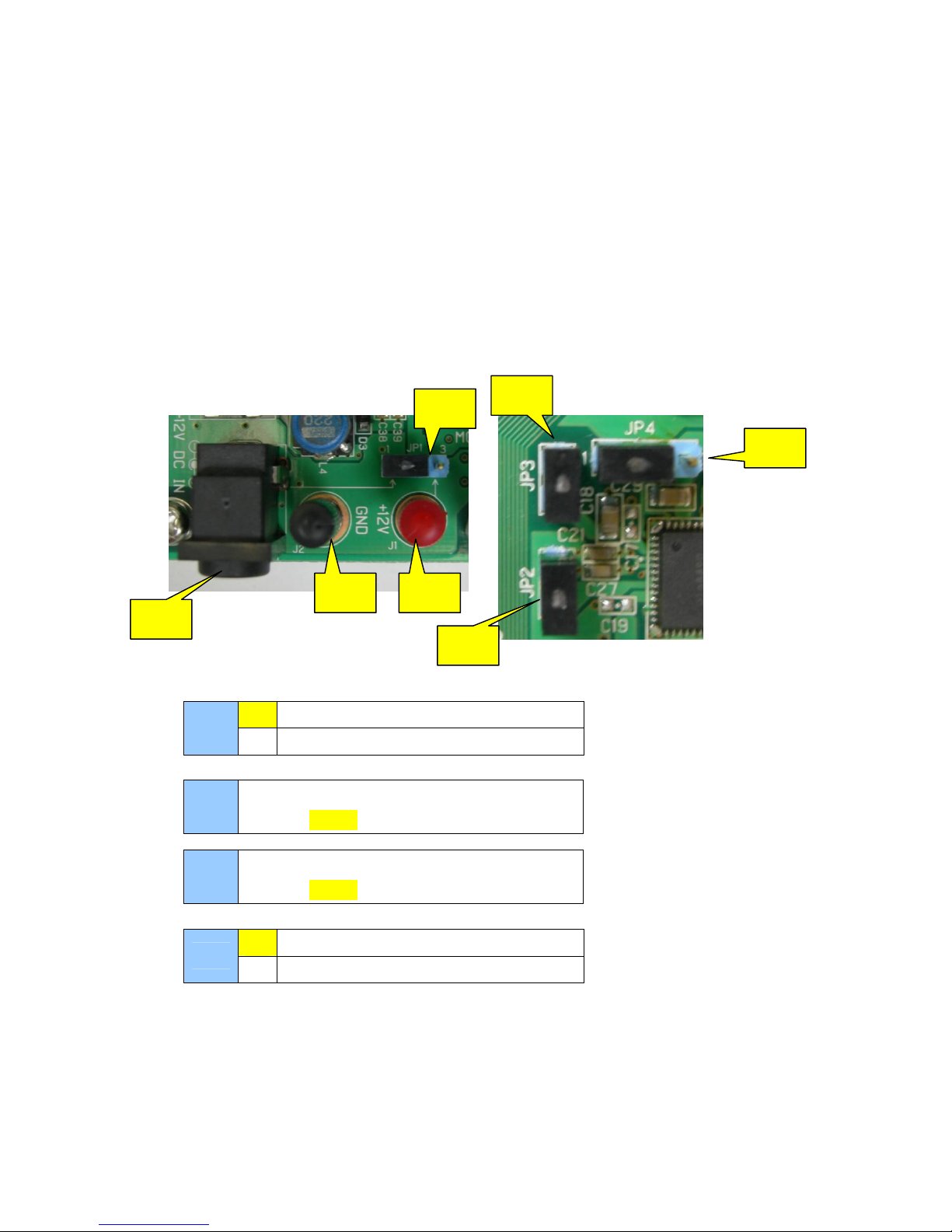

2.5 Power Supply

There are two ways to supply power. One is to supply power from AC JACK (CN4), another is to

supply power from the terminal. The power supply can be selected with JP1. The power voltage

is 12V. Also, there are jumpers for measuring current using on Motor board; D5V (JP2) for digital

and A5V (JP3) for analog.

JP4 is a jumper for controlling power when it is use as stand-alone. Do not change this normally.

Also, this board supplies power to CPU board and Base board when you use Motor board. In this

case, do not supply power to those boards directly.

1-2 Use AC JACK (CN4)

JP1 2-3 Use J1,J2 Terminals

JP2 Digital 5V Current Measurement

Normally, SHORT

JP3 Analog 5V Current Measurement

Normally, SHORT

1-2 When Using with CPU Board

JP4 2-3 When Stand-alone Use

JP3

JP1

JP4

J2 J1

CN4

JP2

- 17 -

Table of contents