TeSuCo Oxyturbo Nitrogen 6000 User manual

1

Operating Instructions

Nitrogen 6000 Regulator

HVAC-R High Flow

www.tesuco.com.au

QUALITY GAS EQUIPMENT

2

CAUTION

1. FUNCTION

TECHNICAL DATA

Read the following instructions carefully before using the

pressure regulator, and keep them for future reference.

The instructions provide all the information necessary

for correct use of the instrument, to avoid damage and

danger. Tesuco®/OxyTurbo is not responsible for any

damage occurring due to incorrect use of the instrument,

or to modifications made to it.

The function of the pressure regulator is to reduce and stabilize the pressure of a gas; the

regulator changes the pressure at which the gas is kept in the cylinder into the pressure

needed to use for the application.

The pressure regulator has been designed so as to be used only and exclusively with the

type of gas and at the pressures which are shown by the marking.

To try and use the pressure regulator with types of gases and pressures other than those

indicated can be dangerous.

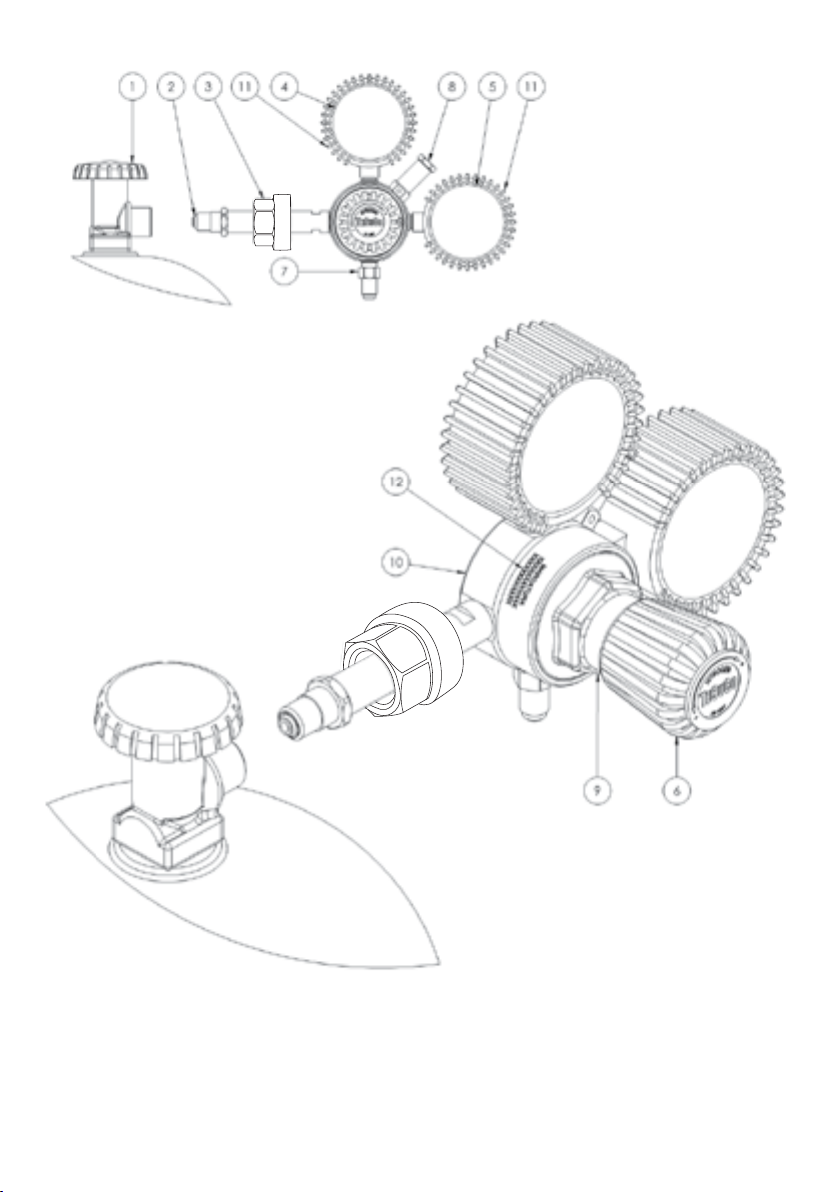

1. Cylinder valve

2. Inlet connection "O" ring (seal)

3. Inlet connection (nut & stem)

4. High pressure gauge

5. Low pressure gauge

6. Pressure adjusting knob

7. Outlet connection

8. Adaptor 1/4 - 5/16

9. Relief valve

10. Bonnet

11. Body

12. Gauge protectors

13. Markings

PARTS LIST (See page 7)

P1 = Inlet Pressure P2 = Outlet Pressure Q1= Maximum Delivery Flow Rate

Gas N2

Colour Blue

ID N

P1 kPa 30,000

K-Class -

P2 kPa 6,000

Q1 m³/h 50

Nitrogen 6000

3

2. ASSEMBLY

3. INSTRUCTIONS FOR USE

1. FUNCTION

2.1 Connection of the Pressure Regulator

Check that the pressure regulator is correct both for the type of gas and the pressure in

the cylinder in use.

Turn the pressure adjusting screw (6) anticlockwise, to check that the pressure regulator

valve is closed.

Replace the "O" ring (2) if it is damaged every time you change the cylinder.

Before screwing on the pressure regulator, briefly open the cylinder valve (1) then close

to remove any impurity, in case using compressed air. Pay attention to direct the cylinder

outlet towards a wall and far from heating sources.

During this operation it is dangerous to stand, or place your hands in front of the

cylinder valve (1).

Position the pressure regulator with the gauges the right way up.

Screw the inlet connection (3) tightly to the cylinder valve, by hand or by using a spanner.

3.1 Opening

Slowly open the cylinder valve (1). The high pressure gauge (4) will show you the

cylinder pressure.

Opening the cylinder valve too quickly may make gauges malfunction.

Open the pressure adjusting screw (6) very slowly. The low pressure gauge (5) will show

the outlet pressure.

CAUTIONS

Incorrect use of the pressure regulator can cause serious damage. Users must

be trained by competent people.

The pressure regulator must be treated as a precision instrument. Protect it from

accidental knocks, dust, oil and other sources of dirt.

Do not use the pressure regulator if it is not in perfect working condition (see 5.1).

When you draw gas, the cylinder must be placed upright and protected from falling.

4

CAUTIONS

Before opening the cylinder valve (1), check carefully that the regulator is

completely closed (turn the pressure adjusting screw (6) anticlockwise).

3.2 How To Regulate Pressure

To increase pressure: slowly turn the regulator pressure adjusting screw (6) clockwise.

To decrease pressure: slowly turn the regulator pressure adjusting screw (6) anticlockwise.

CAUTIONS

Using the pressure adjusting screw (6) it is possible to compensate an eventual

pressure drop.

Outlet pressure must not be regulated higher than the pressure you need to use

when flowing.

Outlet pressure must not be regulated higher than the red mark on the low

pressure gauge (5).

3.3 Closing

Close the cylinder valve (1).

Release the gas until the regulator gauges indicate "zero".

Turn the pressure adjusting screw (6) anticlockwise till it is completely closed.

3. INSTRUCTIONS FOR USE

The pressure regulator must be treated as a precision instrument.

When the pressure regulator is not to be used for long periods, store it in its wrapping or

in its box , to prevent contact with dust, oil and other sources of dirt.

Do not carry out maintenance or repairs, other than the following.

Use only original OxyTurbo spare parts and accessories.

Spare parts are available also from your retailer.

In case of failures which cannot be repaired following these instructions, take your

pressure regulator back to the retailer.

4. STORAGE

5. MAINTENANCE

5

Dispose of the regulator in accordance with local requirements.

Do not clean gauge glasses with petrol, solvents or any other kind of detergent.

5.1 Malfunctioning

In case of malfunction (e.g. leaks in the gauges or in the relief valves) stop use and close

the cylinder valve (1) immediately.

Unless there is visible damage to the outside of the instrument, we suggest that the

pressure regulator be returned to the supplier to be checked and repaired.

CAUTIONS

Do not use the pressure regulator if there are the following malfunctions:

The "O" ring (2) is damaged or lost.

The pressure regulator or any of its parts (gauge, inlet connection, outlet

connection) are damaged or dirty, oily etc.

There are any leaky connections.

The relief valve adjustment has been modified or the valve leaks.

5.2 Relief Valve

For safety reasons, the pressure regulator is equipped with an excess pressure valve.

In case of malfunctioning, this valve allows the excess gas pressure to vent.

CAUTIONS

Do not modify the calibration of the relief valve.

5.3 Checking The Seal

This check must be carried out only in the open air: use either soapy water or a gas leak

detector (Gas Control Part No: OTLDS). Do not use flames.

Spray detector on the area to be checked.

The forming of bubbles or foam is a sign of a leak.

6. INSTRUCTIONS FOR DISPOSAL

5. MAINTENANCE

6

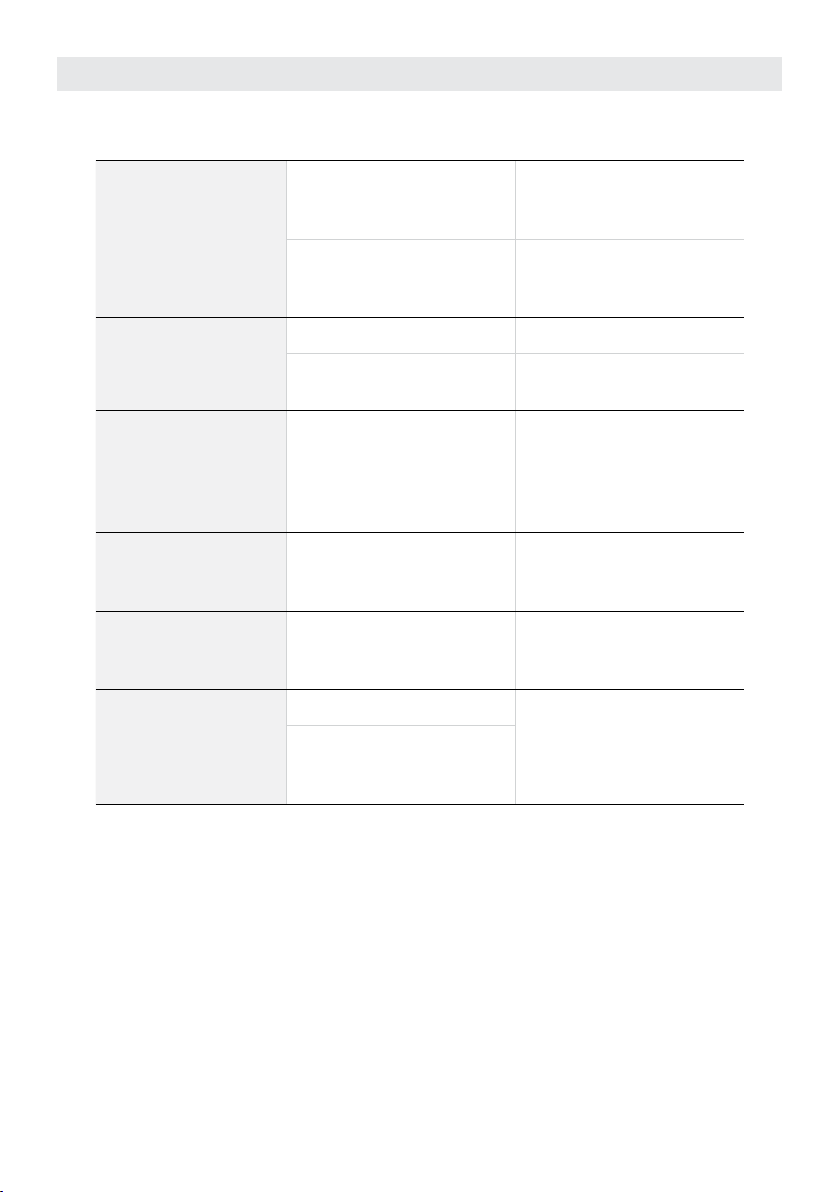

7. MANAGING FAULTS

PROBLEM CAUSE SOLUTION

Cannot connect to

the cylinder.

Incorrect inlet connection.

Only use correct cylinder

connection for the gas

type from AS 2473.2.

Inlet connection damaged.

Replace the inlet

connection with a

genuine part.

Insufficient gas flow.

Regulator undersized. Contact supplier.

Blocked or damaged

equipment downstream. Replace the equipment.

Gas Leak. Connection error.

Release the control knob,

tighten the connections

and re-check. Apply

pressure again, if leak

persists, repair or replace.

Increase in output

pressure, when not

flowing.

Leak through the regulator

seat valve.

Replace the

encapsulated seat.

Unstable output

pressure. Flow rate to high.

Check the flow of the

regulator matches the

requirement.

Vibrations

Flow rate to high.

Limit the flow with

the control knob or a

restricted oriface.

Presence of a quick

opening valve in

downstream equipment.

Note: Any repairs to regulators must be done with genuine OxyTurbo parts by a

qualified technician.

7

Note: Some of the details in the illustration may differ from those of the appliance

supplied. This company reserves the right to modify the product without prior warning.

8

The information contained herein is provided to assist the operator in the safe

use of a Tesuco®Nitrogen 6000 Regulator. However, the ultimate responsibility

for the safe use of this and any attached equipment lies solely with the operator,

including any requirements of associated Australian Standards.

OI_RC1SNI60C_V01

Table of contents

Other TeSuCo Controllers manuals

Popular Controllers manuals by other brands

Emerson

Emerson Fisher 3024S instruction manual

Mitsubishi

Mitsubishi AL2-2PT-ADP installation manual

Sherwood Scuba

Sherwood Scuba maximus SRB5600 Assembly & maintenance guide

Chamberlain

Chamberlain AGO250L instructions

Supreme Heating

Supreme Heating Aqua-Gen 2 instructions

Danfoss

Danfoss EKC 347 instructions