TEV marstair MRC+ Series User manual

55008351-23

INSTALLATION & TECHNICAL MANUAL

MARSTAIR REFRIGERATION CONDENSING UNITS (MRC+)

2/27 55008351-23

CONTENTS

PAGE

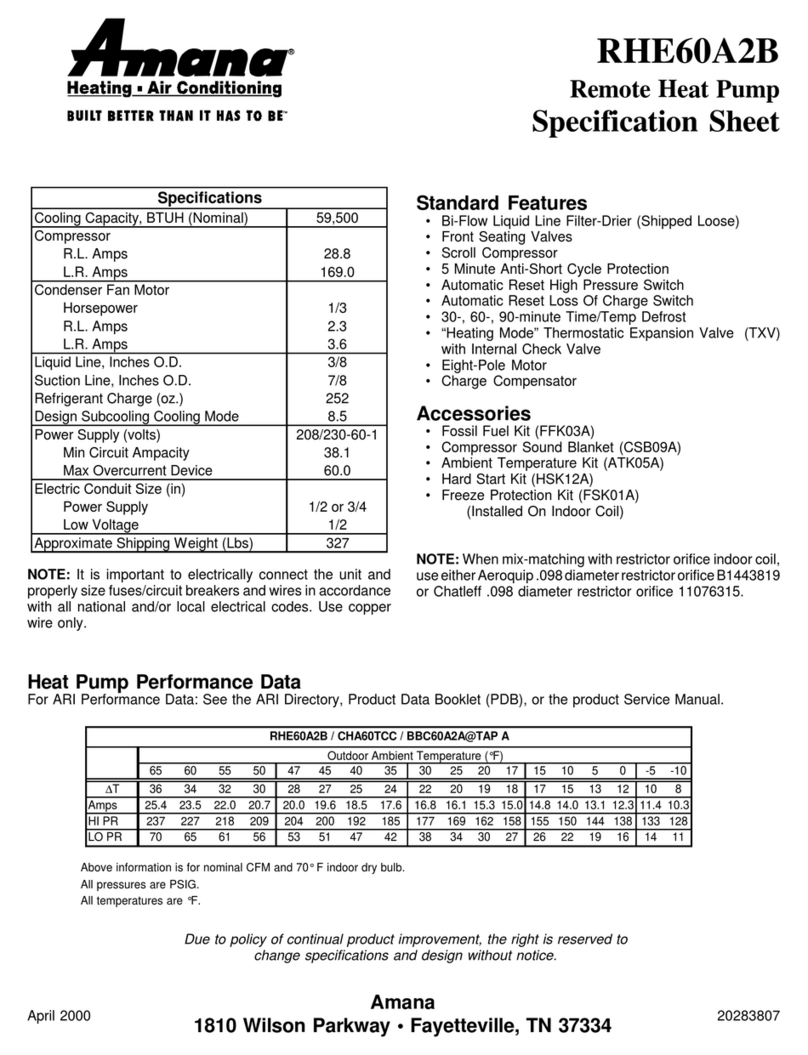

DIMENSIONS & WEIGHTS (packed & unpacked) & SPECIFICATION.

3

PERFORMANCE DATA.

4-11

MOUNTING, DIMENSIONS & WEIGHTS.

12-13

PIPEWORK.

13-14

ELECTRICAL & FUSES.

14-16

REFRIGERANT.

17-18

END OF LIFE REQUIRMENTS.

19

ECO DESIGN INFORMATION TABLES.

20-27

COMPONENT IDENTIFICATION MRC+.

28-29

1. TEV LTD recommend that personnel working on this equipment be skilled and fully conversant

with the appropriate Refrigeration and Electrical practices and have sound knowledge of current

Industrial Safe Working practices.

2. These units are supplied with a holding charge of oxygen free nitrogen and polyolester oil.

Do not mix oils or refrigerants.

3. These units when installed contain live electrical components, moving parts and refrigerant under

pressure. Always site out of reach of children and protect from vandalism.

4. The data plate only gives information for the outdoor unit. For system details add input power and

current of indoor and outdoor unit, including any heater load.

5. FUSES - for recommended fuse size see page 12.

6. The refrigerant used should be identified by locating a refrigerant label on the unit case

INDEX

GENERAL

NOTE

IF MECHANICAL PUMP DOWN OPERATION IS REQUIRED CONNECT A LINK WIRE

BETWEEN TERMINALS L1 & 3.

IF THIS LINK IS USED THEN TERMINAL 5 CAN NOT BE USED AS AN ALARM FACILITY

3/27 55008351-23

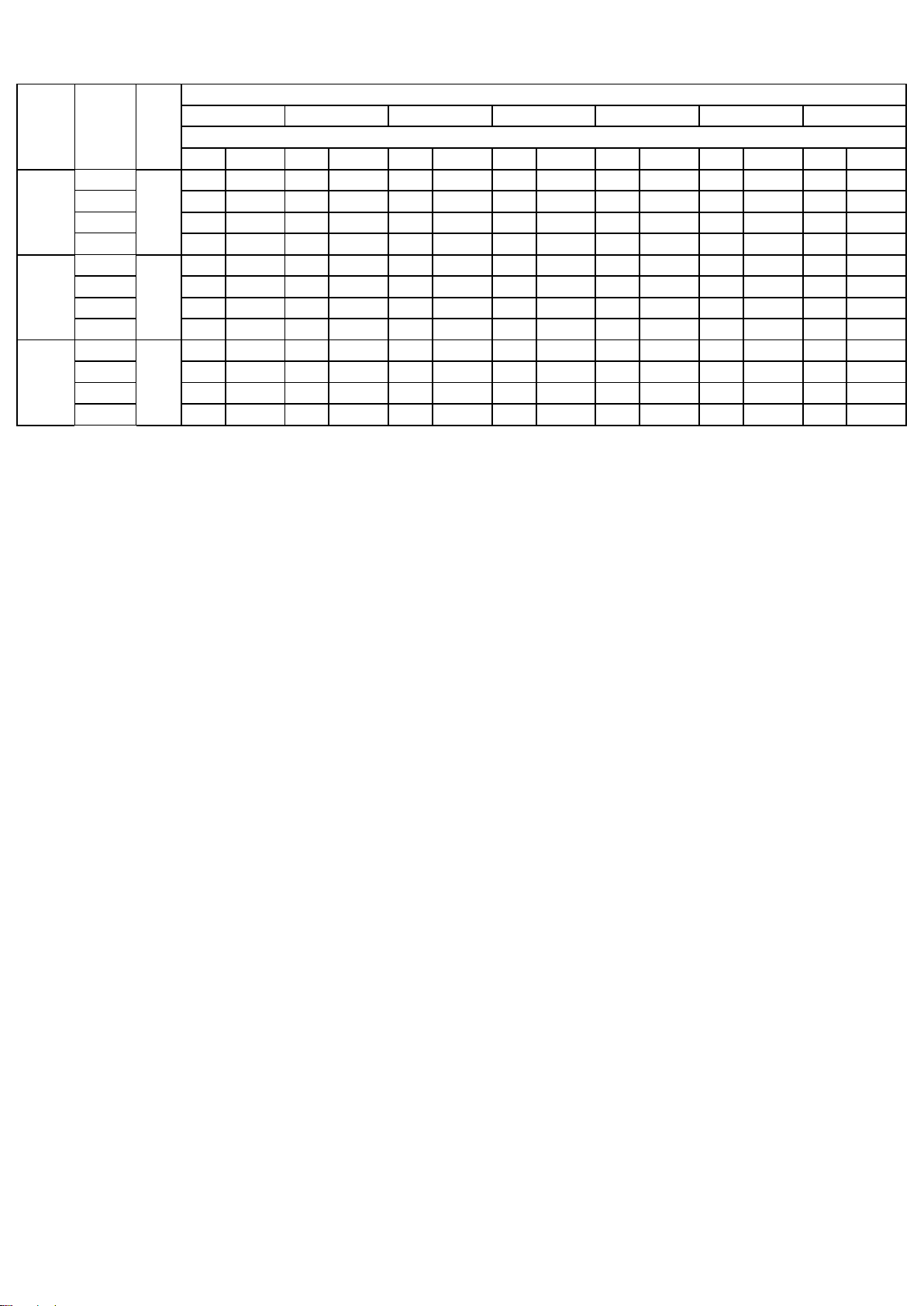

UNPACKED

MRC+ CONDENSING UNITS

MODEL

15

20

30

40

45

50

60

80

90

100

130

150

165

180

HEIGHT

mm

620

620

620

620

720

720

720

720

820

820

1080

1080

1080

1275

WIDTH

mm

900

900

900

900

1000

1000

1000

1000

1000

1000

1000

1000

1000

1100

DEPTH

mm

300

300

300

300

350

350

350

350

350

350

425

425

425

425

1 Ph kg

46

47

48

53

61

64

65

66

76

81

-

103

-

-

3 Ph kg

-

-

48

53

-

64

65

66

76

81

101

103

103

118

PACKED

MRC+ CONDENSING UNITS

MODEL

15

20

30

40

45

50

60

80

90

100

130

150

165

180

HEIGHT

mm

620

620

620

620

720

720

720

720

820

820

1080

1080

1080

1280

WIDTH

mm

980

980

980

980

1090

1090

1090

1090

1090

1090

1090

1090

1090

1215

DEPTH

mm

340

340

340

340

390

390

390

390

390

390

465

465

465

465

1 Ph kg

48

49

50

(43*)

55

(47*)

63

66

67

68

78

85

-

107

-

-

3 Ph kg

-

-

50

55

-

66

67

68

78

85

105

107

107

123

MRC+

15

20

30

40

45

50

60

80

90

100

130

150

165

180

Nominal cooling

capacity (-10°C

evaporating

temp & 32°C

ambient temp)

R404A

kW

1Ph

3Ph

1.1

-

1.4

-

2.0

2.0

2.9

2.9

2.9

2.9

3.9

3.9

4.6

4.6

5.5

5.5

6.4

6.4

7.1

7.1

-

8.1

8.8

8.8

-

10.5

-

11.6

Operating weight

kg

1Ph

46

47

48

53

61

64

65

66

76

81

-

103

-

-

3Ph

-

-

48

53

-

64

65

66

76

81

101

103

103

118

1 Ph (230V 50Hz) compressor load only (at nominal cooling capacity)

Power (nominal)

kW

0.82

1.12

1.42

2.07

1.43

2.03

2.26

2.61

3.03

3.92

-

4.52

-

-

Starting current

LRA

A

23

28

36

50

35

58

61

76

110

114

-

142

-

-

Nominal current

FLA

A

5.9

6.9

8.1

10.2

10.0

8.9

9.8

11.5

16.9

20.5

-

32.3

-

-

3Ph (400v 50Hz) compressor load only (at nominal cooling capacity)

Power (nominal)

kW

-

-

1.42

2.07

-

2.03

2.26

2.61

3.03

3.92

4.46

4.52

5.29

5.82

Starting current

LRA

A

-

-

18

22

-

26

32

40

48

51

62

68

71

71

Nominal current

FLA

A

-

-

3.6

4.8

-

4.2

4.2

4.9

7.1

7.2

7.7

8.7

9.5

11.9

Sound Pressure Levels (SPL) at 10m distance in free field conditions @ 27°C external ambient.

Fan speed max

dBA

34

34

34

34

33

33

33

34

37

38

37

37

37

39

NR

28

28

28

28

27

27

27

27

30

31

30

30

30

32

Condenser fan (1Ph 230V 50Hz)

Airflow (max

speed)

m³/s

0.40

0.40

0.97

0.97

0.97

0.97

0.97

0.97

0.97

0.97

1.85

1.85

1.85

1.85

Fan motor rating

kW

0.65

0.65

0.13

0.13

0.13

0.13

0.13

0.13

0.13

0.13

2x0.13

2x0.13

2x0.13

2x0.13

Nominal current

FLA

A

0.4

0.4

0.6

0.6

0.6

0.6

0.6

0.6

0.6

0.6

2x0.6

2x0.6

2x0.6

2x0.6

Fans: No. x

diameter

#x

mm

1x350

1x350

1x457

1x457

1x457

1x457

1x457

1x457

1x457

1x457

2x457

2x457

2x457

2x457

Fans max speed

r.p.m

940

940

940

940

940

940

940

940

940

940

940

940

940

940

DIMENSIONS AND WEIGHTS

SPECIFICATION DETAILS

4/27 55008351-23

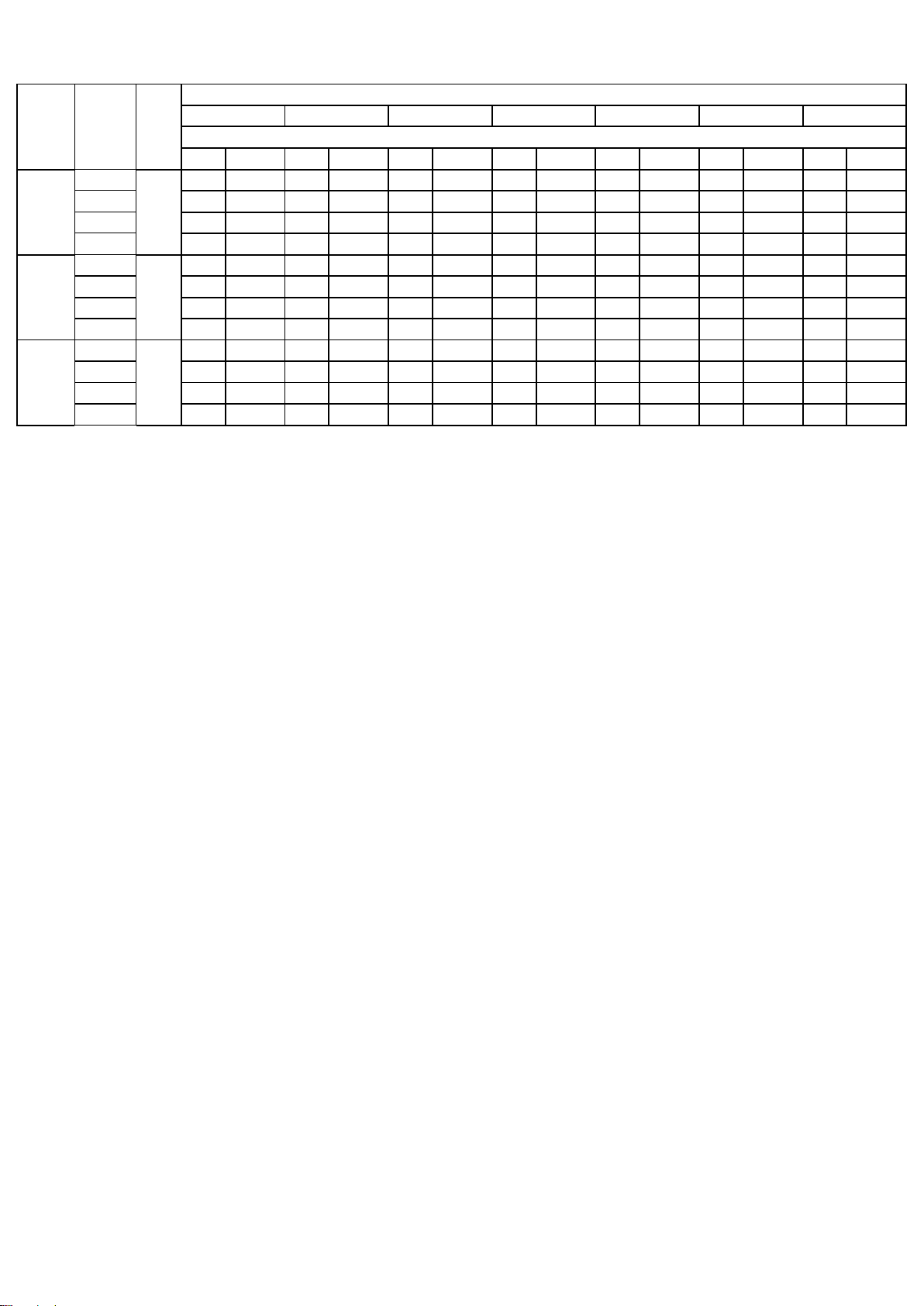

MRC+ 15 –180 CAPACITIES –1 & 3 Phase

(Return gas temperature 20°C, 0°K sub cooling)

R407A

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

15

27

1/2

0.90

0.52

1.20

0.58

1.55

0.65

1.90

0.71

2.37

0.77

2.39

0.80

2.45

0.82

30

0.84

0.52

1.14

0.58

1.47

0.65

1.81

0.72

2.25

0.79

2.28

0.81

2.32

0.85

32

0.81

0.52

1.09

0.58

1.42

0.66

1.74

0.77

2.19

0.80

2.19

0.83

2.24

0.86

35

0.74

0.53

1.03

0.58

1.34

0.67

1.65

0.75

2.05

0.83

2.07

0.85

2.10

0.89

MRC+

20

27

5/8

1.17

0.68

1.56

0.76

2.01

0.85

2.47

0.94

3.07

1.02

3.11

1.05

3.18

1.09

30

1.10

0.68

1.47

0.77

1.91

0.86

2.35

0.95

2.92

1.04

2.96

1.07

3.01

1.12

32

1.05

0.68

1.42

0.77

1.84

0.86

2.26

1.01

2.84

1.06

2.85

1.09

2.91

1.14

35

0.96

0.68

1.34

0.78

1.73

0.88

2.14

0.99

2.66

1.09

2.68

1.13

2.72

1.18

MRC+

30

27

1 3/8

1.74

0.94

2.23

1.04

2.78

1.15

3.32

1.26

4.03

1.36

4.07

1.43

4.40

1.50

30

1.64

0.94

2.11

1.05

2.64

1.16

3.16

1.28

3.83

1.39

3.87

1.46

4.16

1.55

32

1.57

0.95

2.03

1.06

2.53

1.17

3.03

1.35

3.74

1.41

3.72

1.49

4.02

1.58

35

1.44

0.95

1.91

1.07

2.39

1.20

2.87

1.33

3.50

1.45

3.50

1.54

3.75

1.64

MRC+

40

27

1 1/2

2.52

1.40

3.18

1.50

3.93

1.64

4.67

1.80

5.46

1.99

5.75

2.08

6.25

2.21

30

2.39

1.42

3.03

1.53

3.74

1.68

4.64

1.85

5.18

2.05

5.46

2.14

5.90

2.29

32

2.31

1.43

2.92

1.56

3.60

1.70

4.28

1.97

5.04

2.10

5.25

2.19

5.68

2.34

35

2.12

1.44

2.76

1.58

3.41

1.75

4.04

1.94

4.69

2.16

4.91

2.26

5.28

2.42

MRC+

45

27

1 1/2

2.48

1.02

3.01

1.05

3.62

1.10

4.22

1.18

4.87

1.29

5.11

1.37

5.52

1.47

30

2.39

1.09

2.90

1.13

3.49

1.18

4.08

1.25

4.69

1.37

4.92

1.45

5.29

1.57

32

2.33

1.14

2.89

1.17

3.39

1.22

3.95

1.36

4.61

1.42

4.78

1.52

5.31

1.64

35

2.19

1.22

2.72

1.26

3.25

1.31

3.79

1.39

4.36

1.53

4.55

1.62

4.89

1.75

MRC+

50

27

2

3.31

1.50

4.05

1.54

4.89

1.59

5.73

1.67

6.64

1.78

6.98

1.83

7.57

1.88

30

3.20

1.60

3.90

1.65

4.72

1.70

5.54

1.78

6.39

1.89

6.73

1.93

7.26

2.02

32

3.12

1.67

3.89

1.72

4.58

1.76

5.37

1.93

6.29

1.96

6.54

2.02

7.29

2.10

35

2.92

1.79

3.66

1.84

4.39

1.89

5.15

1.98

5.94

2.10

6.23

2.14

6.71

2.24

MRC+

60

27

2 1/2

3.89

1.66

4.75

1.71

5.74

1.77

6.72

1.86

7.80

1.98

8.19

2.03

8.89

2.09

30

3.75

1.78

4.58

1.83

5.55

1.89

6.51

1.98

7.50

2.10

7.90

2.15

8.52

2.25

32

3.66

1.86

4.56

1.91

5.38

1.96

6.30

2.15

7.38

2.18

7.68

2.25

8.56

2.34

35

3.43

1.99

4.29

2.05

5.16

2.11

6.05

2.21

6.97

2.34

7.31

2.40

7.88

2.50

MRC+

80

27

3

4.63

1.90

5.65

1.96

6.84

2.02

8.00

2.13

9.28

2.27

9.75

2.33

10.58

2.41

30

4.47

2.04

5.45

2.10

6.60

2.17

7.75

2.28

8.93

2.42

9.41

2.48

10.14

2.59

32

4.35

2.14

5.43

2.20

6.40

2.26

7.50

2.48

8.78

2.52

9.14

2.60

10.18

2.70

35

4.08

2.30

5.11

2.37

6.14

2.44

7.20

2.55

8.30

2.71

8.70

2.77

9.37

2.90

MRC+

90

27

3 1/2

5.40

2.19

6.60

2.26

7.98

2.34

9.35

2.46

10.84

2.63

11.39

2.70

12.35

2.79

30

5.21

2.37

6.37

2.43

7.71

2.51

9.04

2.64

10.43

2.80

10.98

2.88

11.84

3.00

32

5.08

2.48

6.34

2.55

7.47

2.62

8.76

2.88

10.25

2.93

10.67

3.02

11.89

3.14

35

4.77

2.67

5.96

2.75

7.17

2.83

8.40

2.96

9.69

3.15

10.16

3.23

10.94

3.37

MRC+

100

27

4

6.19

2.89

7.71

2.97

9.14

3.08

10.71

3.24

12.41

3.45

13.05

3.54

14.15

3.65

30

5.97

3.09

7.29

3.17

8.83

3.27

10.36

3.43

11.95

3.64

12.58

3.73

13.57

3.89

32

5.82

3.21

7.02

3.25

8.56

3.39

10.03

3.72

11.75

3.78

12.22

3.88

13.62

4.04

35

5.46

3.43

6.83

3.53

8.21

3.63

9.63

3.80

11.10

4.03

11.63

4.12

12.54

4.30

MRC+

130

27

4 1/2

7.09

3.30

8.84

3.39

10.47

3.51

12.27

3.69

14.22

3.92

14.95

4.03

16.21

4.15

30

6.84

3.53

8.36

3.62

10.11

3.74

11.87

3.91

13.69

4.15

14.42

4.25

15.54

4.43

32

6.67

3.67

8.05

3.71

9.81

3.87

11.50

4.24

13.46

4.31

14.00

4.43

15.61

4.60

35

6.25

3.92

7.83

4.04

9.41

4.15

11.03

4.33

12.72

4.60

13.33

4.70

14.36

4.91

PERFORMANCE DATA

5/27 55008351-23

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

150

27

5

7.74

3.34

9.64

3.44

11.43

3.56

13.38

3.74

15.51

3.97

16.30

4.08

17.68

4.20

30

7.46

3.57

9.11

3.67

11.03

3.78

12.95

3.96

14.93

4.20

15.72

4.30

16.95

4.49

32

7.28

3.71

8.78

3.76

10.70

3.92

12.54

4.29

14.68

4.36

15.28

4.48

17.02

4.66

35

6.82

3.97

8.54

4.09

10.26

4.20

12.03

4.39

13.87

4.66

14.54

4.76

15.67

4.97

MRC+

165

27

6

9.23

3.89

11.50

4.00

13.63

4.14

15.96

4.35

18.51

4.63

19.45

4.76

21.09

4.90

30

8.90

4.16

10.87

4.28

13.16

4.41

15.44

4.62

17.81

4.91

18.76

5.03

20.22

5.25

32

8.68

4.33

10.47

4.38

12.76

4.58

14.96

5.02

17.51

5.10

18.22

5.24

20.31

5.45

35

8.14

4.64

10.19

4.78

12.24

4.91

14.35

5.13

16.55

5.45

17.34

5.57

18.69

5.82

MRC+

180

27

7 1/2

10.20

4.27

12.71

4.39

15.06

4.55

17.64

4.78

20.45

5.09

21.50

5.23

23.31

5.39

30

9.84

4.57

12.02

4.70

14.55

4.85

17.07

5.08

19.68

5.39

20.73

5.53

22.35

5.77

32

9.60

4.76

11.57

4.82

14.10

5.04

16.53

5.52

19.35

5.61

20.14

5.77

22.44

6.00

35

8.99

5.11

11.26

5.26

13.53

5.40

15.86

5.65

18.29

6.00

19.17

6.14

20.66

6.41

6/27 55008351-23

MRC+ 15 –180 CAPACITIES –1 & 3 Phase

(Return gas temperature 20°C, 0°K sub cooling)

R407F

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

15

27

1/2

0.88

0.58

1.19

0.64

1.54

0.71

1.93

0.76

2.37

0.84

2.42

0.86

2.49

0.81

30

0.83

0.59

1.12

0.64

1.46

0.72

1.81

0.79

2.26

0.86

2.30

0.88

2.37

0.92

32

0.79

0.59

1.07

0.64

1.40

0.72

1.74

0.80

2.21

0.87

2.22

0.90

2.29

0.94

35

0.74

0.58

1.01

0.64

1.32

0.74

1.64

0.82

2.05

0.90

2.08

0.92

2.14

0.97

MRC+

20

27

5/8

1.15

0.76

1.54

0.84

2.00

0.93

2.50

1.01

3.08

1.11

3.14

1.14

3.23

1.18

30

1.07

0.76

1.45

0.85

1.89

0.94

2.34

1.04

2.93

1.13

2.99

1.16

3.07

1.21

32

1.03

0.77

1.39

0.86

1.81

0.95

2.26

1.06

2.87

1.15

2.88

1.19

2.97

1.24

35

0.96

0.76

1.31

0.86

1.71

0.97

2.13

1.08

2.66

1.19

2.70

1.23

2.77

1.29

MRC+

30

27

1 3/8

1.72

1.05

2.20

1.15

2.75

1.26

3.36

1.34

4.05

1.47

4.11

1.54

4.47

1.62

30

1.61

1.06

2.08

1.16

2.61

1.28

3.15

1.40

3.84

1.51

3.91

1.58

4.24

1.67

32

1.54

1.06

1.99

1.17

2.50

1.29

3.03

1.42

3.76

1.53

3.76

1.62

4.09

1.71

35

1.44

1.06

1.87

1.18

2.36

1.31

2.85

1.45

3.50

1.57

3.53

1.67

3.82

1.79

MRC+

40

27

1 1/2

2.49

1.58

3.14

1.68

3.89

1.80

4.72

1.92

5.48

2.16

5.81

2.25

6.34

2.39

30

2.34

1.60

2.98

1.71

3.71

1.85

4.62

2.03

5.20

2.24

5.52

2.33

6.01

2.49

32

2.25

1.61

2.87

1.73

3.56

1.88

4.28

2.06

5.08

2.29

5.30

2.39

5.79

2.55

35

2.12

1.61

2.70

1.75

3.35

1.92

4.02

2.12

4.69

2.36

4.96

2.46

5.38

2.64

MRC+

45

27

1 1/2

2.44

1.15

2.97

1.17

3.58

1.21

4.27

1.25

4.89

1.39

5.16

1.48

5.60

1.58

30

2.35

1.23

2.86

1.25

3.46

1.29

4.06

1.37

4.71

1.49

4.97

1.57

5.39

1.70

32

2.28

1.28

2.84

1.30

3.35

1.35

3.95

1.42

4.65

1.55

4.83

1.65

5.42

1.78

35

2.19

1.37

2.66

1.39

3.20

1.44

3.77

1.52

4.36

1.66

4.59

1.76

4.97

1.91

MRC+

50

27

2

3.26

1.69

4.00

1.72

4.85

1.76

5.80

1.79

6.67

1.93

7.05

1.98

7.69

2.04

30

3.13

1.81

3.84

1.84

4.68

1.87

5.52

1.95

6.42

2.06

6.80

2.10

7.40

2.19

32

3.04

1.89

3.82

1.91

4.53

1.95

5.37

2.02

6.33

2.13

6.61

2.19

7.43

2.28

35

2.92

2.01

3.58

2.03

4.32

2.08

5.13

2.16

5.94

2.29

6.28

2.33

6.83

2.45

MRC+

60

27

2 1/2

3.83

1.88

4.70

1.90

5.69

1.95

6.81

1.99

7.82

2.14

8.27

2.20

9.02

2.26

30

3.68

2.02

4.51

2.04

5.49

2.08

6.48

2.17

7.53

2.29

7.98

2.34

8.68

2.44

32

3.57

2.10

4.48

2.13

5.31

2.17

6.30

2.25

7.43

2.38

7.76

2.44

8.72

2.55

35

3.43

2.24

4.20

2.27

5.08

2.32

6.02

2.41

6.98

2.55

7.37

2.61

8.01

2.73

MRC+

80

27

3

4.56

2.15

5.59

2.19

6.77

2.24

8.10

2.28

9.31

2.47

9.85

2.53

10.74

2.61

30

4.38

2.32

5.37

2.35

6.54

2.40

7.71

2.50

8.96

2.64

9.50

2.70

10.33

2.81

32

4.25

2.42

5.33

2.45

6.32

2.50

7.50

2.60

8.85

2.75

9.23

2.82

10.38

2.94

35

4.08

2.59

5.00

2.62

6.04

2.69

7.16

2.79

8.30

2.96

8.77

3.02

9.54

3.17

MRC+

90

27

3 1/2

5.32

2.49

6.53

2.53

7.91

2.58

9.46

2.64

10.87

2.86

11.50

2.93

12.54

3.02

30

5.11

2.69

6.27

2.72

7.63

2.78

9.01

2.90

10.47

3.06

11.10

3.13

12.06

3.27

32

4.96

2.81

6.23

2.85

7.38

2.91

8.76

3.02

10.33

3.20

10.78

3.28

12.12

3.43

35

4.76

3.01

5.84

3.05

7.05

3.13

8.36

3.25

9.69

3.44

10.24

3.52

11.13

3.69

MRC+

100

27

4

6.10

3.29

7.63

3.33

9.06

3.41

10.83

3.47

12.46

3.75

13.17

3.84

14.36

3.95

30

5.85

3.52

7.18

3.56

8.74

3.63

10.32

3.77

11.99

3.98

12.71

4.06

13.82

4.23

32

5.69

3.64

6.90

3.63

8.46

3.76

10.03

3.91

11.83

4.12

12.35

4.23

13.89

4.41

35

5.46

3.87

6.69

3.92

8.08

4.01

9.58

4.16

11.11

4.40

11.73

4.50

12.75

4.71

MRC+

130

27

4 1/2

6.99

3.73

8.74

3.78

10.38

3.87

12.41

3.95

14.27

4.26

15.09

4.36

16.45

4.49

30

6.70

4.00

8.23

4.04

10.02

4.13

11.82

4.29

13.74

4.53

14.56

4.62

15.83

4.81

32

6.51

4.15

7.90

4.13

9.69

4.28

11.50

4.45

13.56

4.69

14.15

4.81

15.91

5.01

35

6.25

4.40

7.66

4.46

9.26

4.57

10.98

4.74

12.72

5.01

13.44

5.12

14.61

5.36

PERFORMANCE DATA

7/27 55008351-23

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

150

27

5

7.62

3.78

9.53

3.83

11.32

3.92

13.54

4.00

15.57

4.31

16.46

4.41

17.95

4.55

30

7.31

4.05

8.98

4.09

10.93

4.18

12.89

4.34

14.98

4.58

15.88

4.68

17.27

4.87

32

7.10

4.20

8.62

4.18

10.57

4.34

12.54

4.50

14.79

4.75

15.43

4.88

17.35

5.08

35

6.82

4.46

8.35

4.52

10.10

4.63

11.97

4.80

13.88

5.08

14.66

5.19

15.94

5.43

MRC+

165

27

6

9.09

4.41

11.37

4.47

13.50

4.57

16.15

4.66

18.57

5.03

19.64

5.15

21.41

5.31

30

8.72

4.73

10.71

4.78

13.03

4.88

15.38

5.07

17.87

5.36

18.95

5.47

20.60

5.70

32

8.48

4.91

10.28

4.89

12.61

5.07

14.96

5.26

17.64

5.56

18.41

5.70

20.70

5.94

35

8.13

5.22

9.97

5.29

12.05

5.41

14.28

5.62

16.55

5.95

17.49

6.08

19.01

6.37

MRC+

180

27

7 1/2

10.05

4.84

12.57

4.91

14.92

5.03

17.85

5.12

20.53

5.53

21.71

5.66

23.66

5.84

30

9.64

5.20

11.83

5.26

14.41

5.37

17.00

5.58

19.75

5.89

20.94

6.01

22.77

6.27

32

9.37

5.40

11.36

5.37

13.93

5.58

16.53

5.79

19.50

6.12

20.35

6.28

22.88

6.54

35

8.99

5.74

11.02

5.82

13.31

5.96

15.79

6.19

18.30

6.55

19.33

6.69

21.01

7.01

8/27 55008351-23

MRC+ 15 –180 CAPACITIES –1 & 3 Phase

(Return gas temperature 20°C, 0°K sub cooling)

R404A

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

15

27

1/2

0.95

0.60

1.23

0.67

1.54

0.73

1.86

0.78

2.26

0.84

2.28

0.85

2.32

0.87

30

0.88

0.60

1.15

0.67

1.45

0.73

1.75

0.80

2.13

0.85

2.15

0.87

2.18

0.89

32

0.84

0.60

1.10

0.67

1.38

0.74

1.67

0.80

2.04

0.86

2.06

0.88

2.08

0.91

35

0.79

0.60

1.03

0.67

1.30

0.75

1.57

0.82

1.91

0.88

1.92

0.90

1.94

0.94

MRC+

20

27

5/8

1.23

0.79

1.59

0.87

2.00

0.95

2.41

1.04

2.93

1.01

2.96

1.13

3.01

1.16

30

1.15

0.79

1.49

0.88

1.88

0.96

2.27

1.05

2.76

1.13

2.79

1.15

2.82

1.18

32

1.09

0.79

1.43

0.88

1.80

0.97

2.17

1.06

2.65

1.14

2.67

1.17

2.70

1.20

35

1.02

0.79

1.33

0.88

1.68

0.98

2.03

1.08

2.48

1.17

2.50

1.18

2.52

1.24

MRC+

30

27

1 3/8

1.84

1.09

2.28

1.19

2.75

1.29

3.24

1.39

3.85

1.47

3.89

1.53

4.16

1.59

30

1.72

1.09

2.13

1.20

2.59

1.30

3.04

1.41

3.63

1.50

3.65

1.56

3.90

1.63

32

1.64

1.09

2.04

1.20

2.48

1.31

2.91

1.42

3.48

1.52

3.49

1.59

3.73

1.66

35

1.53

1.09

1.91

1.21

2.32

1.33

2.73

1.45

3.25

1.55

3.26

1.63

3.48

1.72

MRC+

40

27

1 1/2

2.66

1.64

3.24

1.74

3.89

1.85

4.56

1.99

5.22

2.16

5.49

2.23

5.91

2.35

30

2.51

1.65

3.06

1.76

3.67

1.89

4.47

2.04

4.90

2.22

5.15

2.30

5.53

2.42

32

2.40

1.66

2.94

1.77

3.52

1.91

4.11

2.07

4.69

2.26

4.92

2.34

5.28

2.47

35

2.25

1.66

2.75

1.80

3.30

1.95

3.84

2.12

4.36

2.32

4.58

2.41

4.89

2.54

MRC+

45

27

1 1/2

2.61

1.19

3.07

1.21

3.58

1.24

4.12

1.29

4.66

1.39

4.87

1.47

5.22

1.56

30

2.51

1.27

2.93

1.28

3.43

1.32

3.93

1.37

4.44

1.48

4.64

1.55

4.96

1.66

32

2.43

1.32

2.91

1.33

3.31

1.37

3.80

1.43

4.29

1.53

4.48

1.62

4.94

1.73

35

2.32

1.41

2.71

1.43

3.15

1.46

3.60

1.52

4.06

1.63

4.24

1.72

4.53

1.84

MRC+

50

27

2

3.49

1.76

4.13

1.78

4.85

1.80

5.59

1.85

6.35

1.93

6.66

1.96

7.16

2.00

30

3.35

1.87

3.95

1.89

4.63

1.91

5.34

1.96

6.05

2.04

6.35

2.07

6.81

2.13

32

3.24

1.94

3.91

1.96

4.48

1.98

5.16

2.03

5.85

2.11

6.13

2.15

6.78

2.21

35

3.09

2.07

3.64

2.09

4.26

2.11

4.90

2.16

5.53

2.25

5.80

2.28

6.21

2.35

MRC+

60

27

2 1/2

4.10

1.95

4.85

1.97

5.69

2.00

6.56

2.05

7.45

2.14

7.82

2.18

8.41

2.22

30

3.93

2.08

4.64

2.10

5.44

2.12

6.26

2.18

7.10

2.27

7.45

2.31

7.99

2.37

32

3.81

2.16

4.59

2.18

5.26

2.21

6.06

2.26

6.86

2.35

7.20

2.40

7.95

2.47

35

3.63

2.31

4.28

2.33

4.99

2.36

5.75

2.41

6.49

2.51

6.80

2.55

7.29

2.63

MRC+

80

27

3

4.88

2.24

5.77

2.27

6.77

2.29

7.81

2.36

8.87

2.47

9.31

2.51

10.01

2.56

30

4.68

2.39

5.52

2.42

6.47

2.45

7.46

2.51

8.45

2.62

8.87

2.66

9.51

2.74

32

4.53

2.49

5.46

2.52

6.26

2.55

7.21

2.61

8.17

2.72

8.57

2.77

9.47

2.85

35

4.32

2.67

5.09

2.70

5.95

2.72

6.84

2.79

7.73

2.91

8.10

2.95

8.68

3.04

MRC+

90

27

3 1/2

5.69

2.59

6.74

2.62

7.91

2.65

9.12

2.73

10.35

2.86

10.87

2.90

11.68

2.96

30

5.46

2.77

6.44

2.80

7.56

2.84

8.71

2.91

9.87

3.04

10.35

3.09

11.10

3.18

32

5.29

2.89

6.38

2.92

7.31

2.96

8.42

3.03

9.54

3.16

10.00

3.22

11.05

3.32

35

5.04

3.11

5.94

3.14

6.94

3.17

7.99

3.25

9.02

3.39

9.45

3.44

10.14

3.54

MRC+

100

27

4

6.52

3.43

7.88

3.46

9.06

3.50

10.45

3.60

11.86

3.75

12.45

3.81

13.39

3.88

30

6.25

3.63

7.38

3.67

8.66

3.70

9.97

3.80

11.31

3.95

11.86

4.01

12.72

4.12

32

6.06

3.75

7.06

3.73

8.37

3.83

9.65

3.92

10.93

4.08

11.46

4.15

12.66

4.26

35

5.78

3.99

6.81

4.03

7.95

4.07

9.15

4.16

10.33

4.33

10.83

4.39

11.61

4.52

MRC+

130

27

4 1/2

7.47

3.89

9.03

3.92

10.38

3.97

11.97

4.08

13.59

4.26

14.26

4.32

15.34

4.41

30

7.17

4.12

8.45

4.16

9.92

4.21

11.42

4.32

12.95

4.49

13.59

4.55

14.57

4.68

32

6.95

4.27

8.09

4.24

9.59

4.35

11.05

4.46

12.52

4.64

13.13

4.72

14.50

4.85

35

6.62

4.55

7.80

4.59

9.11

4.63

10.49

4.74

11.84

4.94

12.41

5.00

13.30

5.15

PERFORMANCE DATA

9/27 55008351-23

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

150

27

5

8.15

3.94

9.84

3.97

11.32

4.02

13.06

4.13

14.82

4.31

15.56

4.38

16.73

4.46

30

7.82

4.17

9.22

4.22

10.82

4.26

12.46

4.37

14.13

4.55

14.82

4.61

15.89

4.75

32

7.58

4.32

8.83

4.29

10.46

4.41

12.06

4.52

13.65

4.70

14.32

4.78

15.82

4.92

35

7.22

4.60

8.51

4.65

9.94

4.69

11.44

4.80

12.91

5.00

13.53

5.07

14.51

5.22

MRC+

165

27

6

9.72

4.59

11.74

4.63

13.50

4.69

15.58

4.82

17.68

5.03

18.56

5.11

19.95

5.21

30

9.32

4.87

11.00

4.93

12.90

4.98

14.87

5.11

16.86

5.31

17.68

5.39

18.96

5.55

32

9.04

5.05

10.53

5.02

12.48

5.16

14.38

5.29

16.29

5.49

17.08

5.60

18.87

5.75

35

8.61

5.39

10.15

5.44

11.85

5.49

13.64

5.62

15.41

5.85

16.15

5.93

17.31

6.11

MRC+

180

27

7 1/2

10.74

5.04

12.98

5.09

14.92

5.16

17.22

5.30

19.54

5.53

20.52

5.62

22.05

5.73

30

10.30

5.36

12.16

5.42

14.26

5.47

16.43

5.62

18.63

5.85

19.54

5.93

20.95

6.10

32

9.99

5.56

11.64

5.52

13.79

5.67

15.90

5.82

18.00

6.05

18.88

6.16

20.86

6.33

35

9.52

5.93

11.22

5.99

13.10

6.05

15.08

6.19

17.03

6.45

17.84

6.53

19.13

6.73

10/27 55008351-23

MRC+ 15 –180 CAPACITIES –1 & 3 Phase

(Return gas temperature 20°C, 0°K sub cooling)

R448A –R449A

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

15

27

1/2

0.83

0.53

1.10

0.61

1.41

0.67

1.74

0.73

2.17

0.80

2.21

0.81

2.28

0.85

30

0.77

0.54

1.04

0.61

1.35

0.67

1.66

0.75

2.08

0.81

2.12

0.83

2.18

0.86

32

0.74

0.54

1.00

0.61

1.29

0.68

1.60

0.74

2.01

0.81

2.05

0.84

2.10

0.88

35

0.71

0.54

0.95

0.61

1.24

0.69

1.54

0.76

1.92

0.83

1.95

0.86

2.00

0.90

MRC+

20

27

5/8

1.08

0.71

1.42

0.79

1.83

0.87

2.26

0.97

2.81

1.06

2.87

1.08

2.95

1.13

30

1.01

0.71

1.34

0.80

1.75

0.88

2.16

0.98

2.69

1.07

2.74

1.10

2.81

1.14

32

0.97

0.71

1.30

0.80

1.68

0.89

2.08

0.99

2.61

1.08

2.66

1.11

2.73

1.16

35

0.92

0.72

1.23

0.80

1.60

0.90

1.99

1.01

2.49

1.11

2.54

1.14

2.60

1.19

MRC+

30

27

1 3/8

1.61

0.98

2.04

1.09

2.52

1.19

3.04

1.30

3.69

1.40

3.77

1.47

4.08

1.55

30

1.51

0.99

1.92

1.10

2.40

1.20

2.89

1.32

3.54

1.43

3.59

1.49

3.89

1.58

32

1.45

0.99

1.86

1.09

2.32

1.20

2.80

1.33

3.43

1.44

3.48

1.52

3.77

1.61

35

1.38

1.00

1.76

1.10

2.20

1.23

2.67

1.36

3.27

1.47

3.31

1.56

3.59

1.66

MRC+

40

27

1 1/2

2.33

1.48

2.90

1.59

3.56

1.70

4.27

1.87

5.00

2.06

5.33

2.14

5.80

2.29

30

2.21

1.50

2.76

1.61

3.41

1.74

4.25

1.91

4.78

2.11

5.07

2.20

5.52

2.34

32

2.13

1.51

2.68

1.61

3.29

1.76

3.95

1.94

4.62

2.15

4.90

2.23

5.34

2.39

35

2.02

1.52

2.54

1.64

3.14

1.80

3.76

1.98

4.38

2.20

4.66

2.30

5.05

2.44

MRC+

45

27

1 1/2

2.28

1.07

2.74

1.10

3.27

1.14

3.86

1.21

4.47

1.33

4.72

1.41

5.12

1.52

30

2.21

1.16

2.64

1.17

3.18

1.22

3.73

1.28

4.33

1.41

4.56

1.48

4.95

1.60

32

2.15

1.20

2.65

1.21

3.10

1.26

3.65

1.34

4.23

1.45

4.47

1.55

4.99

1.67

35

2.09

1.29

2.50

1.31

2.99

1.35

3.52

1.42

4.08

1.55

4.31

1.64

4.67

1.77

MRC+

50

27

2

3.05

1.58

3.69

1.62

4.44

1.66

5.24

1.73

6.09

1.84

6.46

1.88

7.02

1.95

30

2.95

1.70

3.56

1.72

4.30

1.76

5.07

1.84

5.90

1.94

6.25

1.98

6.80

2.06

32

2.87

1.77

3.56

1.79

4.19

1.82

4.96

1.90

5.76

2.00

6.11

2.05

6.85

2.14

35

2.78

1.90

3.36

1.91

4.05

1.95

4.79

2.02

5.56

2.14

5.90

2.18

6.41

2.26

MRC+

60

27

2 1/2

3.59

1.76

4.33

1.80

5.20

1.84

6.15

1.92

7.14

2.04

7.59

2.09

8.25

2.16

30

3.46

1.89

4.19

1.92

5.05

1.95

5.95

2.04

6.92

2.16

7.33

2.21

7.97

2.29

32

3.37

1.97

4.18

1.99

4.92

2.03

5.82

2.11

6.76

2.23

7.18

2.29

8.04

2.39

35

3.27

2.12

3.95

2.13

4.74

2.18

5.62

2.25

6.53

2.38

6.91

2.43

7.52

2.53

MRC+

80

27

3

4.27

2.02

5.16

2.07

6.19

2.11

7.32

2.21

8.50

2.36

9.03

2.41

9.82

2.49

30

4.12

2.18

4.98

2.21

6.01

2.26

7.09

2.35

8.24

2.49

8.73

2.55

9.49

2.65

32

4.01

2.27

4.97

2.30

5.86

2.35

6.93

2.44

8.05

2.58

8.54

2.65

9.57

2.76

35

3.89

2.45

4.70

2.47

5.65

2.51

6.69

2.61

7.77

2.76

8.24

2.81

8.96

2.93

MRC+

90

27

3 1/2

5.07

2.36

6.16

2.41

7.42

2.46

8.79

2.55

10.19

2.70

10.79

2.75

11.77

2.83

30

4.90

2.53

5.95

2.58

7.18

2.65

8.50

2.73

9.86

2.87

10.44

2.93

11.36

3.03

32

4.79

2.65

5.94

2.69

7.01

2.76

8.30

2.84

9.63

2.99

10.23

3.06

11.43

3.17

35

4.63

2.86

5.62

2.91

6.76

2.96

8.01

3.06

9.27

3.21

9.82

3.27

10.65

3.37

MRC+

100

27

4

5.78

3.12

7.14

3.16

8.43

3.23

10.03

3.37

11.66

3.54

12.38

3.62

13.55

3.71

30

5.60

3.31

6.76

3.37

8.16

3.42

9.68

3.55

11.28

3.72

11.97

3.80

13.06

3.93

32

5.46

3.43

6.53

3.42

7.96

3.54

9.45

3.66

11.02

3.84

11.68

3.93

13.13

4.06

35

5.29

3.66

6.38

3.72

7.68

3.77

9.11

3.89

10.60

4.08

11.29

4.15

12.29

4.30

MRC+

130

27

4 2/5

6.98

3.54

8.63

3.58

10.10

3.65

11.88

3.79

13.82

4.01

14.67

4.10

15.98

4.23

30

6.74

3.79

8.15

3.82

9.78

3.89

11.47

4.02

13.32

4.24

14.14

4.32

15.39

4.49

32

6.57

3.94

7.84

3.92

9.54

4.03

11.19

4.17

13.03

4.38

13.82

4.49

15.49

4.65

35

6.30

4.23

7.64

4.26

9.17

4.32

10.77

4.45

12.54

4.68

13.29

4.76

14.49

4.95

PERFORMANCE DATA

11/27 55008351-23

MODEL

Ambient

Temp °C

HP

EVAPORATING TEMPERATURE °C

-15

-10

-5

0

5

7

10

COOLING CAPACITY AND POWER INPUT kW

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

CAP.

POWER

MRC+

150

27

5

7.61

3.59

9.40

3.62

11.02

3.69

12.96

3.84

15.07

4.05

16.01

4.15

17.42

4.27

30

7.35

3.83

8.89

3.87

10.67

3.93

12.51

4.07

14.53

4.30

15.42

4.38

16.78

4.55

32

7.16

3.98

8.56

3.96

10.41

4.09

12.21

4.23

14.20

4.44

15.08

4.55

16.90

4.71

35

6.87

4.27

8.34

4.32

10.00

4.38

11.75

4.51

13.67

4.74

14.49

4.83

15.81

5.02

MRC+

165

27

6

9.02

4.13

11.12

4.19

13.09

4.28

15.43

4.46

17.93

4.73

19.02

4.83

20.81

4.99

30

8.70

4.42

10.54

4.49

12.64

4.57

14.92

4.74

17.32

5.00

18.40

5.08

20.08

5.32

32

8.49

4.60

10.18

4.58

12.33

4.74

14.54

4.93

16.96

5.18

17.95

5.32

20.23

5.52

35

8.13

4.94

9.90

5.00

11.90

5.08

14.06

5.25

16.29

5.54

17.34

5.64

18.89

5.88

MRC+

180

27

7 1/2

9.96

4.63

12.28

4.69

14.38

4.78

16.93

4.94

19.64

5.25

20.91

5.37

22.92

5.55

30

9.57

4.93

11.57

5.01

13.87

5.08

16.38

5.27

19.02

5.57

20.27

5.67

22.02

5.90

32

9.33

5.13

11.16

5.10

13.54

5.27

16.00

5.46

18.64

5.74

19.77

5.89

22.16

6.12

35

8.93

5.48

10.88

5.55

13.05

5.63

15.43

5.81

17.97

6.12

19.13

6.23

21.44

6.50

12/27 55008351-23

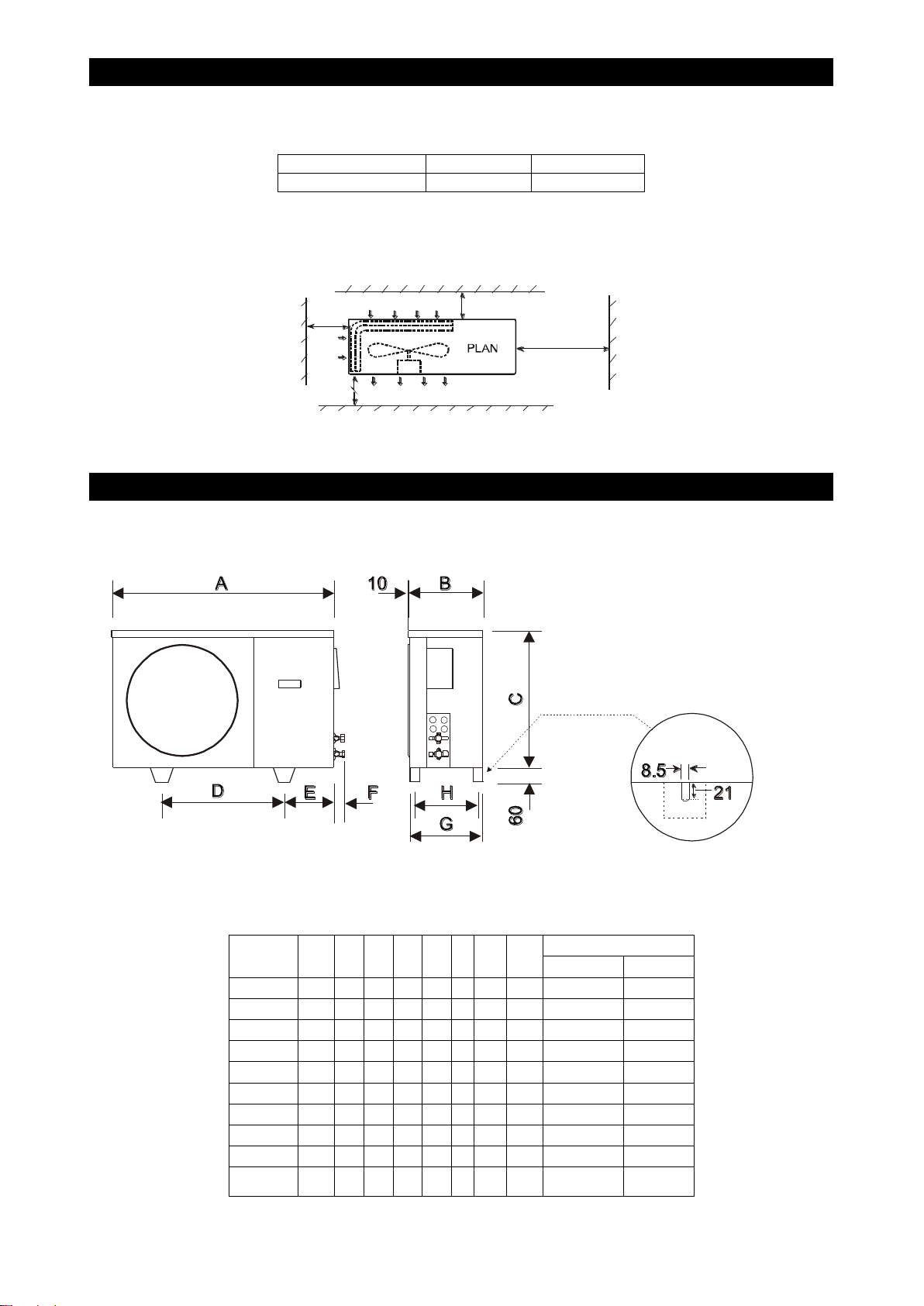

MOUNTING MRC+

These units are designed to stand on a flat surface. If the unit is to be wall mounted the following kits are

available.

KIT

MRC+ 15-80

MRC+ 90-180

Mounting Bracket

55021100

55021101

Whether floor or wall mounted, it is essential that the mounting surface is capable of supporting the unit

weight. Leave space around the unit for air circulation and access for installation and maintenance.

Dimensions in mm.

DIMENSIONS & WEIGHTS MRC+

MRC+ 15-100 (Dimensions in mm.)

MODEL

A

B

C

D

E

F

G

H

Weight (kg)

1 Ph

3 Ph

MRC+ 15

900

300

560

525

185

60

295

275

46

-

MRC+ 20

900

300

560

525

185

60

295

275

47

-

MRC+ 30

900

300

560

525

185

60

295

275

48

48

MRC+ 40

900

300

560

525

185

60

295

275

53

53

MRC+ 45

1000

350

660

495

250

60

345

325

61

-

MRC+ 50

1000

350

660

495

250

60

345

325

64

64

MRC+ 60

1000

350

660

495

250

60

345

325

65

65

MRC+ 80

1000

350

660

495

250

60

345

325

66

66

MRC+ 90

1000

350

760

495

250

70

345

325

76

76

MRC+ 100

1000

350

760

495

250

70

345

325

81

81

1500 min air off

100 min 100 min

600 min

MOUNTING HOLES

13/27 55008351-23

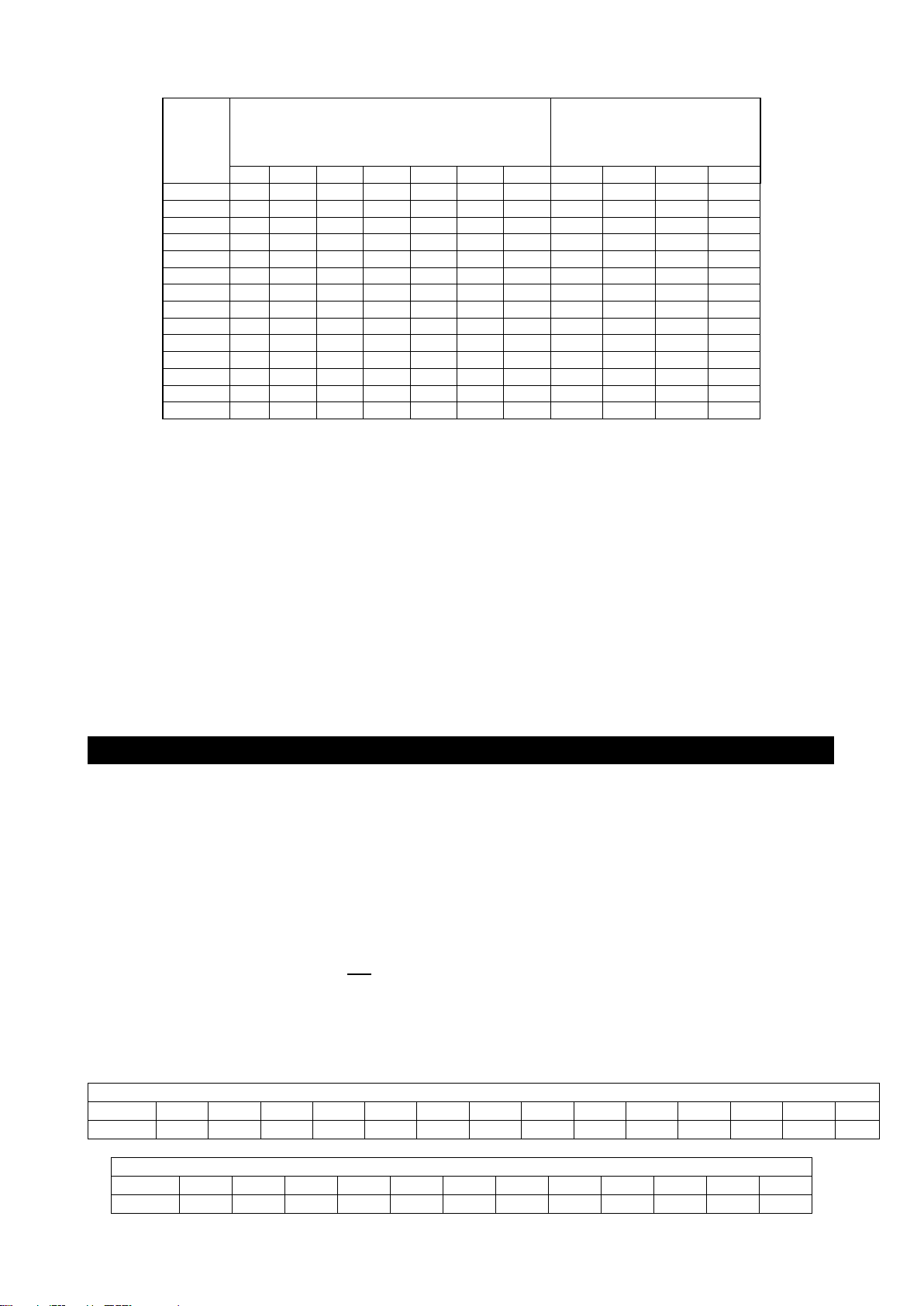

MRC+ 130 –180 (Dimensions in mm.)

PIPEWORK

Supplied male flare connections (sizes in inches)

Model

MRC+ 15-180

Size

15

20

30

40

45

50

60

80

90

100

130

150

165

180

Liquid

3/8

3/8

3/8

3/8

3/8

3/8

3/8

1/2

1/2

1/2

1/2

1/2

1/2

1/2

Suction

3/8

1/2

1/2

1/2

1/2

1/2

5/8

5/8

5/8

3/4

3/4

3/4

3/4

7/8*

* Brazed connections

MAXIMUM PIPE RUNS

45m maximum including 6m lift (20m MRC+ 15-20). There will be no significant loss of capacity for extended

pipe runs provided pipes are correctly sized.

CALCULATING EQUIVALENT LENGTHS

The effects of bends and fittings must be taken into account.

Pipe sizes are based on:

Minimum of 2.5 m/s (500 fpm) suction gas velocity for horizontal or downflow.

Minimum of 5.0 m/s (1000 fpm) suction gas velocity for upflow.

Maximum of 20.0 m/s (4000 fpm) suction gas.

Where vertical risers exceed 3m, oil traps must be formed in the pipe. This will help ensure that oil returns to

the compressor. Typically fit an oil trap every 3m with a trap at the bottom of the riser.

GOOD PRACTICE

▪Keep pipe runs as short as possible.

▪Avoid sharp bends

▪Fully insulate both suction and liquid including mechanical connections

▪Try to avoid running pipes through hot areas.

MODEL

A

B

C

D

E

Weight (kg)

MRC+ 130

1000

1020

495

251

100

101

MRC+ 150

1000

1020

495

251

100

103

MRC+ 165

1000

1020

495

251

100

103

MRC+ 180

1100

1215

675

211

95

118

B

60

A10

CDE

MOUNTING HOLES

417

397

425

14/27 55008351-23

PIPE SIZES

UNIT

SIZE

MAXIMUM LENGTH OF EQUIVALENT

SUCTION LINE PIPE SIZES (m)

LIQUID LINE

⅜

½

⅝

¾

⅞

1⅛

1⅜

⅜

½

⅝

¾

15

7.5

20

20

20

7.5

20

20

30

15

45

45

40

10

36

45

7.5

45

45

10

36

45

7.5

45

50

7.5

18

45

7.5

45

60

14

36

45

7.5

45

80

11

30

45

45

90

10

25

45

20

45

100

7.5

22

45

15

45

130

15

30

45

12

45

150

12

27

45

8

45

165

8

18

45

7.5

40

45

180

7.5

16

45

7.5

35

45

CONNECTING THE UNITS

1. Connecting the pipework:

a. Remove the flare nuts from the service valves and release the nitrogen holding charge by slowly

opening the valves using a 5mm or 8mm allen key.

b. Ensure the suction line is fully insulated.

c. Place the flare nuts over the incoming pipework and flare the pipe ends.

d. Connect the pipework between the units. Do not leave pipes ends, valves etc open to the

atmosphere. Always use 2 spanners when tightening the flare nuts to avoid twisting the pipes.

Use a small amount of refrigerant oil on the mating surfaces.

e. MRC+ 180 has a ⅞¨ suction pipe with brazed connections. Use a protective shield to avoid

scorching the side panel.

EVACUATING

With the valves open, connect a vacuum pump to the service ports on the outdoor unit valves. Evacuate the

interconnecting pipework and indoor unit to 1000 microns (1 Torr) or better. Allow this to be held for a

minimum of 15 minutes.

ELECTRICAL

The installer supplies mains, control and interconnecting cables: equipment must be earthed.

Wiring must be carried out in accordance with local and national codes.

Mains supply cables must be size compatible with the recommended fuse.

Cable clamps for use with stranded cables are supplied in units 15 - 100 and should be used to secure

incoming/outgoing cables. Installers must supply a method of securing solid sheathed cables.

THREE PHASE UNITS WITH SCROLL COMPRESSORS:

On 3 Ph units sizes 50 - 180 it is possible for the scroll compressor to run backwards.

This becomes obvious on start up - the compressor will not develop a normal running pressure differential

and the top will not become warm: it may be excessively noisy. If this happens, switch off the mains power

and exchange the two supply phases not connected to the indoor unit. This will correct the rotation.

FUSES: The system and its supply/interconnecting wiring must be protected by fuses, preferably High

Rupture Current (HRC) motor rated types (to BS EN60269) or miniature circuit breakers to (BS EN60898) or

local codes having similar time lag characteristics, that allow starting of the compressor yet still afford close

overcurrent protection under running conditions. The ratings below are for HRC motor rated fuses.

1PH FUSE SIZE

MRC+

15

20

30

40

45

50

60

80

90

100

130

150

165

180

FUSE

16

16

16

20

20

16

20

25

32

32

-

40

-

-

3PH FUSE SIZE

MRC+

30

40

45

50

60

80

90

100

130

150

165

180

FUSE

10

10

-

10

10

10

16

16

16

20

20

25

15/27 55008351-23

The ratings are for the outdoor unit only. Currents for the indoor units including heaters if applicable should

be noted and the fuse size increased pro-rata.

CONNECTION OF MAINS SUPPLY:

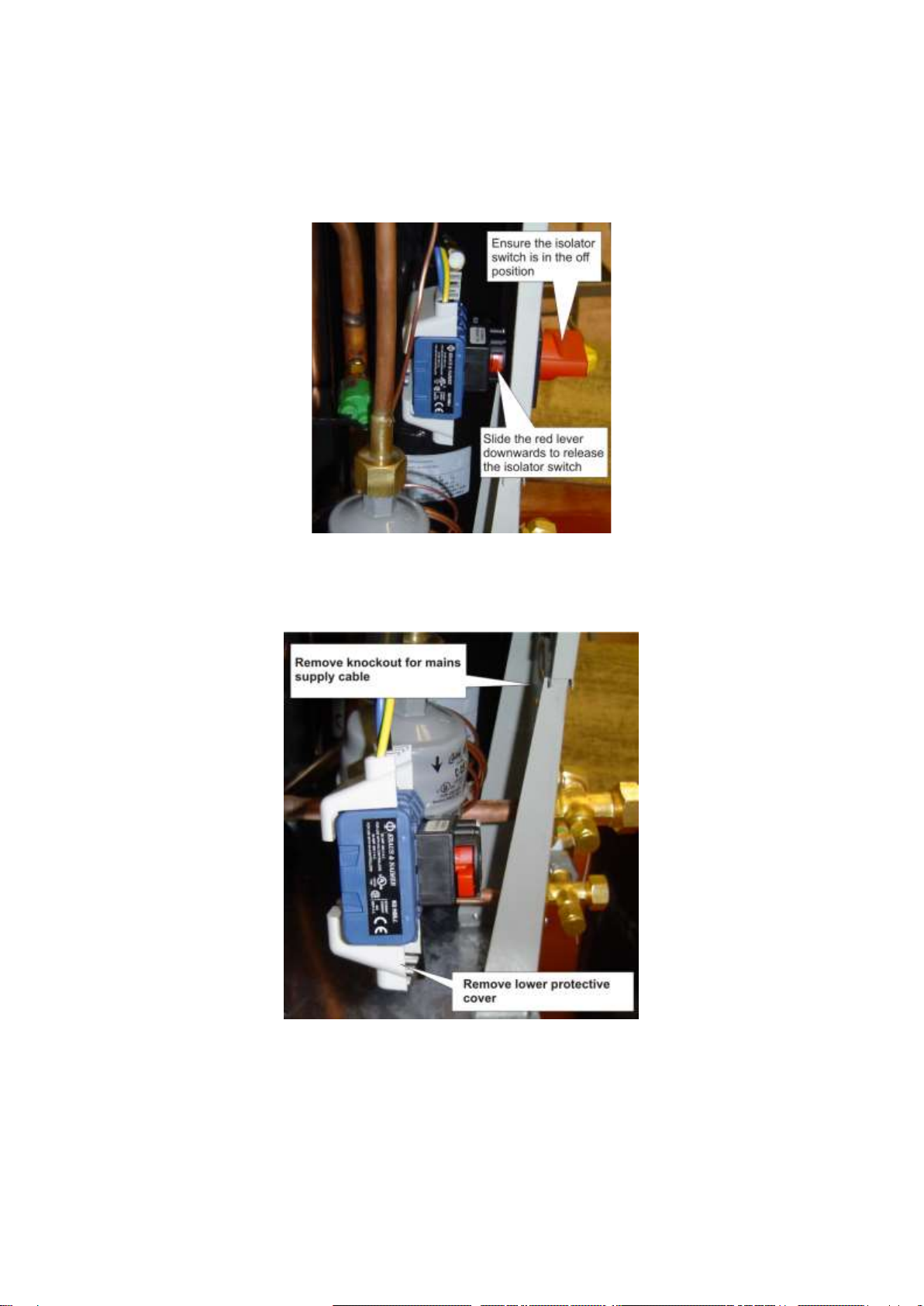

1. Ensure the isolator switch is in the OFF position.

2. Remove front panel. (3screws)

3. Isolator body is located on the inside of the right hand panel.

4. To remove the isolator body from the external switch slide the red lever downwards.

5. Release the main body and lower to the bottom of the unit near the valve panel.

6. Remove lower white plastic cover from the isolator body.

7. Remove knockout hole on the valve panel for your incoming mains supply cable.

16/27 55008351-23

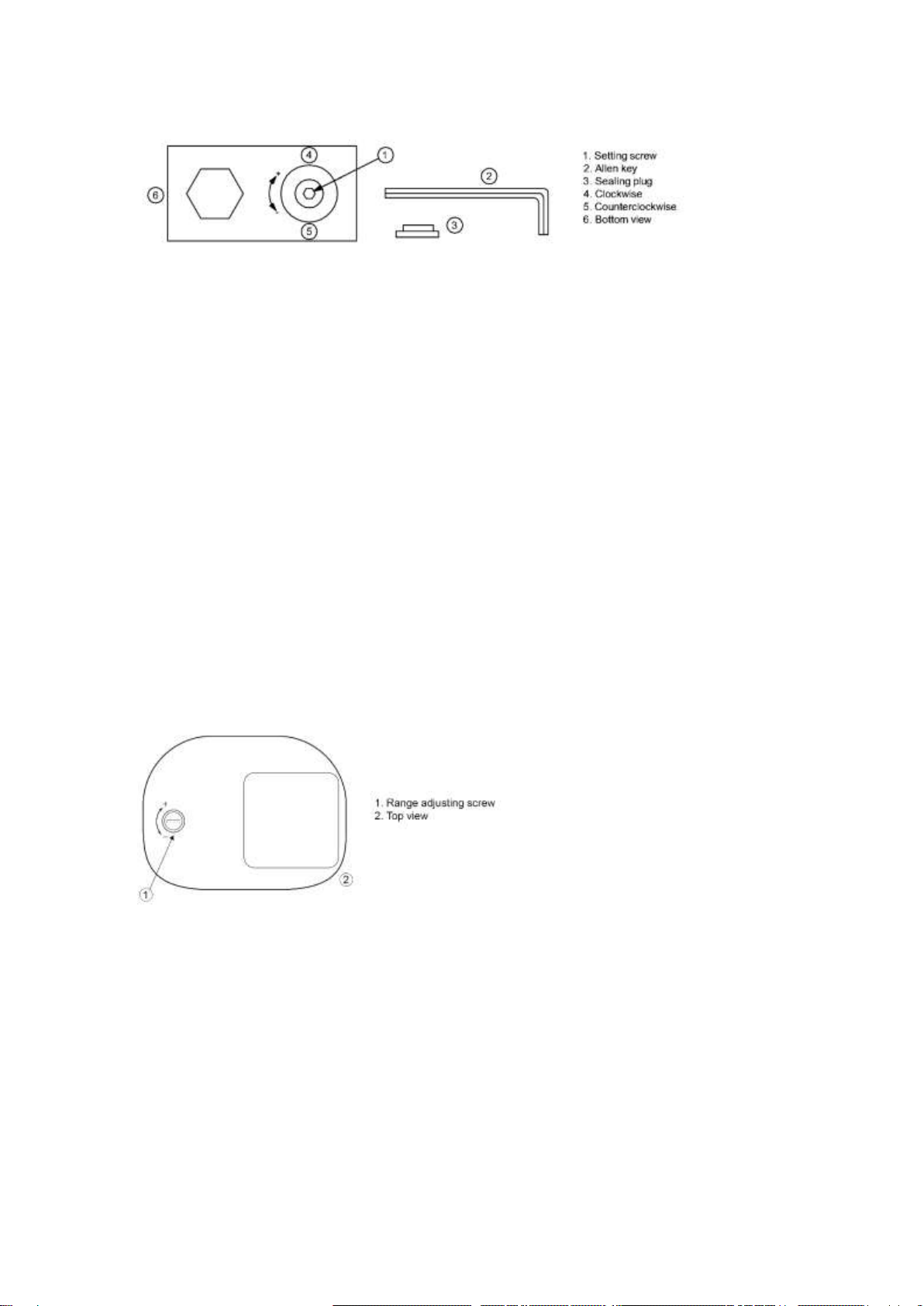

8. Route incoming mains cable through the knockout hole and wire to the required terminals and

replace lower protective cover.

9. Replace main isolator back into the switch and lock into place by sliding the red lever upwards.

10. Replace covers.

17/27 55008351-23

R404A REFRIGERANT

Charging the System:

1. Evacuate the system and interconnecting pipework as page 8 ensuring the service valves are fully

open.

2. Allow the evacuated system to draw in the majority of the refrigerant charge.

3. The final charge should be adjusted with the system running.

4. All units are fitted with head pressure control. The link wire across the orange terminals allows the fan

to operate at full speed. THIS SHOULD BE REMOVED AFTER CHARGING

5. A random start delay of up to 1 minute occurs when mains is first applied. A 3 minute delay occurs

between successive compressor operations on all systems.

6. Refrigerant and polyolester oil should be introduced through the Schrader valve the service port on the

suction service valve on the outdoor unit. Ensure the refrigerant is the correct type, as shown on

the rating plate. R404A must always be added in the liquid state.

7. Run the system for a few minutes to allow it to stabilize. Where possible, charge to a sweat line on the

evaporator. Typical suction pressures on short lines at UK conditions, with high speed evaporator fan,

high speed condenser fan, should be; low temperature system approx 4.4 bar (65 psig).

8. Systems should not be overcharged, to avoid liquid return to the compressor

9. HEAD PRESSURE CONTROL SAGINOMIYA (RGE –ZIN4 –SH)

The head pressure controller is factory set to suit the refrigerant. It may be necessary to adjust this to

suit site conditions, to raise or lower the nominal head pressure.

a. With the system

switched off, connect

a high pressure

gauge to the liquid

line service valve.

b. Switch on the

system, and run for a

few minutes to

stabilise.

c. The head pressure should be approximately:

R404A: 210-220 psig (14.5-15.2barg) to achieve this

adjust the screw clockwise to increase pressure or

anticlockwise to decrease. Each ½ turn will alter the

pressure by approx 5 psig (0.5 barg)

Min fan speed (0 rpm) and fan cut in pressure 200 psig

(13.8 barg) are factory set and not adjustable.

NOTE: The condenser fan may stop if the operating pressure drops below 200 psig (13.8 barg)

10. HEAD PRESSURE CONTROL ALCO (FSY-42S) & SAGINOMIYA (XGE-4C)

The head pressure controller is factory set to suit the refrigerant. It may be necessary to adjust this to

suit site conditions, to raise or lower the nominal head pressure.

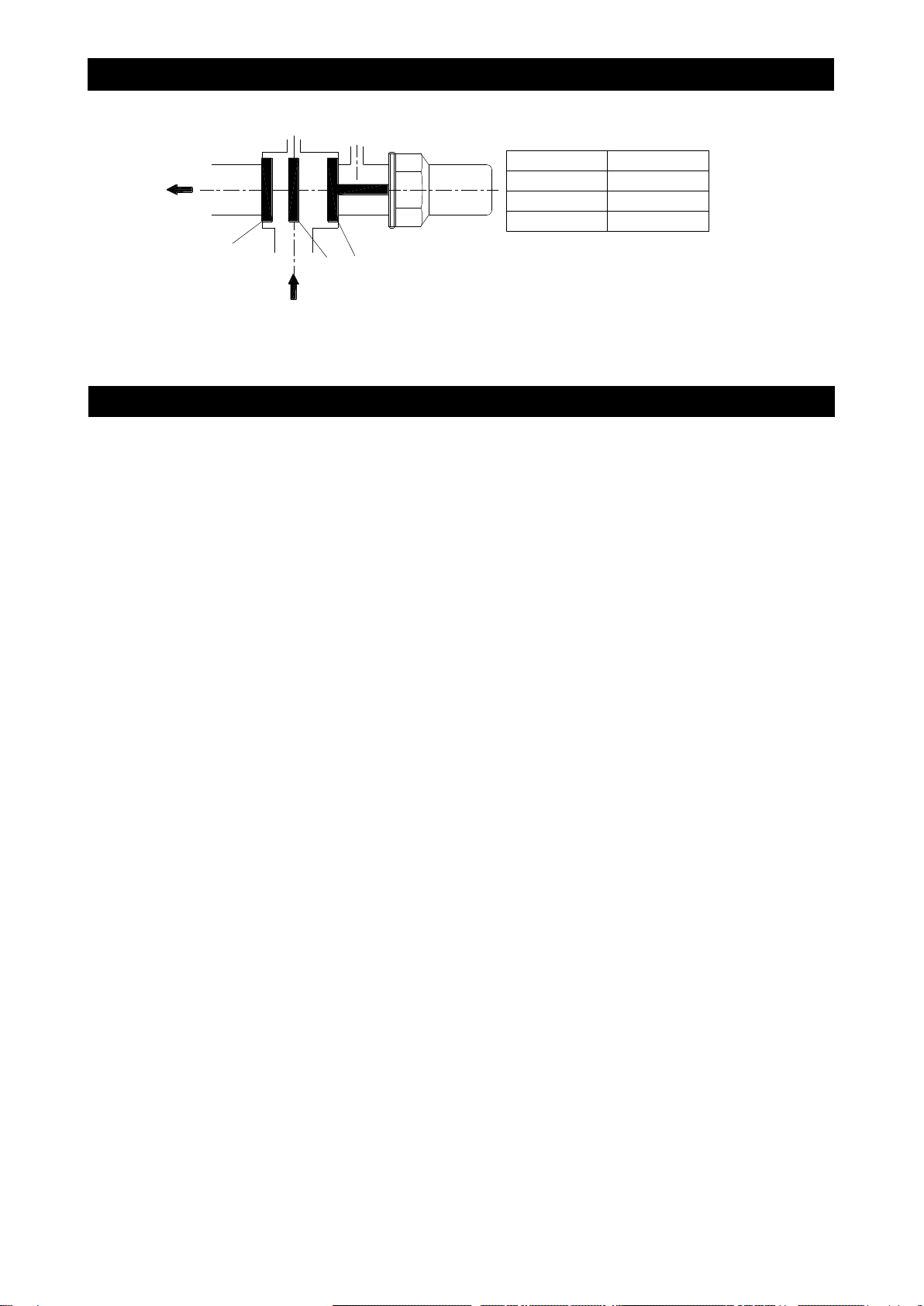

ALCO (FSY-42S)

a. With the system switched off, connect a high pressure gauge to the liquid line service valve.

b. Switch on the system, and run for a few minutes to stabilise.

c. The head pressure should be approximately:

Electricsbox

Headpressure

adjustmentscrew

Fancapacitor

18/27 55008351-23

Min fan speed (0

rpm) and fan cut in

pressure 200 psig

(13.8 barg) are

factory set and not adjustable.

NOTE: The condenser fan may stop if the operating pressure drops below 200 psig (13.8 barg)

R404A: 210-220 psig (14.5-15.2barg) to achieve this remove sealing plug and insert 2mm or 5/64”

allen key into setting screw. Turn allen key clockwise (+) or counter clockwise (-) to readjust the

setting.

Do not turn setting screw more than 3 turns clockwise (+3). Use following table as a quick guideline

for setting:

Pressure changes per turn of adjusting screw:

Pressure change: 9.2 … 21.2 bar:

Clockwise ~ +2,5 bar, counter clockwise ~ -2,5 bar

After adjustment, re-insert sealing plug and make sure that it is properly fitted. IP65 protection

requires firmly sealed plug

NOTES:

Tolerances for condensing temperatures setpoint: ±2K

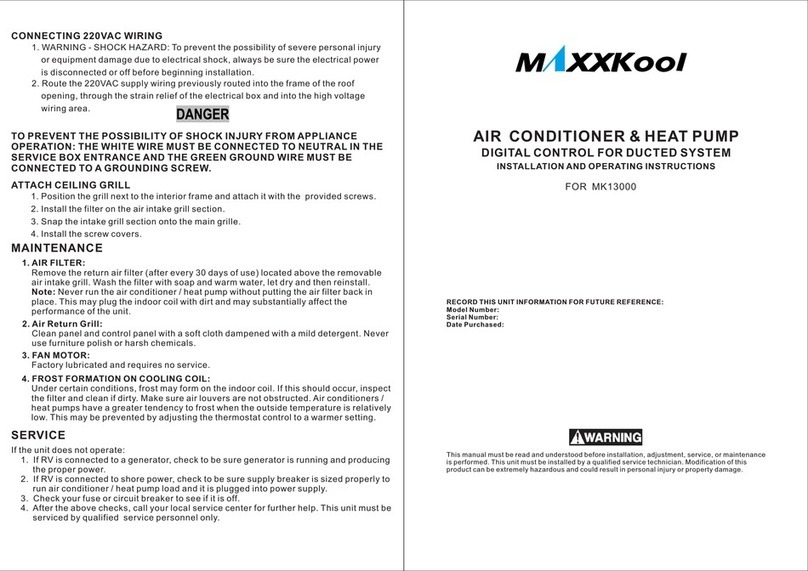

SAGINOMIYA (XGE-4C)

R404A: 210-220 psig (14.5-15.2barg) to achieve this turn the range adjusting screw clockwise (+)

for increasing the setting value or counter clockwise (-) for decreasing the setting value.

Pressure changes per 1 turn of adjusting screw:

Pressure change: 10 … 25bar:

Clockwise ~ +1.5 bar, counter clockwise ~ -1.5 bar

19/27 55008351-23

ROTA-LOCKED VALVES FITTED TO RECIEVER

END OF LIFE REQUIRMENTS

Refrigerant must be recovered by a certificated technician before the plant is dismantled. Modern refrigerant

recovery machines should be able to remove well over 95% of the refrigerant in an old system.

All recovered HFC refrigerants can either be:

a) Sent for destruction by incineration at a licenced waste facility

b) Sent to a specialist plant that can re-process the old refrigerant into a gas with properties identical to

virgin refrigerant, to create “reclaimed refrigerant”

c) Given a basic cleaning process, to create “recycled refrigerant”

Given the HFC supply shortage that will be created by the phase down process, it is worth trying to send the

old refrigerant for reclamation as it may have a good residual value. If the old refrigerant is too contaminated

it cannot be reclaimed and must be sent for destruction. It is important not to mix different gases in the same

recovery cylinder –as this would render them unsuitable for reclamation.

Reclaimed refrigerant can be used in any refrigeration equipment. Recycled refrigerant must always be

used with care as it may be contaminated or of unknown composition. The use of recycled refrigerant with a

GWP above 2,500 is restricted to either (a) the organisation owning the plant from which the gas was

recovered or (b) the organisation that carried out the recovery.

OUT

IN

ABC

P2 P1

POSITION SPINDLE

A

B

C

FUNCTION

OUT CLOSED

ALL OPEN

P1 CLOSED

Pay attention

- P1, P2: optional gages ports.

- The positions IN - OUT could be inverted according to the

employment of client.

- The spindle must be positioned in the position B when the

valve will be connected to the unit.

20/27 55008351-23

ECO DESIGN INFORMATION TABLES

This manual suits for next models

37

Table of contents

Popular Heat Pump manuals by other brands

Daikin

Daikin DRG0361DL00001S Service instructions

CHOFU

CHOFU AEYC-7134SVFU-CH1 Service manual

Rheem

Rheem 13 Series installation instructions

maxxkool

maxxkool MK13000 Installation and operating instructions

Energie

Energie AQUAPURA MONOBLOC 120i Technical manual

Bosch

Bosch Compress 3000 DW FI Series Installation and operating instructions

Bosch

Bosch CS 3000 AWP Installation and operating instructions

Bryant

Bryant 637G Installation and start-up instructions

Lennox

Lennox 2SHP13 Series Installation and maintenance instructions

Nibe

Nibe AG-AC10-42 Installer manual

Zehnder Rittling

Zehnder Rittling ComfoClime 24 Installer manual

Sanyo

Sanyo 09KH11W operating instructions