The drain line MUST be trapped because the coil is located on

the negative side of the supply air blower, and it must be pro-

tected from freezing temperatures.

A7/8" OD drain connection extends through right hand side of

cabinet. Refer to Fig. 7 for recommended drain piping.

The drain connection is located on the same side of the unit as

therefrigerantconnections.Thelineshouldbeinsulatedwhere

moisturedrippagewillbeobjectionableorcausedamagetothe

area.

The 3" dimension must equal or exceed the negative static

pressure developed by the supply air blower. If it does not, the

condensate will not drain properly and may overflow the drain

pan. The trap must be at least 2-1/2" deep to maintain a water

seal under all operating conditions, especially during blower

start-up.

NOTE: The unit may have to be raised off the floor to allow

enough height for the trap.

SUPPLY AIR BLOWER ADJUSTMENT

The RPM of the supply air blower will depend on the required

CFM,theunitaccessoriesandthestaticresistancesofboththe

supply and the return air duct systems. With this information,

the RPM for the supply air blower can be determined from the

blower performance in Table 4.

Knowing the required blower RPM and the blower motor HP,

the setting (turns open) for the supply air motor pulley can be

determined from Table 3.

Each motor pulley has:

1. Athreaded barrel with two flats (or notched recesses) 180

degrees apart.

2. A movable flange with one set screw.

After the movable flange has been rotated to the proper

number of “turns open”, the set screw should be tightened

againsttheflatonthebarreltolockthemovableflangeinplace.

If the pulley includes a locking collar, the locking collar must be

loosened to adjust the setting of the movable flange.

Note the following:

1. The supply air CFM must be within the limitations shown in

Table 2.

2. All pulleys can be adjusted in half turn increments.

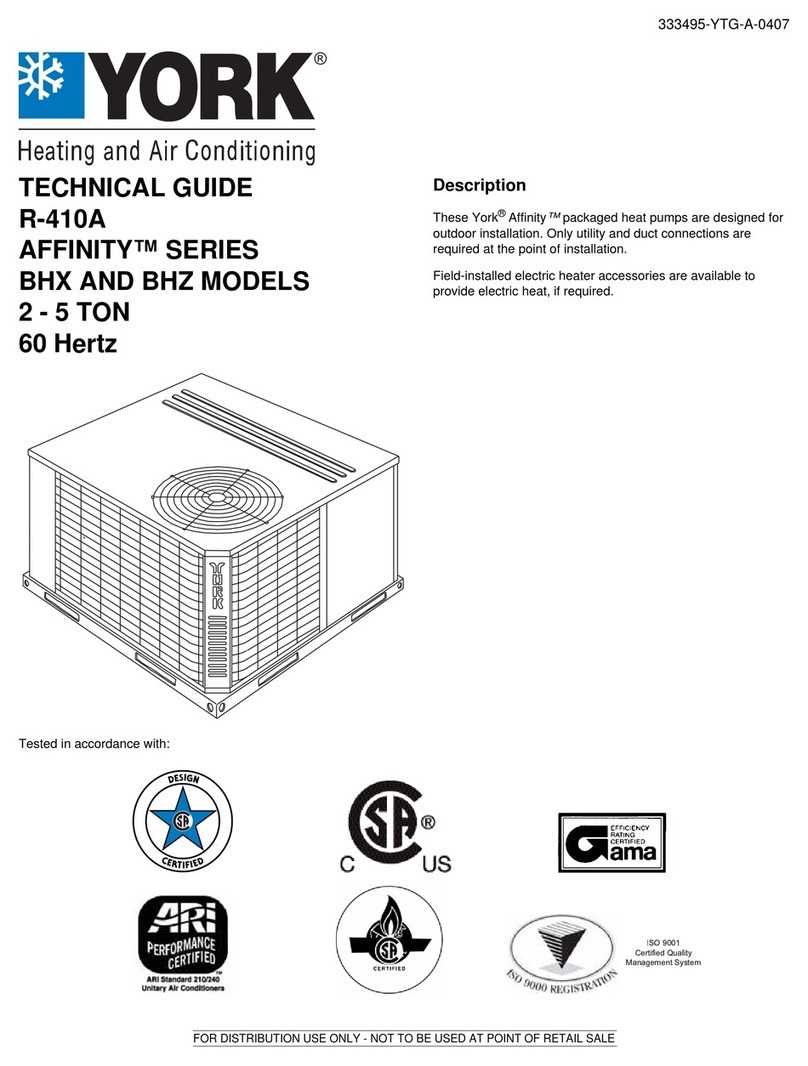

3. The tension on the belt should be adjusted for a deflection

of3/16 of an inch perfoot ofbeltspanwithanapplied force

of 2 to 3 pounds. This adjustment is made by moving the

blowermotormountingplate.RefertoFigure8.Turningthe

adjustment bolt (B) moves the motor mounting plate up or

down.

NOTE: Never loosen the two nuts (C).

Two hex nuts (A) have to be loosened to move the mount-

ingplateandretightenedafterthemountingplatehasbeen

moved to the proper position.

4. All pulleys are factory aligned.

5. All supply air motor pulleys are factory set 3 “turns open”.

After the supply air blower motor is operating, adjust the resis-

tances in both the supply and the return duct systems to bal-

ancetheairdistributionthroughouttheconditionedspace.The

job specifications may require that this balancing be done by

someone other than the equipment installer.

TocheckthesupplyairCFMaftertheinitialbalancinghasbeen

completed:

1. Drill two 5/16 inch holes in the side panel as shown in Fig-

ure 9.

2. Insert at least 6" of 1/4 inch tubing into each of these holes

for sufficient penetration into the air flow on both sides of

the indoor coil.

NOTE: The tubes must be inserted and held in a position

perpendicular to the air flow so that velocity pres-

sure will not affect the static pressure readings.

3. Usinganinclinedmanometer,determinethepressuredrop

across a dry indoor coil. Since moisture on the coil may

varygreatly,measuring the pressuredropacross awetcoil

underfieldconditionswouldbeinaccurate.To assure a dry

coil, the heat pump system should be de-activated while

the test is being run.

4. Knowing the pressure drop across a dry coil, the actual

CFM through the unit can be determined from the curve in

Figure 10.

035-11845-001-A-0304

Unitary Products Group 7

FIG. 8 - TYPICAL MOTOR MOUNTING ASSEMBLY

TURNS

OPEN*

MODEL

FHP090

60 Hz FHP120

60 Hz

5 655 RPM 700RPM

4 760 750

3 745 800

2 790 850

1 835 900

0 880 950

*Pulleys can be adjusted in half-turn increments.

TABLE 3 - SUPPLY AIR BLOWER MOTOR

PULLEY ADJUSTMENT