Tetratec Instruments LFE-LDS User manual

TetraTec Instruments GmbH

Gewerbestr. 8

71144 Steinenbronn

Deutschland

Tel.: 07157/5387-0

Fax: 07157/5387-10

Operation Manual

LFE-LDS

Flow Element

*** VERSION 2.0 ***

Update: 30.03.2012

Manual

LFE-LDS

page 2 LFE-LDS_man_e.doc

GENERAL HINTS

Typographical Conventions

MEANS OF DISPLAY

marks a work procedure, which you must implement

references marks which you should not neglect otherwise your health or the

operability of the equipment is endangered

marks important additional information, hints and recommendations

referring to precautionary measures mark during the handling of electrostati-

cally unloading-endangered elements or modules.

TYPES OF DISPLAY

Menu Items

Texts of screen displays were shown in cursive letter

(e.g.: End Program).

Predefined Parameter

Parameter which are set at the delivery of the unit as factory settings were underlined. (i.e.:

0 ... 9999)

SAFTEY HINTS

Please consider the references of this manual as well as the operating conditions and per-

missible data, which are specified in the data sheets of the device, so that the equipment

functions perfectly and for a long time remains operational:

Adhere with operational planning and the enterprise of the equipment to the general rules

of the technology!

Installation and maintenance work may take place only with technical personnel and with

suitable tools!

Consider the valid accident prevention and safety regulations for electrical devices during

the enterprise and maintenance of the equipment!

Switch off power supply before interferences into the system in any case!

Meet suitable measures, in order to exclude unintentional operation or inadmissible im-

pairment!

Ensure after an interruption of the electrical supply a defined and controlled restart of the

process!

Manual

LFE-LDS

LFE-LDS_man_e.doc page 3

GENERAL HINTS................................................................................................................2

INTRODUCTION .................................................................................................................4

FUNCTIONAL PRINCIPLE .................................................................................................5

OPERATION .......................................................................................................................7

MAINTENANCE ..................................................................................................................8

SPECIFICATIONS...............................................................................................................9

DIMENSIONS....................................................................................................................10

Manual

LFE-LDS

page 4 LFE-LDS_man_e.doc

INTRODUCTION

This manual describes the LFE-LDS slit type Laminar Flow Elements for all kind of different flow

channel shapes which have a full scale flow between 0,05 SL/min to 150 SL/min air. This slit type

LFE can be evaluated with any differential pressure measurement devices to determine the flow of

air and gases. The LFEs are calibrated with air at room temperature between 16 – 26°C. A simple

conversion for other gases can be made with the viscosity relation of air and the operating gas by

using the formula of Hagen-Poiseuille. The LFE-LDS measure the actual volume flow with the dif-

ferential pressure (drop) which is created by friction! The total pressure drop across the LFE is

about 1,5 to 2-times of the measured DP. The flow direction is preferred in unidirectional way, can

be principally also used in bi-directional way. The LFE-LDS are calibrated normally for atmospheric

pressure (1 bar abs.). But they can also be used in the pressure range between 0,1 – 2 bar abs..

Higher static pressures are possible respectively with a reduced DP range.

Suppliable LFE-LDS Laminar Flow Meter

Supplied can be the „LDS-ES“ type made of stainless steel, as well as „LDS-AL“ made of alumin-

ium. The series „ES“ is designed for flow rate full scales between 0,01 l/min to 5 l/min. The series

„AL“ is designed for flow rate full scales between 10 l/min und 150 l/min. The nominal differential

pressure across the LFE -LDS is as a standard for all flow rate full scales 10 mbar. It can be ex-

tended without a bigger problem to 20 mbar on request. Beside of the LFE-LDS standard model

series-we can laso supply on customer request special sizes and intermediate sizes.

Specific safety instructions for secure handling of the LFE-LDS elements

The very small size of the flow channel is quite sensible against pollution. So please ensure that

these LFE are only operated with clean dry air and gases. If the flow channel is closed partially the

characteristics will change and the original calibration may no more be valid anymore. In this case

the LFE-LDS must be cleaned and recalibrated in the factory.

Check Delivery Content

• The LFE-LDS comes along with a manual of operation and a calibration data sheet

• The LFE-LDS were supplied with closing caps on the thread connection. Dismount these and

have a look through the flow channel cross section against a bright light. There should be

none of the flow paths closed.

Installation Requirements

Ensure before mounting: connect the LFE-LDS into a pipe, tube or measurement section only if

there is no dirt or other particles inside to see. If dirt is not to exclude in operation and the section

will not stay clean for ever it is strictly recommended to use an inlet filter with a filter rate of equiva-

lent to 5µm.

The two pressure connection lines for the DP pressure transmitter should have about the same

pipe length and diameter if possible and should be absolutely tight.

The temperature sensor should have a distance of about twice of the used pipe diameter in front of

the LFE-LDS input. If an absolute pressure sensor is used it should be connected at the positive

(+ plus) pressure tap of the DP.

The LFE-LDS can be connected into the line by a thread connection. In any case please verify and

respect the flow direction of the LFE-LDS (see arrow mark). Concerning the mounting direction

there is no limitation. In general the horizontal mounting direction is preferred compared to the ver-

tical direction, because the temperature may increase with 1°C/m height.

To achieve good measurement results one have to pay attention that the free cross section close

to the process connections is reduced as little as possible. This means that the wall thickness of

threads or directly screwed pipes shouldn’t be larger than 2 mm. Is it not possible to hold this rec-

ommendation the LFE-LDS should be calibrated from the manufacturer with the actually used flow

sections. This allows the maximum possible accuracy for your application.

Manual

LFE-LDS

LFE-LDS_man_e.doc page 5

FUNCTIONAL PRINCIPLE

By flow measurement you have to differentiate between mass flow ]/[ skgqMand volume flow

]/³[ smqV. Both values correspond with the density

ρ

of the medium.

VM qq ⋅=

ρ

The laminar flow meters use the pressure drop ∆p in a laminar pipe or crack stream to designate

the volume flow V

q.

The volume flow results by the equation:

p

k

qV∆= *

η

At this is ka device specific absolute term and ηthe dynamic viscosity or durability of the gas.

Because the dynamic viscosity ηof the gases is independent of the pressure in a wide range (up

to 6 bar), it is possible to realize an almost operation pressure independent actual volume flow

measurement.

Conditions therefore are:

Stabilisation of laminar flow, means a lower and upper flow limit mustn’t overshoot. The lower limit

of sensibility is defined by the accuracy of the pressure measuring device only. By the dimension-

ing of the laminar flow meter you have to divers between the entrance region of the stream into the

flow channel and the range of the well-established laminar profile.

entrance region

Manual

LFE-LDS

page 6 LFE-LDS_man_e.doc

A linear device function can be reached only if the inlet length of the section is long enough. In the

development of the laminar flow meter it was paid high attention to eliminate all disturbing fluid

mechanical effects (starting range effects, transition e.g.). To minimize risks by pollution there are

used rectangle cracks or cylindrical ring cracks with a crack waists of 0,5 up to 1 mm.

Advantages of laminar flow meter

Laminar flow meter have no moveable parts. Thereby they are little accident-sensitive.

The temporal response behaviour of the laminar flow meter is very fast. Volume flow variations in

the range of less than 10Hz are resoluted. It is independent to the operation pressure as long as

the product

VSystem qp *

fulfills a limit value, which guarantees a laminar flow. The measuring value ∆P is proportional to the

volume flow qvin the laminar range which makes an evaluation easier. The measuring value ∆P

can be displayed with direct indicating devices, with U-pipes, Betz manometer and micro manome-

ter or with electronical differential pressure transmitter.

The resting pressure drop 1.5-2 * ∆Pis very small. The relative failure lies below one percent of

the measuring value. The resolution is dependent of the used pressure transmitter. The laminar

flow transmitter are calibrated by a ambient air temperature of 20°C. By using established gas data

it is easily possible to convert the calibration factor to other gases and other temperatures. For the

calculation of the mass flow rate qMonly the gas density ρis needed (continuity law).

Ideal laminar elements measure the volume flow qvindependent on gas density ρ.

The measuring value ∆Pis dependent in the laminar range only to the dynamic viscosity of the

medium. For controlling a process the type of flow measurement should be configured to the spe-

cific circumstances. The following table shows the primary measuring dimensions of different flow

meter and the dependence of the measuring dimensions of flow and gas characteristics.

Flow Meter Primary dimension

Volumetric meter Frequency ~V

q

Laminar pipe p∆~ ηV

q

Thermical mass flow meter

T

∆Vp qc

η

~resp.

qcp

~

Venturi flow meter p∆~ ρV

q²

Norm orifice p∆~ ρV

q²

At volumetric laminar pipes it counts the primary measuring dimension

V

qp

η

~∆

whereas ηis the dynamic viscosity of the medium and V

qis the volume flow.

At thermical mass flow meter it counts:

pM cqT ~∆

whereas cp is the specific heat and qMis the mass flow.

For venturi flow meter and norm orifices counts:

²~ V

qp

ρ

∆

According to this the characteristic curve is in qvquadratic. For the determination of qvadditionally

the gas density have to be established.

Manual

LFE-LDS

LFE-LDS_man_e.doc page 7

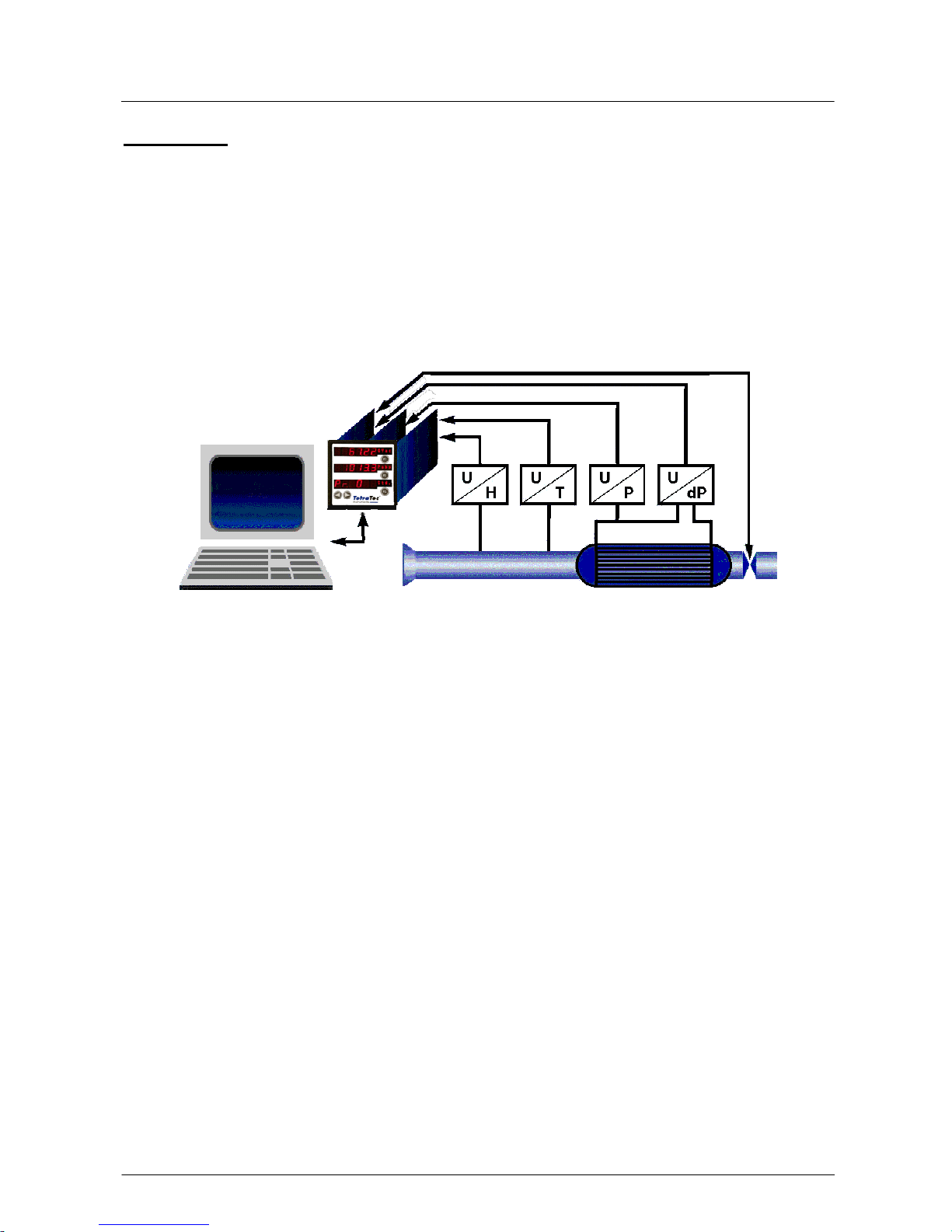

OPERATION

Procedure:

• Put at first the line into operation.

• Measure the differential pressure at the DP-pressure taps.

• Measure the gas temperature and if required the humidity of the flowing air.

• For the accurate evaluation of the volume or mass flow one has to measure also the static ab-

solute pressure in the line to calculate the density and also the viscosity of the flowing gas cor-

rectly.

• With all of these measured sensor data later the evaluation can be done. The flow can be cal-

culated manually or by using a flow computer what does do this calculation online.

Typical Sensors for Evaluation

H = rel. humidity / T = temperature / P = absolute pressure / dP = differential pressure

Calibration curves /- tables

Each LFE-LDS is calibrated against a "calibration master device" which is traceable to the PTB

(the highest german calibration institute). As a standard the LFE-LDS is calibrated with dry clean

air and the calibration results will be converted and corrected on standard calibration conditions of

21,1°C, 1013,25 mbar abs. and 0% rel. humidity.

Every LFE-LDS comes with an own calibration certificate. For this purpose at the order should be

defined the measurement units of the customer at least if they should be different than our stan-

dard. Based on the calibration data the actual flow rate Q can be calculated:

Q = (B x dP + C x dP2) x F = Qcal x F

B, C = calibration coefficients; shown for every LFE-LDS in the calibration certificate

F = viscosity correction factor = calibration viscosity / actual viscosity

Qcal = volume flow at calibration condition

Please confirm that you are using the right calibration certificate for the LFE. (Compare the serial

number).

Calculating the Flow

With the formulas, tables and diagrams shown in the calibration certificate the volume flow can be

calculated.

Air Flow Measurement

Procedure:

• Read the differential pressure.

• Use the formula to calculate the flow:

Qcal = B x dP x + C x dP2

The resulting calibration volume flow must be corrected with the viscosity factor to achieve the

actual volume flow and this again has to be multiplied with the density to receive the mass flow

Manual

LFE-LDS

page 8 LFE-LDS_man_e.doc

Gas Flow Measurement (other gases than air)

The same procedure as described above can be applied in principal for any other Gas than air. But

the actual volume flow must be calculated with the viscosity factor, the actual viscosity of the actual

gas as well as the density of the used media must be used for the calculation of the mass flow.

This procedure is only valid if the LFE-LDS is operated within the same Reynolds number range as

found in the calibration!

MAINTENANCE

Because the LFE-LDS has no moving parts it is almost free of service. But it is recommended to

clean the LFE-LDS in regular periods of 3 to 5 years and shelter it also by a suitable filtration (bet-

ter 5 µm) of the flowing media against bringing in dust and dirt into the slit.

Cleaning

Procedure:

• Take the LFE-LDS out of the line

• Inspect the slits for mechanical damages and on closing dirt of the flow paths

• Try to blow out the LFE-LDS with clean and oil free compressed air against the recommended

flow direction.

• If you find oily or gluing dirt on the LFE-LDS it may only be cleaned with proper and completely

in water resolving cleaning means which don’t build sedimentation. Please contact our com-

pany for accepted cleaning fluids, because not acceptable cleaning fluids can lead to damages

of the LFE.

For maintenance and repair we offer a special cleaning and recalibration

service.

Search and solving problems

Problem Possible cause Solving problem

Recommended straight in- and

outlet sections not present Straight inlet section 10 x D

Straight outlet section 5 x D

i.e.: D = 100 mm

inlet 1 m, outlet section 0,5 m

LFE-LDS slit polluted Clear or change LFE

Line and DP connecting tubes

could be bended to narrow so that

flow and pressure measurement

cannot work properly

Control line and DP connection

tubes for straight and reason-

able bending and correct that if

that solves the error.

DP connecting tubes have a dif-

ferent length and / or diameter or

are laid out in different positions

Correct that if that solves the

error

Display shows unreal-

istic

differential pressure or

wrong flow value

Reducers are directly at the in-

/outlet into the LFE-LDS and are

limiting the flow.

Use an appropriate connection

diameter.

differential pressure is

pulsating Turbulent flow profile in the LFE-

LDS or leakage Leak in DP con-

necting tubes.

Lower static pressure or lower

flow, tightening of the leakage.

Manual

LFE-LDS

LFE-LDS_man_e.doc page 9

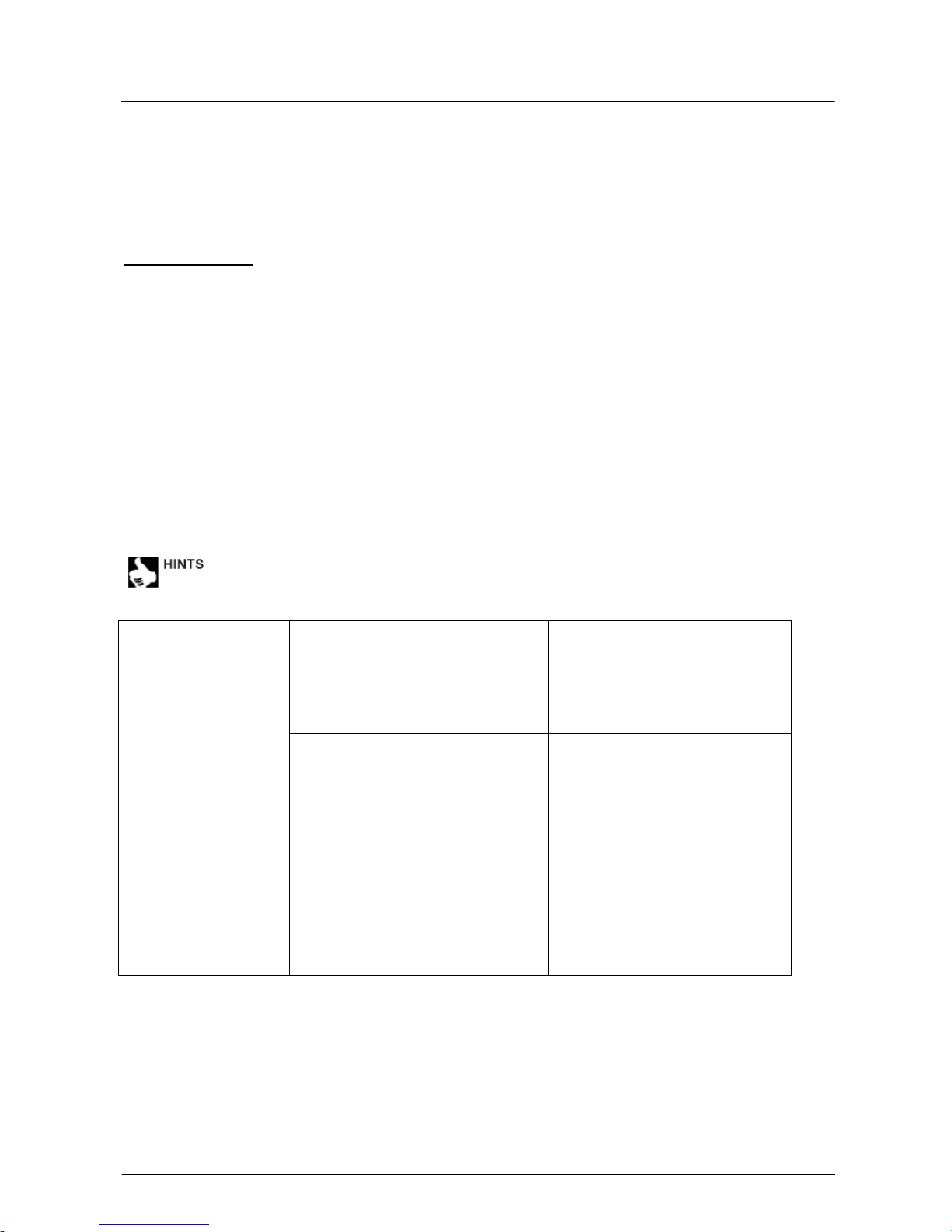

SPECIFICATIONS Serie ES

qvType

LDS-ES- [l/min] [m³/h] DP ∆p [mbar]

0.01 10 0.6 10

0.025 25 1.5 10

0.05-10 50 3 10

0.1-10 100 6 10

0.25-10 250 15 10

0.5-10 500 30 10

1-10 1000 60 10

2.5-10 2500 150 10

5-10 5000 300 10

Measuring range final values:

0 – nominal volume flow

The resolution is defined by the

used pressure transmitter.

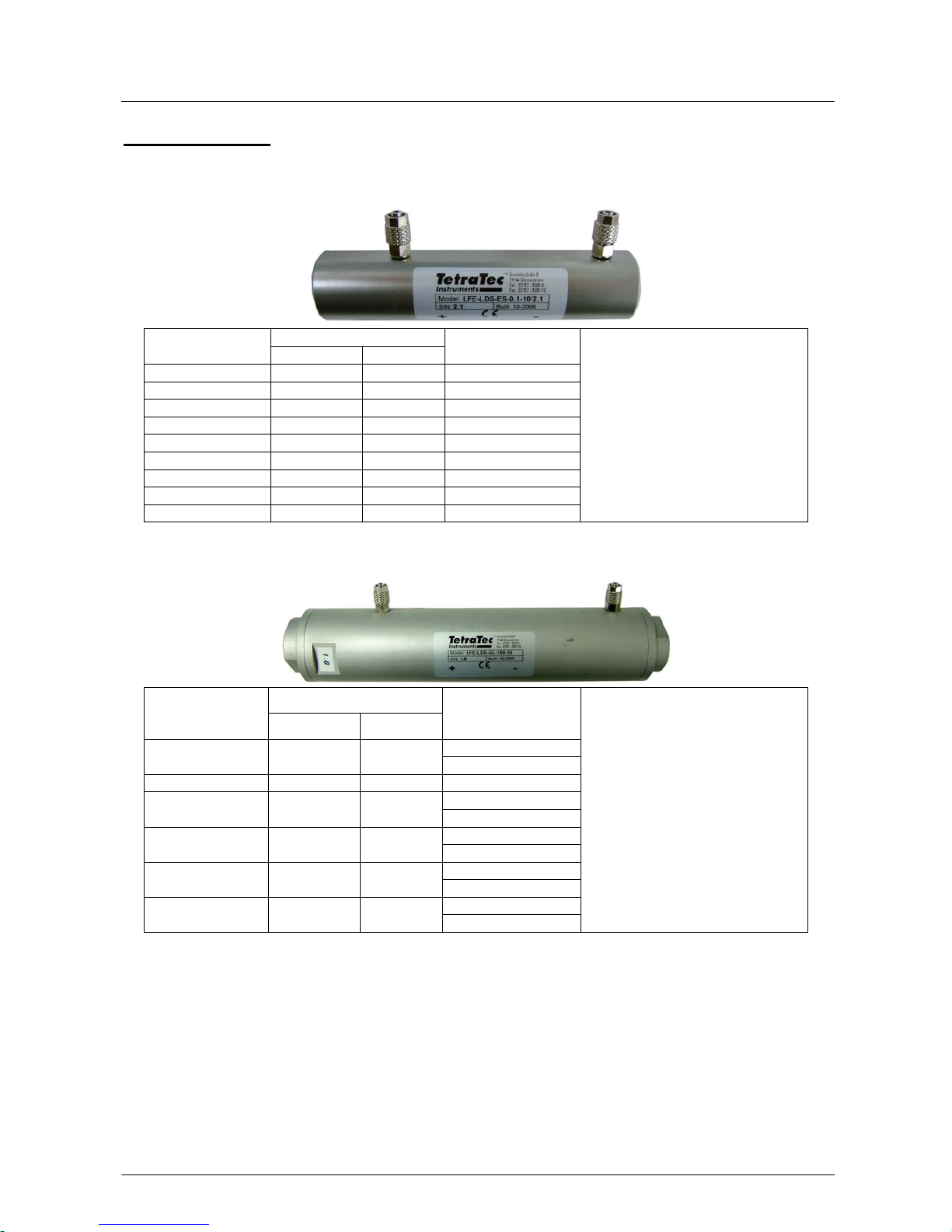

Serie AL

qv

Type

LDS-AL- [l/min] [m³/h] DP ∆p [mbar]

10

10 10 0.6 5

25 25 1.5 10

5

50 50 3 10

5

75 75 4.5 10

5

125 125 7.5 10

10

150 150 9 10

Measuring range final values:

0 – nominal volume flow

The resolution is defined by the

used pressure transmitter.

Manual

LFE-LDS

page 10 LFE-LDS_man_e.doc

DIMENSIONS

Serie ES

LDS-ES-0.01-10 up to LDS-ES-1-10

weight: 480 g

LDS-ES-2.5-10

weight: 630 g

LDS-ES-5-10

weight: 690 g

Manual

LFE-LDS

LFE-LDS_man_e.doc page 11

Serie Al

LDS-AL-10-10 up to LDS-AL-25-10

LDS-AL-50-10 up to LDS-AL-150-10

Table of contents