Description

1-4

General Information

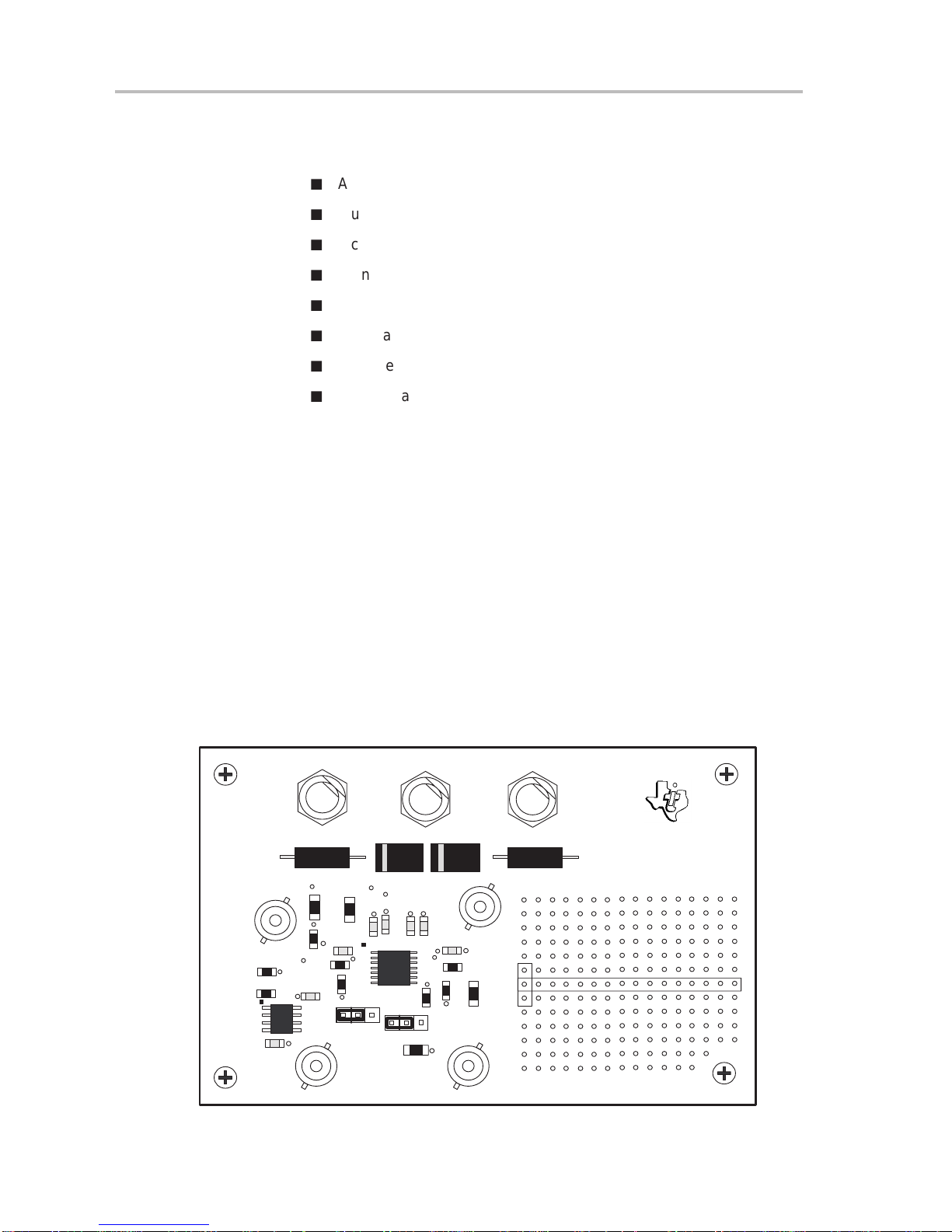

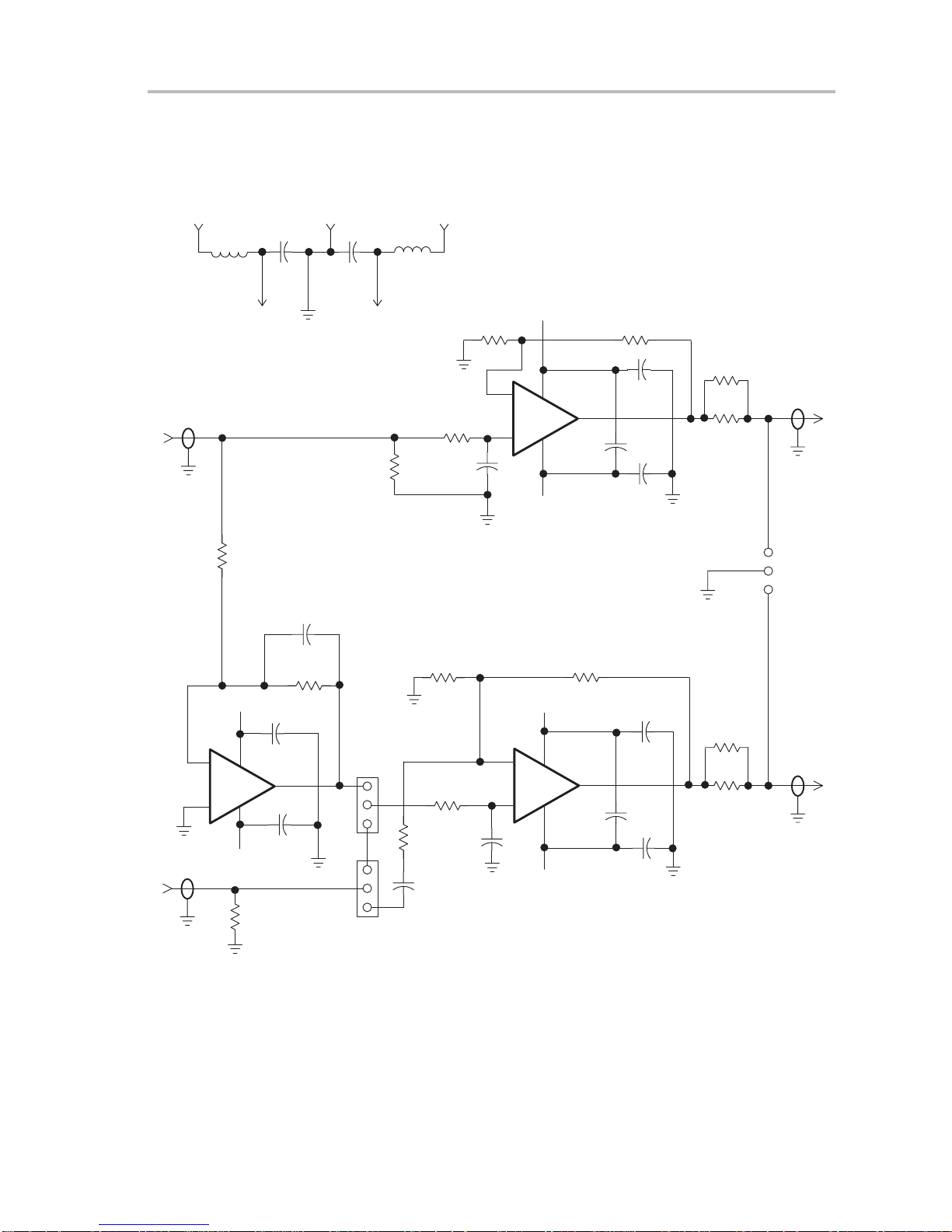

The THS6022 EVM is equipped with a separate BNC connector for the Driver

1 input and the Driver 2 input. Each input is terminated with a 50-Ωresistor to

provide correct line impedance matching (Figure 1–2). Note that using a

source with a 50-Ωoutput impedance will create a voltage divider at the EVM

inputs. Thus, accurate knowledge of the source output characteristics is

required to determine proper input signal amplitudes.

Driver outputs are routed through client side ADSL-standard 49.9-Ωresistors

to provide correct transmission line impedance matching when run through a

1:1 transformer with a 100-Ωline termination. These resistors also allow

separatereceiverstoviewadifferentialinputsignalfromthetransmissionline.

All of the amplifiers on the EVM (THS6022 and THS4001) follow the classic

operational amplifier gain equations:

Inverting Gain

+

–RF

RG(1)

Non-Inverting Gain

+

1

)

RF

RG(2)

The gain of the amplifiers can be easily changed to support different

applications by changing resistor ratios. Any of the components on the EVM

boardcanbe replacedwithdifferentvalues.Also,componentpadshave been

placed in convenient locations on the PCB (shown as components with the

valueTBDintheschematic)toallownumerousmodificationstothebasicEVM

configuration. However, care must be taken because the surface-mount

solder pads on the board are somewhat fragile and will not survive a large

number of soldering/desoldering operations.

The THS6022 IC is a current-feedback amplifier (CFB) and because of this,

extracaremustbe taken to ensure thatafeedbackresistoris always included

in the design. In addition, there must never be a capacitor directly in the

feedback path between the noninverting input and the amplifier output.

Disregarding this guideline will likely result in a part that oscillates. The

THS4001 IC amplifier used on the EVM, however, is a classic

voltage-feedback amplifier (VFB) and has no restrictions on resistors or

capacitors in the feedback path. But, to maximize bandwidth, high value

resistors and capacitors should be used with discretion.

Andfinally,theEVMcircuitboardisagood example of proper boardlayoutfor

high-speed amplifier and PowerPAD designs. It can be used as a guide for

user application layouts.