TESSERA EB-RE01B User manual

1 / 23

TESSERA TECHNOLOGY INC.

TS-TUM09735

Ver 1.02 (2021/3/22)

EB-RE01B

Hardware Manual

2 / 23

TESSERA TECHNOLOGY INC.

Change history

Version

Date

Description

1.00

2021/1/28

Initial version

1.01

2021/3/17

Changed P4, P7

1.02

2021/3/22

Power supply setting explanations are added

Cautionary Notes:

・The contents of this document are subject to change without notice.

・Reproduction of this document in any format is prohibited without written permission from Tessera Technology Inc. (herein

“the Company”).

・This product was designed and fabricated for design engineers for the purpose of evaluation and becoming familiar with

product safety and reliability characteristics.

・The company shall not be liable for the infringement of third party patent, copyrights, or other intellectual property rights

arising from the use of Tessera Technology products in listed in this document. The company does not grant any rights

concerning Tessera Technology or third party patents, copyrights, or other intellectual property rights based on this material.

・Circuitry, software or related information included in this document is provided as semiconductor product operation examples

and application examples. The user is responsible for the appropriate application of the circuitry, software or related

information when designing equipment. The company shall not be liable for loss or damage incurred by the user or other third

party based on the use of this circuitry, software or related information.

・Please handle this product as you would a CMOS device. The user should be particularly careful to protect himself/herself from

accumulated static electricity when using this product.

・Make sure all test and measurement equipment, including the work station, are properly grounded.

・The user should wear an ESD wrist strap to prevent any buildup of static electricity.

・Do not touch connectors or device pins with bare hands

3 / 23

TESSERA TECHNOLOGY INC.

Contents

1. Board overview .................................................................................................4

2. Specification .....................................................................................................4

3. Power supplying mode .......................................................................................5

VCC-IN supply, Normal power supply operation ...............................................6

USB bus power supply, Normal power supply operation ....................................7

Emulator E2 supply, Normal power supply operation ......................................8

Emulator J-Link supply, Normal power supply operation................................ 10

EH(Energy harvest) power supply operating.................................................. 11

4. Startup mode.................................................................................................. 13

Normal startup mode explanation ................................................................ 13

SWD debug mode explanation ..................................................................... 13

Energy harvest start-up mode ..................................................................... 14

SCI boot mode .......................................................................................... 14

5. Explanation of each part................................................................................... 15

Component Layout (Face side)..................................................................... 15

Component Layout (Back side) .................................................................... 16

LED.......................................................................................................... 17

Switch ...................................................................................................... 17

External clock............................................................................................ 17

I/F Connector ............................................................................................ 18

Current measurement ................................................................................ 21

6. Circuit diagram................................................................................................ 22

4 / 23

TESSERA TECHNOLOGY INC.

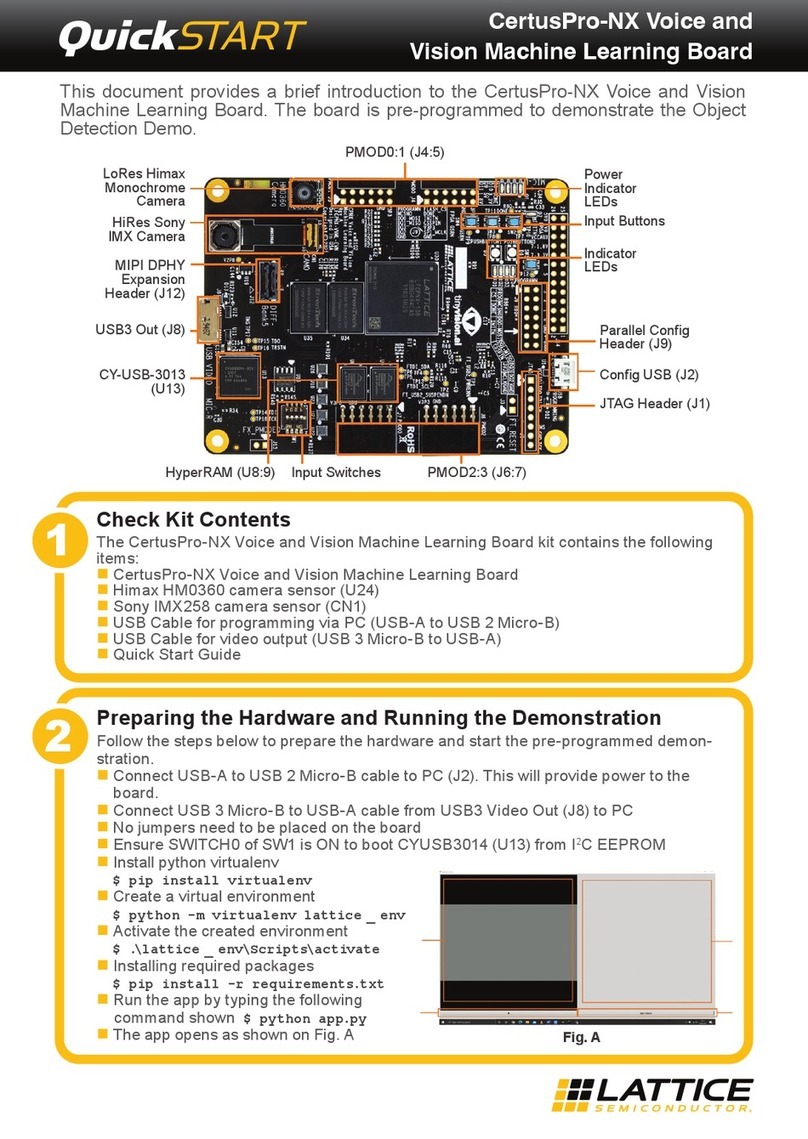

1. Board overview

EB-RE01B board supplies development environment for the RE01B microcomputer

energy harvest control function with Ultra-low current consumption operation and the

software evaluation of the Bluetooth Low Energy(BLE).

2. Specification

MCU

RE01B 64pin, Flash1.5MB, RAM256KB(R7F0E01BD2DNB)

MCU voltage

VCC :1.62~3.6V

VCC_RF :1.8~3.6V

Internal regulated

voltage

Output voltage 3.3V(USB CN4、SWD CN1(11/13Pin) supply)

Main external oscillator

32MHz crystal resonator

Sub external oscillator

32.768kHz crystal resonator

BLE external oscillator

32MHz crystal resonator

I/F

USB connector(USB-Serial bridge、 general purpose

UART/programming)

SWD 20pin 1.27mm Pitch connector(19pin Cortex-M)

PmodTM connector x2(12Pin SPI/12Pin UART)

switches

Reset switch

General purpose momentary switch

MCU mode setting switches x2

Discharge switches x2

LED

Power supply LED

general purpose LED

USB-Serial transmission LED x2

Radio standard

Bluetooth 5.0 Low Energy single mode

Japanese radio law

standard

2.4 GHz band wide-band low-power data communication

system

Radio frequency

2402MHz~2480MHz

RF power

+4dBm

Antenna

Dielectric chip antenna

Please refer to the MCU hardware manual for more detail.

5 / 23

TESSERA TECHNOLOGY INC.

3. Power supplying mode

There are two power supply methods, “Normal power supply mode” supplies internal

board power and “EH mode (energy harvesting mode)” supplies MCU VCC by EHC

(energy harvesting controller) from a power generating device.

Power

operating

mode

Power source

Description

Normal

power

supply

operation

External power supply

(VCC-IN terminal)

Directly supply internal board power from a stable

power supply

USB

Generate internal board power from the USB bus

power

Emulator E2

Directly supply internal board power from E2

emulator

Emulator J-Link

Generate internal board power with supplied power

from J-Link Emulator

EH

operation

Energy generating

device(VSC_VDD)

Supply MCU VCC from a power generating device

via EHC

⚫Power supply block diagram

MCU

VCC

USB

Voltage

Regulator

Emulator J-Link

Emulator E2

EHC

VSC_VCC

Power generating device

VCC-IN terminal

6 / 23

TESSERA TECHNOLOGY INC.

VCC-IN supply, Normal power supply operation

This mode supplies internal board power directly from stable power supply.

Set short-pin and switches below, then supply voltage to TP1(+) TP2(-) for MCU etc.

short-pin and switch setting

Reference number

Setting

Reference number

Setting

SW3

S_Chip(Single chip mode)

JP1

Close

SW4

Normal

JP2

Close

JP3

Close

JP4

1-2(VCC-IN)

JP5

Open

JP7

1-2(Normal mode)

JP8

1-2(Normal mode)

JP9

1-2(Normal mode)

JP10

-(Don’t care)

JP11

-(Don’t care)

JP12

Open

JP13

-(Don’t care)

7 / 23

TESSERA TECHNOLOGY INC.

USB bus power supply, Normal power supply operation

This mode generate internal board power using a USB bus power.

Set short-pin and switches below, then connect a USB cable to the USB connecter (CN4).

short-pin and switch setting

Reference number

Setting

Reference number

Setting

SW3

S_Chip(Single chip mode)

JP1

Close

SW4

Normal

JP2

Close

JP3

Close

JP4

2-3(Regulator Out)

JP5

1-2(USB)

JP7

1-2(Normal mode)

JP8

1-2(Normal mode)

JP9

1-2(Normal mode)

JP10

-(Don’t care)

JP11

-(Don’t care)

JP12

Open

JP13

-(Don’t care)

8 / 23

TESSERA TECHNOLOGY INC.

Emulator E2 supply, Normal power supply operation

This mode supplies internal board power directly from a E2 emulator (E2 emulator Lite).

Set short-pin and switches below, then connect a E2 emulator to the SWD I/F(CN1).

Set the “e2 studio” power supply setting to output 3.3V from the E2 emulator.

short-pin and switch setting

Reference number

Setting

Reference number

Setting

SW3

S_Chip(Single chip mode)

JP1

Close

SW4

Normal

JP2

Close

JP3

Close

JP4

Open

JP5

Open

JP7

1-2(Normal mode)

JP8

1-2(Normal mode)

JP9

1-2(Normal mode)

JP10

-(Don’t care)

JP11

-(Don’t care)

JP12

Open

JP13

-(Don’t care)

9 / 23

TESSERA TECHNOLOGY INC.

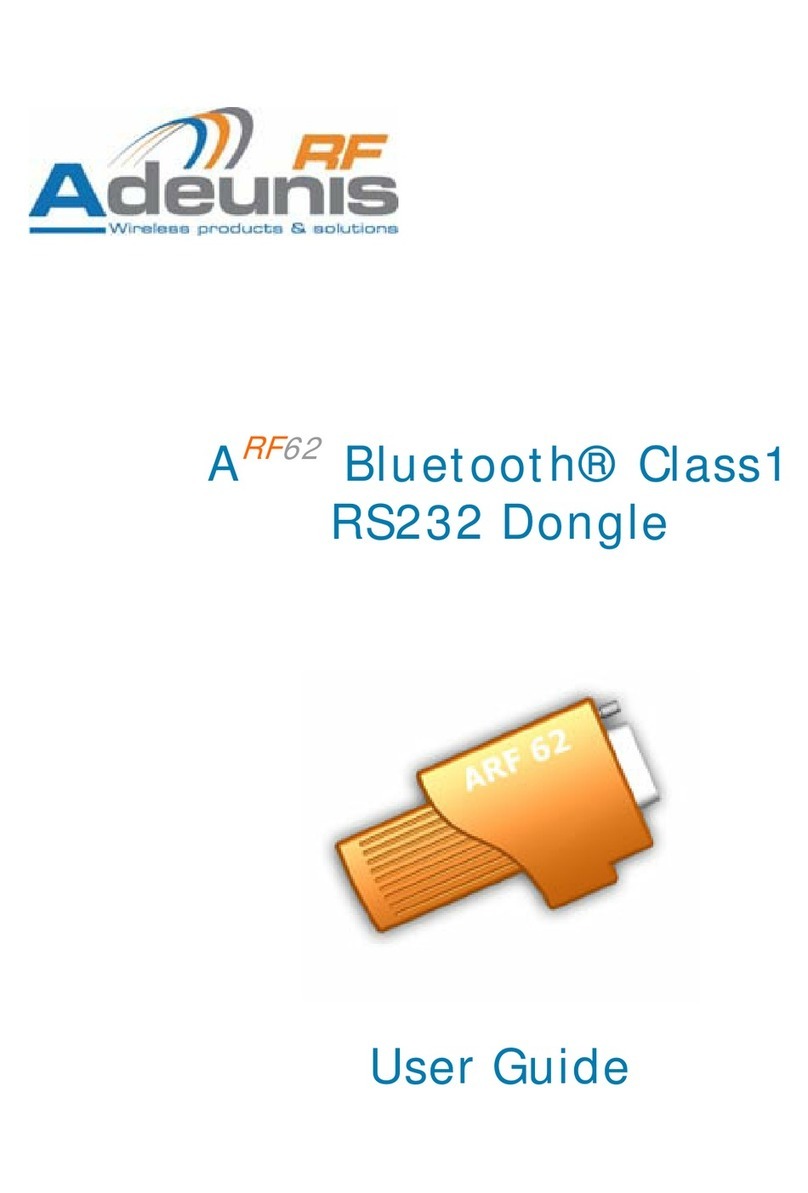

⚫“e2 studio” power supply setting

10 / 23

TESSERA TECHNOLOGY INC.

Emulator J-Link supply, Normal power supply operation

This mode generate internal board power using supply of the J-Link emulator etc.

Set short-pin and switches below, then connect a J-Link emulator to the SWD I/F(CN1)

via J-Link Adapter“.

Generate a internal board power using the supply to pin No.11 and 13 on the CN1 by the

J-Link Emulator.

short-pin and switch setting

Reference number

Setting

Reference number

Setting

SW3

S_Chip(Single chip mode)

JP1

Close

SW4

Normal

JP2

Close

JP3

Close

JP4

2-3(Regulator Out)

JP5

2-3(Emulator)

JP7

1-2(Normal mode)

JP8

1-2(Normal mode)

JP9

1-2(Normal mode)

JP10

-(Don’t care)

JP11

-(Don’t care)

JP12

Open

JP13

-(Don’t care)

11 / 23

TESSERA TECHNOLOGY INC.

EH(Energy harvest) power supply operating

This mode supply the power from power generating device via EHC(Energy Harvesting

Controller)

Set short-pin and switches below, then connect a power generating device to the

TP11(+) TP12(-) (VSC_VCC).

short-pin and switch setting

Reference number

Setting

Reference number

Setting

SW3

S_Chip(Single chip mode)

JP1

Open

SW4

EHC

JP2

Close

JP3

Close

JP4

Open

JP5

Open

JP7

2-3(EHC mode)

JP8

2-3(EHC mode)

JP9

2-3(EHC mode)

JP10

Open

JP11

Open

JP12

Open

JP13

Open

12 / 23

TESSERA TECHNOLOGY INC.

Connect a rechargeable battery or EDLC to VBAT_EHC(TP9(+) TP10(-)).

Connect a attached capacitor (10μF) to C2(MCU_VCC).

Supply the power to the EHC(VSC_VCC) with limitation of 4.0V/10mA.

“VCC_SU” (storage capacitor) on EHC is connected a 100μF capacitor.

Please refer to the “4.3Energy harvest start-up mode” for EHC startup.

13 / 23

TESSERA TECHNOLOGY INC.

4. Startup mode

There are 3 startup mode below.

switch setting

Startup mode

MD

(SW3)

EHMD

(SW4)

description

Normal startup

S_Chip

Normal

Run the user program on code flash memory

SWD Debug

connect emulator with SWD interface

Energy harvest

startup

EHC

Run the user program with EHC

SCI boot mode

Boot

-

Program the flash memory with USB connecting

Normal startup mode explanation

Set switches below and release the reset, then the board starts running the user

program on code flash memory.

Please use on Normal power supply operation mode.

Normal startup mode switch setting

Reference number

Setting

MD(SW3)

S_Chip(Single chip mode)

EHMD(SW4)

Normal

SWD debug mode explanation

Set switches below and connect E2 emulator to “SWD I/F (CN1)“, then you can connect

emulator with SWD interface.

Usuary this mode is used on Normal power supply operation mode, however some low

power consumption mode cannot entering to OCD mode.

Please refer to the MCU hardware manual for more detail.

SWD debug mode switch setting

Reference number

Setting

MD(SW3)

S_Chip(Single chip mode)

EHMD(SW4)

Normal

14 / 23

TESSERA TECHNOLOGY INC.

Energy harvest start-up mode

This mode running with the EHC.

Please use on “3.5EH(Energy harvest) power supply operating”.

When the power generator device connected to the VSC_VCC finishes charging the

capacitor connected to the VCC_SU, then EHC stars supply of power to the VCC.

When the reset releases by a power-on reset, back bias voltage control (VBBC) circuit

also enabled, then Run the user program on code flash memory.

Energy harvest start-up mode switch setting

Reference number

Setting

MD(SW3)

S_Chip(Single chip mode)

EHMD(SW4)

EHC

SCI boot mode

The flash memory can be programmed by using a RFP(Renesas Flash Programmer).

Set short-pin and switches below, then connect a USB cable to the USB connecter (CN4).

Please use on Normal power supply operation mode.

SCI boot mode switch setting

Reference number

Setting

Reference number

Setting

SW3

Boot(SCI boot mode)

JP1

Close

SW4

-(Don’t care)

JP2

Close

JP3

Close

JP4

-(Don’t care)

JP5

1-2(USB)

JP7

1-2(Normal mode)

JP8

1-2(Normal mode)

JP9

1-2(Normal mode)

JP10

1-2(RFP)

JP11

2-3(RFP)

JP12

Open

JP13

Close

15 / 23

TESSERA TECHNOLOGY INC.

5. Explanation of each part

Component Layout (Face side)

JP2

JP3

JP4

JP5

SW5

JP1

SW2

PMOD2

SW1

JP13

JP12

JP11

JP10

CN4

CN1

SW4

SW3

SW6

JP9

JP7

JP8

PMOD1

C2

16 / 23

TESSERA TECHNOLOGY INC.

Component Layout (Back side)

17 / 23

TESSERA TECHNOLOGY INC.

LED

Reference

number

Connection

Explanation

LED1

CPU_VIN

Turned on when internal MCU power supply.

LED2

MCU P506

General use LED.

LED is turned on with P506 Low output.

LED3

FT232RL Tx

LED is turned on when USB-Serial converter accessed

on the USB connecter (CN4).

LED4

FT232RL Rx

Switch

Mode setting switches

Reference number

Connection

Explanation

SW3

MD/P201

Single Chip Mode / SCI boot mode

SW4

EHMD

Normal Mode / EHC Mode

Momentary switch

Reference number

Connection

Explanation

SW1

RES#

MCU reset

SW2

P505/IRQ1_C

General use push switch.

If you push the switch, Signal connect to the GND.

SW5

(MCU_VCC)

Discharge the MCU_VCC.

SW6

(VCC_SU)

Discharge the VCC_SU.

External clock

Reference

number

Connection

Explanation

XTAL1

Main clock oscillator(MOSC)

32MHz crystal resonator

XTAL2

Sub clock oscillator(SOSC)

32.768kHz crystal resonator

XTAL3

clock oscillator for Bluetooth (BLECLK)

32MHz crystal resonator

Please set the Sub-Clock Oscillator Drive Capability (SODRV、SODRV0) to “Low CL4”

below.

SODRV = 1、 SODRV0 = 0

18 / 23

TESSERA TECHNOLOGY INC.

I/F Connector

SWD I/F(CN1)

You can make debugger connection on the SWD debug mode by connecting E2 emulator,

E2 emulator Lite, IAR I-jet and SEGGER J-Link.

20pin 1.27mm Pitch connector is mounted.

“19pin Cortex-M Adapter” perhaps be require.

Do not set the JP10 and JP11 to ” 1-2(RFP)”.

Connecter signal and connection

Pin

connection

Pin

connection

1

VCC (internal voltage)

2

SWDIO

3

GND

4

SWCLK

5

GND

6

Pull-Up

7

-

8

N.C.

9

GND

10

RESET

11

5V (Voltage regulator input)

12

Pull-Down

13

5V (Voltage regulator input)

14

N.C.

15

GND

16

N.C.

17

GND

18

N.C.

19

GND

20

N.C.

USB connector (CN4)

This connector is connected to a USB-Serial transfer IC, and is recognized as a virtual

COM port by a PC.

Please download a USB driver from below URL.

URL: http://www.ftdichip.com/

Usually, the USB driver is install automatically on Windows PC.

You can use a virtual COM port as general purpose UART or serial programming with SCI

boot mode.

Set JP13 short-pin close.

19 / 23

TESSERA TECHNOLOGY INC.

When you do the serial programming with the SCI boot mode, set the short-pin below.

Do not connect emulator to SWD I/F(CN1) when using with SCI boot mode.

When you make the serial communication by UART, set the short-pin below.

Do not connect anything to PmodTM connecter(CN3、CN7) when you use a UART.

PmodTM connecter(CN3)

This connector is a Digilent PmodTM compatible connector as the 12pin SPI connection.

When you use this connecter, set JP10, JP11 OPEN and do not connect anything to

PmodTM connecter (CN7).

Pin

connection

Pin

connection

1

P606

7

P300

2

P609

8

P301

3

P608

9

P305

4

P607

10

P704

5

D_GND

11

D_GND

6

IOVCC1

12

IOVCC1

Reference number

Settings

JP10

1-2(RFP)

JP11

2-3(RFP)

JP12

Open

JP13

Close

Reference number

Settings

Connection

JP10

2-3(UART)

P609(TXD2_C)

JP11

2-3(UART)

P608(RXD2_C)

JP12

1-2(CTS)

2-3(RTS)

P607

JP13

Close

20 / 23

TESSERA TECHNOLOGY INC.

PmodTM connecter(CN7)

This connector is a Digilent PmodTM compatible connector as the 12pin UART connection.

When you use this connecter, set JP10, JP11 OPEN and do not connect anything to

PmodTM connecter (CN3).

Pin

connection

Pin

connection

1

P607

7

P107

2

P609

8

P112

3

P608

9

P113

4

P606

10

P012

5

D_GND

11

D_GND

6

IOVCC1

12

IOVCC1

Table of contents

Other TESSERA Computer Hardware manuals