TETA Electric MA610 Series Operator's manual

Preface

Thanks for choosing our products.

TETA MA610 series inverters are newly-designed by our company for controlling

asynchronous AC inductance motors. Applying the most advanced speedless sensor vector

control technology, DSP control system, and our product enhances its reliability to meet the

adaptability to the environment, customized and industrialized design with more optimized

functions, more flexible application and

m

ore stable performance.

The vector control performance of TETA MA610 series inverters is as outstanding as that of

the leading sophisticatedinverters on worldwide market. Its speed and torque control can be

simultaneously, comparing with the other kinds, its function of anti-trip and strong

adaptability to worse grid, temperature, humidity and dust make it meet the high

performance requirement of thecustomer application.

TETA MA610 series inverters apply modularized design to meet the specific demand of

customers, as well as the demand of the whole industry flexibly and follow the trend of

industrial application to the inverters on the premise of meeting general need of the market.

Powerful speed control, torque control, simple PLC, flexible input/output terminals, pulse

frequency reference, traverse control can realize various complicate high-accuracy drives

and provide integrative solution for the manufacturers of industrial devices, which contributes

a lot to the cost reducing and improves reliability.

TETA MA610 series inverters can meet the demand of environmental protection which

focuses on low noise and weakening electromagnetic interference in the application sites for

the customers.

This manual provides installation and configuration, parameters setting, fault diagnoses

and daily maintenance and relative precautions to customers. Please read this manual

carefully before the installation to ensure a proper installation and operation and high

performance of TETA MA610 series inverters.

If the product is ultimately used for military affairs or manufacture of weapon, it will be listed

on the export control formulated by Foreign Trade Law of the People's Republic of China.

Rigorous review and necessary export formalities are needed when exported.

Our company reserves the right to update the information of our products.

Quick Start-up

Content

Preface

..............................................................................................................................

1

Content

..............................................................................................................................

2

1 Safety Precautions

..........................................................................................................

1

1.1

W

hat this chapter

c

ontains

..................................................................................

1

1.2 Safety definition

..................................................................................................

1

1.3 Warning symbols

................................................................................................

1

1.4 Safety guidelines

................................................................................................

2

2 Quick Start-up

.................................................................................................................

4

2.1

W

hat this chapter contains

..................................................................................

4

2.2 Unpacking inspection

..........................................................................................

4

2.3 Application confirmatio

n......................................................................................

4

2.4 Environment

.......................................................................................................

4

2.5 Installation confirmation

......................................................................................

5

2.6 Basic commission

...............................................................................................

5

3 Product Overview

..........................................................................................................

6

3.1 What this chapter contains

..................................................................................

6

3.2 Basic principles

...................................................................................................

6

3.3 Product specification

...........................................................................................

7

3.4 Name plate

.........................................................................................................

8

3.5 Type designation key

..........................................................................................

9

3.6 Rated specifications

............................................................................................

9

3.7 Structurediagram

.............................................................................................

10

4 Installation Guidelines

..................................................................................................

12

4.1 What this chapter contains

................................................................................

12

4.2 Mechanical installation

......................................................................................

12

4.3 Standard wiring

.................................................................................................

16

4.4 Layout protection

..............................................................................................

22

5 Keypad Operation Procedure

.........................................................................................

24

5.1 What this chapter contains

................................................................................

24

5.2 Keypad

.............................................................................................................

24

5.3 Keypad displaying

.............................................................................................

26

5.4 Keypad operation

..............................................................................................

26

6 Function Parameters

.....................................................................................................

28

6.1

W

hat this chapter contains

................................................................................

28

6.2 TETA MA610 general series function parameters

............................................

28

7 Basic Operation Instruction

............................................................................................

93

7.1

W

hat this chapter contains

................................................................................

93

7.2 First powering on

..............................................................................................

93

7.3 Vector control

....................................................................................................

95

7.4 Torque control

...................................................................................................

96

7.5 Parameters of the motor

...................................................................................

97

7.6 Start-up and stop control

...................................................................................

98

7.7 Frequency setting

.............................................................................................

99

7.8 Simple PLC .....................................................................................................100

7.9 Multi-step speed running..................................................................................100

7.10 PID control.....................................................................................................101

7.11 Pulse counter.................................................................................................103

8 Fault Tracking...............................................................................................................104

8.1 What this chapter contains...............................................................................104

8.2 Alarm and fault indications

...............................................................................104

8.3 How to reset....................................................................................................104

8.4 Fault

history

.....................................................................................................104

8.5 Fault instruction and solution............................................................................104

8.6 Common fault analysis.....................................................................................108

8.6.1 The motor does not work...............................................................................108

8.6.2 Motor vibration..............................................................................................109

8.6.3 Overvoltage

..................................................................................................109

8.6.4 Undervoltage fault

.........................................................................................

110

8.6.5Abnormal motor heat

.....................................................................................

110

8.6.6 Inverter overheating

......................................................................................

111

8.6.7 Stall during the acceleration of the motor

.......................................................

111

8.6.8 Overcurrent.....................................................................................................112

8.7 Inverter system interference troubleshooting

....................................................

112

8.8 Maintenance and hardware diagnostics

...........................................................

113

8.8.1 Overcurrent.....................................................................................................113

8.8.2 Cooling fan

...................................................................................................

115

8.8.3 Capacitors

....................................................................................................

116

8.8.4 Power cable

..................................................................................................

117

9 Communication Protocol

...............................................................................................

118

9.1 What this chapter contains

...............................................................................

118

9.2 Brief instruction to MODBUS protocol

..............................................................

118

9.3 Application of the inverter

.................................................................................

119

9.4 RTU command code and communication data illustration.................................122

Appendix A Technical Data..............................................................................................135

A.1 What this chapter contains...............................................................................135

A.2 Ratings............................................................................................................135

A.3 Electric power network specification ................................................................136

A.4 Motor connection data.....................................................................................136

A.5 Applicablestandards .......................................................................................136

A.6 EMC regulations..............................................................................................137

Appendix B Dimension Drawings.....................................................................................139

B.1What this chapter contains...............................................................................139

B.2 Keypad structure .............................................................................................139

B.3 Inverter chart .....................................................................................................140

Appendix C Peripheral Options and Parts........................................................................144

C.1 What this chapter contains ..............................................................................144

C.2 Peripheral wiring .............................................................................................144

C.3 Power supply ..................................................................................................145

C.4 Cables............................................................................................................145

C.5 Breaker 、electromagnetic contactor and leakage protection switch ...............148

C.6 Reactors..........................................................................................................150

C.7 Filters Filters selection table

............................................................................ 151

C.8 Braking system ..................................................................................................152

C.9 Other optional parts.........................................................................................155

Appendix D Further Information.......................................................................................156

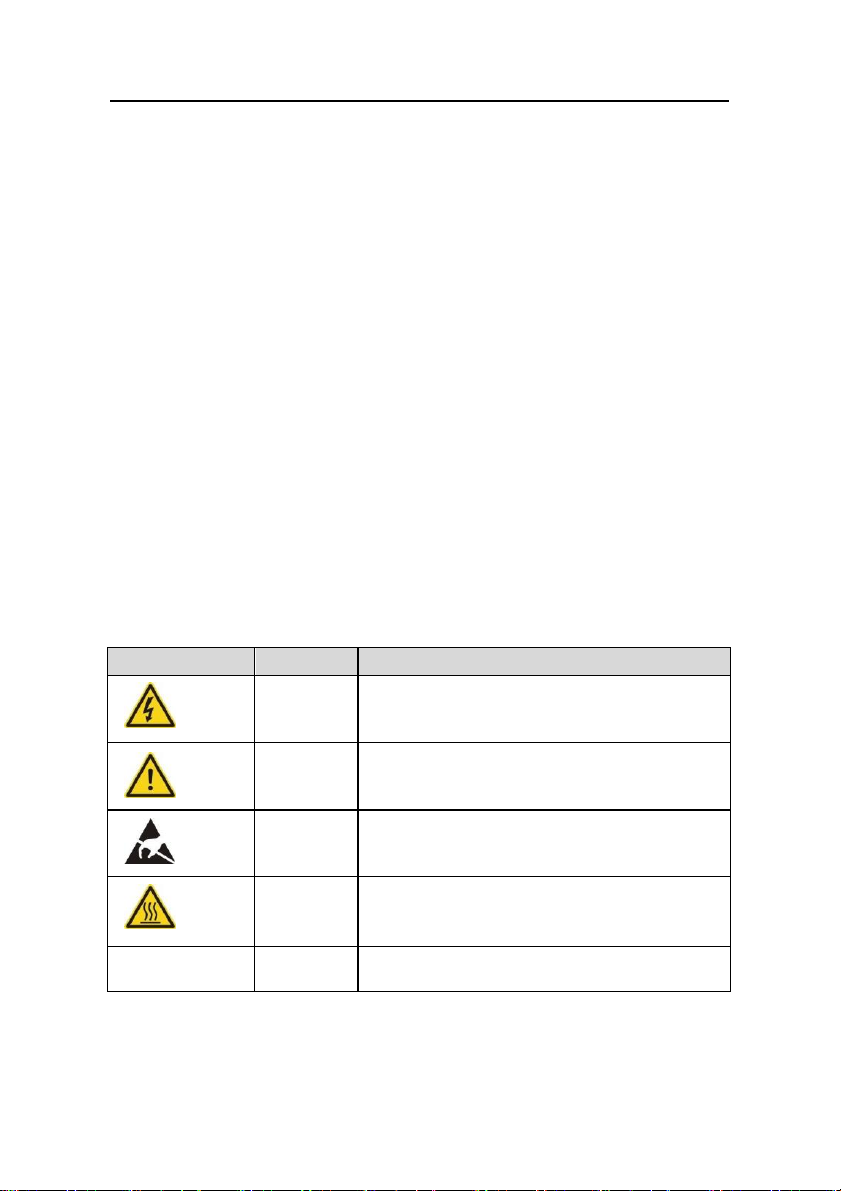

1

Symbols

Name

Instruction

Danger

Electrical

Danger

Serious physical injury or even death may occur if

not follow the

relative requirements

Warning

General

danger

Physical injury or damage to the devices may

occur if not follow the

relative requirements

Do not

Electrostatic

discharge

Damage to the PCBA board may occur if not

follow the relative

requirements

Hot sides

Hot sides

Sides of the device may become hot. Do not touch.

Note

Note

Physical hurt may occur if not follow

the relative requirements

Safety Precautions 1

1.1 What this chapter contains

Please read this manual carefully and follow all safety precautions before moving, installing,

operating and servicing the inverter. If ignored, physical injury or death may occur, ordamage

may occur to the devices.

If any physical injury or death or damage to the devices occurs for ignoring to the safety

precautions in the manual, our company will not be responsible for any damages and we are

not legally bound in any manner.

1.2 Safety definition

Danger: Serious physical injury or even death may occur if not follow

relevant requirements

Warning: Physical injury or damage to the devices may occur if not follow

relevant requirements

Note: Physical hurt may occur if not follow relevant requirements

Qualified

electricians: People working on the device should take part in professional

electrical and safety training, receive the certification and befamiliar

with all steps and requirements of installing,

commissioning, operating and maintaining the device to avoid any

emergency.

1.3 Warning symbols

Warnings caution you about conditions which can result in serious injury or death and/or

damage to the equipment, and advice on how to avoid the danger. Following warning

symbols are used in this manual:

Safety precautions

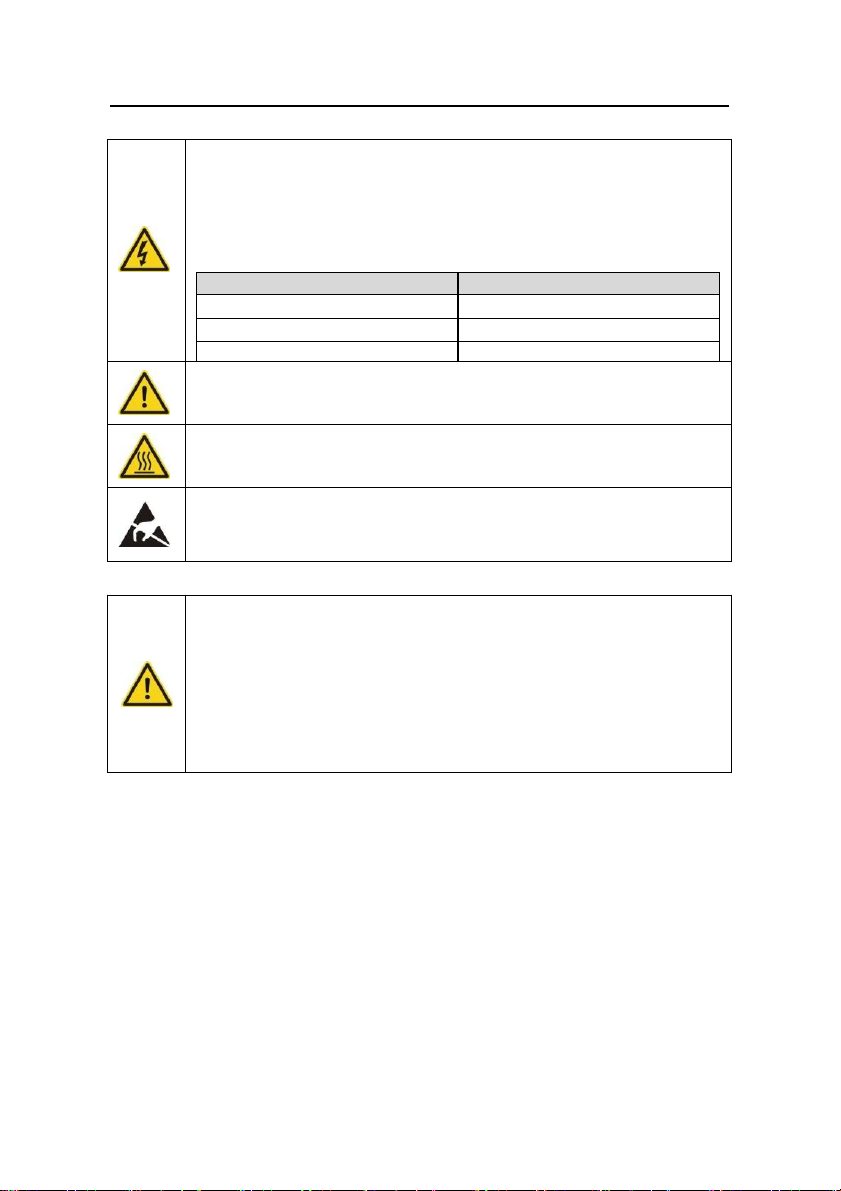

1.4 Safety guidelines

Only qualified electricians are allowed to operate on the inverter.

Do not carry out any wiring and inspection or changing components when the

power supply is applied. Ensure all input power supply is disconnected

before wiring and checking and always wait for at least the time designated on

the inverter or until the DC bus voltage is less than 36V. Below is the table of the

waiting time:

Inverter model

Minimum waiting time

380V 1.5kW-110kW

5minutes

380V 132 kW-315 kW

15minutes

380V above 350 kW

25 minutes

Do not refit the inverter unauthorized; otherwise fire, electric shock or other

injury may occur.

The base of the heat sink may become hot during running. Do not touch to

avoid hurt.

The electricalparts and componentsinsidethe inverter are electrostatic. Take

measurements to avoid electrostatic dischargeduring relevant operation.

1.4.1 Delivery and installation

Please install the inverter on fire-retardant material and keep the inverter

away from combustible

m

aterials.

Connect the braking optional parts (braking resistors, braking units or

feedback units) according to the wiring diagram.

Do not operate on the inverter if there is any damage or components loss to

the inverter.

Do not touch the inverter with wet items or body, otherwise electric shock

may occur.

Note:

Select appropriate moving and installing tools to ensure a safe and normal running of

the inverter and avoid physical injury or death. For physical safety, the erector should

take some mechanical protective measurements, such as wearing exposure shoes and

working uniforms.

Ensure to avoid physical shock or vibration during delivery and installation.

Do not carry the inverterby its cover. The cover may fall off.

Install away from children and other public places.

The inverter cannot meet the requirements of low voltage protection in IEC61800-5-

1 if the sea level of installation site is above 2000m.

Please use the inverter on appropriate condition (See chapter Installation

Environment).

Don't allow screws, cables and other conductive items to fall inside the inverter.

The leakage current of the inverter may be above 3.5mA during operation. Ground

2

3

Safety precautions

with proper techniques and ensure the grounding resistor is less than 10Ω. The

conductivity of PE grounding conductor is the same as that of the phase conductor

(with the same cross sectional area).

R, S and T are the input terminals of the power supply, while U, V and W are the motor

terminals. Please connect the input power cables and motor cables with proper

techniques; otherwise the damage to the inverter may occur.

1.4.2 Commission and running

Disconnect all power supplies applied to the inverter before the terminal wiring

and wait for at least the designated

tim

e after disconnecting the power supply.

High voltage is present inside the inverter during running. Do not carry out

any operation except for the keypad setting.

The inverter may start up by itself when P01.21=1. Do not get close to

the inverter and motor.

The inverter can not be used as “Emergency-stopdevice”.

Theinverter cannot be used to break themotor suddenly. A mechanicalbraking

device should be provided.

Note:

Do not switch on or off the input power supply of the inverter frequently.

For inverters that have been stored for a long time, check and fix the capacitance and try

to run it again before utilization (see Maintenance and Hardware Fault Diagnose).

Cover the front board before running, otherwise electric shock

m

ay occur.

1.4.3 Maintenance and replacement of components

Only qualified electricians are allowed to perform the maintenance,

inspection, and components replacement of the inverter.

Disconnect all power supplies to the inverter before the terminal wiring.

Wait for at least the time designated on the inverter after disconnection.

Takemeasuresto avoid screws, cables and other conductive

m

atters to fall into

the inverter during maintenanceand component replacement.

Note:

Please select proper torque to tighten screws.

Keep the inverter, parts and components away from combustible materials during

maintenance and component replacement.

Do not carry out any isolation and pressure test on the inverter and do not measure

the control circuit of the inverter by megameter.

Carry out a sound anti-electrostatic protection to the inverter and its internal

components during maintenance and component replacement.

1.4.4 What to do after scrapping

There are heavy metals in the inverter. Deal with it as industrial effluent.

4

Quick Start-up 2

2.1 What this chapter contains

This chapter mainly describes the basic guidelines during the installation and commission

procedures on the inverter, which you may follow to install and commission the inverter

quickly.

2.2 Unpacking inspection

Check as followings after receiving products:

1. Check that there are no damage and humidification to the package. If not, please

contact

with local agents.

2. Check the information on the type designation label on the outside of the package to

verify that the drive is of the correct type. If not, please contact with local dealers.

3. Check that there are no signs of water in the package and no signs of damage or breach

to the inverter. If not, please contact with local dealers.

4. Check the information on the type designation label on the outside of the package to

verify that the name plate is of the correct type. If not, please contact with local dealers.

5. Check to ensurethe accessories (including user’s manual, control keypad and extension

card) inside the device is complete. If not, please contact with local dealers.

2.3 Application confirmation

Check the machine before beginning to use the inverter:

1. Check the load type to verify that there is no overload of the inverter during work and

check that whether the drive needs to modify the power degree.

2. Check that the actual current of the motor is less than the rated current of the inverter.

3. Check that the control accuracy of the load is the same of the inverter.

4. Check that the incoming supply voltage is correspondent to the rated voltage of the

inverter.

2.4 Environment

Check as followings before the actual installation and usage:

1. Check that the ambient temperature of the inverter is below 40℃. If exceeds, derate 3%

for every additional 1℃.

temperature is above 50℃. Additionally, the inverter can not be used if the ambient

Note: for the cabinet inverter, the ambient temperature

m

eans the air temperature inside

the cabinet.

2. Check that the ambient temperature of the inverter in actual usage is above -10℃. If not,

add heating facilities.

Note: for the cabinet inverter, the ambient temperature means the air temperature inside

the cabinet.

55

3. Check that the altitude of the actual usage site is below 1000m. If exceeds, derate1% for

every additional 100m.

. Check that the humidity of the actual usage site is below 90% and condensation is not

allowed. If not, add additional protection inverters.

5. Check that the actual usage site is away from direct sunlight and foreign objects can not

enter the inverter. If not, add additional protective measures.

6. Check that there is no conductive dust or flammable gas in the actual usage site. If not,

add additional protection to inverters.

2.5 Installation confirmation

Check as followings after the installation:

1. Check that the input and output cables meet the need of actual load.

2. Check that the accessories of the inverter are correctly and properly installed. The

installation cables should meet the needs of every component (including reactors, input

filters, output reactors, output filters, DC reactors, braking units and braking resistors).

3. Check that the inverter is installed on non-flammable materials and the calorific

accessories (reactors and braking resistors) are away from flammable

m

aterials.

4. Check that all control cables and power cables are run separately and the

routation complies with EMC requirement.

5. Check that all grounding systems are properly grounded according to the requirements

of the inverter.

6. Check that the free space during installation is sufficient according to the instructions in

user’s manual.

7. Check that the installation conforms to the instructions in user’s manual. The drive must

be installed in an upright position.

8. Check that the external connection terminals are tightly fastened and the torque is

appropriate.

9. Check that there are no screws, cables and other conductive items left in the inverter. If

not, get them out.

2.6 Basic commission

Completethe basic commissioning as followings before actual utilization:

1. Select the motor type, set correct motor parameters and select control mode of the

inverter according to the actual motor parameters.

2. Autotune. If possible, de-coupled from the motor load to start dynamic autotune. Or if not,

static autotuneis available.

3. Adjust theACC/DEC time according to the actual running of the load.

4. Commission the device via jogging and check that the rotation direction is as required. If

not, change the rotation direction by changing the wiring of motor.

5. Set all control parameters and then operate.

Quick Start-up

66

Product Overview 3

3.1 What this chapter contains

The chapter briefly describes the operation principle, product characteristics, layout, name

plate and type designation information.

3.2 Basic principles

TETA MA610 series inverters are wall, flange and mountable devices for controlling

asynchronous AC inductance motors.

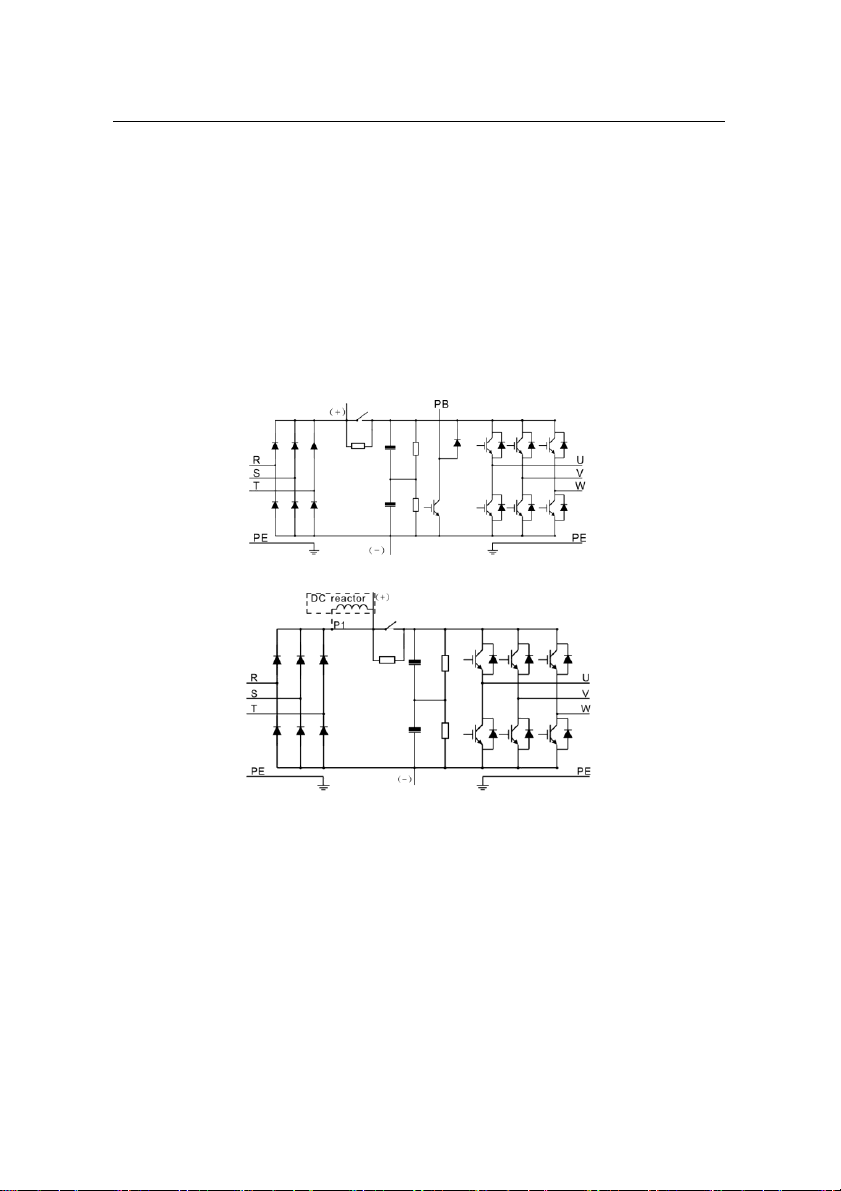

The diagram below shows the main circuit diagram of the inverter. The rectifier converts

three-phase AC voltage to DC voltage. The capacitor bank of the intermediate circuit

stabilizes the DC voltage. The converter transforms the DC voltage back to AC voltage for

the AC motor. The brake pipe connects the external braking resistor to the intermediate DC

circuit to consume the feedback energy when the voltage in the circuit exceeds its maximum

limit.

Diagram 3-1 The main circuit diagram (≤30kW )

Note:

Diagram 3-2 The main circuit diagram (≥37kW )

1. The inverter above 37kW (including 37kW) supports external DC reactor which is an

optional part. Before connecting, it is necessary to remove the copper row between P1 and

(+).

2. The inverters (≤30kW ) havestandard embedded braking units and the braking resistor

is optional.

3. The inverters (≥37kW ) can be installed with optional braking units and the braking

unit and resistor are optional.

77

Product Overview

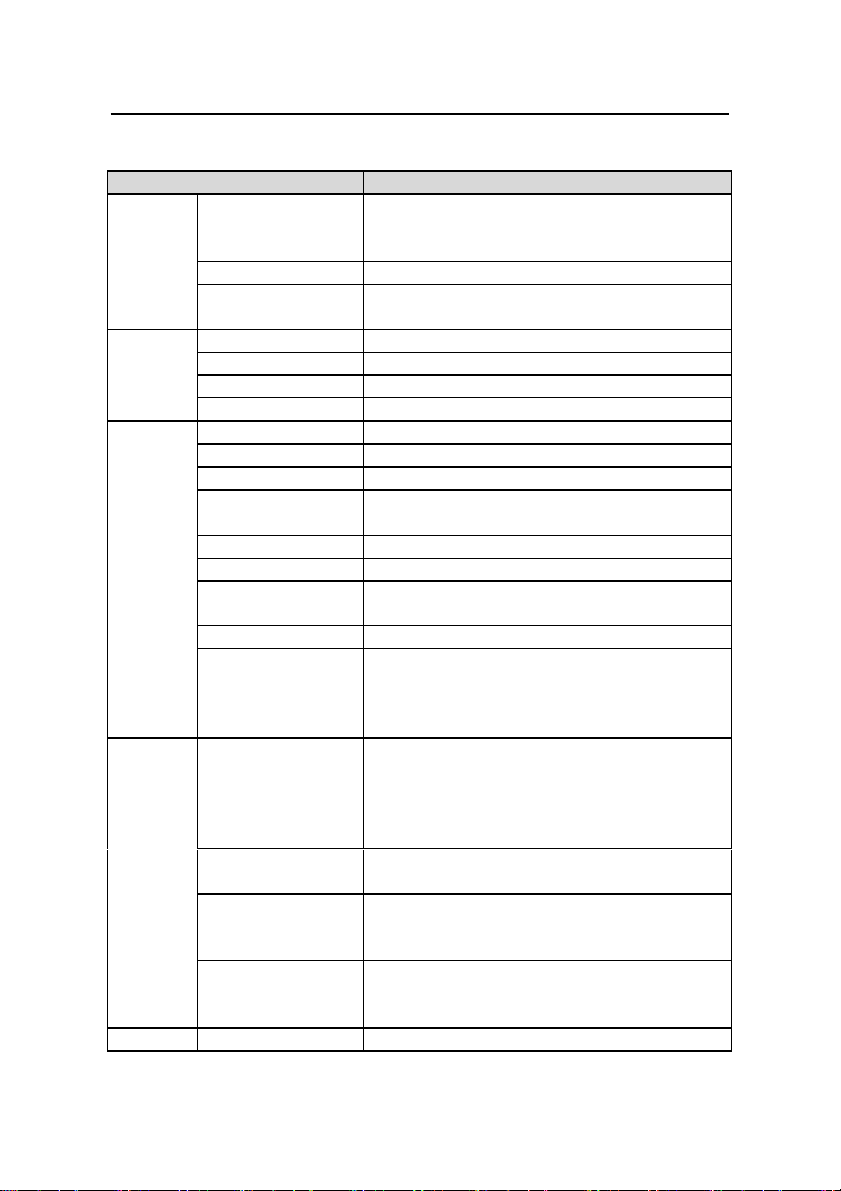

3.3 Product specification

Function

Specification

Input

Input voltage (V)

AC 3PH 220V(-15%)~240V(+10%)

AC 3PH 380V(-15%)~440V(+10%)

AC 3PH 520V(-15%)~690V(+10%)

Input current (A)

Refer to the rated value

Input frequency (Hz)

50Hz or 60Hz

Allowed range: 47~63Hz

Output

Output voltage (V)

0~Input voltage

Output current (A)

Refer to the rated value

Output power (kW)

Refer to the rated value

Output frequency (Hz)

0~400Hz

Technical

control

feature

Control mode

SVPW M, SVC

Motor type

Asynchronous motor

Speed ratio

Asynchronous motor 1:100 (SVC)

Speed control

accuracy

±0.2% (sensorless vector control)

Speed fluctuation

± 0.3%(sensorlessvector control)

Torque response

<20ms(sensorless vector control)

Torque control

accuracy

10%(sensorless vector control)

Starting torque

Asynchronous motor: 0.5Hz/150% (SVC)

Overload capability

G type:

150% of rated current: 1 minute

180% of rated current: 10 seconds

200% of rated current: 1 second

Running

control

feature

Frequency setting

Digital setting, analog setting, pulse frequency

setting, multi-step speed running setting, simple

PLC setting, PID setting, MODBUS communication

setting.

Shift between the set combination and set channel.

Auto voltage

adjustment

Keep a stable voltage automatically when the grid

voltagetransients

Fault protection

Provide over 30 fault protection functions:

overcurrent, overvoltage, undervoltage, overheating,

phase loss and overload, etc.

Speed tracking

Restart the rotating motor smoothly

Note: This function is available for the inverters of

4kW and above 4kW.

Peripheral

Terminal analog input

≤20mV

88

Function

Specification

interface

resolution

Terminal switch input

resolution

≤2ms

Analog input

1 channels ( AI2) 0~10V/0~20mA and 1 channel

(AI3) -10~10V

Analog output

2 channels (AO1, AO2) 0~10V /0~20mA

Digital input

8 channels common input, the Max. frequency:

1kHz, internal impedance: 3.3kΩ;

1 channel high speed input, the Max. frequency:

50kHz

Digital output

1 channel high speed pulse output, the Max.

frequency: 50kHz;

1 channel Y terminal open collector pole output

Relay output

2 channels programmablerelay output

RO1A NO, RO1B NC, RO1C common terminal

RO2A NO, RO2B NC, RO2C common terminal

Contactor capability: 3A/AC250V,1A/DC30V

Others

Mountable method

Wall, flange and floor mountable

Temperature of the

running environment

-10~50℃, derate above 40℃

Ingress protection

IP20

Cooling

Air-cooling

Braking unit

Built-in braking unit for inverters below 30kW

(including 30kW )

External braking unit for others

EMC filter

Built-in C3 filter: meet the degree requirement of

IEC61800-3 C3

External optional filter:meet the degree requirement

of IEC61800-3 C2

3.4 Name plate

Fig 3-3 Name plate

Note: This is the example of the name plate for the standard products, and CE\TUV\IP20 will

be marked according to the actual situations.

Product Overview

99

3.5 Type designation key

The type designation contains information on the inverter. The user can find the type

designation on the type designation label attached to the inverter or the simple name plate.

Fig 3-4 Product

type

Key

Instructions

A

MA610: abbreviation of TETA MA610

B,

D

3-digit code: output power. “R”means the decimal point;

”011”:11kW

;

“015”:15kW

C,

E

C

G:Constant torque load

E

P:Variable torque load

F

Input voltage degree:

2: AC 3PH 220V(-15%)~240V(+10%)

4: AC 3PH 380V(-15%)~ 440V(+10%)

6: AC 3PH 520V(-15%)~690V(+10%)

3.6 Rated specifications

Model

Constant torque

Variable torque

Output

power

(kW)

Input

current

(A)

Output

current

(A)

Output

power

(kW)

Input

current

(A)

Output

current

(A)

MA610-0R7G-4

0.75

3.4

2.5

MA610-1R5G-4

1.5

5.0

3.7

MA610-2R2G-4

2.2

5.8

5

MA610-004G/5R5P-4

4

13.5

9.5

5.5

19.5

14

MA610-5R5G/7R5P-4

5.5

19.5

14

7.5

25

18.5

MA610-7R5G/011P-4

7.5

25

18.5

11

32

25

MA610-011G/015P-4

11

32

25

15

40

32

MA610-015G/018P-4

15

40

32

18.5

47

38

MA610-018G/022P-4

18.5

47

38

22

56

45

MA610-022G/030P-4

22

56

45

30

70

60

MA610-030G/037P-4

30

70

60

37

80

75

MA610-037G/045P-4

37

80

75

45

94

92

MA610-045G/055P-4

45

94

92

55

128

115

MA610-055G/075P-4

55

128

115

75

160

150

MA610-075G/090P-4

75

160

150

90

190

180

MA610-090G/110P-4

90

190

180

110

225

215

MA610-110G/132P-4

110

225

215

132

265

260

Product Overview

10

Note:

1. The input current of 1.5~315kW inverters is measured when the input voltageis 380V and

no DC reactor and input/output reactor.

2. The input current of 350~500kW inverters is measured when the input voltage is 380V

and the circuit is with input reactor.

3. The rated output current is defined as the output current when the output voltageis 380V.

4. In the allowable voltage range, the output power and current can not exceed the rated

output power and current in any situation.

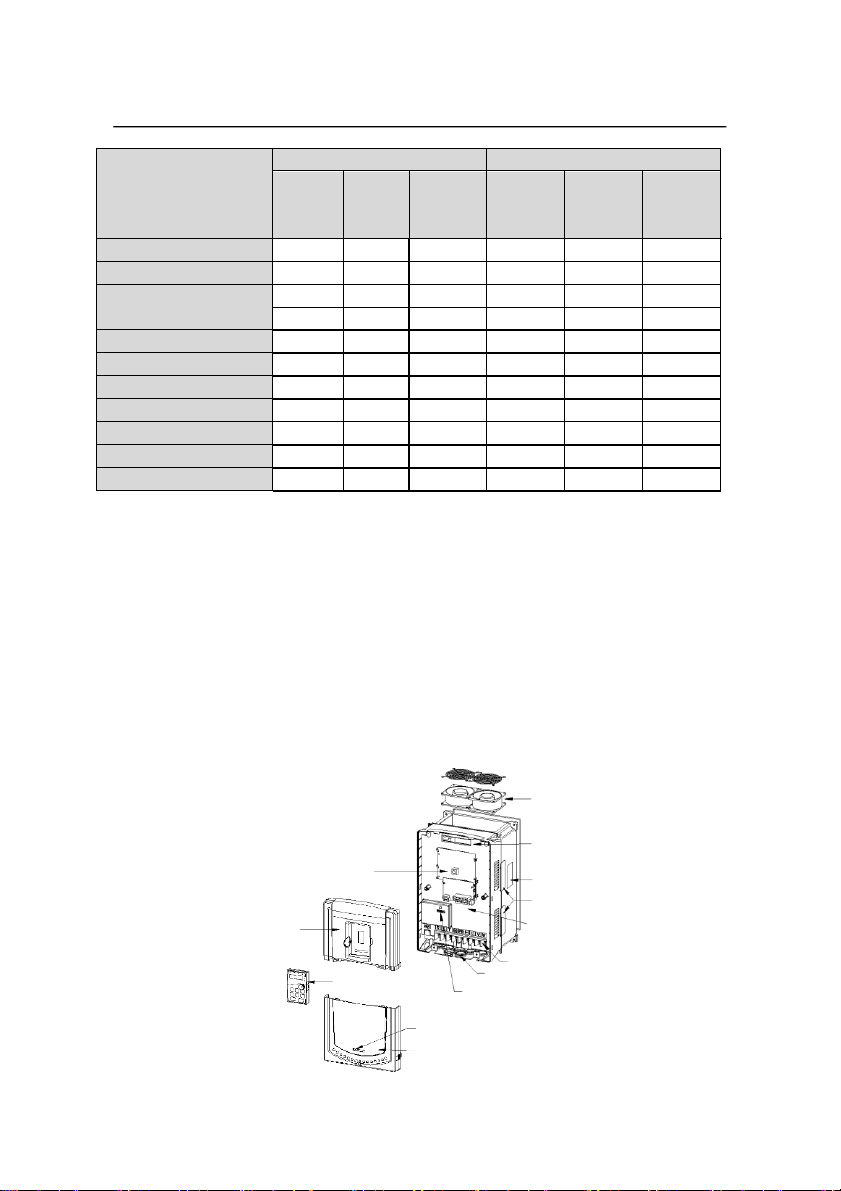

3.7 Structure diagram

Below is the layout figure of the inverter (take the inverter of 30kW as the example).

4

5

1 6

7

2 8

9

3 10

11

12

13

Fig 3-5 Product structure diagram

Model

Constant torque

Variable torque

Output

power

(kW)

Input

current

(A)

Output

current

(A)

Output

power

(kW)

Input

current

(A)

Output

current

(A)

MA610-132G/160P-4

132

265

260

160

310

305

MA610-160G/185P-4

160

310

305

185

345

340

MA610-185G/200P-4

185

345

340

200

385

380

MA610-200G/220P-4

200

385

380

220

430

425

MA610-220G/250P-4

220

430

425

250

485

480

MA610-250G/280P-4

250

485

480

280

545

530

MA610-280G/315P-4

280

545

530

315

610

600

MA610-315G/350P-4

315

610

600

350

625

650

MA610-350G/400P-4

350

625

650

400

715

720

MA610-400G-4

400

715

720

MA610-500G-4

500

890

860

Product Overview

Product Overview

11

Serial

No.

Name

Illustration

1

Keypad port

Connect the keypad

2

Upper cover

Protect the internal parts and components

3

Keypad

See Keypad Operation Procedure for detailed

information

4

Cooling fan

See Maintenance and Hardware Fault Diagnose for

detailed

inform

ation

5

Wires port

Connect to the control board and the drive board

6

Name plate

See Product Overview for detailed

inform

ation

7

Side cover

Optional part. The side cover will increase the

protective degree of the inverter. The internal

temperature of the inverter will increase, too, so it is

necessary to derate the inverter at the same time

8

Control terminals

See Electric Installation for detailed information

9

Main circuit terminals

See Electric Installation for detailed information

10

Main circuit cable entry

Fix the main circuit cable

11

POWER light

Power indicator

12

Simplename plate

See Product Overview for detailed information

13

Lower cover

Protect the internal parts and components

12

Environment

Conditions

Installation site

Indoor

Environment

temperature

-10~+50℃

If the ambient temperature of the inverter is above 40℃, derate 3%

for every additional 1℃.

It is not recommendedto use the inverter if the ambient

temperature is above 50℃.

In order to improve the reliability of the device, do not use the

inverter if the ambient temperature changes frequently.

Please provide cooling fan or air conditioner to control the internal

ambient temperature below the required one if the inverter is used

in a close space such as in the control cabinet.

When the temperature is too low, if the inverter needs to restart to

run after a long stop, it is necessaryto provide an external heating

device to increase the internal temperature, otherwise damage

to

the devices may occur.

Humidity

RH≤90%

No condensation is allowed.

Installation Guidelines 4

4.1 What this chapter contains

The chapter describes the mechanical installation and electric installation.

Only qualified electricians are allowed to carry out what described in this

chapter. Please operate as the instructions in Safety Precautions. Ignoring

these

m

ay cause physical injury or death or

dam

age to the devices.

Ensure the power supply of the inverter is disconnected during the operation.

Wait for at least the time designated until the POWER indicator is off after the

disconnection if the power supply is applied. It is recommended to use the

multimeter to monitor that the DC bus voltage of the drive is under 36V.

The installation and design of the inverter should be complied with the

requirement of the local laws and regulations in the installation site. If the

installation infringes the requirement, our company will exempt from any

responsibility. Additionally, if users do not comply with the suggestion, some

damagebeyond the assured maintenancerange may occur.

4.2 Mechanical installation

4.2.1 Installation environment

The installation environment is important for a full performance and long-term

stable functions of the inverter. Check the installation environment as followings:

13

Note:

TETA MA610 series inverters should be installed in a clean and ventilated environment

according to enclosure classification.

Cooling air must be clean, free from corrosive materials and electrically conductive dust.

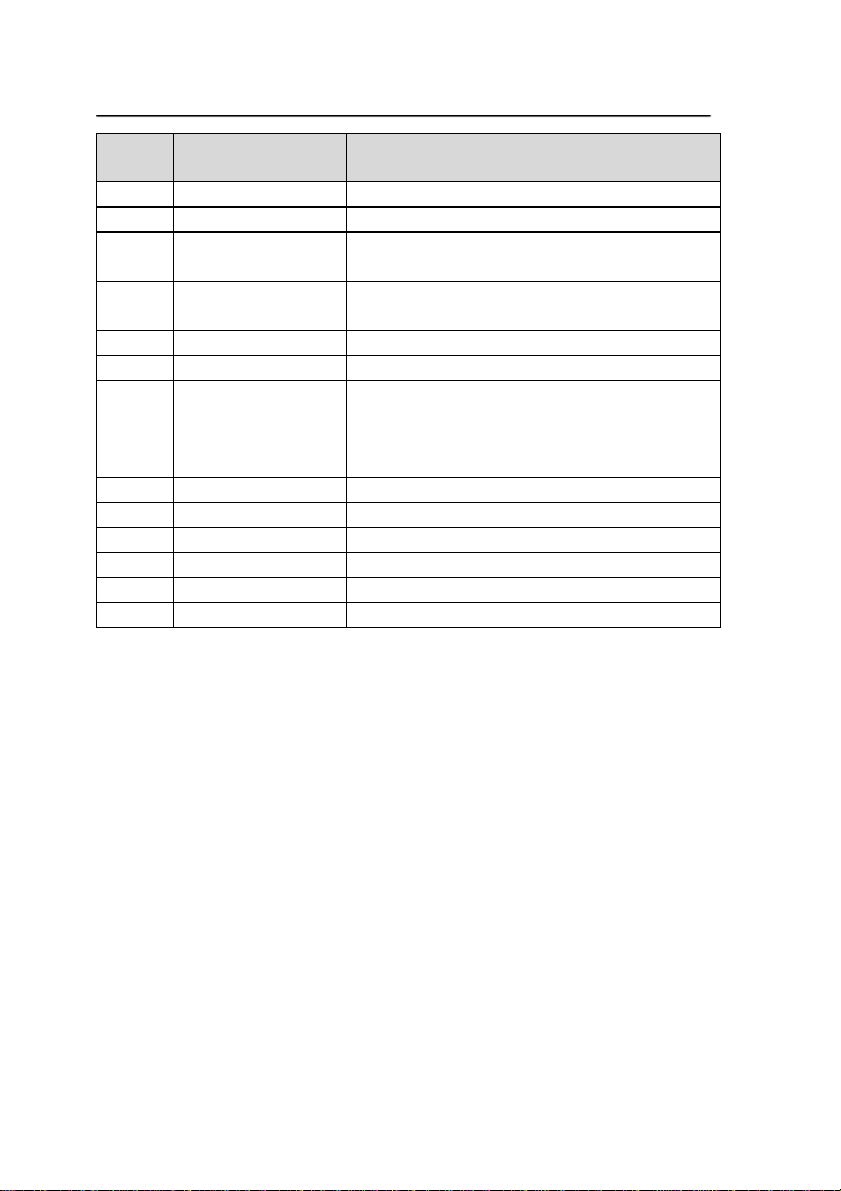

4.2.2 Installation direction

The inverter may be installed on the wall or in a cabinet.

The inverter must be installed in an upright position. Check the installation site according to

the requirements below. Refer to chapter Dimension Drawings in the appendix for

frame details.

Fig 4-1 Installation direction of the inverter

Environment

Conditions

The maximum relative humility should be equal to or less than

60% in corrosive air.

Storage

temperature

-30~+60℃

Running

environment

condition

The installation site of the inverter should:

keep away from the electromagnetic radiation source;

keep away from contaminative air, such as corrosive gas, oil mist

and flammablegas;

ensure foreign objects, such as metal power, dust, oil, water can

not enter into the inverter(do not install the inverter on the

flammable materials such as wood);

keep away from direct sunlight, oil mist, steam and vibration

environment.

Altitude

Below 1000m

If the sea level is above 1000m, please derate 1% for every

additional 100m.

Vibration

≤ 5.8m/s2(0.6g)

Installation direction

The inverter should be installed on an upright position to ensure

sufficient cooling effect.

Installation Guidelines

14

4.2.3 Installation manner

The inverter can be installed in two different ways, depending on the frame size:

a) Wall mounting (for the inverter≤315kW )

b) Flange mounting (for the inverter≤200kW ). Some need optional flange installation

board. c) Floor mounting (220kW ≤the inverter≤500kW ). Some need optional base.

Fig 4-2 Installationmanner

(1) Mark the hole location. The location of the holes is shown in the dimension drawings in

the appendix.

(2) Fix the screws or bolts to the marked locations.

(3) Position the drive onto the wall.

(4) Tighten the screws in the wall securely.

Note:

1. The flange installation bracket is needed in the flange installation of 1.5~30kW inverters,

which the flange installation of 37~200kW inverters does not need the installation bracket.

2. 220~315kW inverters need optional base in the floor installation.

4.2.4 Multiple installations

Parallel installation

Note:

Fig 4-3 Parallel installation

Before installing the different sizes inverters, please align their top position for the

convenience of later maintenance.

The minimum space of B, D and C is 100mm.

Installation Guidelines

15

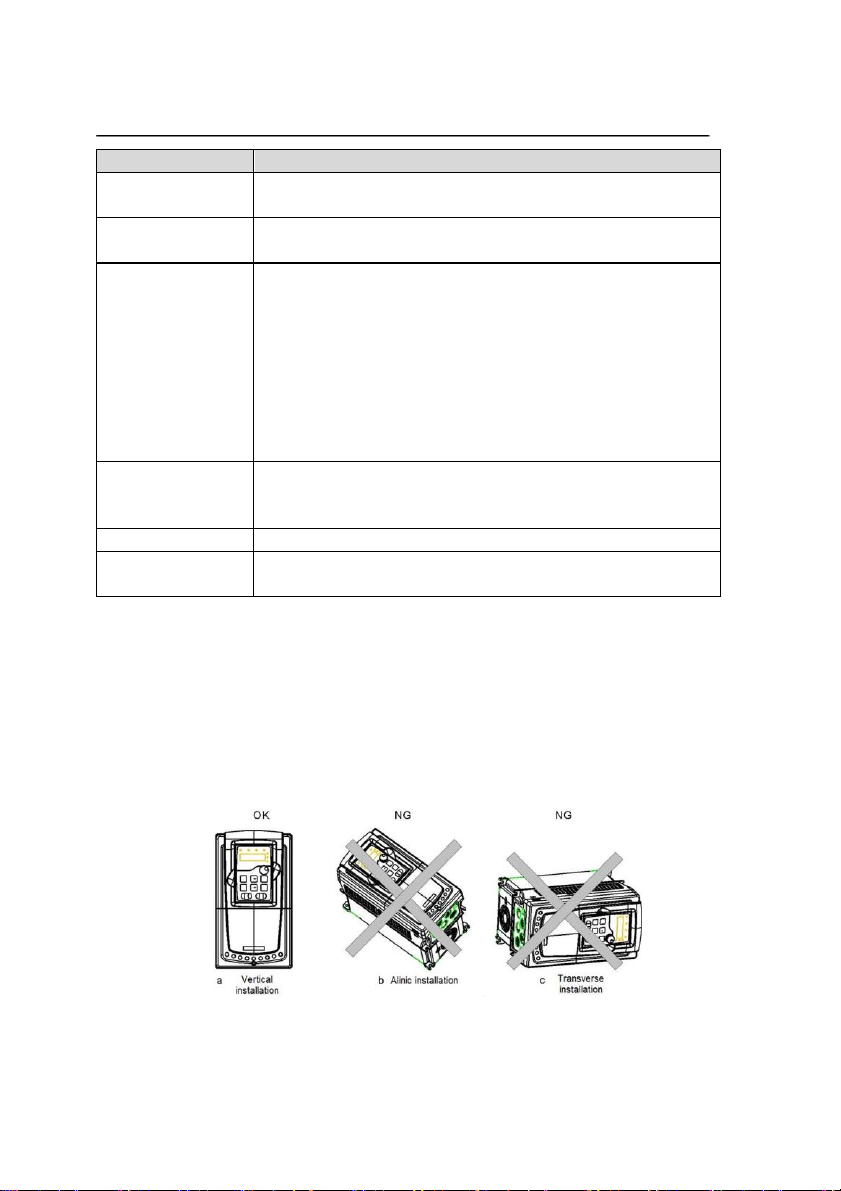

4.2.5 Vertical installation

Fig 4-4 Vertical installation

Note:

W

indscreen should be added in vertical installation for avoiding mutual impact and

insufficient cooling.

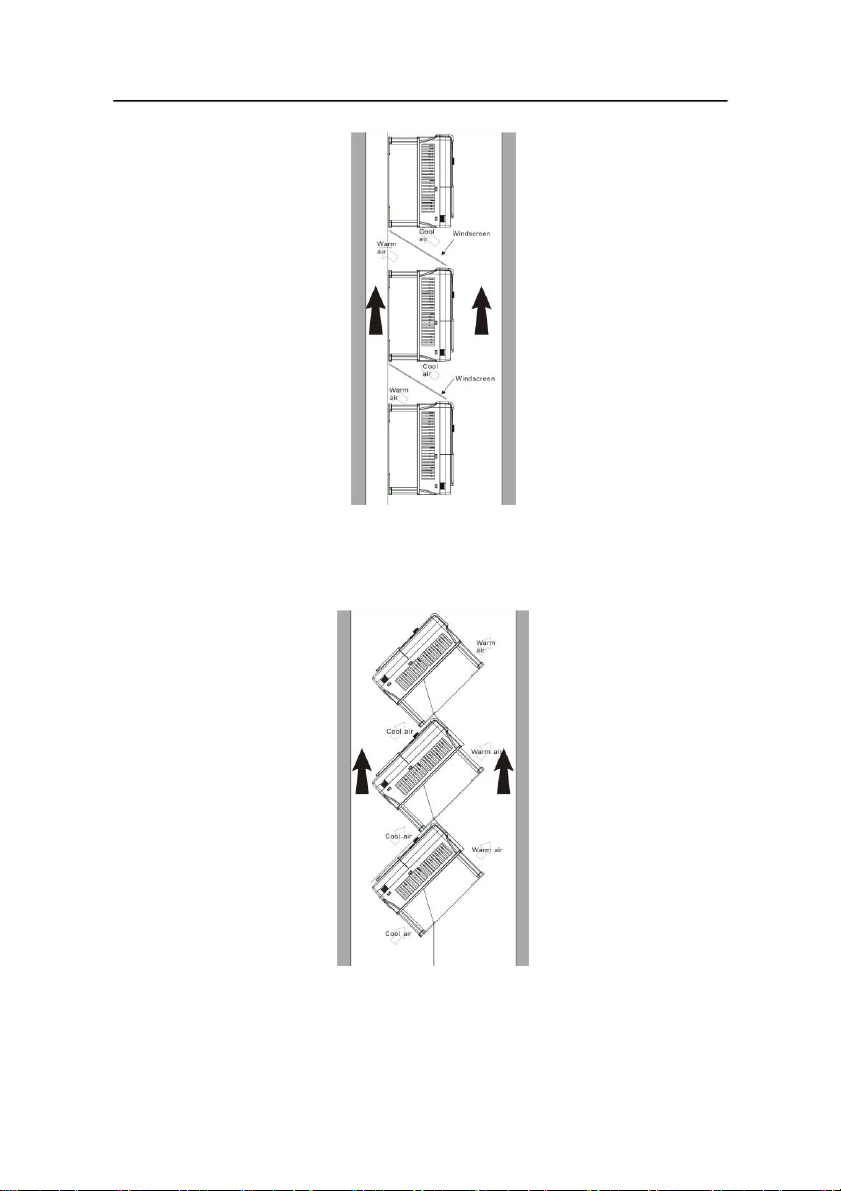

4.2.6 Tilt installation

Fig 4-5 Tilt installation

Note: Ensure the separation of the wind input and output channels in tilt installation for

avoiding mutual impact.

Installation Guidelines

16

4.3 Standard wiring

4.3.1 Wiring diagram of main circuit

Note: Fig4-6Wringdiagram of maincircuit

Thefuse, DC reactor, braking unit, braking resistor, input reactor, input filter, output

reactor, output filter are optional parts. Please refer to Peripheral Optional Parts for

detailed information.

A1 and A2 are optional parts.

P1 and (+) are short circuited in factory, if need to connect with the DC rector, please

remove the contact tag between P1 and (+).

4.3.2 Terminals figure of main circuit

Fig 4-7 0.75~5.5 kW terminals of main circuit

Fig 4-8 7.5~15kW terminals of main circuit

Installation Guidelines

This manual suits for next models

28

Table of contents

Other TETA Electric Inverter manuals